INOXPA CPG Series Installation and user guide

INSTALLATION, SERVICE AND MAINTENANCE

INSTRUCTIONS

CPG AGITATOR FOR WINE

c/Telers, 54 Aptdo. 174

E-17820 Banyoles

Girona (Spain)

Tel. : (34) 972 - 57 52 00

Fax. : (34) 972 - 57 55 02

MICPG-01_EN

ED. 15.02/08

EC DECLARATION OF CONFORMITY

(In accordance with Directive 98/37/EC, annex II, part A)

We, the manufacturer: INOXPA, S.A.

c/ Telers, 54

17820 Banyoles (Girona) - Spain

Hereby declare that the products

WINERY AGITATOR CPG 200

Year of

Manufacture

Name Type

are in conformity with the provisions of the Council Directives:

Machine Directive 98/37/EC, and comply with the essential requirements of

said Directive and the harmonised standards:

UNE-EN ISO 12100-1/2:2003

UNE-EN 1050:1996

UNE-EN 294/A1/AC:1993

UNE-EN 953:1997

UNE-EN 563/A1/AC:2000

Low-Voltage Directive 2006/95/CE (replacing Directive 73/23/CE), and conform

to UNE-EN 60204-1:1997 and UNE-EN 60034-1/A11:2002.

Electromagnetic Compatibility Directive 2004/108/CE (replacing Directive

89/336/CE), and conform to UNE-EN 60034-1/A11:2002.

In conformity with Regulation (CE) No. 1935/2004 on materials and objects intended to

come into contact with foodstuffs (repealing 89/109/EEC), in accordance with which the

materials in contact with the product do not transfer its constituents to the foodstuffs in

quantities large enough to put human health at risk.

Declaration of Incorporation (Directive 98/37/EC, annex II, part B):

The aforementioned equipment shall not be commissioned until the

machine in which they will be incorporated has been declared as being in

conformity with the Machine Directive.

Josep Mª Benet

T

echnical mana

g

er

Ban

y

oles

,

Februar

y

2008

2013

december

2013

ED.15.02/08 1.Safety 3

1. Safety

1.1. INSTRUCTIONS MANUAL

This manual contains information about the receipt, installation, operation, assembly, disassembly and maintenance of the CPG

agitators.

The information published in the instruction manual is based on updated information.

INOXPA reserves the right to modify this instruction manual without prior notice.

1.2. START-UP INSTRUCTIONS

This instruction manual contains vital and useful information to appropriately handle and maintain your agitator.

Read these instructions carefully before starting up the agitator; become familiar with the operation and use of your agitator

and follow the instructions closely. These instructions should be kept in a safe location near the installation.

1.3. SAFETY

1.3.1. Warning symbols

Danger of injury caused by rotating

equipment parts.

Danger for persons in general

Electrical danger Danger! Caustic or corrosive agents.

Danger to the correct operation of the

equipment.

Danger! Suspended loads

Protective goggles requirement.Commitment to safety at the workplace.

1.4. GENERAL SAFETY INSTRUCTIONS

Read this instruction manual carefully before installing and starting the agitator. Contact INOXPA in

case of doubt.

1.4.1. During installation

The

Technical Specifications

of Chapter 8 should always be observed.

Check that the agitator anchoring is correct and that the shaft is perfectly aligned. Otherwise, this

may lead to serious mechanical problems in the agitator.

Check that the motor specifications meet the requirements, especially when working under

conditions that involve the risk of explosion.

During the installation, all the electric work should be carried out by authorised personnel.

1.4.2. During operation

The

Technical Specifications

of Chapter 8 should always be observed. Under no circumstances can the

limit values specified be exceeded.

NEVER touch the agitator during operation if it is being used in a hot-liquid tank due to the risk of

burns.

4 1.Safety MICPG-01_EN

The agitator contains moving parts. Never place your fingers inside the agitator while it is in

operation.

Remove the agitator before closing the valve.

NEVER spray the electrical motor directly with water. The standard protection for the motor is

IP- 55: Protection against dust and sprayed water.

The agitator cannot operate without fluid. Standard agitators are not designed to work during the

filling or emptying of tanks.

1.4.3. During maintenance

The

Technical Specifications

of Chapter 8 should always be observed.

NEVER disassemble the agitator until its temperature has decreased and can be handled safely.

Always use appropriate protective clothing while operating the agitator.

Do not leave parts loose on the floor.

ALWAYS disconnect the agitator from the power supply before starting maintenance work. Remove

the fuses and disconnect the cables from the motor terminals.

All electrical work should be carried out by authorised personnel.

1.4.4. Compliance with the instructions

Any non-fulfilment of the instructions may result in a risk for the operators, the environment and the machine, and may result

in the loss of your right to claim damages.

This non-fulfilment may result in the following risks:

•Failure of important functions of the machines/plant.

•Failure of specific maintenance and repair procedures.

•Possibility of electric, mechanical and chemical risks.

•Will place the environment in danger due to the release of substances.

1.4.5. Guarantee

Any warranty provided shall immediately be cancelled and void

ipso jure

, and INOXPA shall be compensated for any product

liability claim from third parties, if:

•the service and maintenance work was not carried out in accordance with the service instructions, or the repair work has

not been carried out by our personnel or it has been conducted without our written authorization;

•our equipment has been changed without prior written authorization;

•the parts or lubricants used are not original INOXPA parts and products;

•the materials were used incorrectly or negligently, or not in accordance with these instructions and their intended use;

•agitator parts were damaged by excessive pressure owing to the lack of a safety valve.

