Shibuya Hoppmann Cap Star FCCPSTLDSA Instruction Manual

➟

Please copy this

information from the

CapStar

serial plate.

Cap Feeder

ANSI/Metric Installation

& Maintenance Manual

Refer all servicing to

qualified personnel.

This manual is intended

for use by qualified

mechanics and electricians

who install or service the

CapStar Cap Feeder

Inventory Number (Check One):

❑FCCPSTLDSA ❑FCCPSTRDSA

❑FCCPSTLASM ❑FCCPSTRASM

Cap Star

First Edition, Publication Version, All Rights Reserved

Copyright © 2002 by Hoppmann Corporation.

15395 John Marshall Highway

Haymarket, VA 20169

Phone: (703) 753-8888

Toll Free: (800) 368-3582

Fax: (703) 753-7485

http://www.hoppmann.com

Inventory/Serial Number:

CapStar Feeder Installation/Maintenance Manual

2

About this Manual

Assumptions Hoppmann Corporation assumes that all procedures contained in

thismanualwillbeperformedbyaqualifiedmechanicorelectrician

whomustinstall or servicetheCapStar Cap Feeder.Allprocedures

in this manual should be performed by qualified personnel or

under their direction.

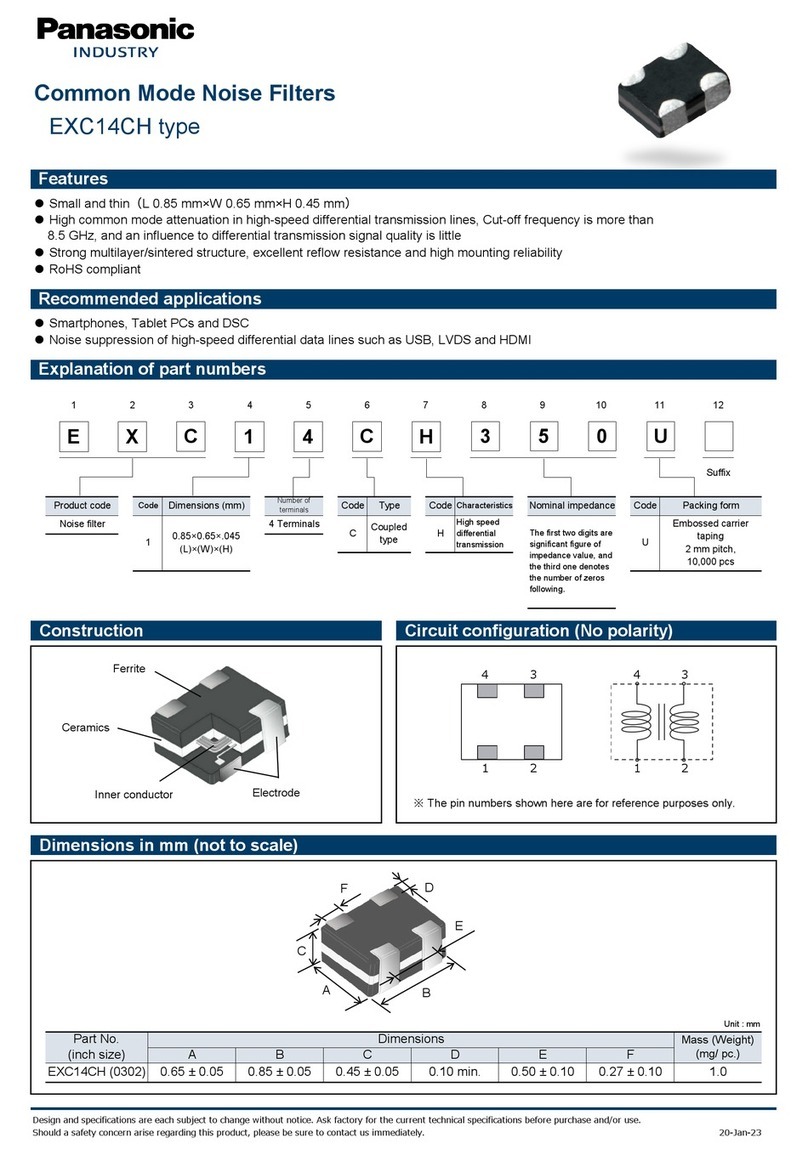

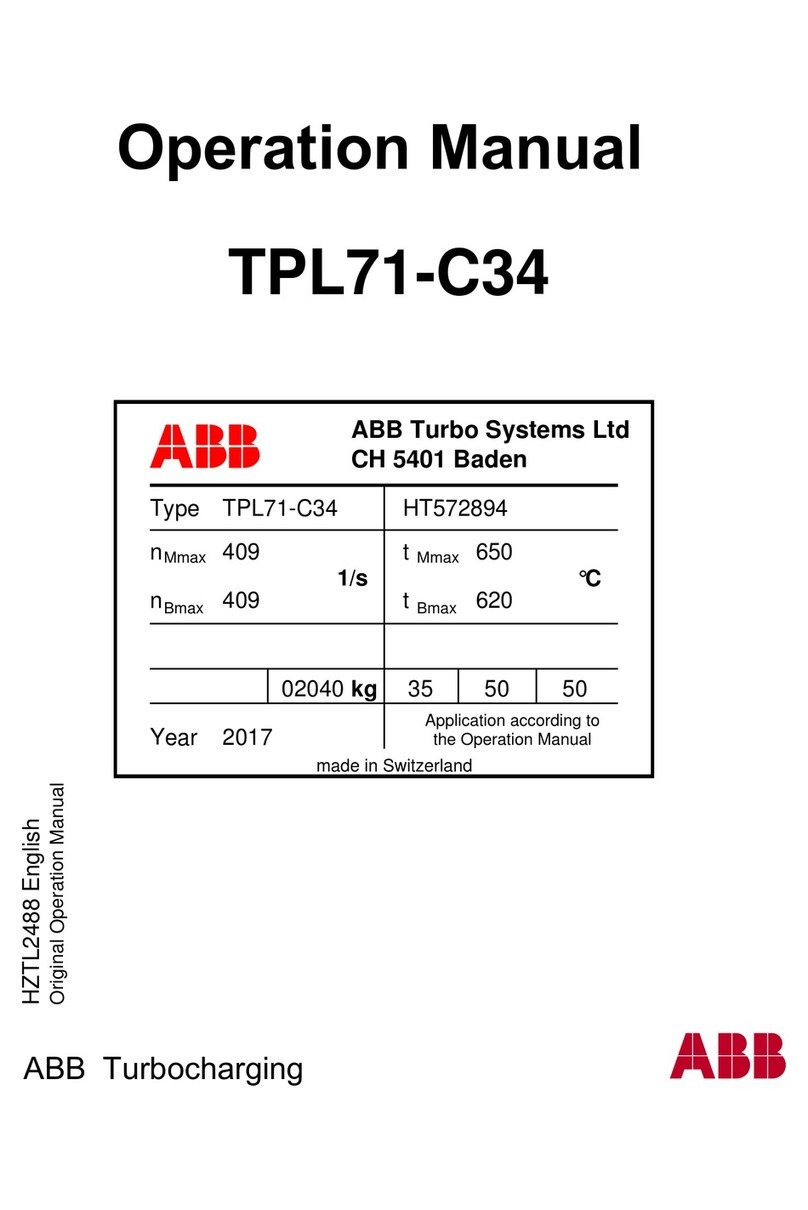

Models Covered This manual covers four models. For spare parts purposes and/or

troubleshooting, locate the inventory number on the serial plate of

the equipment prior to contacting Hoppmann.

Inventory No.

FCCPSTLDSA............... Left Hand, SS, 90 Volt DC Motor

FCCPSTLASM .............. Left Hand, SS, 50 Hz AC Motor

FCCPSTRDSA .............. Right Hand, SS, 90 Volt DC Motor

FCCPSTRASM.............. Right Hand, SS, 50 Hz AC Motor

Caution Symbols Caution symbols and messages in this manual call attention to

and Messages hazardous voltages, moving parts and other hazardous conditions.

The exclamation point caution symbol denotes possible personal

injury and/or damage to the equipment.

Thelightningbolt caution symboldenotespossible personal injury

and/or damage to the equipment from electrical hazards.

Before You Start

Tools You Will Need The CapStar Cap Feeders are offered in both ANSI and metric

versions. For maximum compatibility, ANSI units are classified as

“soft ANSI” construction, meaning that metric threads and hard-

ware are used throughout. Both metric and ANSI units require

metric tools for repair or adjustment.

