TrojanLabel T3-OPX User manual

T3-OPX user guide

Version 1.2

T3-OPX installation

Page | 1

1 Specification and general information ...................................................................................................... 5

1.1 Certificate and Compliance ............................................................................................................... 5

1.1.1 Emissions ................................................................................................................................... 6

1.2 Warning Symbols............................................................................................................................... 7

1.3 Introduction....................................................................................................................................... 8

1.3.1 Original instructions .................................................................................................................. 8

1.3.2 Purpose...................................................................................................................................... 8

1.3.3 Accessibility ............................................................................................................................... 8

1.3.4 Knowledge ................................................................................................................................. 8

1.4 General Information .......................................................................................................................... 8

1.4.1 Manufacturer............................................................................................................................. 8

1.4.2 The machine’s designation ........................................................................................................ 8

1.4.3 Machine plate............................................................................................................................ 8

1.5 Specification and Application ............................................................................................................ 9

1.5.1 General description ................................................................................................................... 9

1.5.2 The machine’s purpose and intended use ................................................................................ 9

1.5.3 Warning about foreseeable misuse........................................................................................... 9

1.5.4 Specifications T3-OPX .............................................................................................................. 10

1.5.5 Specifications MailTable 1 (MT1) ............................................................................................ 13

1.5.6 Specifications MailTable 2 (MT2) ............................................................................................ 14

2 T3 OPX physical overview........................................................................................................................ 15

2.1 Front side......................................................................................................................................... 15

2.2 Backside ........................................................................................................................................... 16

2.3 Inlets detail ...................................................................................................................................... 17

2.4 Bottom............................................................................................................................................. 17

2.5 Media Entry side (feeder side) ........................................................................................................ 18

2.6 Media exit side ................................................................................................................................ 18

3 Installing the T3 OPX................................................................................................................................ 20

3.1 IMPORTANT: .................................................................................................................................... 20

3.2 Pre-requisites................................................................................................................................... 21

3.3 MailTable 1 or 2 setup..................................................................................................................... 21

3.4 T3 OPX Bracket system installation process.................................................................................... 22

3.5 Connect encoder and table controls (Trojan MT1 and MT2).......................................................... 28

T3-OPX installation

Page | 2

3.6 Remove service tray plastic protection ........................................................................................... 29

3.7 Connect T3-OPX power supply cord and network cables ............................................................... 29

3.8 Connect MT1/2 power supply cord................................................................................................. 29

3.9 Powering on..................................................................................................................................... 30

3.9.1 Safety Check ............................................................................................................................ 30

3.9.2 Power on process .................................................................................................................... 30

3.10 Calibrate the table position and level unit ...................................................................................... 30

3.11 Installing Ink Cartridges ................................................................................................................... 31

3.12 Purging the unit ............................................................................................................................... 31

3.13 Calibrate the print head optional .................................................................................................... 34

3.13.1 Nozzle alignment ..................................................................................................................... 34

3.13.2 Color Density ........................................................................................................................... 36

3.13.3 Nozzle health alignment .......................................................................................................... 36

4 General Settings (HOME tab) .................................................................................................................. 37

4.1 Overview menu ............................................................................................................................... 37

4.2 Settings menu.................................................................................................................................. 38

4.2.1 Consumables Button: .............................................................................................................. 38

4.2.2 Network Button ....................................................................................................................... 39

4.2.3 Updater Button........................................................................................................................ 40

4.2.4 User Preferences Button ......................................................................................................... 40

4.2.5 User Management button ....................................................................................................... 41

4.2.6 Printing prefrences button ...................................................................................................... 42

4.3 Statistics menu ................................................................................................................................ 43

4.3.1 Last Printed Jobs button: ......................................................................................................... 43

4.3.2 Engine & Printhead Usage button: .......................................................................................... 44

4.4 Shutdown......................................................................................................................................... 45

4.5 Exporting statistics data to a CSV file/ viewing statistics from a browser ...................................... 46

5 Transferring print jobs to the T3-OPX using the Xitron RIP..................................................................... 48

5.1 Starting the Xitron RIP Server.......................................................................................................... 48

5.2 Transferring a job from the web client............................................................................................ 48

5.2.1 Print direction.......................................................................................................................... 50

5.2.2 Rotation, offsetting and media size......................................................................................... 50

6 Printing a job from the Job Library.......................................................................................................... 54

7 Operations menu..................................................................................................................................... 55

7.1 Handling overview ........................................................................................................................... 55

7.1.1 Initialize height control............................................................................................................ 56

T3-OPX installation

Page | 3

7.1.2 Print unit height....................................................................................................................... 56

7.1.3 MailTable (MT1/2) controls..................................................................................................... 56

7.2 Maintenance overview .................................................................................................................... 57

7.2.1 Light clean................................................................................................................................ 58

7.2.2 Medium clean.......................................................................................................................... 58

7.2.3 Remove service tray ................................................................................................................ 58

7.2.4 Install service tray.................................................................................................................... 58

7.2.5 Go to Print ............................................................................................................................... 58

7.2.6 Uncap print head ..................................................................................................................... 58

7.2.7 Cap Print Head......................................................................................................................... 59

7.3 Media settings overview ................................................................................................................. 59

7.3.1 Profile control section ............................................................................................................. 59

7.3.2 Basic tab................................................................................................................................... 60

7.3.3 Advanced tab........................................................................................................................... 61

7.3.4 Fans tab ................................................................................................................................... 62

7.3.5 Setting up a media (job) profile in Media settings .................................................................. 62

8 Automatically calibrating the job/media height ..................................................................................... 63

9 Printing on uneven surfaces (die-to-die overlap feature)....................................................................... 65

10 Edge sensor (TOF control) ................................................................................................................... 66

10.1 Sensor overview .............................................................................................................................. 67

10.2 Adjusting the sensor to the media .................................................................................................. 67

11 User replaceable parts......................................................................................................................... 67

11.1 Ink cartridge part numbers.............................................................................................................. 67

11.2 Service tray replacement................................................................................................................. 67

11.2.1 Service tray replacement process ........................................................................................... 68

11.2.2 Moving the service tray manually ........................................................................................... 70

11.3 Fuse power inlet .............................................................................................................................. 70

11.3.1 Fuse replacement process....................................................................................................... 70

11.4 Aerosol filter .................................................................................................................................... 71

11.4.1 Aerosol filter replacement process ......................................................................................... 72