The General Delivery Terms already provided also apply.

No change can be made to the equipment without prior discussion with the manufacturer. For your

safety, please use original spare parts and accessories.

The use of other parts will exempt the manufacturer from any liability.

The service terms can only be changed with prior written authorisation from INOXPA.

Please do not hesitate to contact us in case of doubts or if more complete explanations are required on specific data

(adjustments, assembly, disassembly, etc.).

ED.15.02/08 2.Table of Contents 5

2. Table of Contents

1. Safety

1.1. Instructions manual......................................................................................................... 3

1.2. Start-up instructions........................................................................................................ 3

1.3. Safety............................................................................................................................. 3

1.4. General safety instructions............................................................................................... 3

2. Table of contents

3. General information

3.1. Description...................................................................................................................... 6

3.2. Range of application........................................................................................................ 6

4. Installation

4.1. Receiving the agitator...................................................................................................... 7

4.2. Transport and storage ..................................................................................................... 7

4.3. Location.......................................................................................................................... 8

4.4. Electrical installation........................................................................................................ 8

5. Start-up

5.1. Start-up.........................................................................................................................10

6. Operating problems

7. Maintenance

7.1. General information........................................................................................................12

7.2. Storage..........................................................................................................................12

7.3. Cleaning ........................................................................................................................12

7.4. Disassembly / assembly of the agitator............................................................................13

8. Technical Specifications

8.1. Technical Specifications ..................................................................................................14

8.2. Weights.........................................................................................................................14

8.3. CPG agitator dimensions.................................................................................................15

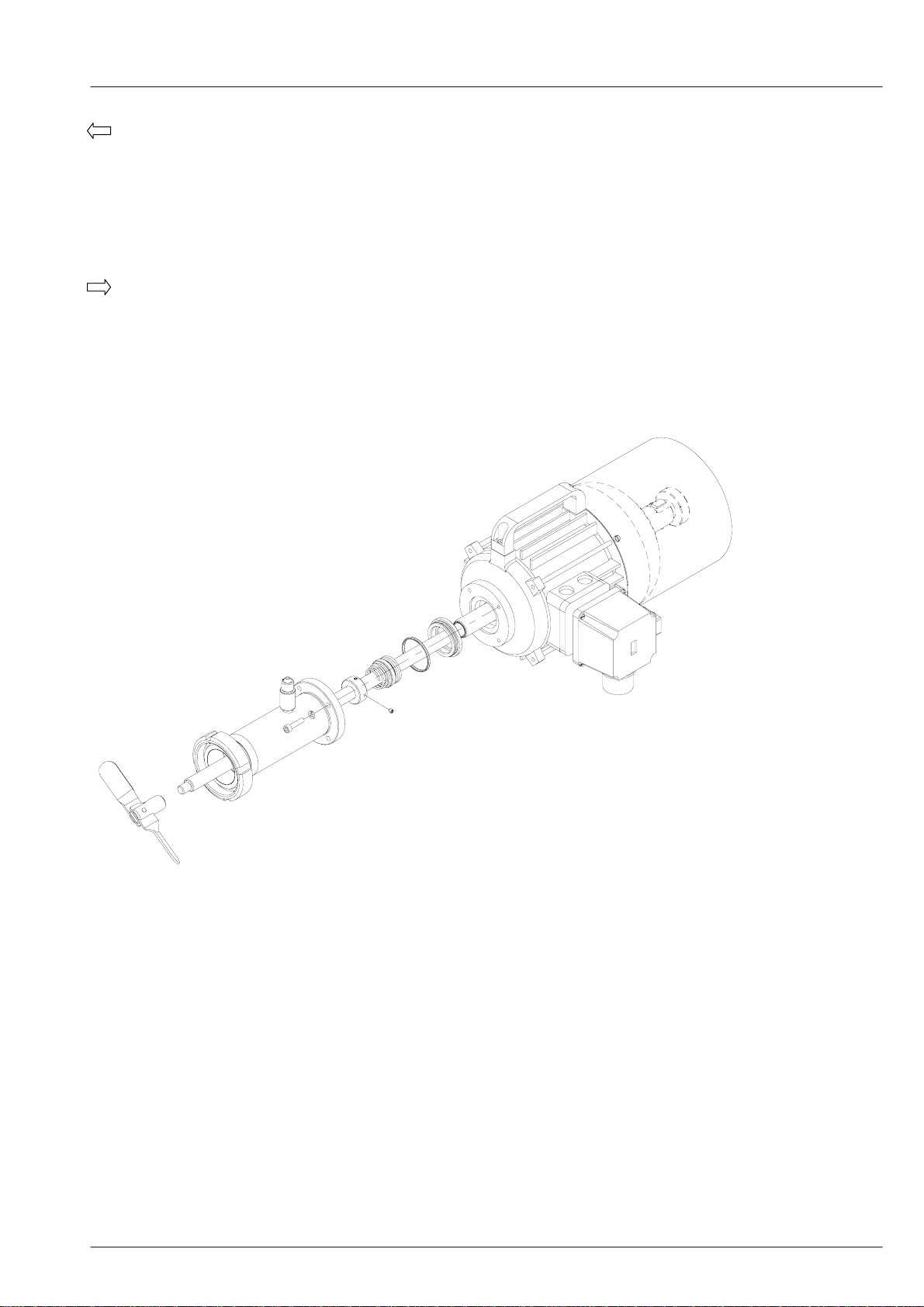

8.4. CPG-211A / B agitator exploded view...............................................................................16