▲

Quick Start

Equipment Improvements & Hoppmann Corporation continually improves its products and reserves the right to change or

Document Revisions Notice discontinue specifications and designs shown in this manual without notice and without

incurring obligation. Hoppmann Corporation has made every effort to verify the information

contained in this manual, but reserves the right to correct any error at the time of the manual’s next

revision. This manual is subject to change without notice. 7/22/02

3

Quick Start 2About this Manual

2Before You Start

CapStar Description 5The CapStar Cap Feeder: An Overview

& Specifications 6Cap Feeding Process

Figures/Tables:

5Figure 1-1. CapStar Cap Feeder

7Figure 1-2. CapStar Head

8Figure 1-3. CapStar Tooling

9Table 1-1. CapStar Feeder Specifications

10 Figure 1-4. CapStar Feeder Specifications

Safety Precautions 11 Warnings

Installation & Startup 13 If the CapStar Cap Feeder is Already Set Up

13 Unpacking and Inspection

14 Physical Setup

15 Setup

15 Initial Settings

17 Making Tooling Adjustments

19 Motor/Speed Reducer/Idler Assembly

22 Electrical Wiring

Figures:

14 Figure 3-1. Adjusting the Height

17 Figure 3-2. Secondary Hopper Location

18 Figure 3-3. CapStar Tooling

19 Figure 3-4 Height Adjustment

19 Figure 3-5. CapStar Speed Reducer

20 Figure 3-6. DC ANSI Suggested Wiring Diagram

21 Figure 3-7. AC Metric Suggested Wiring Diagram

23 Figure 3-8. CapStar Wiring Schematic

24 Figure 3-9. CapStar Wiring Schematic

ChapterPage

Table of Contents

2

3

1

CapStar Feeder Installation/Maintenance Manual

4

Repair and 25 Preventive Maintenance

Maintenance 25 General Maintenance

25 General Cleaning

25 Conveyor Belt Installation and Replacement

28 Elevator Belt Installation and Replacement

Figures:

26 Figure 4-1. Conveyor Belt Replacement - Exploded View

Replacement Parts 29 Notice to Hoppmann Corporation Customers

31 Warranty

32 Scheduled Preventive Maintenance Log

Figures:

29 Figure 5-1. Serial Plate Layouts

5

ChapterPage

Table of Contents Continued

4

5

1

Description & Specifications

The CapStar Cap Feeder: An Overview

The CapStar Cap Feeder will integrate into an in-line product

handling system, or stand-alone and orient caps (see Figure 1-1).

Function The CapStar Cap Feeder is designed to dispense a wide variety of

cap sizes and shapes, at a cap delivery speed of 40 to 600 parts per

minute. Changeover from one cap style to another takes less than

five minutes and is straightforward. No special training is needed.

Figure 1-1. CapStar Cap Feeder (Right Hand Unit)

Polypropylene

Elevator Belt

Electrical

Cabinet

Primary

Hopper

Singulation

Wiper Horizontal

Conveyor Feed

Belt

Hand Crank

Leveling

Feet

Casters

Pulley

Take Up

Secondary

Hopper

Air Prox

Positive Pressure

Sensor

Return Chute

CapStar Feeder Installation/Maintenance Manual

6

Standard Equipment Standard design features of the CapStar Feeder are:

Features ➤Simple design and ease of use

➤White polypropylene cleated belt

➤FDA approved white urethane impregnated continuous belt

➤No tools required to changeover to another cap style

➤Small footprint

➤Easy retrofit to existing cappers

➤Right-hand and left-hand cap feeders available

Cap Feeding Process

The following description explains the cap feeding process as the

capgoesthroughtheCapStarCapfeederstartingwithadescription

of the unit and then how the CapStar works. Understanding the

process will help the operator or technician in setting up the

machine as well as servicing and troubleshooting the equipment.

Positioning,initial setup and poweringthecapfeederwithelectrical

and pneumatic power will be described in Chapter 3.

The CapStar Cap Feeder is bolted onto an adjustable center stand

using two support arms. The support arms ride on friction guides

that are used to raise and lower the unit when the hand crank is

turned. The vertical movement combined with the caster wheels

allow the unit to be positioned exactly where it is needed.

