Version:1027130315

1

Thesheetmetalisinsertedinto

thecorrespondinghole,a

vertical pressdown,toensure

thatthesheetmetalcloseto

base

Base

Sheetmetal

Base

sheetmetal

The screwdriver

inserted intothe

roundholefromthe

baseandpushthe

sheetmetalout.

InstuctionMannal of JTY-GD-S832 Point-type

Photoelectric SmokeDetector

Pleaseread through theseinstructionscarefullybeforeinstallationand use!

I. General

JTY-GD-S832 point-typephotoelectricsmokedetectorisaphotoelectric

smokedetector.As anon-polar two-wirepower inputisadoptedinthedetector,

itcandetect thesmokeand send outalarmsignalintimewhen firetaking

place.Asmicrocontrollerisadoptedinthedetector,itcanidentifythesmoke

concentration intellectually.Thedetector monitorssmokeconcentration inthe

workplaceinrealtime.Whilemonitoring,theredindicator blinksandthe

workingcurrent islow.Whentheworksitesmokeconcentrationhasexceeded

thepresetalarmthreshold,thedetectorisalarming and thered indicator

remainson,relayisdriven.Thedetector hasthefunctionofrelaycontact

output, alarmsignalisshownasthechangeofrelaycontact output, alarm

signalcanbekeptandthealarmcanonlyberesetbytheinstantpower

disconnection.Thedetectorhasan automaticcompensation functionagainst

dustaccumulation and canreducetheeffect ofduston thesensitivityofthe

detector.

Thesmokedetector isapplicableinplaceswherefiremightgenerate

volumesmoke,i.e.inindustrialandcivil buildingssuchasintherestaurant,

hotel,teaching building,officebuilding,computer cabinet, archivesandstack

room.