8.5. CPG-211A / B parts list ...................................................................................................17

8.6. CPG-330 agitator - exploded view....................................................................................18

8.7. CPG-330 parts list...........................................................................................................19

6 3.General Information MICPG-01_EN

3. General Information

3.1. DESCRIPTION

CPG-series winery agitators are bottom side agitators. They are designed so that they can be installed and disassembled while

the tank is full of fluid, it is inserted through a valve without losing pressure and without using tools or special implements. This

design is based on the sliding agitation shaft and folding propeller that opens automatically when started up. Sealing is

achieved using a mechanical seal.

All the parts into contact with the fluid are manufactured in stainless steel, AISI-304 (1.4301). The surface finish is

electropolished. The standard agitation element is a type-12 folding propeller.

This equipment is suitable for use in food-processing.

3.2. RANGE OF APPLICATION

The CPG agitator main field of application is in the wine industry in general, maintaining solids in suspension, mixing wines

(blending), gasification (SO and CO

2 2), temperature homogenisation, syrup distribution, etc. The maximum tank volume for this

agitator is 100,000 litres with a viscosity of 1 to 100 cPs (depending on the characteristics of the fluid).

Each agitator has performance limits. The agitator was selected for a given set of agitation

conditions when the order was placed. INOXPA shall not be liable for any damage resulting from the

incompleteness of the information provided by the purchaser (nature of the fluid, viscosity, RPM,

etc.).

ED.15.02/08 4.Installation 7

4. Installation

4.1. RECEIVING THE AGITATOR

INOXPA cannot be held responsible for the damage sustained by the equipment during transport or

unpacking. Visually check that the packaging is not damaged.

The agitator will be accompanied by the following documents:

•Dispatch notes.

•Agitator Instructions and Service Manual.

Unpack the agitator and check:

•The agitator anchor connection, removing any remaining

packaging materials.

•Check that the agitator and the motor have not suffered any

damage.

•If the equipment is not in good condition and/or any part is

missing, the carrier should draw up a report accordingly as

soon as possible.

4.1.1. Identifying the agitator

YEAR

TYPE No.

KW min v Hz

Serial number QM3/h Hm IMPELLER

Agitator identification plate

4.2. TRANSPORT AND STORAGE

CPG agitators are often too heavy to be handled and stored manually.

Do not handle the agitator by the shaft as it may become deformed.

•Lift the agitator at the points indicated on the drawing.

•Secure the supports so that they can not slip.

8 4.Installation MICPG-01_EN

4.3. LOCATION

Once the agitator location has been determined, it must be fixed to the tank using the nut found on the discharge pipe and

firmly tightening it with the appropriate spanner.

Take into account that when fitting the agitator, to prevent any deformation the agitation shaft must not be struck or forced.

Install the agitator so as to allow sufficient ventilation.

If the agitator is installed outdoors, it should be protected by a roof. Its location should enable easy

access for any inspection or maintenance operations.

Force must never be applied on the end of the agitation shaft, since it can easily acquire a

permanent deformation.

The CPG-330 agitator must always be fixed by a support when mounted on the tank.

4.4. ELECTRICAL INSTALLATION

The connection of the electrical motors must be performed by qualified personnel.

Take all necessary measures to preventdamage to connections and cables.

The electrical equipment, terminals and components of the control systems may still contain electric

current when switched off. Contact with them may be dangerous for operators or cause irreversible

damage to the equipment.

Before handling the agitator, make sure that the engine is fully disconnected from the power.

•Connect up the motor following the manufacturer’s instructions.

•Check the direction of rotation (see the label on the agitator).

Start up the agitator motor briefly. Ensure that the direction is consistent with the one indicated on the plate. If the agitator

operates in the wrong direction, the folding propeller may fall into the tank.

ALWAYS check the direction of rotation of the motor with fluid inside the agitator.

ED.15.02/08 4.Installation 9

•The agitator is supplied with a connection ready for operation at 400 V (left photo). If the client has a 230 V, it should

change the connection as indicated in the photo on the right.

380 – 480V 220-280V

10 5.Start-up MICPG-01_EN

5. Start-up

Before starting the agitator, carefully read the instructions provided in Chapter 4. Installation.

5.1. START-UP

Read Chapter 8

Technical Specification

carefully. INOXPA cannot be held responsible for the incorrect

use of the equipment.

NEVER touch the agitator when working with high-temperature liquids.

5.1.1. Checks before starting up the agitator

yCheck that the agitator shaft is aligned and that it slides smoothly through the hollow shaft.

yCheck the level of fluid in the tank. When not specified in the order, the agitator cannot be operated during the filling or

emptying of the tank.

yOpen the valve where the agitator is fixed.

yIntroduce the shaft into the tank.

yRemove any air in the mechanical seal area by opening the drainage ports of the housing until liquid comes out.

The agitator must never operate when dry, as this may lead to serious damage to the mechanical

seal.

•Check that the power supply matches the rating indicated on the engine plate.

