PRODUCT INSTALLATION MANUAL DH13 HOT FOOD

_________________________________________________________________________________________________________________________

Page 1 Hussmann

Contents

Pre-installation 2

Important Safety Instructions 2

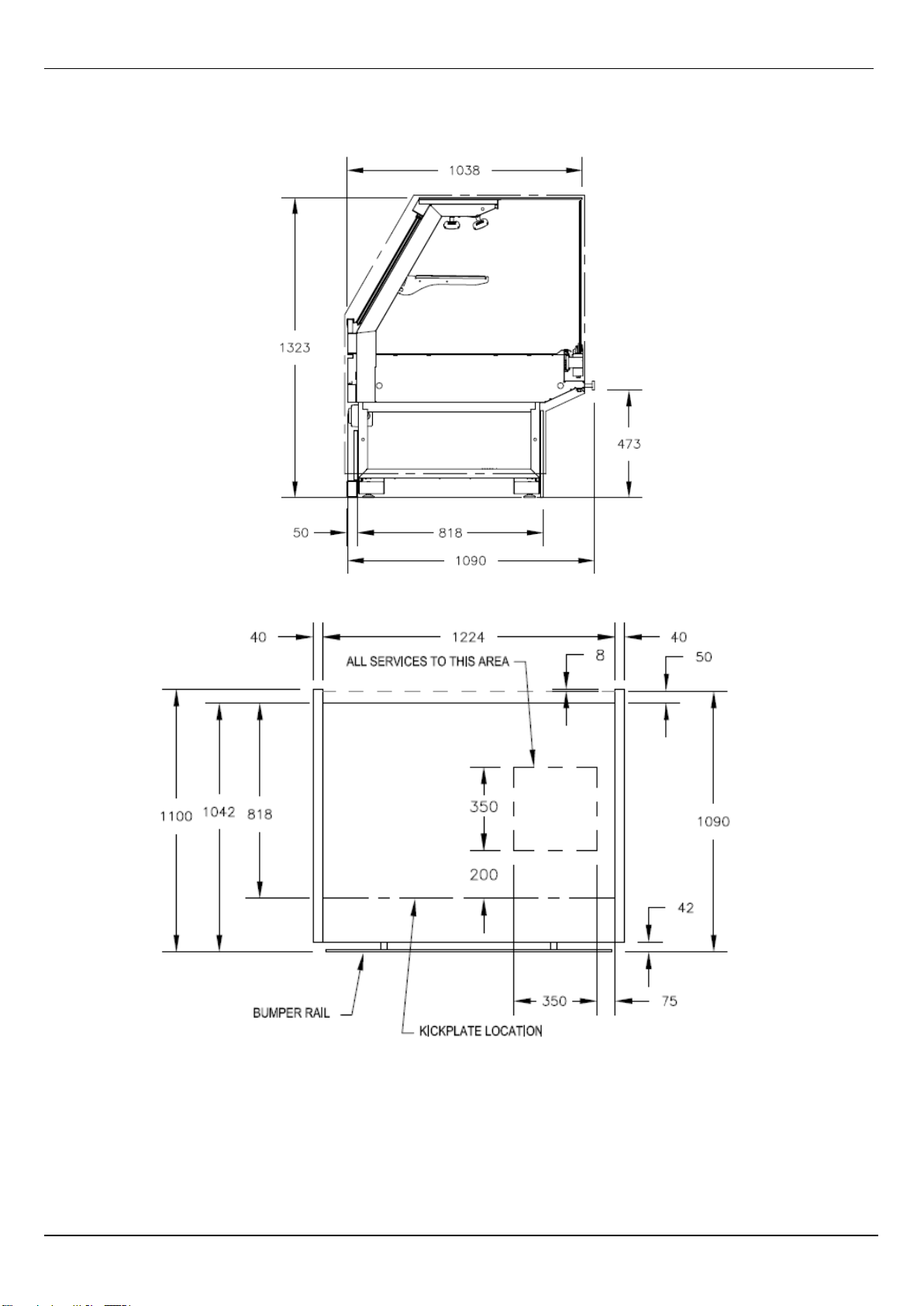

Case services dimensions 3

Operating environment 4

Handling and transporting cases 4

Shipping damages and shortages 4

Installation 5

