Shengzao Mechanical & Electrical Equipment SZ-1800 User manual

Operating Manual of SZ-1800

1/18

SZ-1800

Precise Mould Cold Welding Machine

Operating Manual

Shanghai Shengzao Mechanical & Electrical Equipment Co., Ltd

Operating Manual of SZ-1800

2/18

1. Overview

Machine working principle:

This machine can release electrical power in capacitor with pulse arc form instantly onto

tungsten and work pieces. The high temperature arc will make metal material work pieces

and welding wire dissolve immediately and then welding together, and achieve welding

effect.

Character of this kind of welding method: short time and low calorific value.

This welding machine can finish melt between electrode and work pieces less than a second.

Compared to normal welding machine (normal welding machine needs several seconds),

the heat send to work pieces of this machine is very small. So, to work pieces, it is low

calorific, low temperature increase except welding spot, no annealing, and no discoloration.

As each welding pulse volume is less than 2mm3, so the stress is also small. Though the

welding needs combine many dissolving pool, the welding spot stress direction is dispersive,

so the deformation is very small after welding.

Advantages of sz-1800 precise mould Cold welding machine

1. High welding intensity: metallurgical welding totally, each after welding part can be

grinded, milled, filed and other processing.

2. High precise welding: can use circle wire material to weld, thus redundant welding

material is very less, and easy to be reshaped. The minimum welding is 0.05mm (use

0.15mm diameter welding material).

3. Newly increased resistance welding function for better adapt to weld complex shape

work pieces and increase welding speed.

4. Fast welding speed: the fastest welding amount up to 100mm3/min.

5. Small damage on nature material: thermal point is small and no annealing and no

deformation to nature material.

6. Reasonable distribution of power: control by micro computer core. Different diameter

material will all get best power.

7. Wide range of voltage adaption: the machine can keep normal work when the voltage

variation is surged within 20% and hold steady output power.

8. Wire control light changing mask, shield arc light effectively: interior LED strong light,

provide better operating vision.

9. Easy to connect wire: match fast joint connector for convenient connection and

installation.

Operating Manual of SZ-1800

3/18

2. Performance Index

Welding material: all metal material

include copper, aluminum and other

work pieces except some low melting

and hard alloy material like Tin, Zinc.

Welding position: 1. Partial abrasion for

equipment and mould in welding

process.

2. Processing defect in

manufacture, like sand hole, gas hole,

size tolerance, corner edge damage and

shortage for arc welding.

3. Rust spot of cavity

and other hollow or defect.

Power: single phrase 220V, 50HZ

Power consumption: 10-1200W

Max output power instantaneously: more than 40 KW

Power mode: arc welding output (mode 1- mode 4): output pulse current 1-99 button;

output pulse time 1-99. Resistance output (single or continuous): electrode

size: 0.1mm-1mm

Consecutive output pulse frequency: four modes (1Hz, 2Hz, 3Hz, 5Hz ).

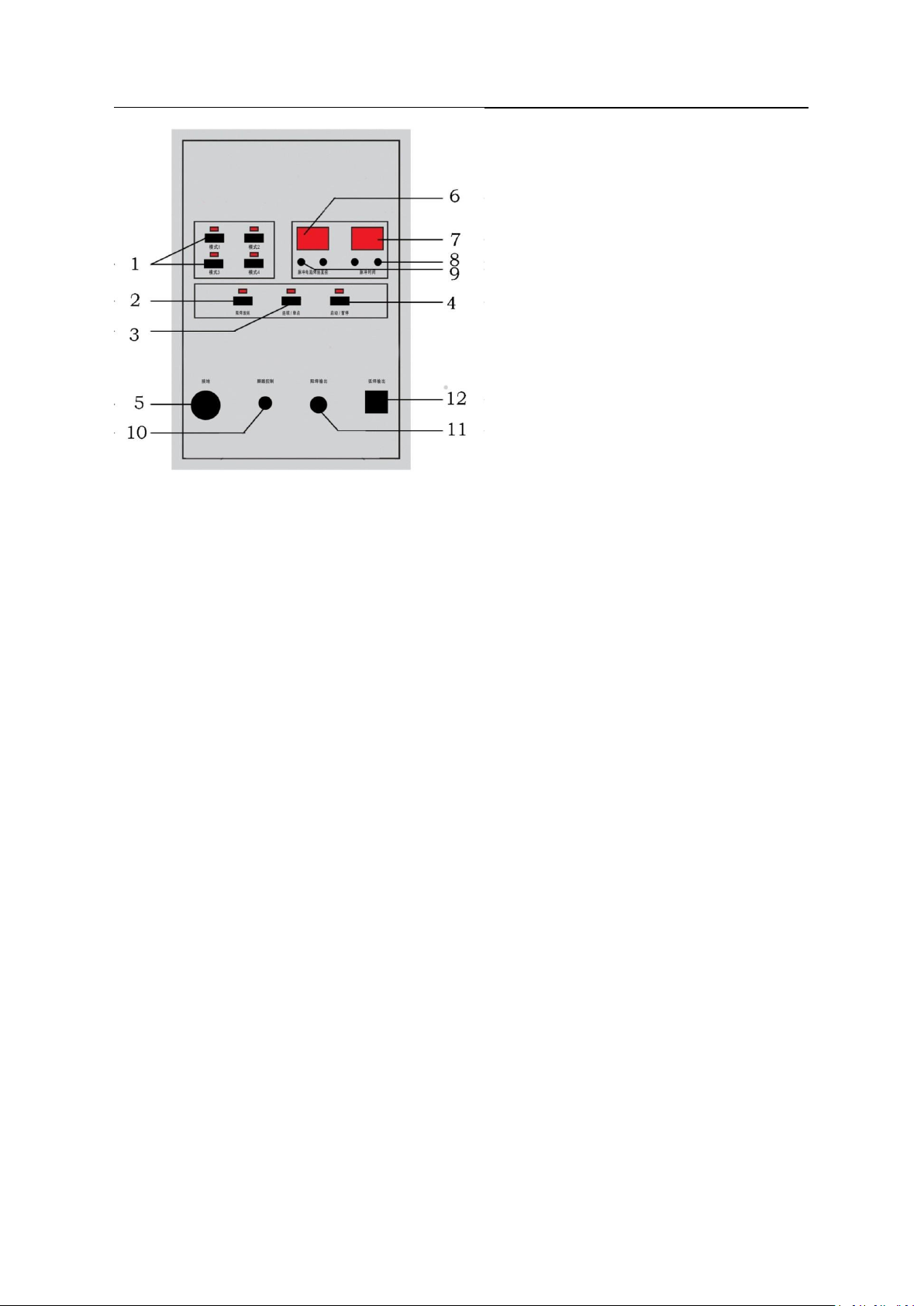

3. Operating Panel and Installation Diagram

Front Panel Part:

3.1. Connect arc welding gun coupling nut tightly to socket 12.

3.2. Connect grounding wire joint tightly to socket 5 in clockwise.

3.3. Plug resistance welding gun to socket 11.

3.4. Plug foot switch connecting wire to socket 10

①Mode option ⑦Pulse time value show screen

②Resistance welding ⑧Pulse time adjust key

③single / continuous ⑨Pulse current adjust

④Start/Pause ⑩Foot switch control socket

⑤Grounding wire ⑾Resistance welding gun

⑥Pulse current show screen ⑿Arc welding gun socket

Real panel part:

Operating Manual of SZ-1800

4/18

1. Plug argon tube ( Note: press plastic material in the connection part when pull out

argon tube)

2. Plug above control wire

3. Plug the socket to 220V 50HZ single phase socket; and the socket grounding wire should

available touch to ground.