•Check that the motor’s direction of rotation is correct.

5.1.2. Checks when starting up the agitator

•Check that the agitator is not making any unusual noises.

•Check that there are no leaks through the sealed areas.

Introducing an object or solid raw material may cause the agitation component and other

mechanical parts to break and compromise its safety or guarantee.

Check the motor’s power consumption to avoid electric overload.

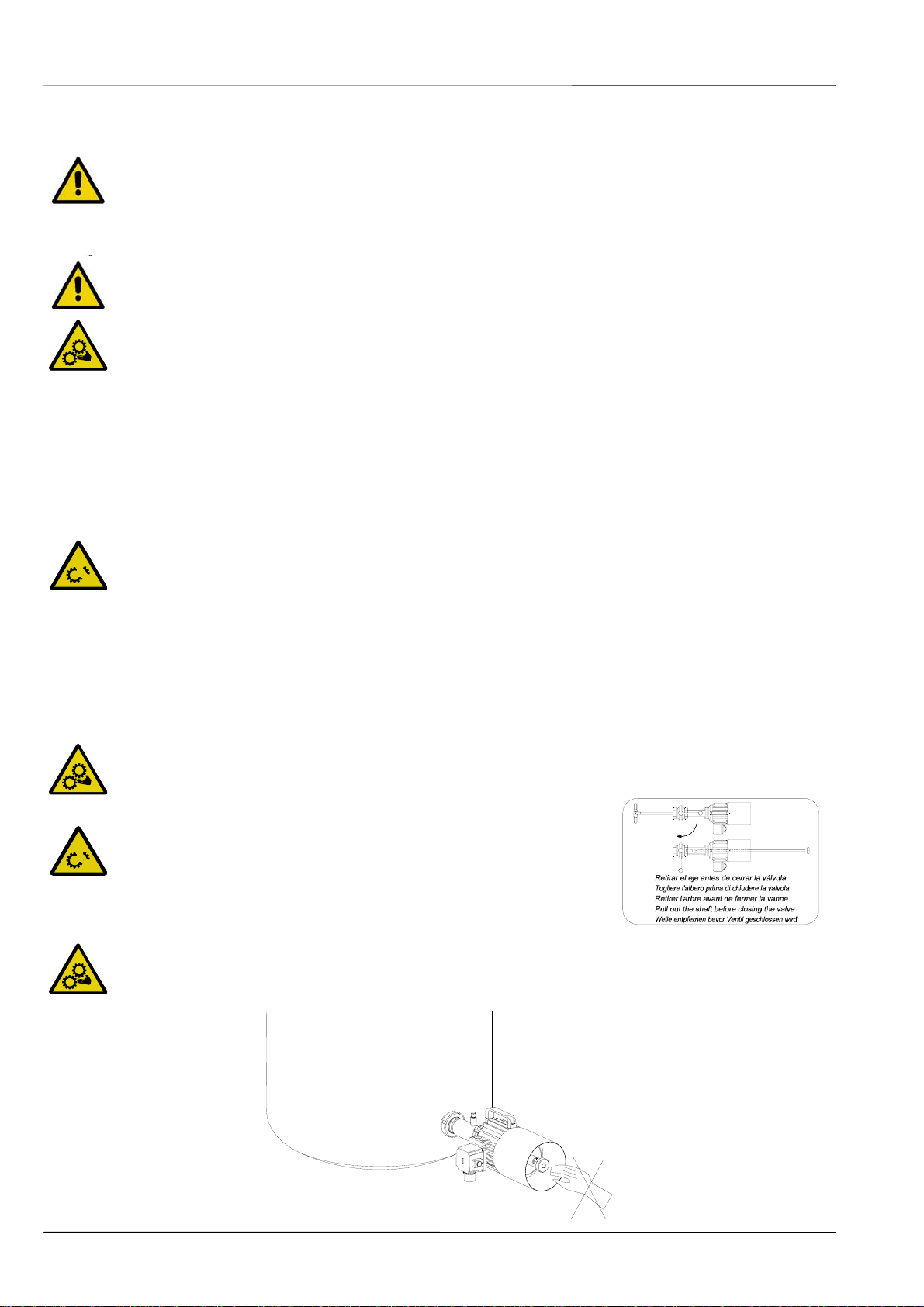

Remove the agitator shaft before closing the valve, as

indicated on the sticker found on the agitator.

Once the agitator is operational, take precautions to ensure that you do not put your hand on the

back of the agitator, inside the motor hood, because it contains rotating parts that may cause

serious personal injury.

ED.15.02/08 6.Operating Problems 11

6. Operating Problems

The following table provides solutions to problems that might arise during agitator operation. The agitator is assumed to have

been properly installed and correctly selected for the application.

Please contact INOXPA if technical assistance is required.