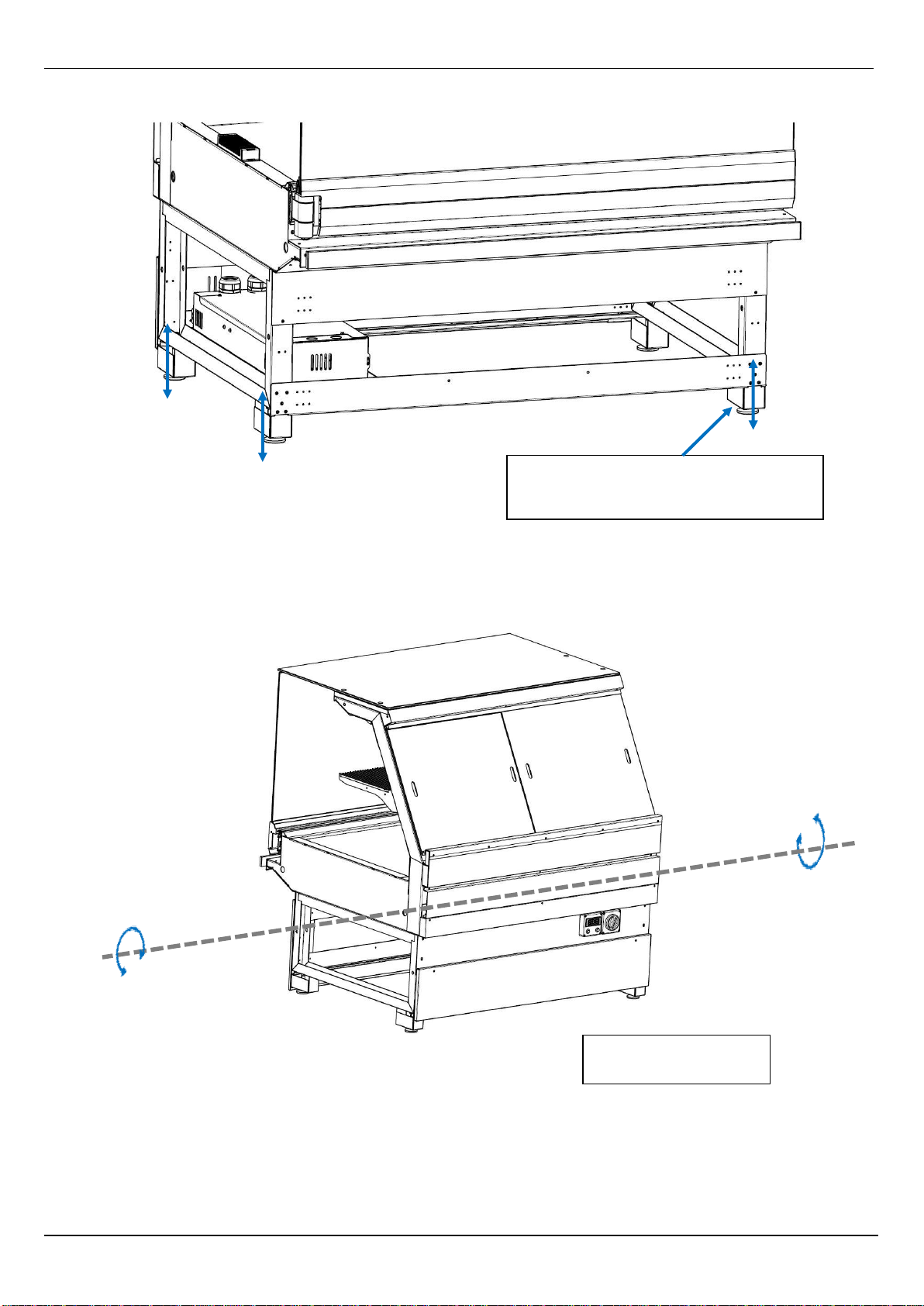

Positioning and levelling 5

Joining the cases 8

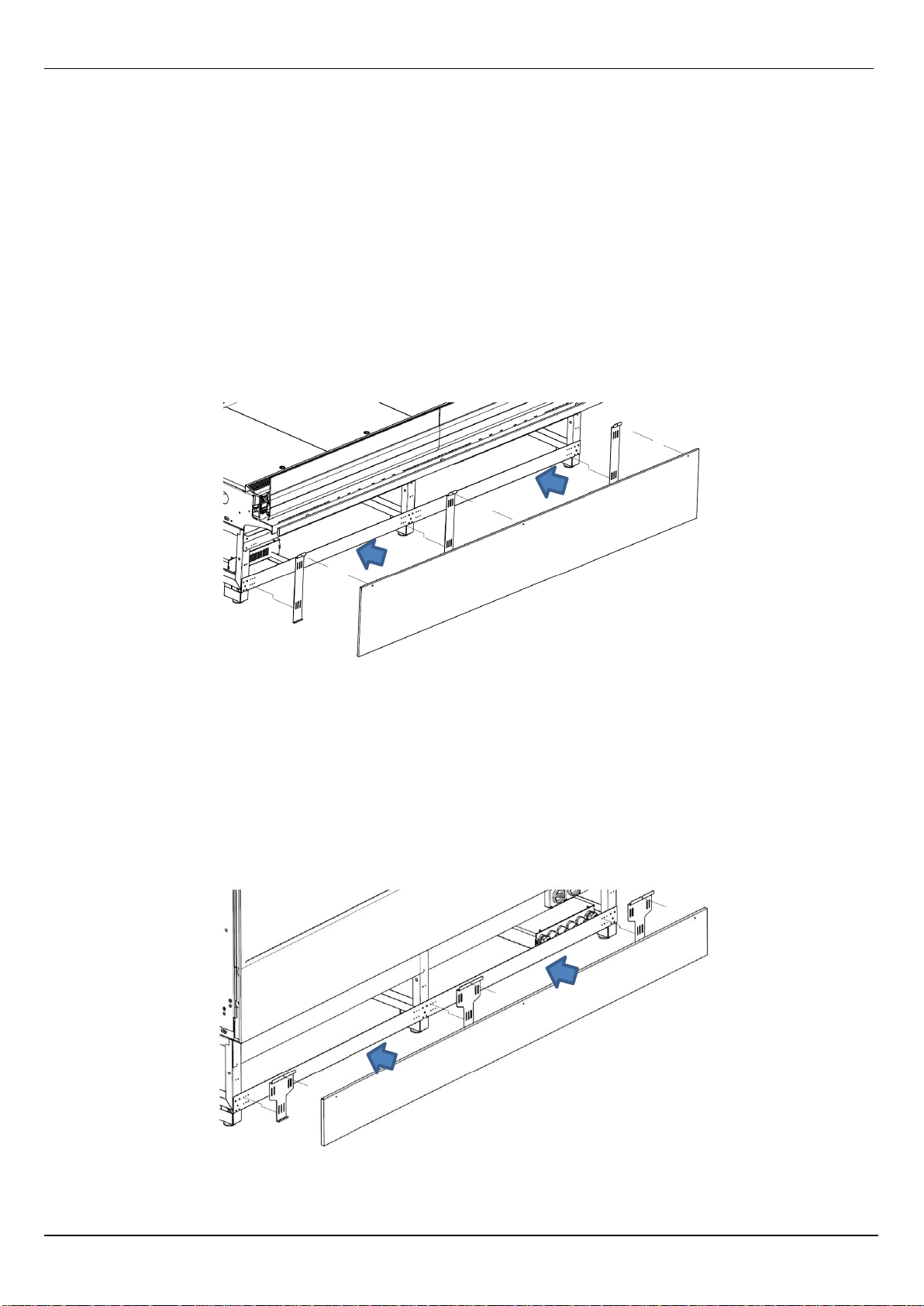

Attaching kick plates 9

Connecting power supply 11

Installing sensor probes 11

Mounting fixtures 12

Commissioning 13

Cleaning case 13

Starting up 13

Start-up checks 13

Decommissioning 13

Disposal 13

Operation 14

Loading Merchandise 14

Cleaning and Maintenance 14

Daily Checks 14

Cleaning 15

Important Notes 15

Cleaning Procedure 15

Six Monthly Maintenance 16

Operation Servicing 16

Troubleshooting 17

Appendixes 18

Appendix 1 Wiring diagrams 18

Appendix 2 Produce Engineering Datasheets 18

Appendix 3 Setting table 18

Appendix 4 Attaching case ends 18

Appendix 5 Top glass horizontal adjustment 20

Appendix 6 Front glass camber adjustment 22

Appendix 7 Risk analysis 23

Appendix 8 Controller 24

Appendix 9 Warranty 25