4. OPERATING

Safety Preparation:

During welding process, some strong electric arc flash and high temperature splash will

burn eyes or skin. Please make sure to use our special light shielding and black lens screen.

Please install special mast before operating, and step on foot switch to inspect light

shielding will turn black automatically and non-transparency.

4.1 Electrode preparation and installation: electrode is a kind of tungsten Cerium electrode

(General welding material store on sale this electrode). Generally, defect on angular part

or small defect on surface part use 1.60mm diameter electrode. If you need welding

large defect parts, and the welding current is also large, please choose 2.0mm-2.5m

electrode.

4.2 When welding plane or corner angle part, you can grind the tungsten needle terminal to

70-90 degree cone for more steadily welding. If you need weld interior angels or narrow slit,

please grind the tungsten needle to 20-25 degree cone. If you need weld copper, aluminum

or other metals, please grind tungsten needle to hemisphere. Generally, the length of the

tungsten show out air nozzle must be around 8mm. Too long electrode will cause the

welding point turn yellow or black. Too short of the electrode will cause bad operating sight.

4.3 Choose suitable electrode (more details are in chapter ten)

Generally, choose the same material electrode as work pieces. If they are totally

different, please choose similar material electrode/ welding wire. For example: some

high carbon material, like cast iron work pieces, the welding point will turn harden

when welding, so we choose high nickel content welding wire for reduce welding point

Operating Manual of SZ-1800

5/18

hardness. Choose fine welding wire or small power can also reduce welding spot stress

work.

4.4 Charging: turn on the power button on real panel, the machine will on pause status, and

the pause indicator on panel will on.

4.5 Working: Press start/ pause button, the mode 2 indicator on the panel will on; the

welding power and welding time will show as “20”,”20” respectively. ( This is start on

default state).

4.6 Option mode: there are four mold button, choose suitable mode according to welding

quantity. Mode 1 is the smallest output, and mode 4 is the biggest. Each mode has

channel storage function in on power state of the machine. You can storage

different electrodes’ best welding parameter (pulse current and pulse time) in

suitable mode, which will be very convenient for operating.

4.7 Choose pulse current value: press the key can rise or deduce the show figure, the

figure will rise or deduce automatically if you press the

key over 1 second.

4.8 Choose pulse time value: press the key can rise or deduce the show figure, the figure

will rise or deduce automatically if you press the key over 1 second.

4.9 Grounding: put the grounded copper sheet under work pieces; clamp the work pieces

and copper sheet tightly when welding small work pieces.

4.10 Start welding:

01. Clean the surface rust, grease on the work pieces before welding.

02. Turn on the power button (red button on the rear cover).

03. Press start button on the panel.

04. Choose suitable mode, pulse current, and pulse time according to requirement.

(Please refer to chapter 5 of the detail instruction)

05. Open argon bottle valve, adjust throttle valve under suitable angel. (Attention:

Tread foot switch when adjust the throttle valve, normally 1L/min is economy

and appropriate.)

06. Put the welding electrode on suitable place, tread the switch, then come into a

welding spot.

07. Continuously repeat such action will get a high and wide welding wire. If you are

very skilled with the operation, you can press the “consecutive /single point

button on “consecutive “mode. Press the foot switch tightly, then the machine

will output pulse consecutively and get welding spot.

08. When stop working, please close machine power and argon bottle valve.

Remarks: the figure on the panel will continuous show a while after turn off the

machine. The figure will disappear until all the power in the machine released

completely.

4.11: Resistance welding mode:Choose this mode, we should use resistance welding

electrode gun. Following preparation should be finished before operating:

4.11.1 Check grounding fast connector is screwed tightly.

Operating Manual of SZ-1800

6/18

4.11.2 Put the copper sheet under work pieces (Please use vise fasten the copper sheet

tightly when welding small work pieces, for secure good touching.)

4.11.3 Check the resistance electrode tip, secure it is clean and smooth:

The method is like this: Press resistance welding button, choose suitable value

according to the electrode diameter. Press the electrode gun tightly on welding

wire, in case of striking fire.

5. Common Steel Work Pieces Welding

5.1:Plane Welding:

Plane welding include plane and other similar plane circular arc. Work pieces are

the most important part of arch heating in welding. The welding wire can form a

qualified welding spot only when the welding part of work pieces is melting. In practical

operating, the distance between tungsten needle and work pieces is small than the

distance between tungsten needle and welding wire.

Please check following diagram of tungsten needle. Please refer to following pulse

current and time setup.