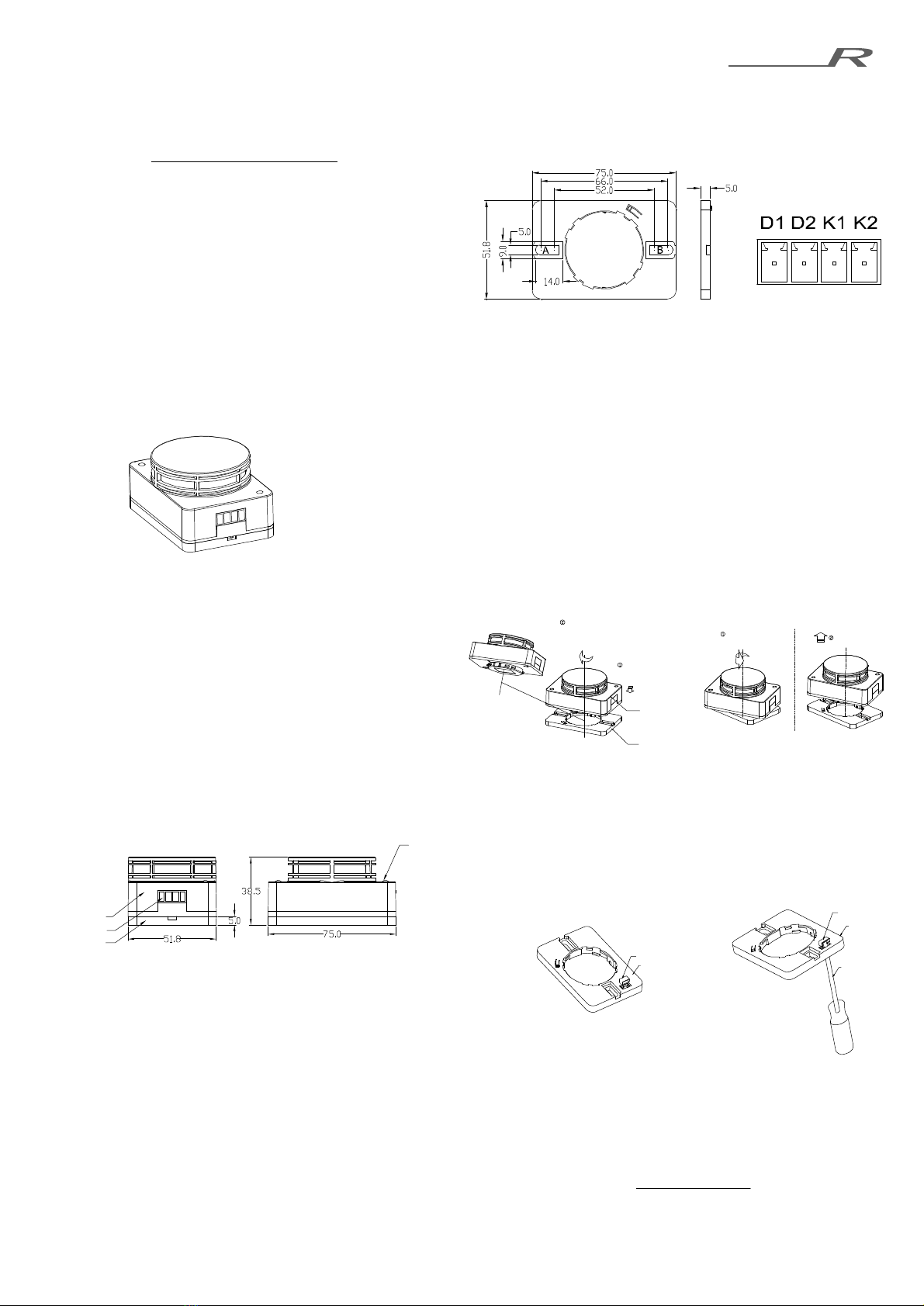

Fig.1

II. Features andtechnicalparameters

1.Executivestandard: GB4715-2005

2.Working voltage: DC12V/24V(allowance:9V~30V)

3.Working current:

During monitoring <1mA@DC12V<5mA@DC24V

Firealarm<30mA@DC12V<35mA@DC24V

4.Relayoutput: normallyopen (closed when alarm)

switchingcapacity 1A30VDC

5.Working indicator:

During monitoring, thered indicatorblinksonceabout per 6s.

Inalarmmode, theredindicatorremainson.

Infault mode, theredIndicator continuouslyblinkstwiceabout per6s.

6.Environment: Temperature: -10℃~+65℃

Relativehumidity:≤95%(40℃2℃non-condensing)

7.Exterior size: 75mm×51.8mm×38.5mm(withbase),asshowninfigure2,

Fig.2

8.Weight: about 80g

9.Standardpackingquantity: 100 PCS/CTN

10.Distancefromfloor: ≤12m

11.Areascovered:seetheprovisionsintheGB50116-98“Codefor Design

ofAutomatic FireAlarmSystem

III. Installation and commissioning

Determinethelocation,mountingdistanceandnumbersformounting the

smokedetectorsintheprotection area inaccordancetotherelevant

stipulationsofGB50116-98.