12 RIP installation (XITRON) ..................................................................................................................... 73

12.1 Link TrojanControl ........................................................................................................................... 73

12.2 Installing just the client ................................................................................................................... 74

13 Debugging connections. ...................................................................................................................... 75

13.1 Controls for T1030 (webpath board)............................................................................................... 76

14 Revision history ................................................................................................................................... 77

T3-OPX installation

Page | 4

T3-OPX installation

Page | 5

1Specification and general information

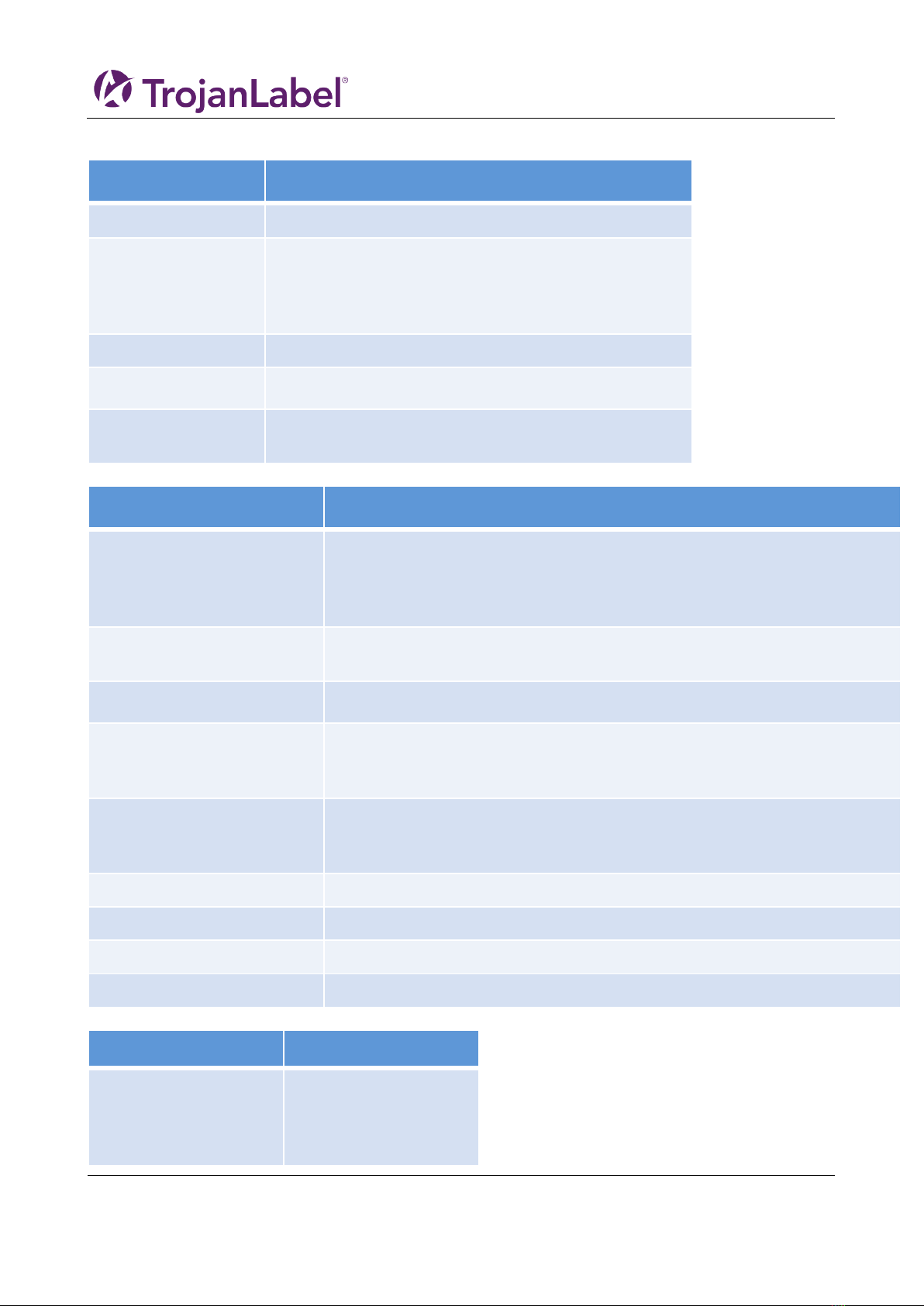

1.1 Certificate and Compliance

T3-OPX specific

CFR Title 47 Part 15 Subpart B (2020)

ISED ICES-003 Issue 6 Published 2016 Updated 2019

CENELEC EN 55024:2011+A1:2015, CISPR 35:2016Ed.1.0

CENELEC EN 55032:2015, CISPR 32:2015

CENELEC EN 61000-3-2:2014, IEC 61000-3-2 Ed 5:2018

CENELEC EN 61000-3-3:2008, IEC 61000-3-3 Ed 3.1:2017

Audio/Video, Information and Communication Technology Equipment - Part 1:

Safety Requirements (R2019) [CSA C22.2#62368-1:2014 Ed.2]

Audio/Video, Information and Communication Technology Equipment - Part 1:

Safety Requirements [UL 62368- 1:2014 Ed.2]

Audio/Video, Information and Communication Technology Equipment - Part 1:

Safety Requirements [IEC 62368- 1:2014 Ed.2+C1;C2]

Audio/Video, Information and Communication Technology Equipment - Safety

Requirements [EN 62368- 1:2014+C1;C2]

Mail Table specific

CFR Title 47 Part 15 Subpart B (2020)

ISED ICES-003 Issue 6 Published 2016 Updated 2019

CENELEC EN 55024:2011+A1:2015, CISPR 35:2016Ed.1.0

CENELEC EN 55032:2015, CISPR 32:2015

CENELEC EN 61000-3-2:2014, IEC 61000-3-2 Ed 5:2018

CENELEC EN 61000-3-3:2008, IEC 61000-3-3 Ed 3.1:2017

Motor-Operated Appliances [UL 73:2011 Ed.10+R:08Aug2018]

Motor-Operated Appliances (Household and Commercial) [CSA C22.2#68:2018

Ed.8]

Electrical Standard for Industrial Machinery [NFPA 79:2017 Ed.2018]