Caps are loaded into the primary hopper bin (see Figure 1-1

previous page). The elevator uses a continuous belt to transport a

steady supply of caps from the hopper, up and over the center

stand where they are then loaded into a secondary hopper (see

Figure 1-2). The secondary hopper is a settling area to prevent caps

from bouncing away from the horizontal feeder belt.

The caps settle onto the horizontal FDA approved white urethane

feed belt. The belt carries the caps past the singulation wiper and

the height qualifier (see Figure 1-2 and 1-3). These two tooling

features allow only single file caps (one cap diameter at a time) to

pass by and continue down the conveyor. Caps which are

7

misoriented or do not meet the requirements set by the wiper and

qualifier are deflected down the return chute and recirculated.

The single row of caps pass by a positive pressure sensor (the air

prox - see Figure 1-3). The positive pressure sensor continually

blows a low volume, low pressure stream of air at the caps.

As each cap passes the sensor, the air stream blowing down creates

a back pressure. The sensor reads the back pressure, and, if the cap

is misoriented, triggers a reject airjet to blow the cap down the

return chute. Correctly oriented caps are allowed to pass the airjet

and positive pressure sensor, and continue down the conveyor.

Chapter 1 Description and Specifications

Figure 1-2. CapStar Head

Polypropylene

Elevator Belt

Electrical

Cabinet

Singulation

Wiper

Horizontal

Conveyor Feed

Belt

Secondary

Hopper

Return

Chute

Air Prox

Positive Pressure

Sensor

Height

Qualifier

CapStar Feeder Installation/Maintenance Manual

8

See Chapter 3, Installation & Start-up, for the setup details.

Figure 1-3. CapStar Tooling

Height

Qualifier

Air Prox

Conveyor

Tooling

Support

Wall

Orientation

Qualifier

Wiper

Singulation

Wiper

9

Product Specifications ANSI Metric

Inventory No. FCCPSTLDSA FCCPSTLASM

FCCPSTRDSA FCCPSTRASM

Electrical Specifications

Elevator Motor Size 1/4HP 186 Watts

Conveyor/Feed Belt Motor Size 1/5HP 150 Watts

Supply Voltage Refer to Chapter 3 Wiring Diagram

Drive Motor Voltage Refer to Chapter 3 Wiring Diagram

Power Usage Refer to Chapter 3 Wiring Diagram

Weight ≈1000 lbs ≈453.6 kg

Hopper Capacity 4 ft3115 liters

Dimensional Specifications

A. Overall Height 65"- 81"1655 mm - 2060 m

B. Load Height 35"- 51 "908 mm - 1314 mm

C. Discharge Height 46"- 62"1174 mm - 1580 mm

D. Overall Length 60"1536 mm

E. Overall Width 54"1371 mm

F. Belt Width (Horizontal) 6"152 mm

G. Interfaced Conveyor Clearance 7"178 mm

Performance Specifications

Elevator Max Speed 37 feet/min

Conveyor Max Speed 43 feet/min

Table 1-1. CapStar Cap Feeder Specifications

Your direct supplier may have changed some of these specifications

during tooling to better match your application’s requirements.

CapStar Cap Feeder Specifications

Chapter 1 Description and Specifications

CapStar Feeder Installation/Maintenance Manual

10

Figure 1-4 CapStar Cap Feeder Specifications

Your direct supplier may have changed some of these specifications

during tooling to better match your application’s requirements.

CapStar Cap Feeder Specifications

E

F

F

A

BC

L

C

G

11

Warnings

Turn Off Power! Before servicing, make sure you have turned off

compressed air and electrical power in a way which prevents

accidental reactivation. Padlock and clearly tag the appropriate

electrical and pneumatic disconnects. Lockout/tagout procedures

are covered in United States Code of Federal Regulation (CFR)

Title 29 Part 1910.147, “The Control of Hazardous Energy.”

Dress Appropriately! Reduce the risk of injury from moving parts

by securing loose sleeves and other clothing. Do not wear loose

jewelry or neckties near the equipment. Wear safety glasses or

otherprotectiveeye wear whenservicingor operating theCapStar.

Never place hands or tools in the equipment when it is operating.