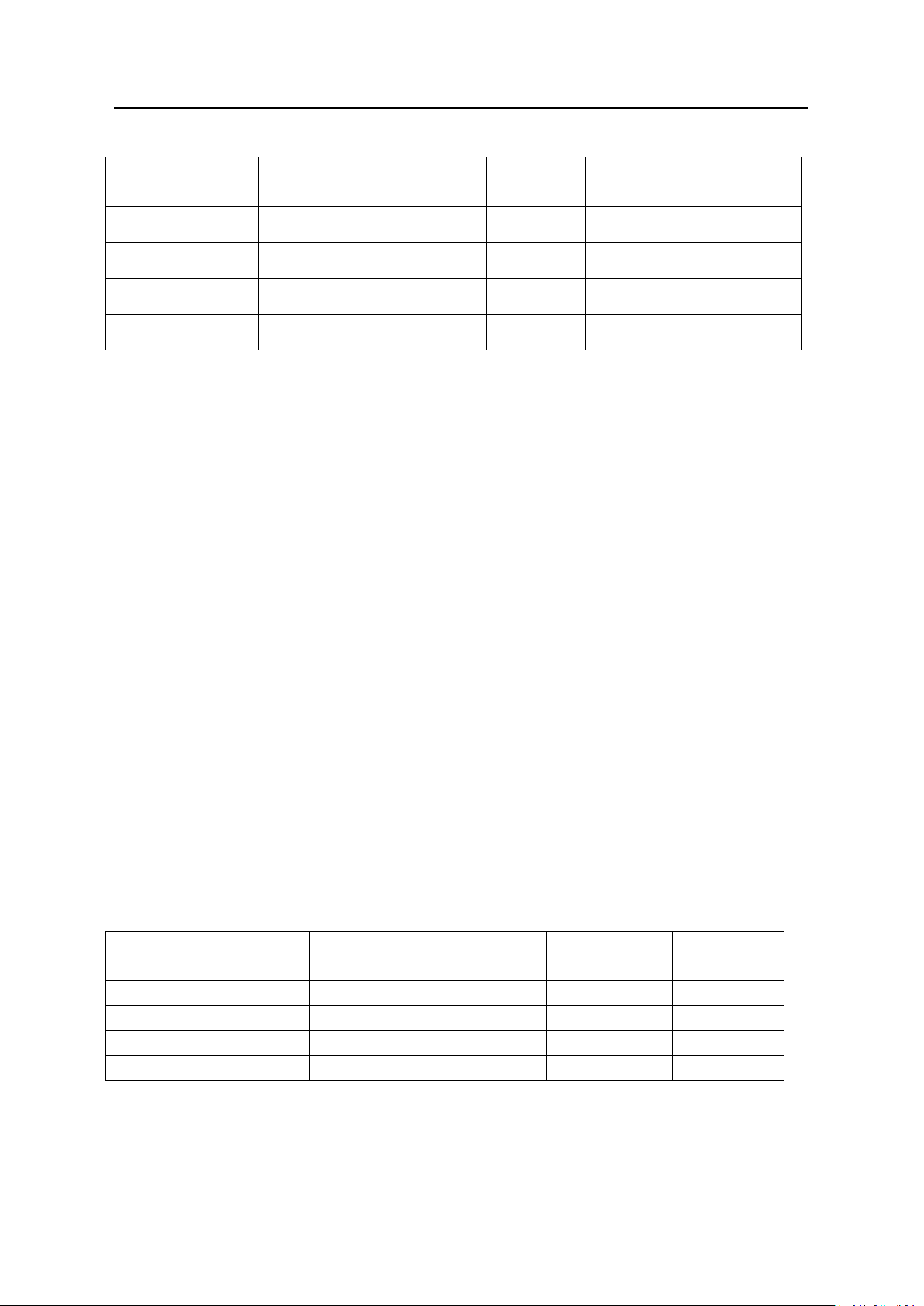

Iron and steel material plane welding parameters:

The data show in this sheet is referred to skilled operator. New operator should add

each figure in the sheet 30% for getting better precise welding effect.

Operating Manual of SZ-1800

7/18

Electrode

Specification(mm)

Mode

Pulse

Current

Pulse

time

Distance from Work

pieces v(mm)

Distance from

Electrode l(mm)