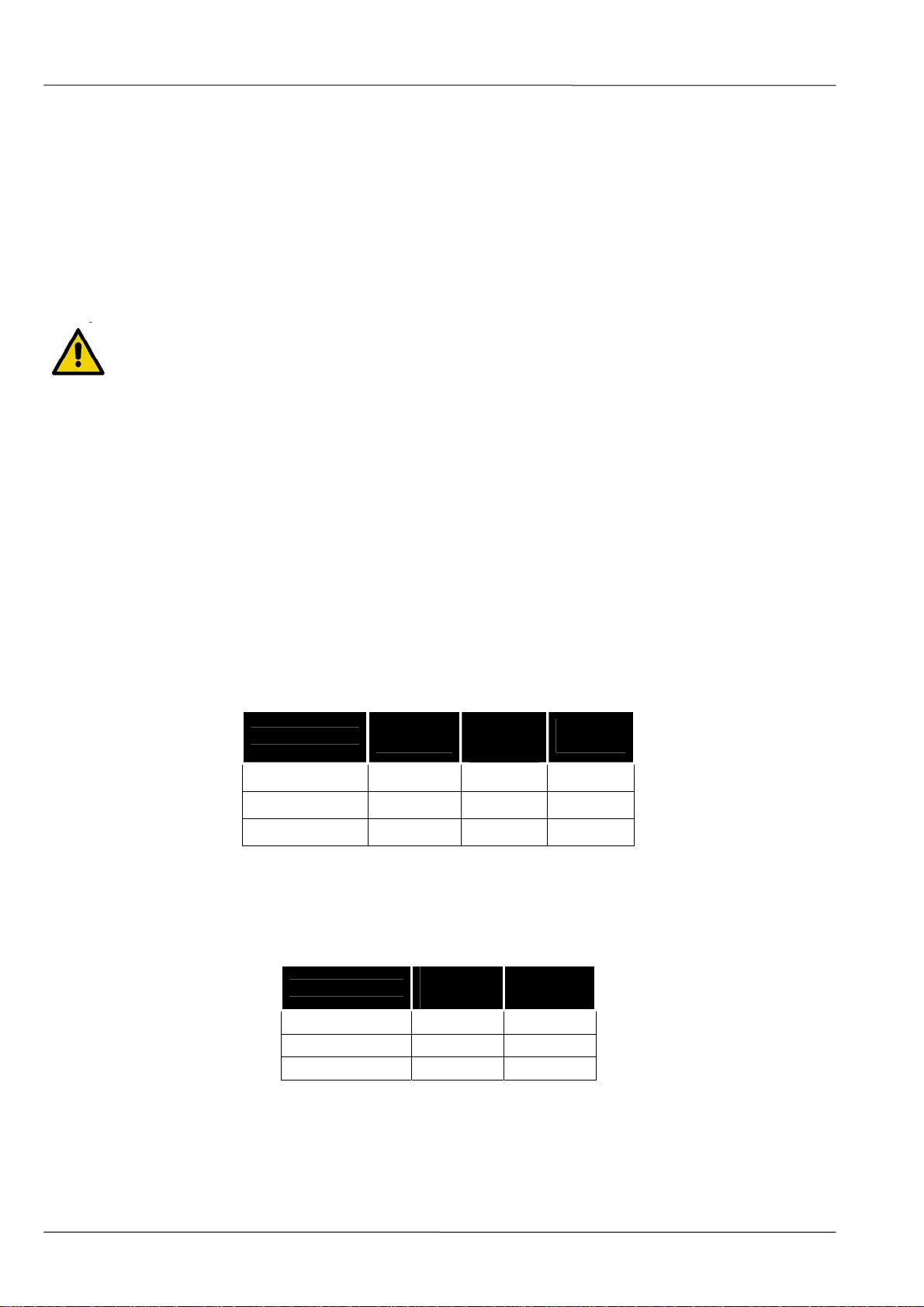

Operating Problems Probable causes

Motor overload 1, 2.

Not enough stirring. 1, 3, 4.

Vibration and noise. 5, 6, 7, 8, 9, 11.

Mechanical seal. 5, 10.

O-ring 7, 11.

Probable causes Solutions

1 Fluid viscosity too high Reduce the viscosity, e.g. by heating the fluid.

2 High density Reduce the propeller diameter.

3 Tank oversized for the agitator selected. Check with the Technical Dep.

4 Wrong direction of rotation Reverse the direction of rotation.

5 Liquid level too low or no liquid. Check the level of fluid in the tank.

6 Twisted shaft. Replace the shaft.

7 Scratched shaft. Replace the shaft.

8 Critical speed. Check shaft gap.

9 Brass bushings worn. Replace brass bushings.

10 Replace the mechanical seal

Mechanical seal damaged or worn.

11 O-ring damaged or worn. Replace the O-ring.

If the problems persist, stop using the agitator immediately. Contact the agitator manufacturer or

their representative.

12 7.Maintenance MICPG-01_EN

7. Maintenance

7.1. GENERAL INFORMATION

Like any other machine, this agitator requires maintenance. The instructions contained in this manual cover the identification

and replacement of spare parts. The instructions have been prepared for maintenance personnel and for those responsible for

the supply of spare parts.

Please carefully read Chapter 8

Technical Specification

.

All replaced material should be duly eliminated/recycled according to the directives in effect in the

area.

ALWAYS disconnect the agitator from the power supply before undertaking maintenance work.

7.1.1. Checking the mechanical seal

Regularly check that there are no leaks at the front of the motor. If there are leaks through the mechanical seal, replace it

following the instructions given under the Assembly and Disassembly section.

7.2. STORAGE

The agitator must be completely emptied of fluid before storage. If possible, avoid exposing the components of the agitator to

excessively damp environments.

7.3. CLEANING

The use of aggressive cleaning products such as caustic soda and nitric acid may cause burns to the

skin.