EN 60204-1:2006+A1;C1: Safety Of Machinery - Electrical Equipment Of

Machines - Part 1: General Requirements

T3-OPX installation

Page | 6

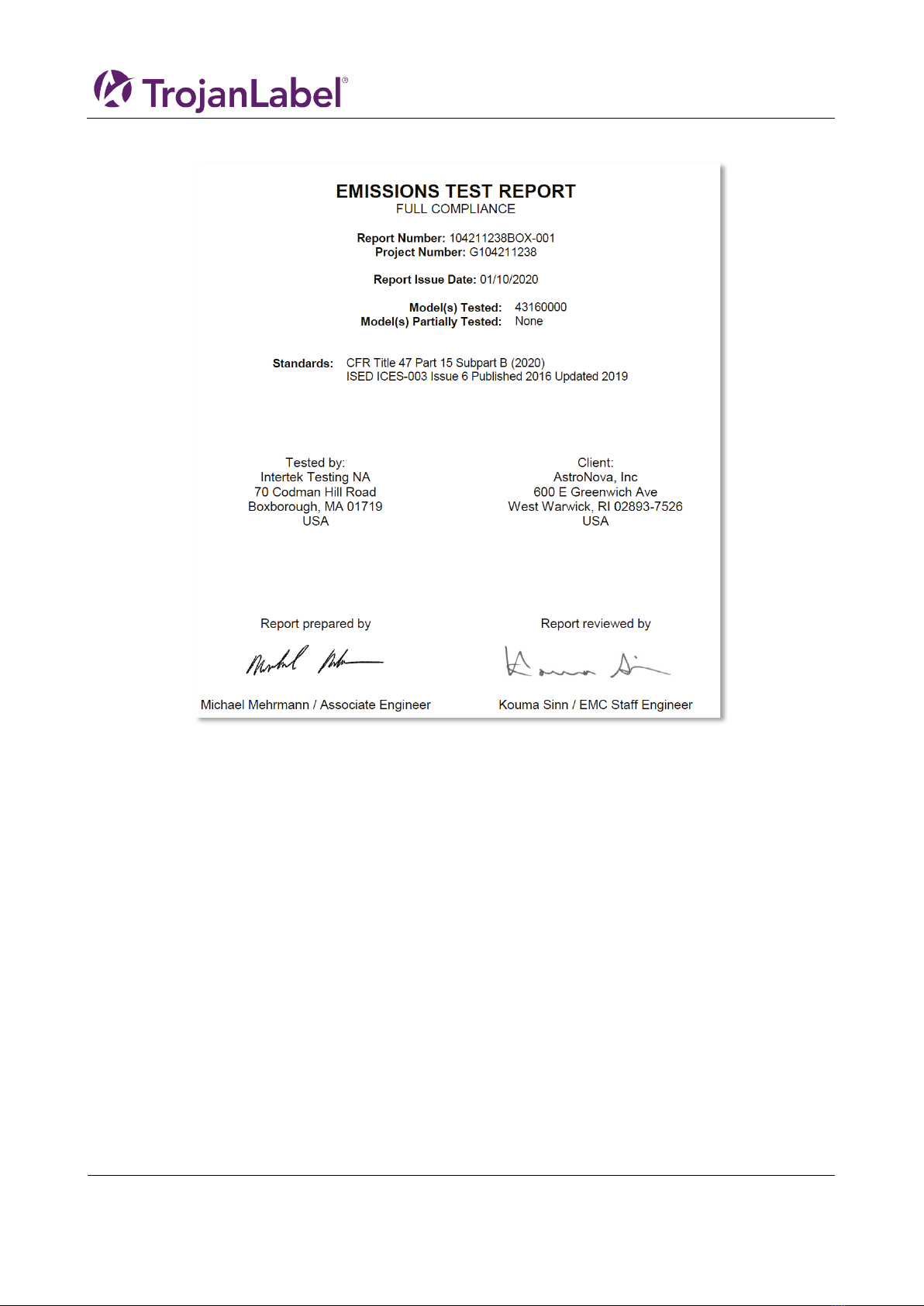

1.1.1 Emissions

T3-OPX installation

Page | 7

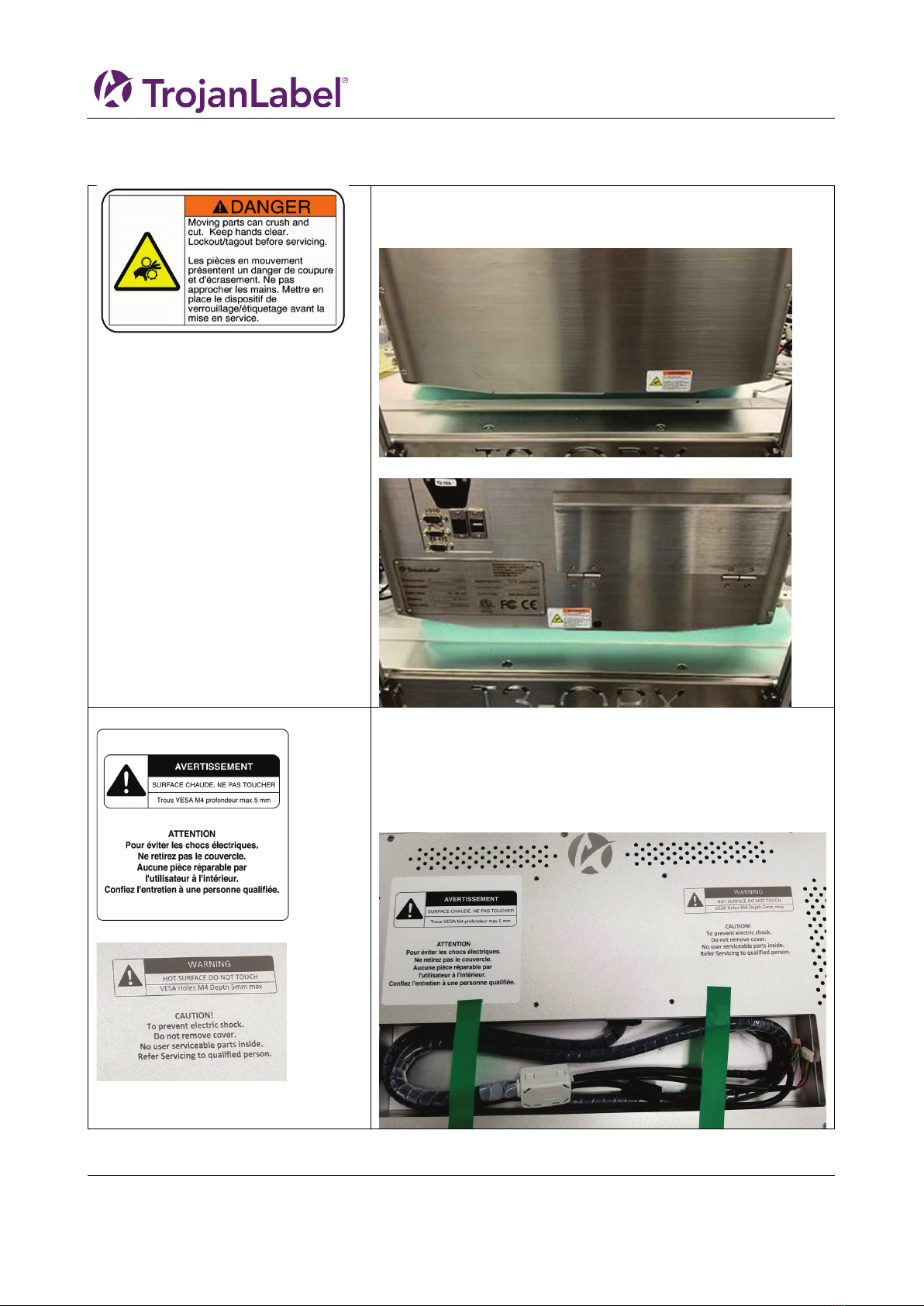

1.2 Warning Symbols

There are crush warning stickers placed on the front and back

side of the unit, as the unit can move down towards the table.

Front

Back

Sticker in French

Engravement in English

Warning stickers and engravements on the back side of the

touch screen, indicating the depth of the VESA holes (5mm),

that the screen can become hot on the back side and the used

should never open the cover of the screen, as this may only be

serviced by an experienced and product trained technician.

T3-OPX installation

Page | 8

1.3 Introduction

1.3.1 Original instructions

These instructions are original instructions made by Trojanlabel for the Trojanlabel digital

over-printer T3-OPX.

1.3.2 Purpose

The purpose of these instructions is to ensure correct installation, use, handling and

maintenance of the machine.

1.3.3 Accessibility

The instructions are to be kept in a location known to the staff and must be easily

accessible for the operators and maintenance personnel.

1.3.4 Knowledge

It is the duty of the employer (the owner of the machine) to ensure that anyone who is to

operate, service, maintain, or repair the machine have read the instructions. As a

minimum, they should have read the part(s) relevant for their work. In addition, anyone

who is to operate, service, maintain, or repair the machine is under obligation to look for

information in the instructions themselves.

1.4 General Information

1.4.1 Manufacturer

The machine has been manufactured by:

AstroNova, Inc.

600 E Greenwich Ave

West Warwick, RI 02893

USA

1.4.2 The machine’s designation

The machine’s complete designation is Digital Over-Printer type T3-OPX.

1.4.3 Machine plate

The machine plate is situated on the back side of the machine at the lower left corner:

T3-OPX installation

Page | 9

1.5 Specification and Application

1.5.1 General description

The machine consists of a metal cabinet, ink delivery system, service door, print engine,

embedded PC, touchscreen, media sensor, printhead and four ink cartridges.

If any changes or alterations are made to the machine, these changes or alterations must