Φ0.2

1

04

05

0.3

0.4

Φ0.3

1

06

06

0.3

0.4

Φ0.4

1

10

10

0.4

0.5

Φ0.5

1

15

15

0.5

0.6

Φ0.6

2

20

20

0.6

0.8

Φ0.7

2

25

25

0.8

1.0

Φ0.8

3

30

30

0.9

1.2

Φ1.0

3

35

35

1.1

1.3

Φ1.2

4

40

40

1.2

1.4

Φ1.6

4

55

55

1.3

1.6

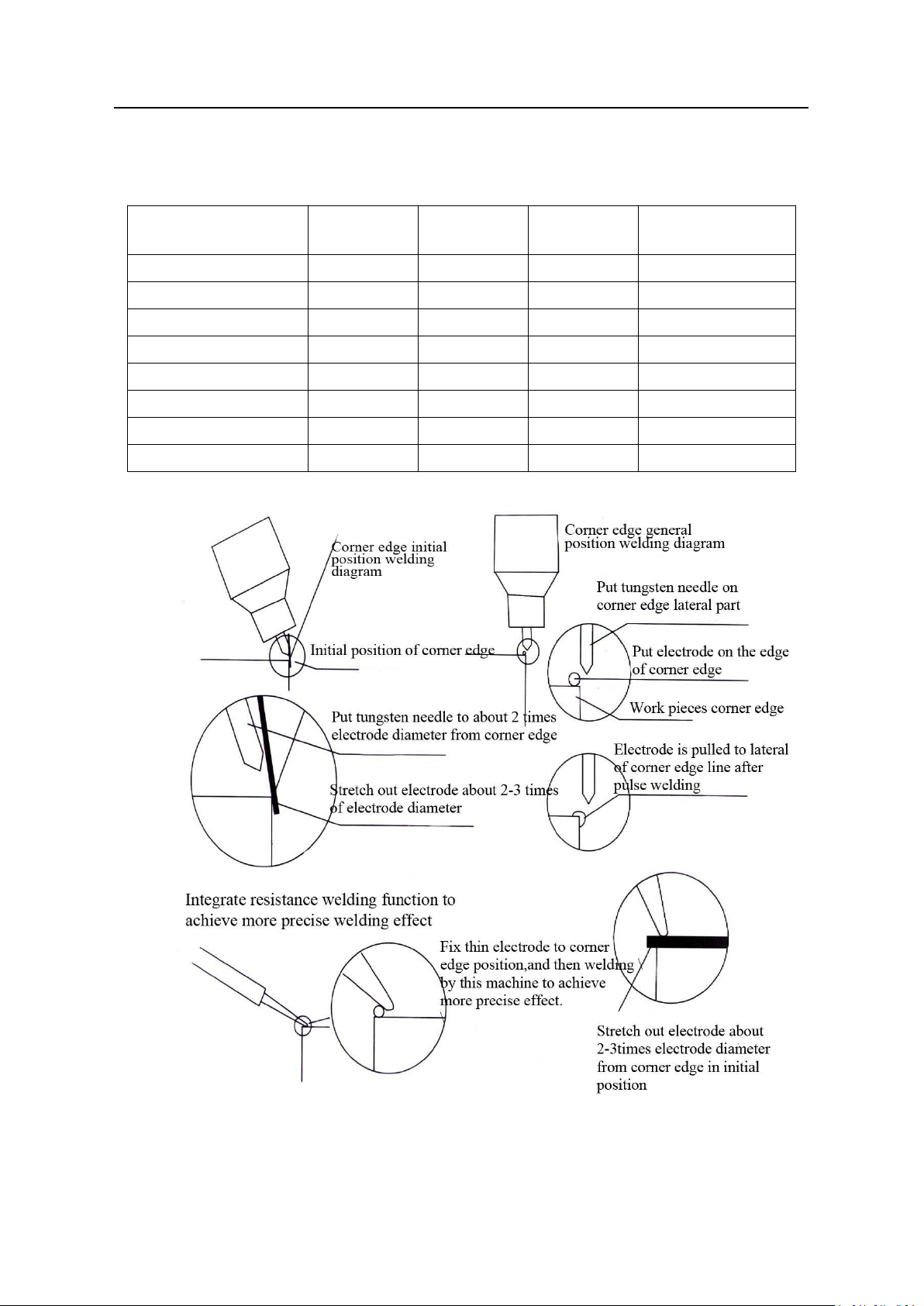

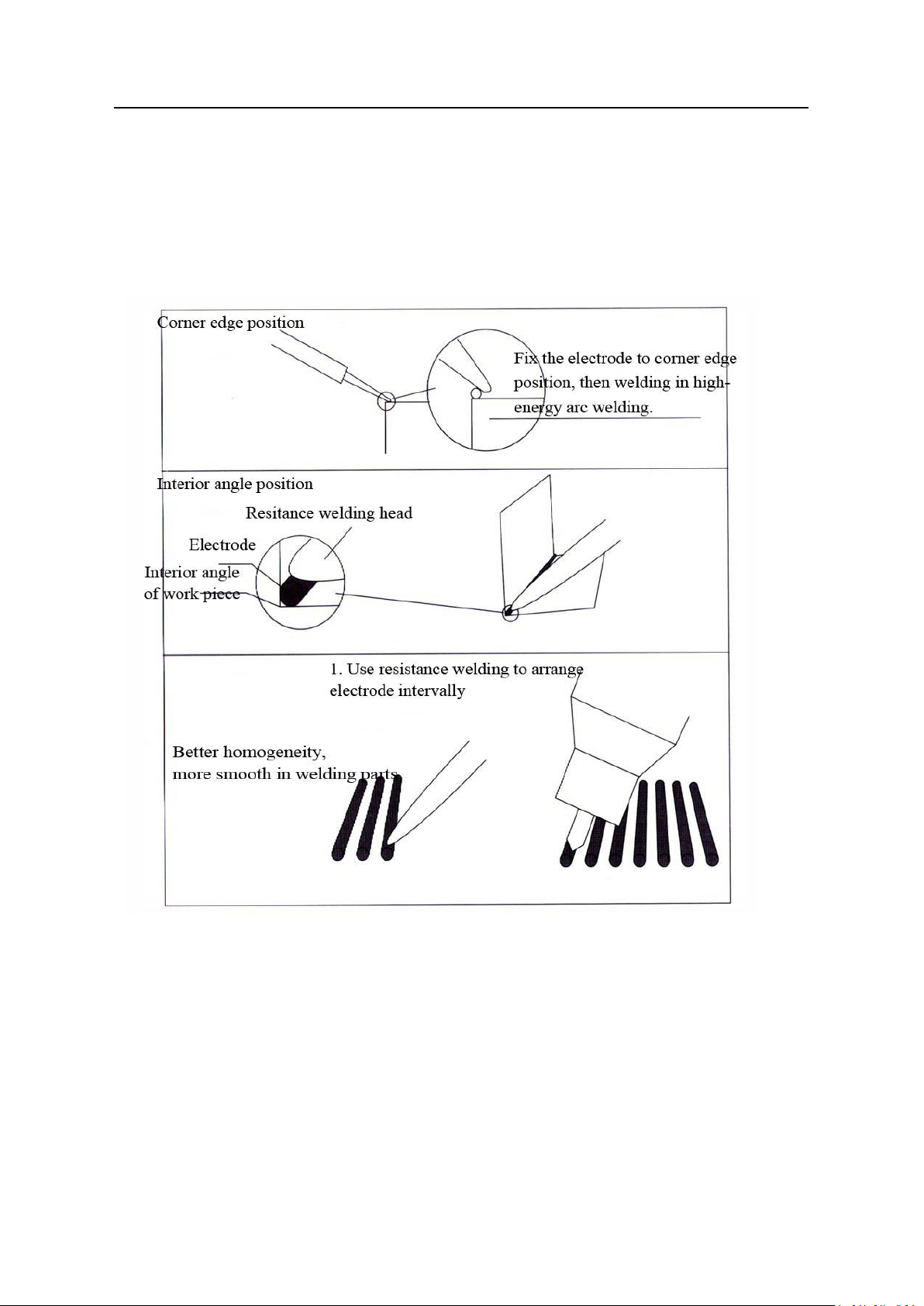

Multi seam welding method diagram 5.2、Corner Edge Welding

Welding corner edge of work pieces is

easy to raise undercut in its top or terminal

part. As corner edge work pieces dissipate

heat is small, the focus of arc heating is

different between plane welding and

corner welding. The heating center of

corner edge can be a little focus on

electrode, while use high heat electrode

fluid to melt the sharp corner edge in the

work pieces. So, the two parts will be

merged together, which avoid undercut of

the work pieces.

5.3 Interior Angle Welding

The interior angel is the inclined angle formed in two work pieces which is equal or

less than 90 degree. If use normal welding method to weld, some bottom parts can’t be

welded well, especially in welding small parts. You should grind tungsten needle into very

sharp shape (less than 20 degree). The distance between tungsten needle tip and bottom

angle, side profile is very small, and then the two sides’ materials will be melted together

into the center part, and form a welding spot. If no welding spot formed in the center,

please try to remove tungsten needle to near bottom position, or try to increase welding

current until a welding spot formed in the center.

Next step is remove the center of tungsten needle to 1/2 position between welding

spot and welding edge.

Operating Manual of SZ-1800

8/18

Iron and steel material corner edge welding parameters

The data in this sheet is for skilled operator reference. New operator please adopts

resistance welding.

Electrode

specification (mm)

Mode

Pulse

current

Pulse time

Distance to

electrode(mm)