Use rubber gloves during the cleaning process.

Always use protective goggles.

If the agitator is installed in a system with a CIP process, it is not necessary to dismantle the agitator.

If there is no automatic cleaning process, dismantle the agitator as indicated in the Assembly and Disassembly section.

Cleaning solutions for CIP processes.

Only use clear water (chlorine-free) to mix with the cleaning agents:

a) Alkaline solution: 1% by weight of caustic soda (NaOH) at 70ºC (150ºF)

1 Kg NaOH + 100 l. of water = cleaning solution

o

2.2 l. NaOH at 33% + 100 l. of water = cleaning solution

b) Acid solution: 0.5% by weight of nitric acid (HNO ) at 70ºC (150ºF)

3

0.7 litres HNO at 53% + 100 l. of water = cleaning

3

Check the concentration of cleaning solutions; it may cause the deterioration of the watertight seals

of the agitator.

To eliminate the remains of cleaning products, ALWAYS carry out a final rinse on completion of the cleaning process.

ED.15.02/08 7.Maintenance 13

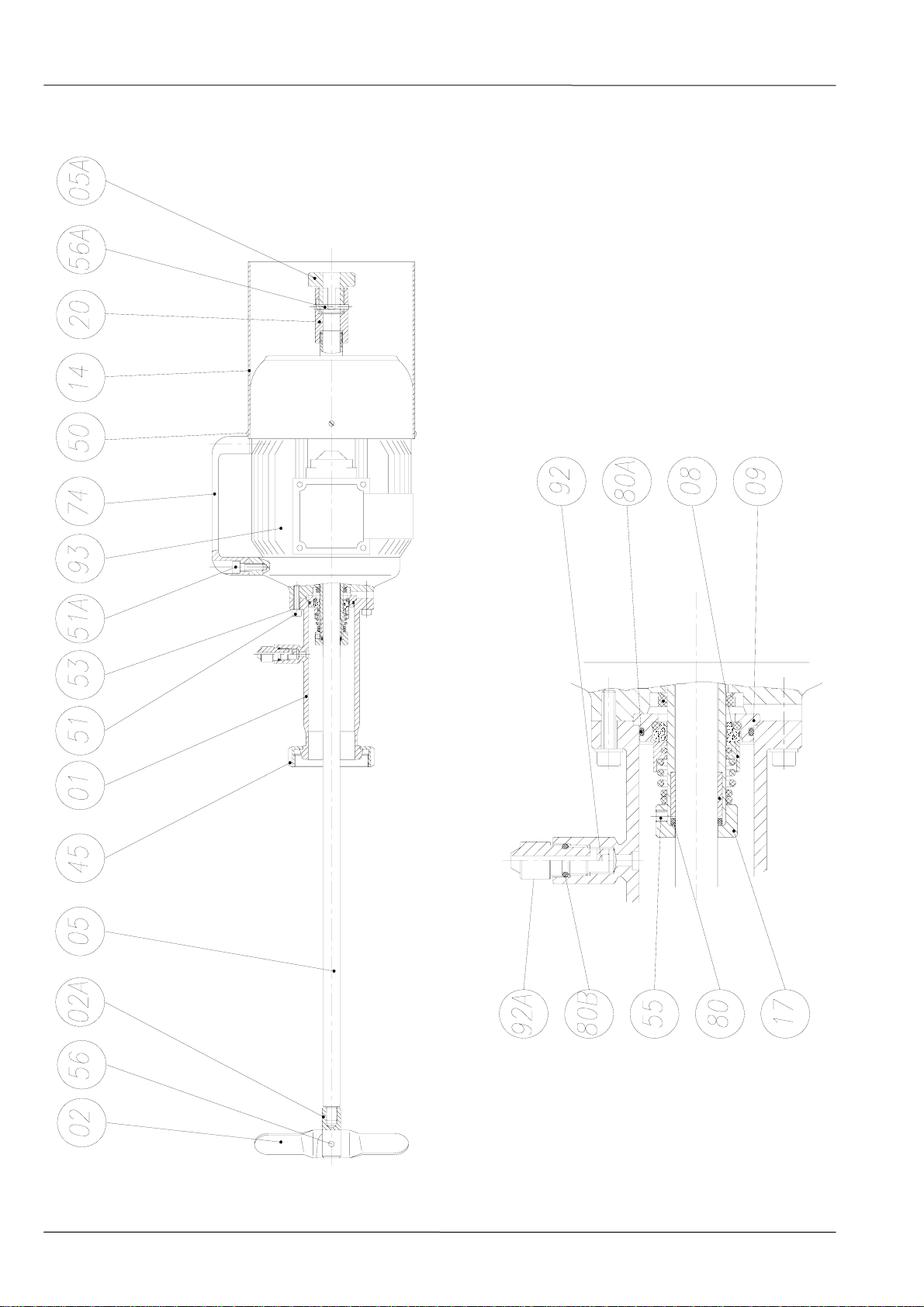

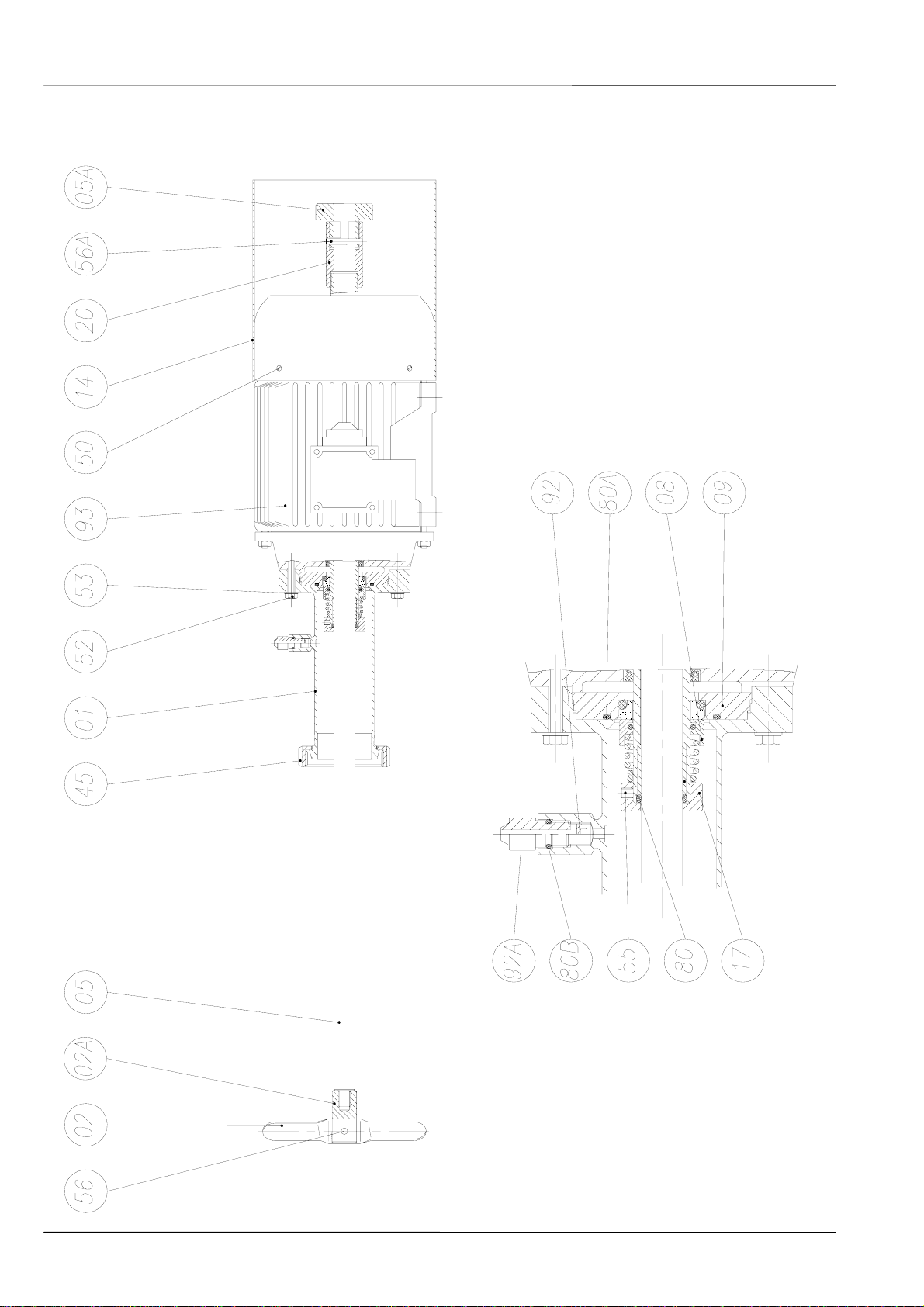

7.4. DISASSEMBLY / ASSEMBLY OF THE AGITATOR.

Disassembly

Remove the agitator through the valve to which it is fixed by means of the nut (45). Remove the agitator element (02, 02A) by

unthreading it from the agitator shaft (05). Remove the shaft (05) behind the motor (93) by sliding it off its hollow shaft. First

turn the pin (56A) properly in conjunction with the shaft turner (05A) at the end of the shaft. Remove the discharge pipe with