be reflected in these instructions as necessary.

1.5.2 The machine’s purpose and intended use

Application: The machine is only to be used to print on materials which meet the material

specification requirements. The machine must not be used for any other purpose than the

purpose mentioned above.

1.5.3 Warning about foreseeable misuse

The T3-OPX may not be used with inks not endorsed by Trojanlabel. All inks purchased

from Trojanlabel or from official Trojanlabel distributors worldwide are endorsed by

Trojanlabel.

T3-OPX installation

Page | 10

1.5.4 Specifications T3-OPX

Operation

Ink Type

Pigmented ink, 4 Individual CMYK cartridges

Resolution

High Resolution Mode:

1200 x 1200 optimized dpi from 600 x 600 input dpi.

Production Mode:

600 x 1200 optimized dpi from 300 x 300 input dpi.

Print speed

Up to 18 ips (27m/min)

Print Area

Width: 11.7” (297mm)

Media Sensors

- Optical TOF sensor, adjustable position

- Pressure sensor for height control

Environmental & Physical

Printer operation

Operation 20° to 30° C (59° to 86° F)

Transport –40° to 60° C (–40° to 140° F)

Relative humidity 20 to 80%

Altitude 0 to 3048 m

Power requirements

100-240V AC – 50/60

(9A power supply)

Power consumption peak

103.2 watts

Print unit dimensions

Width 518 mm

Length 516 mm

Height 290 mm (excluding height adjustable bracket)

Media cleaning unit

dimensions

Width 457.5 mm

Length 154 mm

Height 261 mm

Touchscreen

15.6”

Print unit weight

20 kg

Media cleaning unit weight

3.5 kg

Drop detection

Print then scan process, using offline scanner (Epson v600).

Supplies

Ink Cartridges

CMYK pigmented:

C: 238 ml

M: 233 ml

Y: 225 ml

T3-OPX installation

Page | 11

K: 498 ml

ISO pages:

K: 20.000 pages

CMY: 16.000 pages

Maintenance

Replaceable service tray

Ink Type:

Pigmented aqueous inks

Average drop volume

10 pl K, 8.5 pl CMY

Nozzle count

59136 (4224 x 14)

Material

Types

Uncoated Paper, Card board, paper

board, wooden boards, paper bags

Most porous materials

Width

Depends on transport/installation

600mm (Trojan standard table)

1000mm (Trojan wide table)

Supported image lengths

25,4 mm – 914,4 mm (1 in - 36 in)

Thickness

0 – 95mm (automatic height calibration)

Connectivity

Wired connection (802.3 LAN (10/100/1000) Ethernet port)

2 x serial ports (I/O and encoder)

USB for scanner

Wired LAN

Software:

TrojanControl Software

RIP

Hardware:

Windows PC

T3-OPX installation

Page | 12

T3-OPX installation

Page | 13

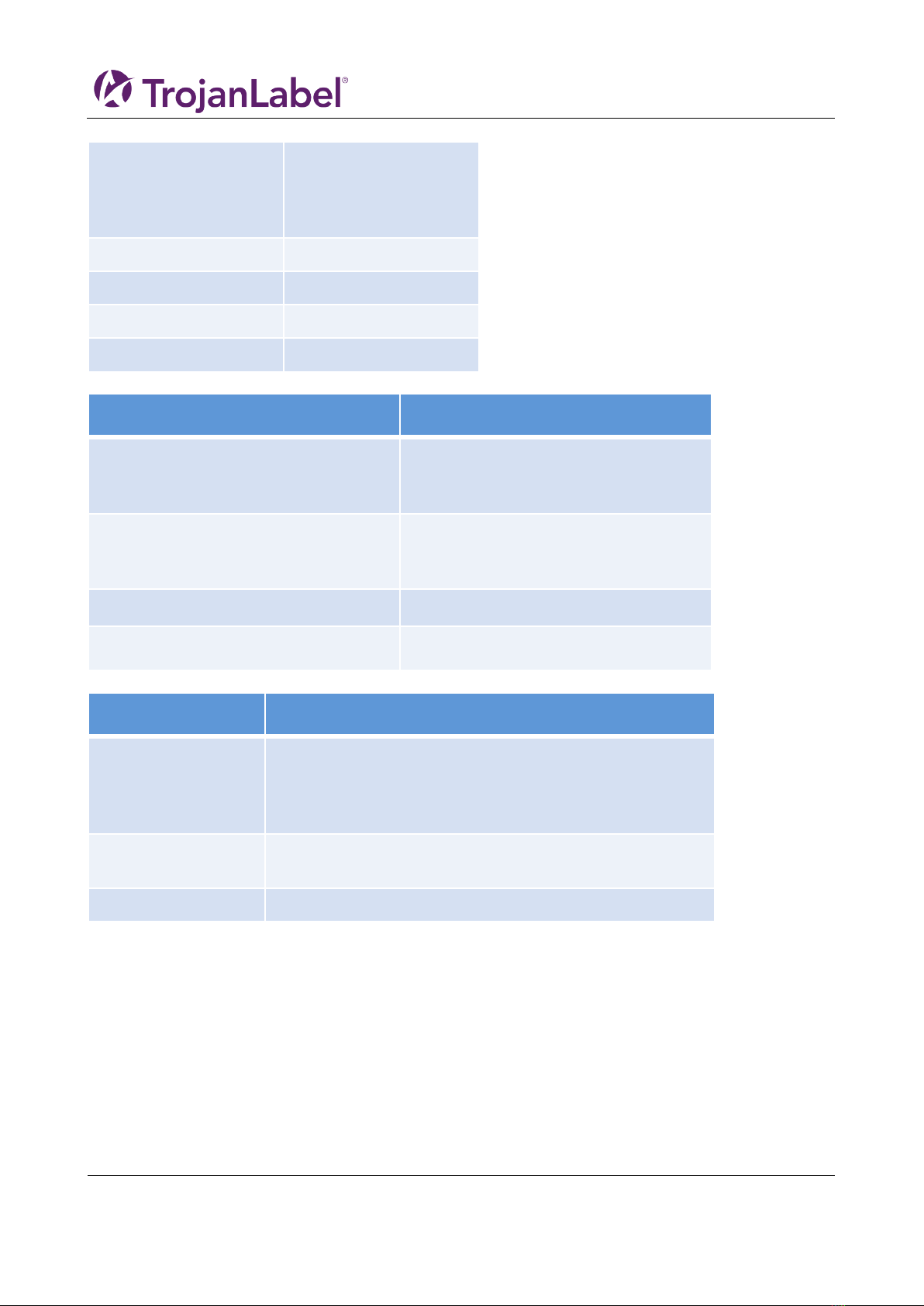

1.5.5 Specifications MailTable 1 (MT1)

MailTable 1 Standard

Speed

Up to 18 ips (27m/min)

Power requirements

100-240V AC – 50/60 Hz

(2.5A power supply)

Dimensions

Width: 626 mm (incl Emergency stop button)