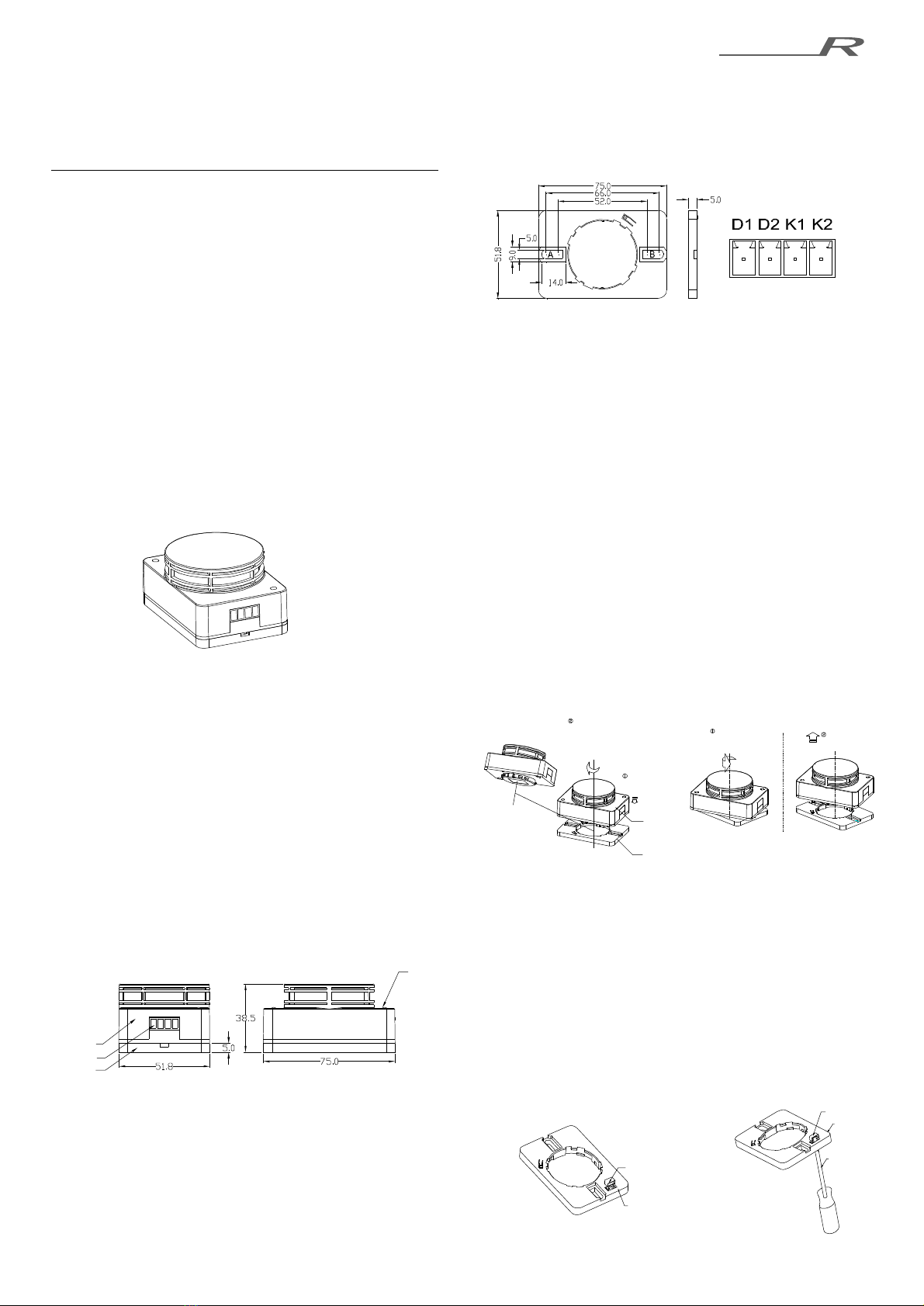

Abaseshowninfigure3isrequiredfor mounting thesmokedetector;its

exterior sizeis75mm×51.8mm×5mm(L×W×H),thesizeofthefixing holeis

5mm×10mmand thedistancebetween theholesis52mm~66mm.

Thesmokedetectorconnectswithpower and other devicevia4PIN

PluggableTerminalBlock.AsShowninfigure4,D1 &D2 pinsarethepower

input terminals; K1& K2pinsaretheoutput terminalsoftherelay.

Fig.3Fig.4

Detailsoftheinstallation andcommissioning areasfollowing:

1.Installed basecanbeusedasfollows:

1)Preparetheshop drawing and fixtheauxiliarybaseontothe

defined location withtwoM4boltsinstalledthroughthetwofixing

holes(A、B showninfigure 3).

2)According totheshop drawing, useadrill toboretwo Φ6mm holes

ontodefinedlocation,then puttwoexpandableplasticstoppers into

theholesseparately, fixtheauxiliarybaseontothedefinedlocation

withtwoST3.5×20mm tappingscrewsinstalledthroughthetwo

fixing holes(A& B showninfigure3);

3)Magnet install intodesignated A, B fixedholeasshowninfigure3,

afterthebaseand thedetectorassembly,adsorbed detector onthe

metalcabinetorrackthrough themagnet, thisinstallationcouldbe

selected.

2.Disconnect thepower,connect all basescorrectlyaspertheshop

drawing,andthenconnect thecontrollerstothecorrespondinginput

ports.

3.Makesurethatall smokedetectorstypescorrespondwiththeones

notedintheshop drawing.

4.Tobeinstalledand disassembledthesmokedetector,asshowninfigure

5and figure6.

Fig.5Fig.6

5.Don’tpower on thecontrolleruntil all smokedetectorshavebeen

mounted correctly;toconfirmcorrect, connect detector powersupply.