Φ0.2

1

03

6

0.4

Φ0.3

1

03

8

0.4

Φ0.4

1

05

11

0.5

Φ0.5

1

08

13

0.6

Φ0.6

2

10

15

0.8

Φ0.7

2

14

20

1.0

Φ0.8

2

18

25

1.2

Φ1.0

2

22

30

1.3

Operating Manual of SZ-1800

9/18

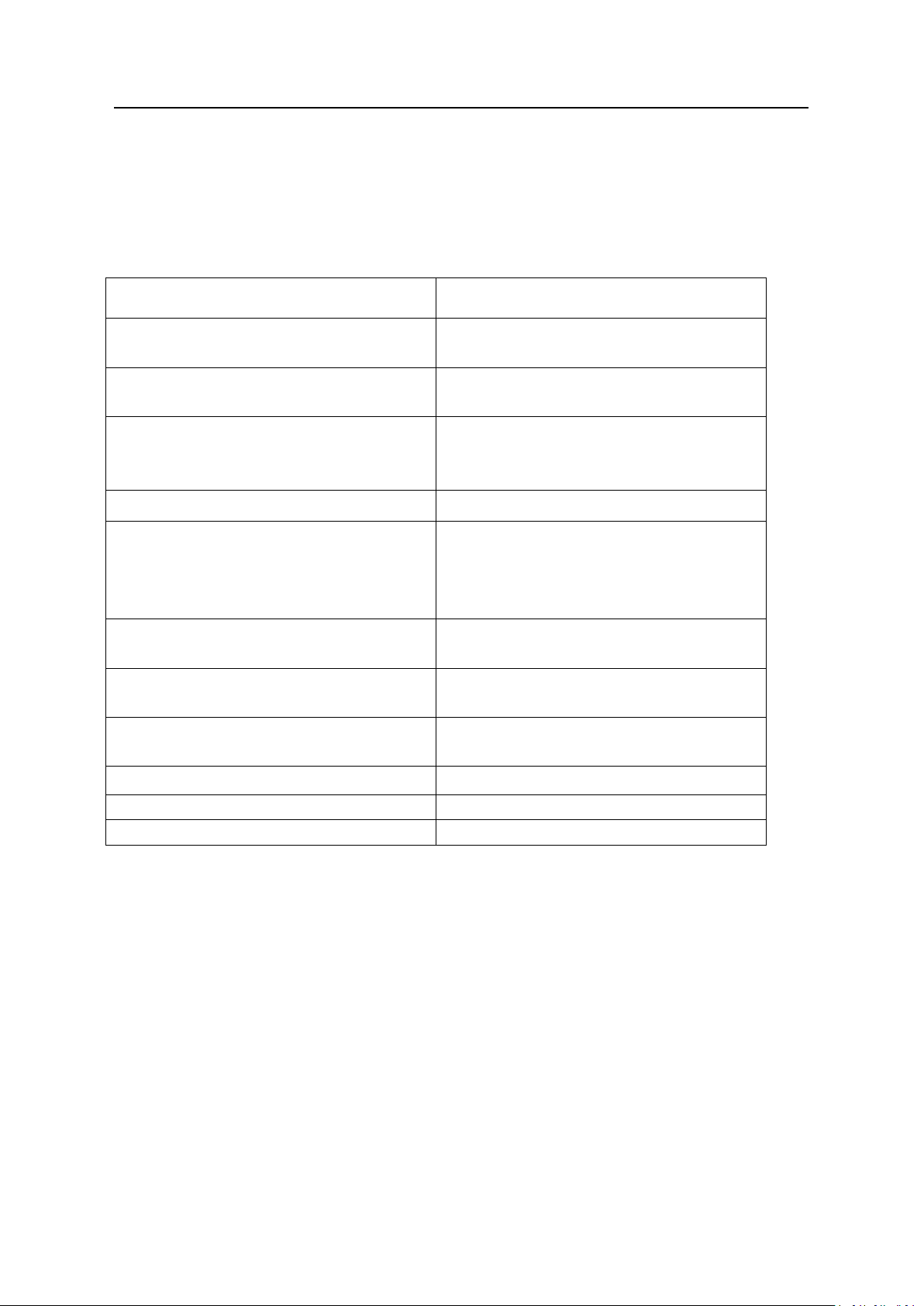

Iron and Steel Material Interior Angle Welding Basic Parameters

Basic angle

welding (mm)

Mode

Pulse

current

Pulse time

Distance to basic

angle(mm)

0.3

1

05

05

0.2

0.5

1

10

15

0.3

0.8

2

18

20

0.4

1.2

2

22

25

0.5

1.6

3

25

30

0.6

2.0

3

28

30

0.8

NOTE: The data in this sheet is when the tungsten needle tips in good condition. If the

tungsten needle is not sharp, electrode and work pieces will not be fused well. We should

increase pulse current for reparation though it is not best option.

Operating Manual of SZ-1800

10 /18

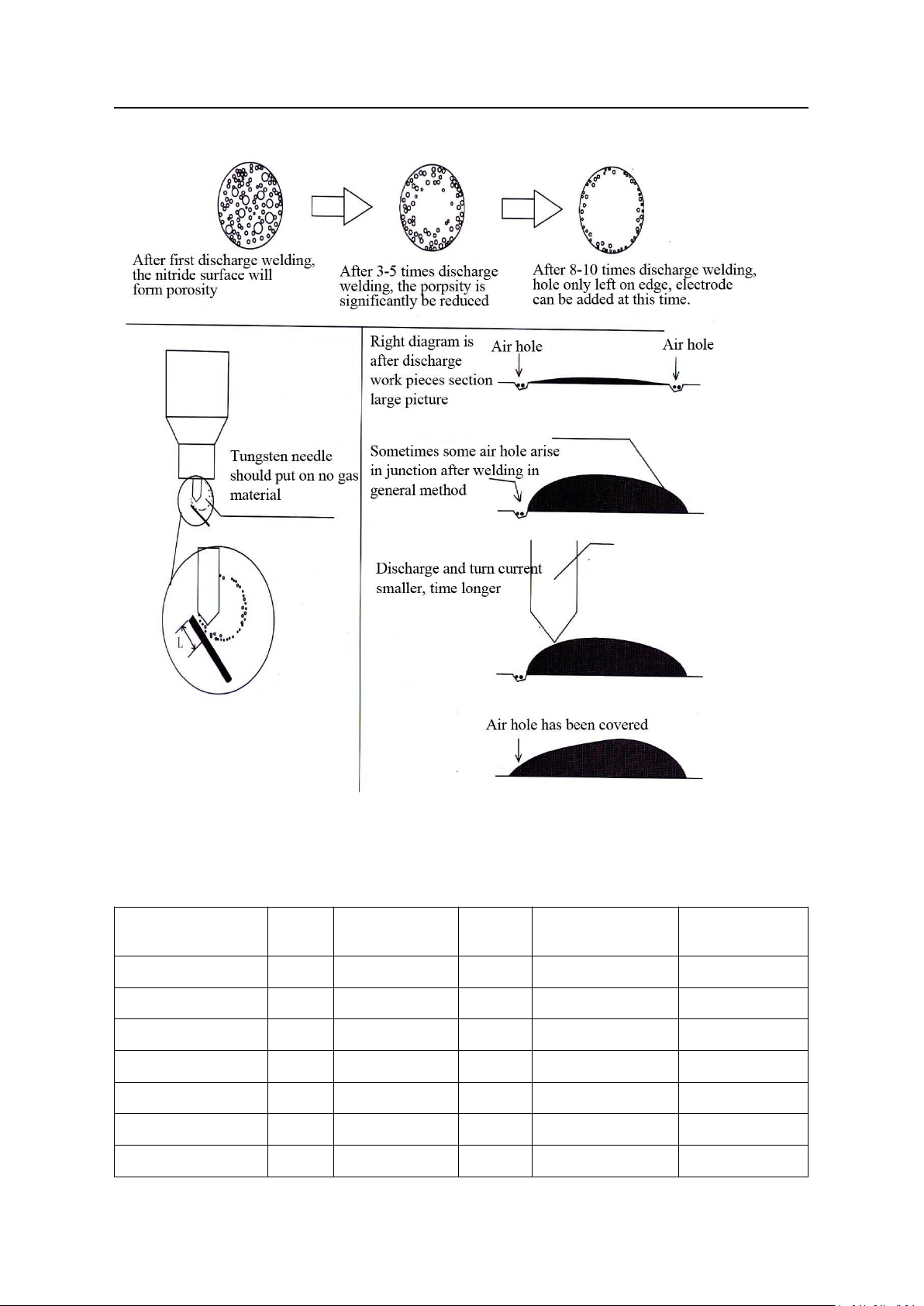

6: Nitriding work pieces welding

Much nitrogen molecule will penatrate into the workpieces when do nitriding.