Length: 1507 mm

Height: From 892 mm to 595 mm

Support material width

600 mm

Weight

75 kg/ 165 lbs without accessories

Suction

5 fans adjustable speeds

Belts

6

1.5.5.1 MT1 Machine plate

T3-OPX installation

Page | 14

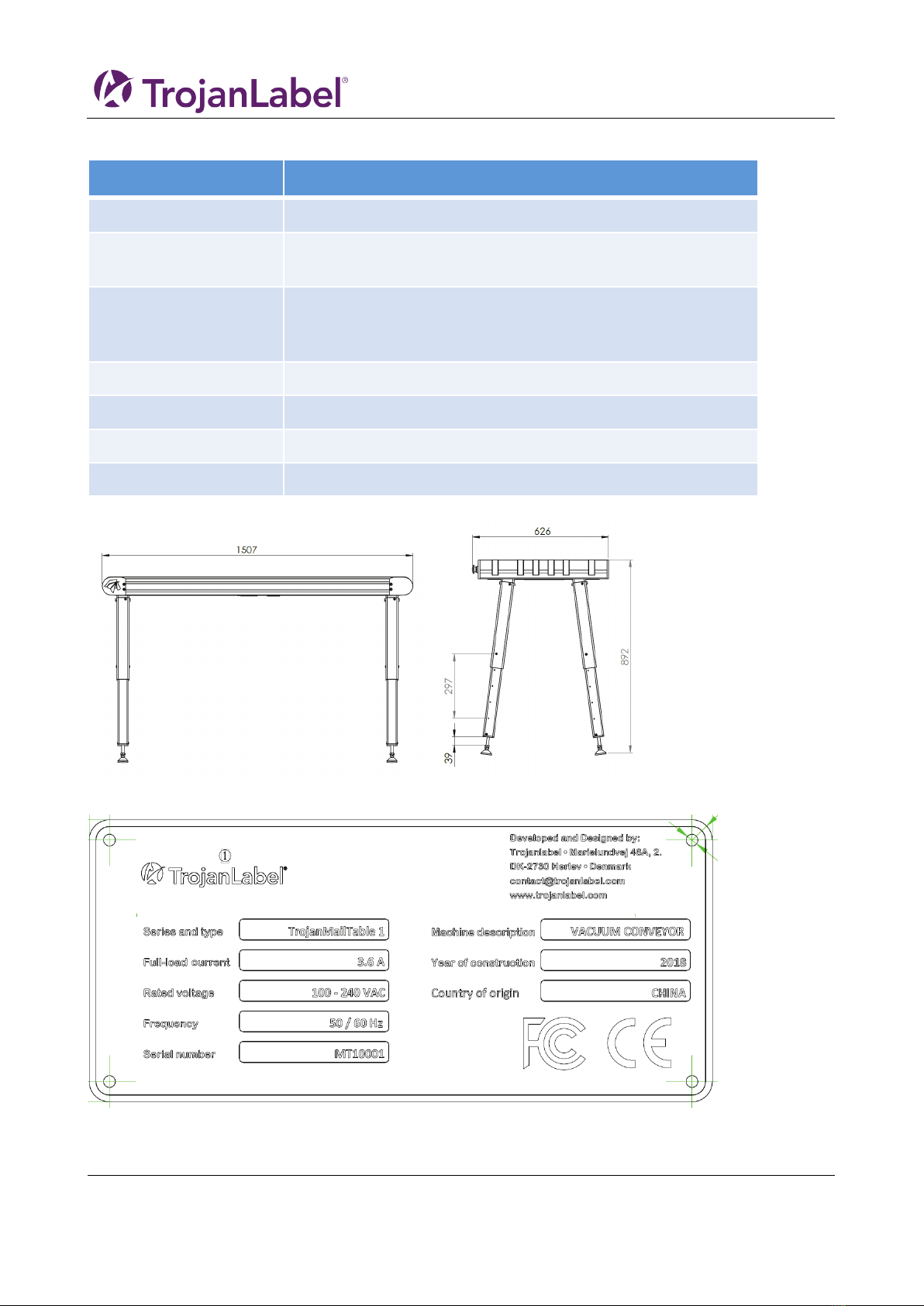

1.5.6 Specifications MailTable 2 (MT2)

MailTable 1 Wide

Speed

Up to 18 ips (27m/min)

Power requirements

100-240V AC – 50/60 Hz

(2.5A power supply)

Dimensions

Width: 1026 mm (incl Emergency stop)

Length: 2007 mm

Height: From 890 mm to 590 mm (5 positions)

Support material width

1000 mm

Weight

117 kg/ 258 lbs without accessories

Suction

5 fans adjustable speeds

Belts

8

T3-OPX installation

Page | 15

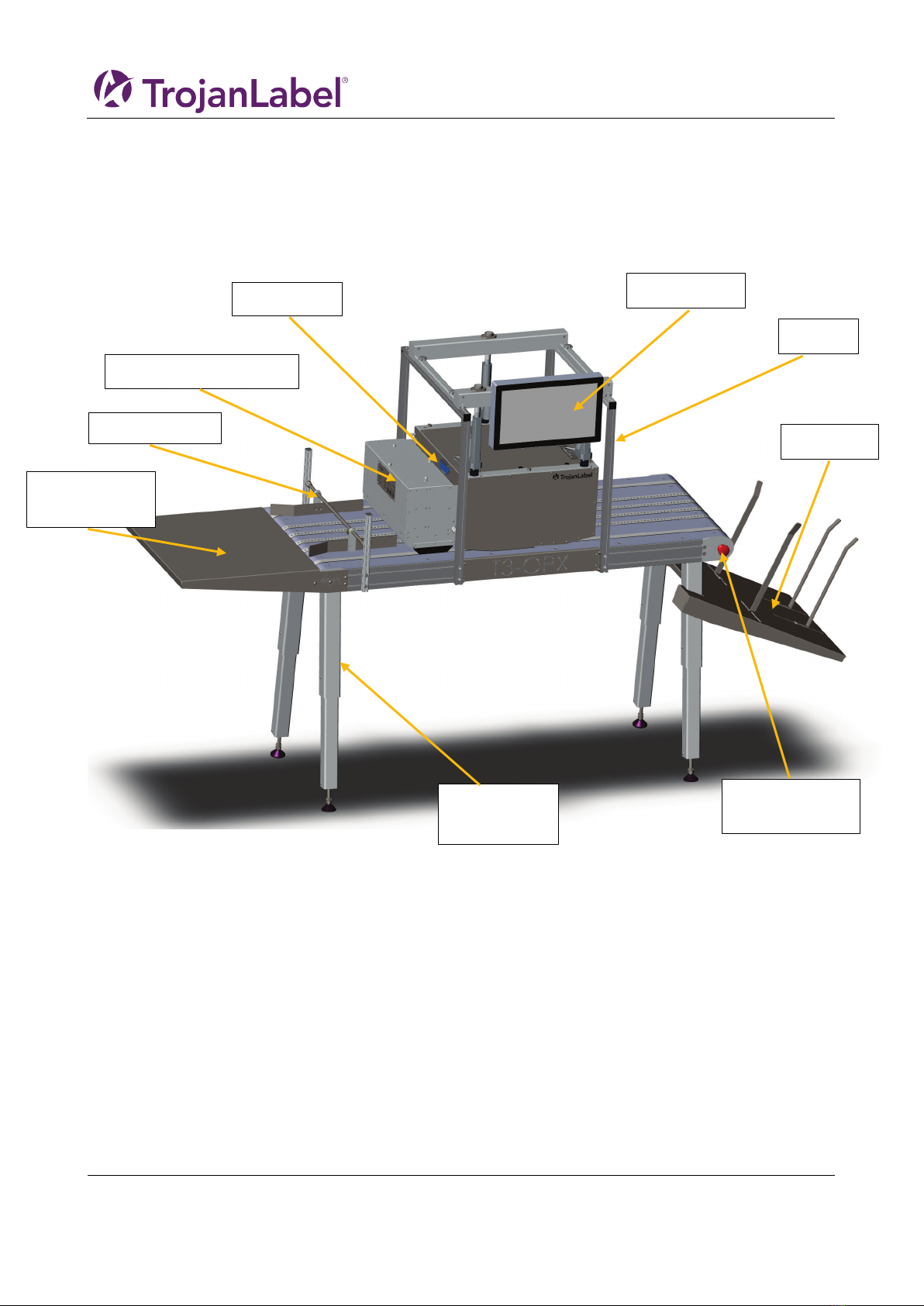

2T3 OPX physical overview

This is example

2.1 Front side

Edge Sensor

Adjustable

legs

Touch Screen

Feeder table

(optional)

Media Guides

Vacuum unit (optional)