Avoid Pinch Points! Exposed pinch points include the elevating

belt at the bottom of the hopper and at the intersection of the

horizontal belt. At the horizontal belt where the cap sorter guides

deflect caps.

Avoid Dangerous Conditions! This machine is not designed to

workin explosive or wet environments. Dryconditions arecritical

for a long life. Normal operation inherently causes static electricity

tobuildup;avoid explosive or potentiallyexplosiveenvironments.

Safety Precautions

2

13

3

Installation & Startup

If the CapStar is Already Set Up

IfyoubuyaHoppmann CapStar Cap FeederaspartofaHoppmann

feeder system, then your direct supplier will have performed all

the procedures in this chapter. You will still need to:

▲

Position your CapStar Cap Feeder. Follow the equipment

layout drawing provided by your direct supplier.

▲

Connect Electrical Wiring. Follow as-built electrical diagrams

provided by your direct supplier.

▲

Make Pneumatic Connections. If your CapStar has a hopper

agitator,yourdirect supplier will provideyousetup specifications.

▲

Install and Test the Rest of the System. Installation is complete.

If the Hoppmann CapStar Cap Feeder is drop-shipped to your location,

follow the procedures in this chapter to finish setting up the feeder.

Unpacking and Inspection

Step1—InspectandUnpack the Crate. Removepackingmaterials

from sensors, tooling and moving parts. Make a visual check to be

sure parts have not come loose during shipping. If you find any

concealed damage, call the shipping carrier and your direct sup-

plier immediately. Do not attempt to fix the problem yourself

unless told to do so by your direct supplier.

Step2—Record Serial Number of the CapStar.If you have not

already done so, record the CapStar’s inventory/serial number on

the front of this manual. This information is necessary when ordering

replacement parts or service.

The CapStar Feeder is secured to the floor of the crate and the

weight of the unit is on four leveling footpads. When the unit is

lifted from the floor of the crate, the leveling feet can be raised to

allow the casters to rest on the shop floor. Once the unit has been

positioned, the casters can be locked or the footpads can be

lowered for a stable footing. The leveling feet can be used to level

the unit and they have anchor holes to allow anchoring.

CapStar Feeder Installation/Maintenance Manual

14

Physical Setup

Step 1—Position the CapStar Cap Feeder. Place the feeder as

shown on the equipment layout drawing provided by your direct

supplier.

Step2—Position the CapStar Cap Feeder.The CapStar can be

moved around on it’s casters into position. Press the tab on each

wheel to lock the wheel and keep it from turning. The casters are

locked by stepping down on the locking tabs. When the wheel is

free,step onor press down on theouter edgeof thelocking tab. The

brake engages the wheel and the wheel brake tab protrudes above

the larger locking tab.

To release the brake, step on the small wheel brake tab or lift up on

the larger locking tab.

Lower the feet until the weight is transferred to the feet and engage

the locknuts.

A level should be placed on the horizontal continuous belt and the

unit should be leveled.

The unit can be raised or lowered into position

by turning the hand crank that is located at the

bottom of the center post. The hand crank can

be turned with little effort in either direction

(refer to Figure 3-1).

➮To raise the unit:

- turn the hand crank clockwise.

➮To lower the unit:

- turn the hand crank counterclockwise.

Figure 3-1. Adjusting the Height

Hand

Crank

Pulley

Take Up

Caster

15

Setup

The CapStar Cap Feeder must be setup to run the particular style

of cap. As a point of reference, the hand crank and electrical box

is on the front of the machine. The hopper is the back. The hand

crank is at the bottom and electrical box is at the top of the unit.

Left and right hand CapStar units are distinguished by standing

at the front of the unit and looking back to the hopper. The

pneumatic regulator is located on the support arm.

Initial Settings

To setup for the initial run or to change to another size or style

of cap, block the end of the qualifier with a recirculating plate.

This will allow a quantity of caps to be run without introducing

them into the system.

Step 1—Adjust the Height. Adjust the height qualifier wiper by

loosening the knob and setting the height 1/8"to 1/4" above the cap.

Step 2—Set the Angle. Set the angle of the singulation wiper by

loosing the hand knob and pivoting the wiper so that only one cap

(by diameter) can pass the wiper.

The CapStar Cap Feeder is now setup to send a line of caps to the

orientation qualifier.