Nitrogen will overflow fastly in welding under high temperature, which lead to many gas

holes in weld pool, even some melted metal will splash to tungsten needle and influence

welding. So, we should eliminate nitrogen for qualified welding. We adpot repeat arc

melting method to eliminate nigtrogen. Usually it takes 5-10 times arc melting. Please grind

the nitriding layer first if the welding work pieces is large.

To eliminate seam with many pin holes after welding, we should adpot this method.

Put tungsten needle on the junction of welding spot and nitriding layer 0.4mm-0.6mm

part. The length of tungsten needle is about 0.4mm, and put electrode on lateral of junction

part (please check following picture). Adjust welding spot temperature which can melt

electrode and cover junction seam. If the height of welding spot is over 0.5mm in this

process, please grind it below 0.2mm for easy delimiate the pin holes.

Operating Manual of SZ-1800

11 /18

Nitrogen Work Pieces Welding Parameters

Electrode

specification(mm)

Mode

Pulse current

Pulse

time

Distance to work

pieces V(mm)

Distance to

electrode(mm)

Φ0.2

1

04

12

0.3

0.4

Φ0.3

1

04

12

0.3

0.4

Φ0.4

1

06

18

0.3

0.4

Φ0.5

1

08

22

0.4

0.5

Φ0.6

2

11

25

0.6

0.8

Φ0.7

2

15

30

0.6

0.9

Φ0.8

2

18

35

0.8

1.0

Operating Manual of SZ-1800

12 /18

Chip welding 0.2

2

10

10

0.4

0.4

NOTE: The data in this sheet is used in sharp tungsten needle tip. If the tungsten needle is

not sharp, please repair it immediately. The data in this sheet is used for eliminating

the pin hole of welding spot edge. The data is not suitable for those have eliminated

gas or grinded nitride layer part welding. Please refer to Iron and Steel Material Work

Pieces Sheet for eliminated gas or grinded nitride layer welding.

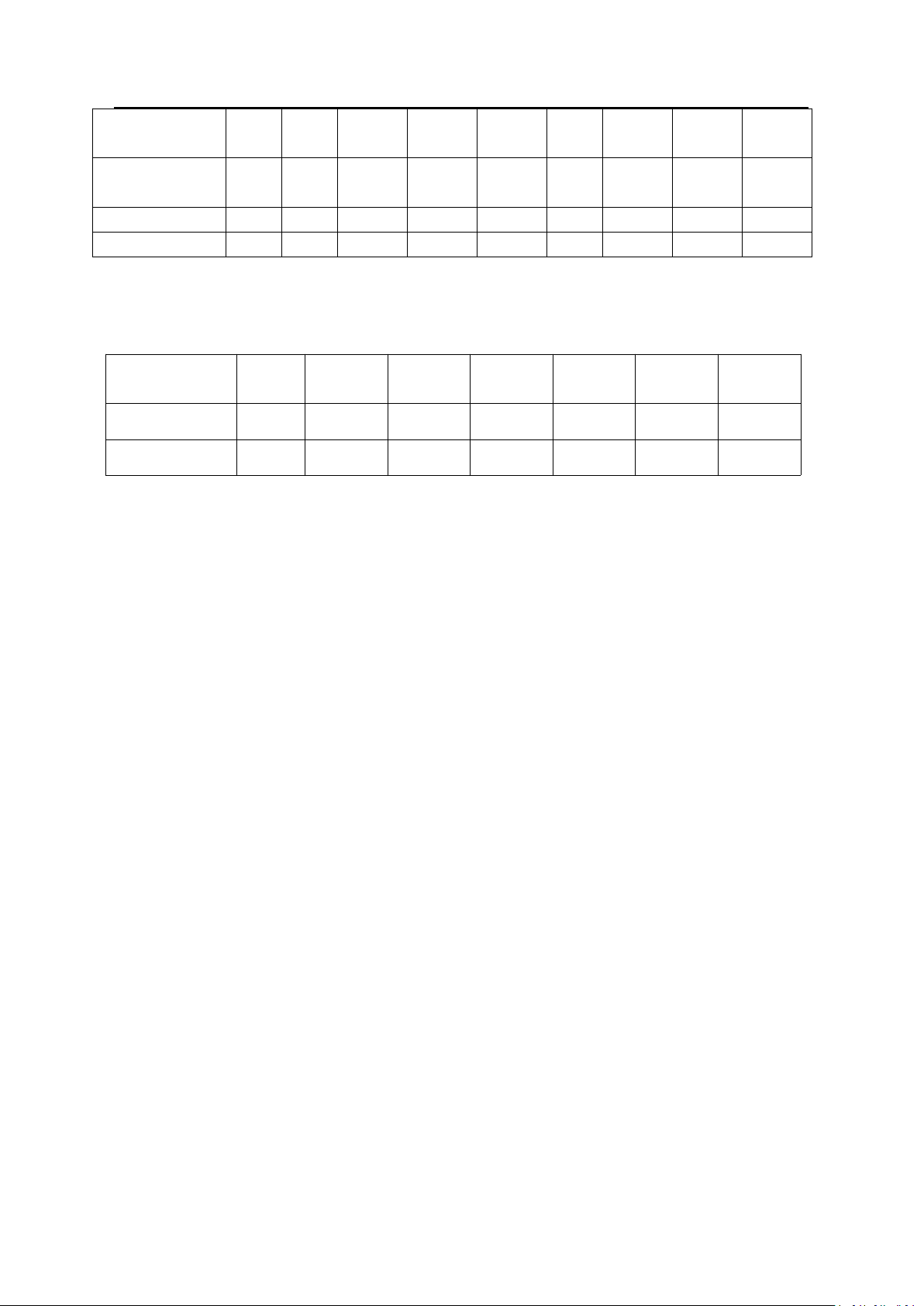

7: Stainless Steel Plate Welding

7.1: Splicing

Splicing is: Splicing two same thickness plates together to be one plate; or welding rolled

plate as a whole.

Spare parts jointing seam should be small and smooth in splicing and welding.

Generally, adjust parameter is as follow:

Plate

Thickness(mm)

0.50

0.60

0.70

0.80

Pulse current

value

12

20

30

40

Pulse time value

12

20

30

40

Inspect welding power standard:

Check the back seam of welding spot whether it is fused. Use two same thickness

plates and same welding parts for trial welding. Fold the work pieces after welding;

check if there is a thin seam. Increase the welding current and time if a seam left. Or,

please increase time, to make the time value is bigger than current value. The smaller

value in current, the less material in work pieces, and the time value is bigger, weld

crater is deeper.