Table

emergency stop

Catch tray

Bracket

T3-OPX installation

Page | 16

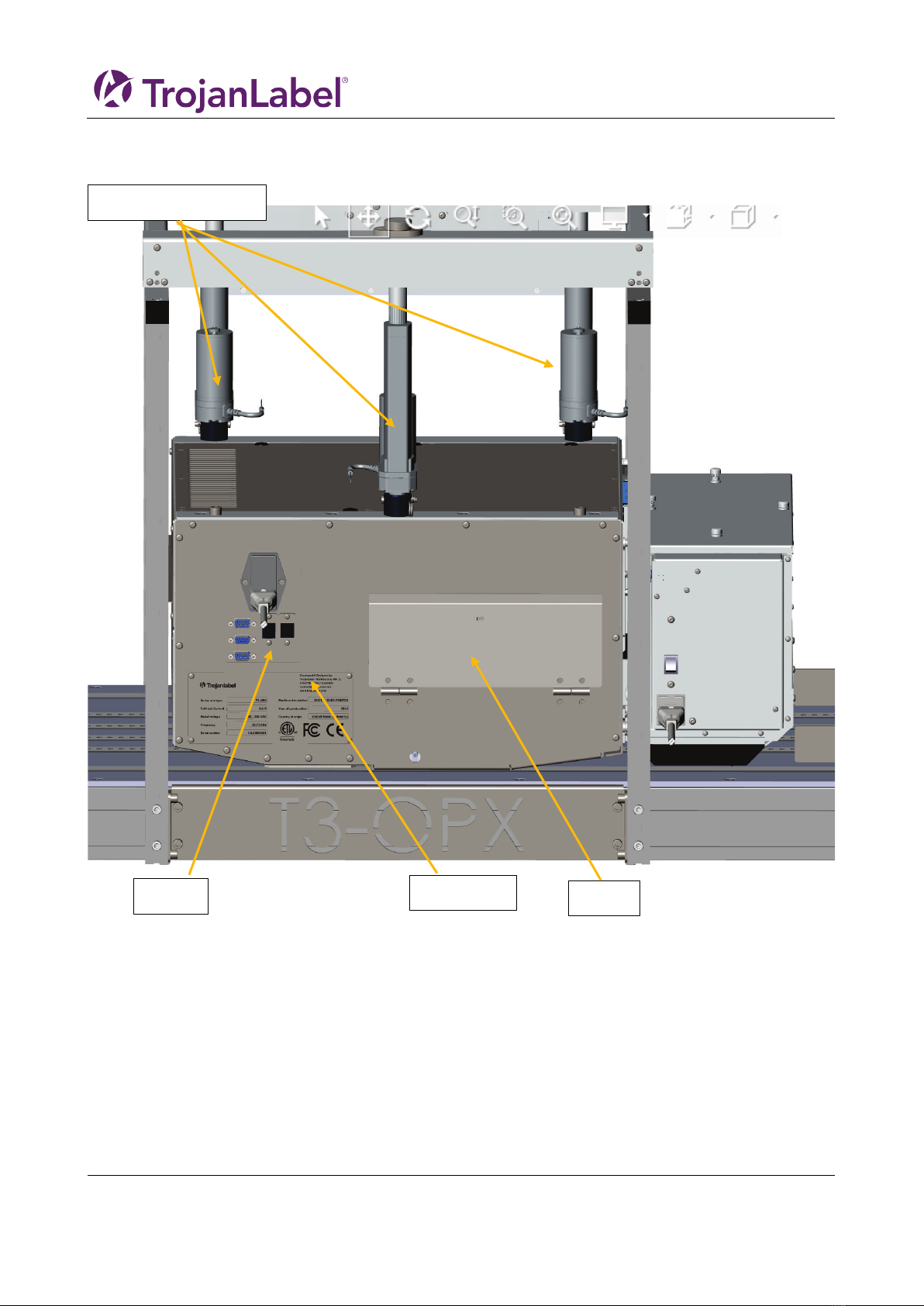

2.2 Backside

Height controllers (3)