Step 3—Orientation. The orientation qualifier is set to allow one

cap (one cap diameter form the edge of the belt to the face of the

singulation wiper) to pass along the conveyor. Any side-by-side

caps will be rejected and pushed by a reject airjet down the return

chute for recirculation. Additionally, the orientation qualifier has

a height adjustment. The adjustment is based on height of one cap

with an allowance of approximately 1/8". To adjust the height

loosen the knobs holding the plate in place, and raise/lower the

plate so that there is a gap of 1/8" between the qualifier and a cap.

Retighten the hand knobs.

Chapter 3 Installation & Startup

Continued

▲

CapStar Feeder Installation/Maintenance Manual

16

Step 4—Fill Hopper. Fill the hopper with a quantity of product to

be fed.

Before connecting air, turn the pneumatic regulator

counterclockwisetopreventthesystemfrombecoming pressurized

when the shop air is attached.

Step5—Connect Power and Air.Connect the CapStar to power and

compressed air to the regulator and set the pressure to and initial

setting of 40 - 50 psi (see Figure 3-1).

The orientation sensor bleeds air continuously. This is normal.

Since bleeding air makes noise, feel around the air lines and the air

line connectors for leaks.

Connect the electrical power by plugging in the end of the power

cord into a properly grounded 115 VAC receptacle. The plug end

should prevent connecting to the wrong voltage.

Turn the main power switch on. Rotate the switch clockwise to

energize. The EMERGENCY STOP switch should be pulled out

and illuminated. When the EMERGENCY STOP switch is pushed

in the electrical power is cut off and the light is off.

If the motors do not start to run, turn the speed controls up until

the elevator belt starts to lift caps out of the hopper. It is

recommended to start at a slow belt speed through the setup.

Watch the caps as they are dropped onto the horizontal feed belt.

Watch the caps pass by the height qualifier. Stacked caps should

be pushed aside and sent down the return chute.

A single line of caps should be passing under the orientation

qualifier. Cavity up caps should pass through and cavity down

caps should be blown down the return chute.

Once the setup is complete, press the stop button.

Remove the recirculating plate from the downstream path of the

caps.

17

Secondary

Hopper

Horizontal

Conveyor

Belt

Electrical

Control

Box

Cleated

Elevator

Belt

Chapter 3 Installation & Startup

The CapStar Cap Feeder is now ready to feed cavity up caps into

the system.

The CapStar Cap Feeder is equipped with a cleanout door in the

base of the hopper, and can be used to quickly empty product for

changeover.

Making Tooling Adjustments

Product which is carried from the primary hopper by the elevator,

belt, is metered into a secondary hopper (see Figure 3-2). The

secondary hopper assists with settling the parts before they enter

the tooling area and horizontal conveyor.

Step 1—Adjust the Speed. The speed at which the elevator is run

shouldbesetso that the productinthesecondaryhoppermaintains

a consistent level. Parts leave the secondary hopper at the same

rate or faster than they enter ensuring the proper fill level of the

secondary hopper.

Figure 3-2. Secondary Hopper Location - CapStar Topview

CapStar Feeder Installation/Maintenance Manual

18

Height

Qualifier

Air Prox

Conveyor

Tooling

Support

Wall

Orientation

Qualifier

Wiper

Singulation

Wiper

Product metered from the secondary hopper loads onto the

conveyorand into the tooling sectionof theCapStar for singulation

and qualification.

Step2—Adjust Height Qualifier. The

height qualifier plate is adjusted to

allow only one part thickness to pass

underneath it. This wiper has 1.88” of

vertical adjustment allowance. The

height qualifier plate is attached to the

deflector plate (see Figure 3-3).

Step 3—Adjust Singulation Wiper.

The singulation wiper is a hinged wall

which can be adjusted to different

angles. The height qualifier wiper and

the singulation wiper work together

(see Figure 3-3). They are adjusted to

allow only one single level of parts to

pass in a single file line.

Step 4—Adjust Air Proximity Vertical and Horizontal Position.

When caps enter the second stage of tooling - or the orientation

qualifier area, the air prox will qualify the part to a cavity up

position. The air prox is attached to the tooling support wall. To

adjust the wall loosen the hand knobs on the back side of the wall,

and move it up or down, in or out, based on the cap size being run.