7.2: Extend Plate

Sometimes the chip terminal is undersized, please welding more material for extend

plate. We advice the power is as follow:

Plate Thickness(mm)

0.20

0.30

0.40

0.50

0.60

Pulse Current Value

02

03

04

05

06

Pulse Time Value

15

20

25

30

35

7.3: Riveting

7.3.1 Hole riveting power adjustment( unit: mm)

Thickness

0.20

0.30

0.40

0.50

0.60

0.70

0.80

0.90

1.00

Operating Manual of SZ-1800

13 /18

Punching

diameter

0.80

0.80

1.00

1.00

1.00

1.20

1.20

1.20

1.5-2

Welding head

diameter

0.60

0.60

0.80

0.80

0.80

0.90

0.90

0.90

1.00

Current value

05

04

04

06

07

10

12

15

20

Time value

10

12

20

25

30

30

30

30

25

*Welding head diameter is discharge part diameter.

7.3.2:No hole riveting power option:

Thickness(mm

)

0.20

0.30

0.40

0.50

0.60

0.70

0.80

Current value

02

03

04

05

08

12

16

Time value

60

65

70

99

99

99

99

8: Copper and Aluminum Work Pieces Welding

8.1: Purple copper work pieces welding:

The melting point of purple copper is low but good thermal conductivity, so the

instantaneous power of welding might be large, and also the pulse current and pulse time

might be larger in welding process, especially for pulse time is even longer. The tungsten

needle should be grinded spherical. There are two functions:

01: Prevent too intensive current to make the melting copper material splashed out and

formed some small pit.

02: Prevent tungsten needle be stuck and broken then pollute welding spot. The distance

between tungsten needle, welding wire and work pieces in welding are very near. Tungsten

needle is stuck with welding spot sometimes, but the quality of welding spot will not be

influenced if the tungsten is not broken. As the purple copper material of welding spot is

loosen, please hammer the work pieces after welding and use it after it become compact.

8.2: Brass work pieces welding:

As the brass is rich in zinc (the ignition point of zinc is low and easy to be burned and

volatilized), so the pulse current is smaller than in welding steel, and pulse time is longer

than welding steel. Please choose thinner than 1.2mm diameter welding wire, and not

sharp in tungsten terminal.

8.3: Bronze work pieces welding:

Bronze welding is easy to be operated, please refer to iron and steel welding method.

8.4: Aluminum work pieces welding:

Operating Manual of SZ-1800

14 /18

Aluminum is good thermal conductivity, and low ignition. Please refer to purple copper

welding method for aluminum welding.

8.5: Purple Copper Welding Parameters:

Electrode

specification(mm)

Mode

Pulse current

Pulse time

Distance for Tungsten

needle to electrode(mm)

Φ0.3

2

10

20

0.2

Φ0.6

3

20

40

0.2

Φ0.8

3

28

50

0.2

Φ1.0

4

35

70

0.2

Note: The distance from tungsten needle to work pieces is the same as tungsten needle to

welding wire. The data in this sheet is suitable for the work pieces which thickness is more

than 10 mm. The pulse current and pulse time will deduce 5% respectively when the

thickness of the work pieces decreases 1mm. The pulse current only need 50% of above

data when welding corner edge, and keep the same pulse time value.

8.6: Brass Welding Parameters:

Electrode

specification(mm)

Mode

Pulse current

Pulse time

Distance for tungsten

needle to electrode (mm)

Φ0.3

2

06

20

0.3

Φ0.6

3

13

40

0.3

Φ0.8

4

20

50

0.4

Φ1.0

4

25

60

0.5

Note: The distance between tungsten and work pieces can be the same as the tungsten

needle and electrode. The pulse current only need 50% of above data when welding

corner edge, and keep the same pulse time value.

Operating Manual of SZ-1800

15 /18

8.7: Aluminum Welding Parameters

Electrode

specification(mm)

Mode

Pulse

current

Pulse time

Distance for tungsten

needle to electrode (mm)

Φ1.0

3

35

40

0.5

Φ1.2

3

40

45

0.6

Φ1.6

3

55

60

0.8

Φ2.0

3

65

70

1.0

Note: The distance between tungsten and work pieces can be the same as the tungsten

needle and electrode. The pulse current only need 70% of above data when welding corner

edge, and keep the same pulse time value.

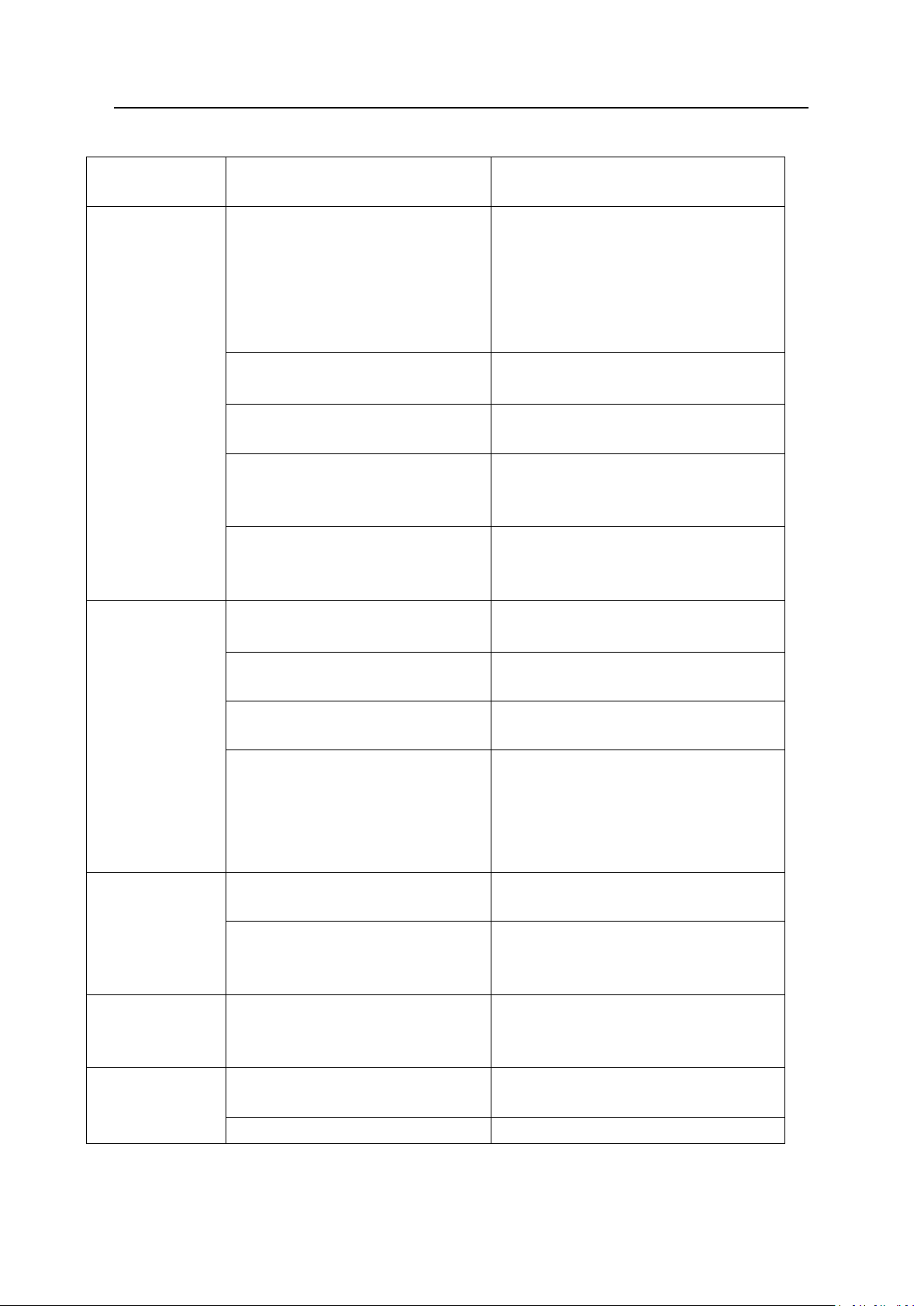

9. Special Technology Skills

9.1When is resistance welding function is suitable?