drainage port (01) joined to the motor with screws (51, 52 for CPG-330) and washers (53). Remove the stop ring (17) after

taking out the Allen pins (55). Remove the rotary part of the mechanical seal (08). Remove the seal cover (09) along with its

O-ring (80A). Remove the fixed part of the mechanical seal (08).

Assembly

Place the O-ring (80A) inside the seal cover (09). Place the stop ring (09) inside the motor flange housing (93). Carefully insert

the fixed part of the mechanical seal (08) into its housing inside the seal cover (09). Then, slide the rotary part of the

mechanical seal (08) over the motor shaft. Attach the stop ring (17) until it touches the motor shaft, and fasten the Allen pins

(55). Insert the agitator shaft (05) through the hollow shaft at the back of the motor. Insert the discharge pipe with drainage

port (01) and attach it to the motor with screws (51, 52 for CPG-330) and washers (53). Finally, attach the folding blades (02,

02A) by threading them onto the agitator shaft (05).

14 8.Technical Specifications MICPG-01_EN

8. Technical Specifications

8.1. TECHNICAL SPECIFICATIONS

Maximum viscosity ................................................................. 100 mPa.s.

Maximum pressure ................................................................. 2 bar

Maximum temperature ........................................................... +80ºC

+176 ºF

Noise level ............................................................................. 60-80 dB(A)

Anchor connection DIN 11851 (nut)

Use special protection when the noise level in the operation area exceeds 85 dB(A).