Place a cap between two flanges (see Figure 3-4 following page),

leaving an 1/8" gap between the top of the cap and the top flange,

and retighten the hand knobs. With regards to the reject airjet,

place a cap beneath the airjet nozzle and adjust the nozzle so that

the vertical tip is no greater than .100” above the surface of the cap.

Adjust the airjet horizontally so that the airflow hits the surface of

the cap as close to the centerline as possible.

Figure 3-3. CapStar Tooling

19

Chapter 3 Installation & Startup

Step 5—Set Air Proximity. The air pressure at the air proximity is

to be set just high enough to trigger the airjet which will fire the

airjet and reject a cavity down part.

Note: All qualified product is discharged at

the end of the conveyor in a single stream

andcontinuestothecustomersdownstream

equipment. Any rejected product, enters the

return chute and is reintroduced into the

system for recirculation.

Motor/Speed Reducer/Idler Assembly

Speed Reducer—No Lubrication Required. The speed reducer

used in the CapStar is lubricated for life with synthetic lubricant

and requires no regular maintenance (see Figure 3-5).

Figure 3-5. CapStar Speed Reducer

Reducer Idler

Assembly

Motor

Motor Mount

Figure 3-4. Height Adjustment

Height

Adjustment

Knobs

Height

Qualifier

Place

Caps

between

Flanges

CapStar Feeder Installation/Maintenance Manual

20

Specifications

CapStar Motor Wiring Diagram - DC ANSI

Elevator Motor

Conveyor Belt Motor

Figure 3-6. DC ANSI Suggested Wiring Diagram

DC Motor Speed

Controller

Line Input

Plug-In Horsepower

Resistor (R21)

KBIC-118

115 VAC

0.05 Ohm 1/4HP

0.10 Ohm 1/5HP

1/4HP Hoppmann Part Number MOTRPM25HP

1/5HP Hoppmann Part Number MOTRP.20HP

1

2

3

4

P2

L2

L1

F -

ACCEL

DECEL

MAXMIN P1

P3

A -

A + F+

R21

IR CL

AC LINE IN

5K Main Speed Potentiometer

P3 - Violet

P2 - Orange

P1 - White

ARMATURE

D.C. MOTOR

CW

RED

BLK

KBIC - 118

&

KBIC - 218

1

3

2

4

Notes:

▲

Do not use this diagram if your CapStar has an AC motor or a different motor speed controller

than shown. Follow the suggested wiring drawing provided by your direct supplier.

▲

Motor Controller Start-Stop Options:

Option 1: Open P3 circuit of speed pot with a pilot duty switch circuit for stop.

Option 2: Interrupt line voltage.

▲

To reverse motor rotation interchange leads A+ and A-.

▲

If equipped with shunt motor then F+ and F- are connected.

▲

For additional info: See “KBIC® Solid State DC Motor Speed Control Installation and Operating

Instructions” in U.S.A. from KB Electronics, Inc., Brooklyn, NY 11207. Plug-In Horsepower Resistor

is a registered trademark of KB Electronics Inc. for its electronic motor control circuit apparatus.

21

Specifications

CapStar Motor Wiring Diagram - AC Metric Drive

Elevator Motor

Conveyor Belt Motor

Figure 3-7. AC Metric Suggested Wiring Diagram

Mounting IEC 63A Face Mounting

186 Watts; Hoppmann Part Number MOTORMAC025

150 Watts; Hoppmann Part Number MOTRM.20HP

T6 T4 T5

T1 T2 T3

L1 L2 L3

T6 T4 T5

T1 T2 T3

L1 L2 L3

HIGH VOLTAGELOW VOLTAGE

220V - 50 HZ 380V - 50 HZ

FRAME

SINGLE

SPEED

DFT 71

DFT 8fl

Protection Level IP54 Protection Level

Chapter 3 Installation & Startup

This manual suits for next models

3

Table of contents

Popular Industrial Equipment manuals by other brands

Flexco

Flexco Clipper Pro 200 Operation manual

ABB

ABB HT572894 Operation manual

TrojanLabel

TrojanLabel T3-OPX user guide

Hussmann

Hussmann austral DH13-1 Series installation manual

Siemens

Siemens Power M12 Plug PRO Compact operating instructions

INOXPA

INOXPA CPG Series Installation, service & maintenance instruction