Resistance welding is a very useful auxiliary function. We can fix electrode on work

pieces simply when use resistance welding, and then arc welding. Resistance welding is

suitable for following:

9.1.1 New operator can do trial welding in advance, for better master the distance

between tungsten needle, work pieces and electrode.

9.1.2 The welding position is too narrow; we can fix the electrode simply, and then do

consecutive welding. This method can improve operating effect.

9.1.3 When some position should be in high smooth and high conductivity, we can

arrange the electrode intensively in advance, and than do consecutive welding.

9.1.4 If some position needs high precise welding effect, any tiny undercut is not

permitted. We can fix electrode for protection in prepared to be welded area.

9.2 Resistance Welding Parameters

Note:

Resistance welding is only suitable for all kinds of copper, steel and stainless steel.

Press purple copper welding head tightly on electrode to prevent damage the surface of

work pieces.

Electrode

specification(mm)

Mode

Pulse current

Pulse time

Φ0.3

Resistance welding

30

---

Φ0.6

Resistance welding

60

---

Φ0.8

Resistance welding

80

---

Φ1.0

Resistance welding

99

---

Operating Manual of SZ-1800

16 /18

It is null if the pulse time screen show”---“when using resistance welding mode. At this

time, adjust relevant pulse current value is available (refer to above sheet). Adjust relevant

pulse current value lower about 30% when use stainless steel wire.

The welding spot density should be 4-7 times as electrode diameter when fix electrode.

That is: if we use 0.6mm electrode, the distance for two resistance welding spot should be

at 2.4mm-4.3mm. The working time will be increased if the welding spot is too density; the

electrode will be instable if the welding spot is too scattered.

9.3 Why use lateral opening ceramic nozzle?

There are two lateral opening ceramic nozzles in tool kits. One side opening

should toward operator’s sight, and abridge the tungsten needle which nearly hide

inside the ceramic nozzle. (If the tungsten needle show out short, it will be better). This

kind of design is better for argon protection, so it can save argon and make welding

spot better. Operator will get better view about the tungsten needle’s position and

height for the opening, which will also bring more convenient and steady operating.

Operating Manual of SZ-1800

17 /18

10: Electrode / Welding Wire Option

Welding wire should be chose the same or similar material as nature. Too large

difference in structure could lead to sand holes, air holes or even can be welded well. If the

welding hardness it too low, the welding part will be abraded or sloughed. If the welding

hardness is too high, the after processing is difficult or will rub the work pieces.

Work Pieces Type

Available Electrode

Common plastic mold steel, hardness is

HRC25-35

H08Mn2SiA,P20

High-grade plastic mold steel, hardness is

HRC30-40

S136、NAK80

Hardware cold mold, damping mold, cutting

mold or tool hard surface, hardness is

HRC50-60

SKD11

All stainless steel work pieces

All stainless steel wire

Grey cast iron, some low hardness spherical

graphite cast iron, hardness is HRC10-20

Don’t use natural material in general ( cast

steel welding hardness is too high), please use

special cast steel welding wire or pure nickel

welding wire

Cast steel, some high hardness spherical

graphite cast iron, hardness is HRC20-40

Nature material, H08Mn2SiA or other similar

hardness welding wire

Special fissile work pieces

Special anti-cracking tensile welding wire, like

import 888T

Purple copper

Purple bronze filament, like purple copper core

in cable

Brass

Similar brand brass wire

Bronze

Relevant bronze

Aluminum, and other AL alloy

Relevant aluminum electrode

Operating Manual of SZ-1800

18 /18

11: FAQ (Frequently Asked Question)

Common

Phenomenon

Reason

Solutions

Electrode not

melt into work

pieces

Far distance from tungsten needle to

work pieces, but short distance from

tungsten needle to electrode.

Put the tungsten needle on

0.3mm-1.0mm position of the electrode,

and keep distance to the work pieces in

about 0.2-0.7mm height. Don’t deviate

the tungsten needle when step on foot

switch.

Machine output power is a little

small

Adjust the machine’s pulse time and

pulse current for increase output power.

Welding spot is not sharp and

disperse

Please check Page 3 and grind the

welding head sharply

The welding gun is too oblique, so

cause the discharge to the electrode

directly.

Try to keep welding gun and work pieces

vertical, 90 degree angle is the best.

The terminal part of the electrode

hasn’t touched work pieces.

Keep welding wire terminal and work

pieces close touching, adjust it when the

welding wire terminal is a little upwards.

Welding spot turn

black or yellow

Tungsten needle is too long and

cause argon protection is not good.

Readjust tungsten needle and keep

exposed part at about 8mm

Machine’s output power is too large

Adjust machine’s pulse time and pulse

current

Work pieces surface is dirty.

Clean work pieces surface oil, oxide

impurities.

Argon is not on or use out

Check whether there is argon spray out of

the spray nozzle when step on foot step.

Please check argon bottle valve, reducing

pressure valve for normal working if no

feeling of the argon.

Though can hear

arc sound, can’t

weld

Grounding cable hasn’t connected

with work pieces

Connect grounding wire to work pieces

Handle it too high and haven’t

touched metal induction coil of the

welding gun.

Keep one finger or palm touching metal

induction coil to secure arc when handle

welding gun.

Can’t be welded

after bead in

electrode

The diameter is larger than original

welding bead section. Then welding

power is not enough.

Cut bead section, or put tungsten needle

lower than standard position.

Tungsten needle

always stick work

pieces

The distance is too near to work

pieces

Adjust the distance from tungsten needle

to work pieces a little far.

Too much material in electrode

Put electrode far or cut bead section.

Table of contents

Popular Welding System manuals by other brands

Lincoln Electric

Lincoln Electric Airgas RED-D-ARC DX500e Operator's manual

ESAB

ESAB Origo Mig 4001i instruction manual

Parkside

Parkside P-ES 120 Operation and safety notes

CHICAGO

CHICAGO 3223 Assembly and operating instructions

ESAB

ESAB Caddyt Tig 150i Service manual

Lincoln Electric

Lincoln Electric MAGNUM PRO 400A Series Operator's manual