Materials

Parts in contact with fluid........................................ AISI 304

Other parts in stainless steel. ....................................... AISI 304

Gaskets in contact with fluid ................................... Viton

Other materials for optional gaskets ...................................... Check with the supplier

Surface finish ...................................................................... Sand blasted

Mechanical seal

Type of seal ........................................................................... Single interior seal

Stationary parts material ........................................................ graphite

Rotary parts material .............................................................. AISI 316L

Sealing material ..................................................................... EPDM

Agitator type Volume in

Power Speed

HO

[kW] [r.p.m.]

23

[m ]

CPG-211A

1.1 20 1390

CPG-211B

1.1 25-50 1390

CPG-330

3 50-100 1390

8.2. WEIGHTS

Agitator type Weight Weight

[Kg] [lbs]

CPG-211A

19 40

CPG-211B

19 42

CPG-330

42 92

ED.15.02/08 8.Technical Specifications 15

8.3. CPG AGITATOR DIMENSIONS

φdφH

DN ABCL

Agitator type

CPG-211A

50 / 2” 425 960 495 18 950 155

CPG-211B

50 / 2” 425 960 495 18 950 165

CPG-330

65 / 3” 465 1175 560 25 1145 200

16 8.Technical Specifications MICPG-01_EN

8.4. CPG-211A / B AGITATOR EXPLODED VIEW

ED.15.02/08 8.Technical Specifications 17

8.5. CPG-211A / B PARTS LIST

Position Description Quantity Material

01 Discharge pipe with drainage port 1 AISI 304

02 Blade 2 AISI 304

02A Blade holder 1 AISI 304

05 Agitator shaft 1 AISI 304

05A Shaft turner 1 AISI 304

08 Mechanical seal * 1 -

09 Seal cover 1 AISI 304

14 Motor hood 1 AISI 304

17 Stop ring 1 AISI 304

20 Centring pipe 1 Brass

45 Nut 1 AISI 304

50 Screw 4 A2

51 Allen screw 4 A2

51A Allen screw 2 A2

53 Grower washer 4 A2

55 Allen pin 2 A2

56 Blade pin 1 AISI 304

56A Pin 1 AISI 304

74 Handle 1 Engineering plastic

80 O-ring * 1 FPM

80A O-ring * 1 FPM

80B O-ring 1 FPM

92 Drainage shaft 1 AISI 304

92A Drainage knob 1 PTFE

93 Hollow-shaft motor 1 -

(*) Recommended spare parts

18 8.Technical Specifications MICPG-01_EN

8.6. CPG-330 AGITATOR - EXPLODED VIEW

ED.15.02/08 8.Technical Specifications 19

8.7. CPG-330 PARTS LIST

Position Description Quantity Material

01 Discharge pipe with drainage port 1 AISI 304

02 Blade 2 AISI 304

02A Blade holder 1 AISI 304

05 Agitator shaft 1 AISI 304

05A Shaft turner 1 AISI 304

08 Mechanical seal * 1 -

09 Seal cover 1 AISI 304

14 Motor hood 1 AISI 304

17 Stop ring 1 AISI 304

20 Centring pipe 1 Brass

45 Nut 1 AISI 304

50 Screw 4 A2

52 Hexagonal screw 4 A2

53 Grower washer 4 A2

55 Allen pin 2 A2

56 Blade pin 1 AISI 304

56A Pin 1 AISI 304

80 O-ring * 1 FPM

80A O-ring * 1 FPM

80B O-ring 1 FPM

92 Drainage shaft 1 AISI 304

92A Drainage knob 1 PTFE

93 Hollow-shaft motor 1 -

(*) Recommended spare parts

Мешалки для виноделия — Боковая мешалка CPG

http://k-tep.com.ua/

Office +38 044 2091823

МТС +38 066 9076563

Kиевстар +38 098 3676414

Skype: k-teppumps

Замечания

Условия поставки:DDP склад г. Киев

Заметки

Время поставки рассчитано согласно дате предложения иизменяется взависимости от даты

подтверждения заказа.

Размещая заказ, покупатель принимает предложение ивсе спецификации, характеристики и

условия, указанные вданном документе.

This manual suits for next models

3

Table of contents

Other INOXPA Industrial Equipment manuals

INOXPA

INOXPA MCR Ex Manual

INOXPA

INOXPA INNOVA Mini N Manual

INOXPA

INOXPA KIBER KSF Ex Manual

INOXPA

INOXPA SLR Ex Manual

INOXPA

INOXPA BFI Manual

INOXPA

INOXPA BCI Series Manual

INOXPA

INOXPA KIBER KS Ex Manual

INOXPA

INOXPA NHS VERTICAL AGITATOR Ex Manual

INOXPA

INOXPA HYGINOX Ex SE Manual

INOXPA

INOXPA MM-1 Manual

Popular Industrial Equipment manuals by other brands

Condair

Condair Defensor OptiSorp Installation and operating instructions

KMT

KMT STREAMLINE SL-V SRP 100 Operation and maintenance manual

Lamtec

Lamtec BT300 BurnerTronic manual

TRAK

TRAK SAND TRAK ST1-075A la Owner's/operator's manual

Brano

Brano Z420-A Operation manual

Station Road Steam

Station Road Steam STAFFORD Assembly instructions