Inlets

Ink lid

Serial plate

T3-OPX installation

Page | 17

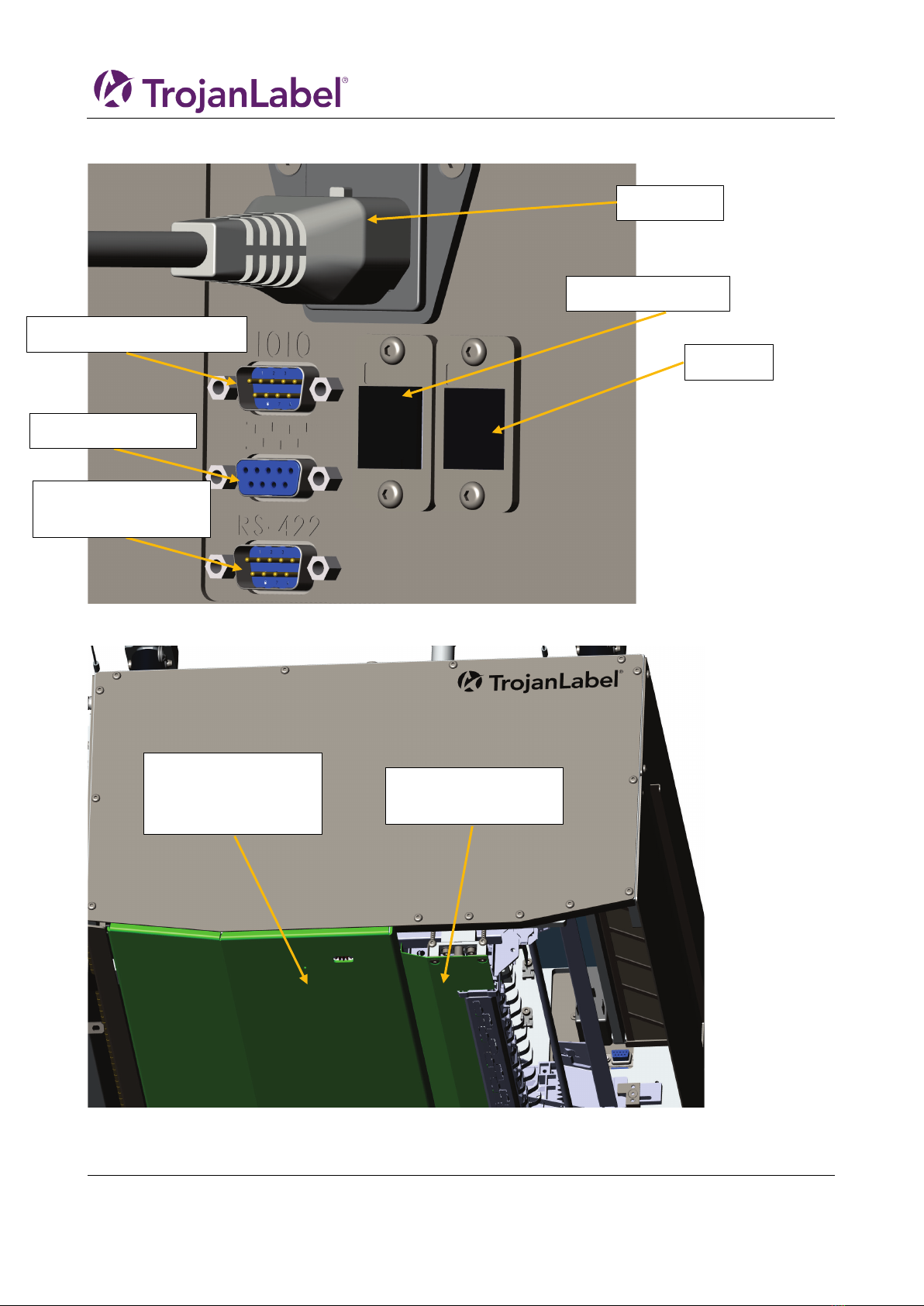

2.3 Inlets detail

2.4 Bottom

Power inlet

IO serial port (fx for feeder)

Encoder serial port

Table communication

port

Network (ethernet)

USB port

Pressure plate, area

that is used to detect

the media height

Crash plate. Protects

the print head.

T3-OPX installation

Page | 18

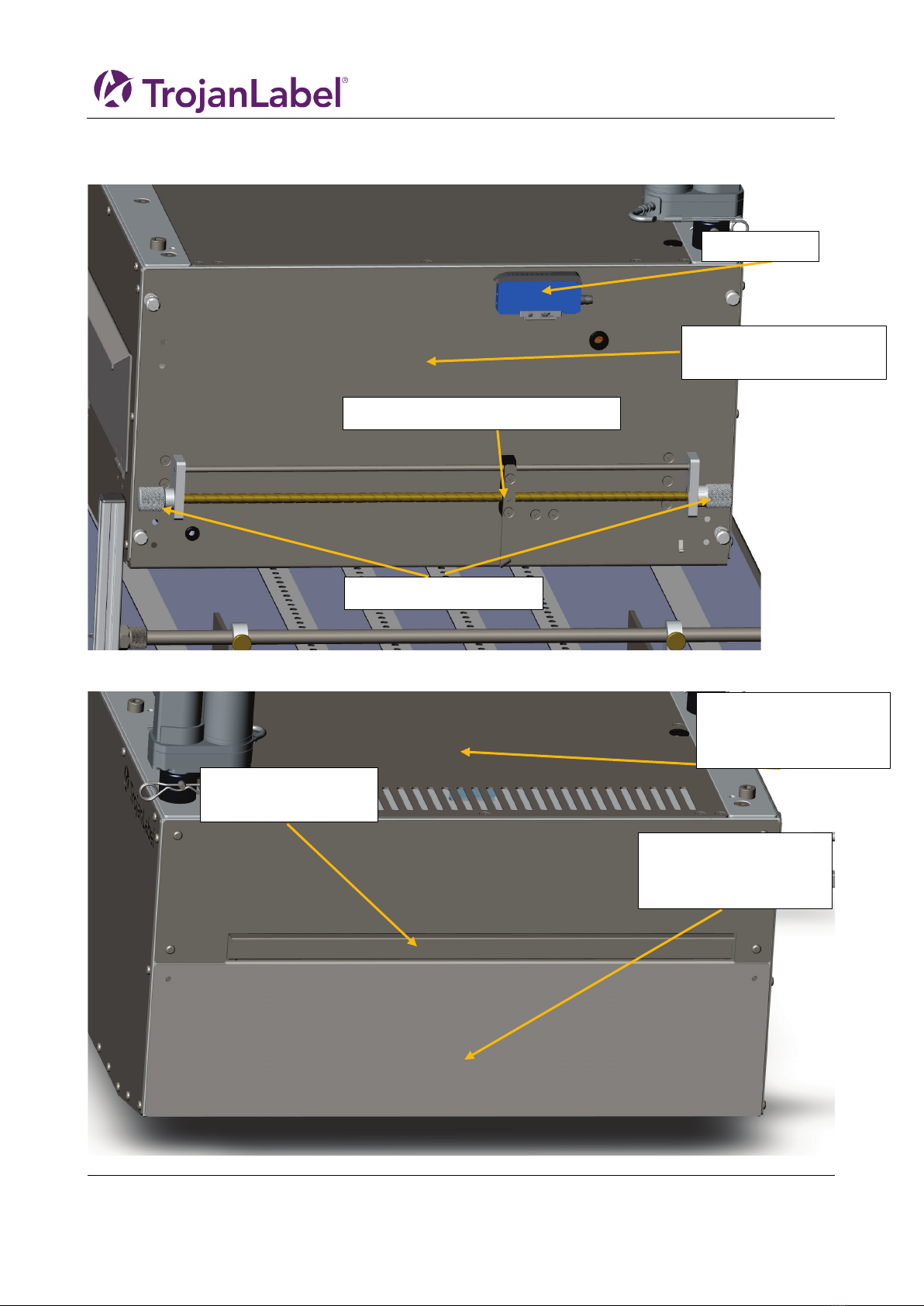

2.5 Media Entry side (feeder side)

2.6 Media exit side

Aerosol filter.

Replaceable filter

Front plate.

Removeable to access

print head area

Top lid.

Access to electronic

components

Edge Sensor

Knobs to move sensor

Edge sensor reflective light emitter

Service door, access to

print engine and service

T3-OPX installation

Page | 19

Table of contents

Other TrojanLabel Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Diamond Products

Diamond Products CVG1 Operator's manual

Venture Industries

Venture Industries VMS ATEX Operating and assembly instructions

JUKI

JUKI KE-750 Setup guide

Jäger

Jäger Z62-H370.01 S5W2 manual

SCHUNK

SCHUNK SLD Assembly and operating manual

Samoa

Samoa LARIUS PNEUMATIC HOIST 30 LT Operating and maintenance manual