First, thered indicator blinks once,and then enterthenormalstateto

monitoraboutevery6secondsblinksonce,indicatingthatdetectors

havebegun working;

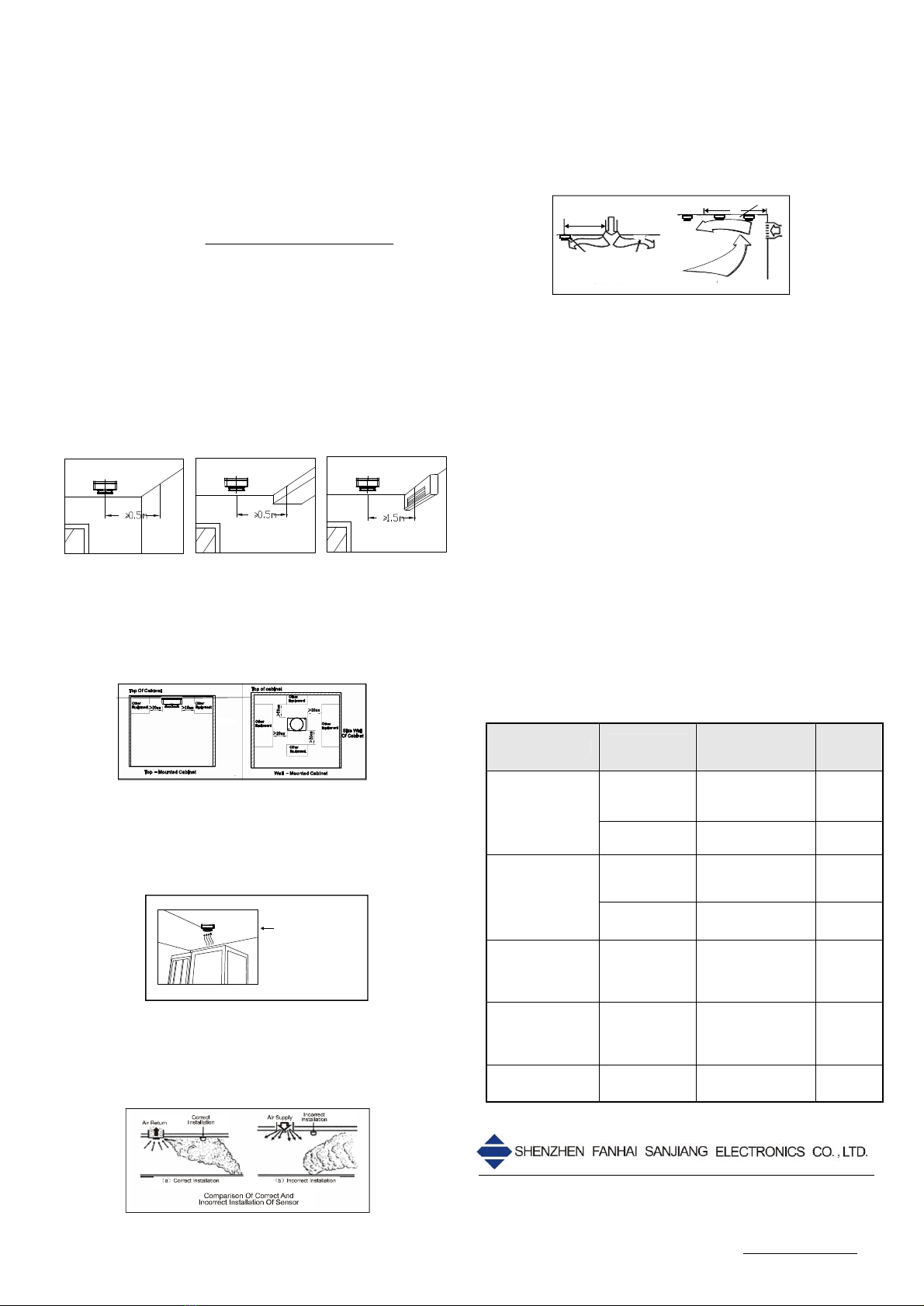

6.Alarmtestofthedetector isperformedbyspecialtoolor puffing smoke

directly.Thered indicator remainsonafterthedetectoralarms.After

testing reset thedetector tomonitoring state.

7.After thebaseandthedetector assembly, Internaltermination

resistor(47KΩ) will beconnectedbetweenthe outputterminalsofthe

relay(K1,K2) throughthesheetmetalon thebase.Installation and

removalofthesheet metal, asshowninfigure7andfigure8.

Fig. 7Fig. 8

Turnthesensor

anticlockwise tothe

arrowed in the top view

Pullupthesensor

fromthebase

【The appearancehas

been applied for patents,

all rights reserved.】

Base

Smoke Sensor

Push down the

smoke sensor make

it align to the base

Turn the smoke

sensor clockwise in

thetop view,when

its bottom downto

the base,continue

turn it to arrowed

Bottom

Indicator

Sensor

Wiring port

Base