Shield Omega-X User manual

Shield Fire, Safety and Security Ltd.

Shield Omega - X Panel Installation Manual SH3514-00, Revision E03.04

Issue Date: 1 April 2014

Shield Omega - X Panel Installation Manual

Underwriters Laboratories (UL)

File number (S 8485)

Fire Alarm Equipment

Shiled Fire, Safety and Security Ltd.

The Shield Omega - X Panel is suitable as follows:

• Local Signaling Unit

•Releasing for Omega - X Panels only. Non-Releasing for Omega - X Panels.

• Types of signaling services are automatic fire alarm, manual fire alarm, waterflow alarm and sprinkler supervisory.

• Style 4, 6 or 7 for Signaling Line Circuits

• Style Y for Notification Appliance Circuits

• Non-coded Signaling, DACT requires Integrated Dialer

•Remote Station (RS) Protected Premises Unit (PPU) Omega - N no communication on models SA-P20XX and SA-P2EXX and

SA-P4LXX and SA-P4EXX and each of these models with a Modem Dact SA-DACT

•Central Station (CS) Protected Premises Unit (PPU) Omega - N no communication on models SA-P20XX and SA-P2EXX and SA-

P4LXX and SA-P4EXX and each of these models with a Modem Dact SA-DACT

•Proprietary (P) Protected Premises Unit (PPU) provides releasing, non-releasing and Omega - N no communication on models SA-

P20XX and SA-P2EXX and SA-P4LXX and SA-P4EXX and each of these models with a Modem Dact SA-DACT

Shield Fire, Safety and Security Ltd.

Shield Omega - X Panel Installation Manual

SH3514-00, Revision E03.04

Issue Date: 1 April 2014

FCC

Shield Fire, and Safety Ltd.

This equipment complies with Part 68 of the FCC rule and the requirements adopted by the ACTA. On the Inside cover of this equipment is a label that

contains, among other information, a product identifier US:KNTAL00BASA-FACP. If requested, this number must be provided to the telephone company.

The Integrated Dialer is incorporated on the Main Board of the Omega - X Panel to provide TELCO communication on certain models.

Connect permissive data equipment to TELCO line 1 and line 2 of the Omega - X Panel using independent RJ31X jacks. Reference Section 3,

Installation, Connecting Communication, page 25 of this manual for details concerning these connections.

Reference the following:

- ATIS Technical Report No. 5 for connector details

- Facility Interface Code 02LS2

- Service Order Code 9.0Y

A plug and jack used to connect this equipment to the premises wiring and telephone network must comply with the applicable FCC Part 68 rules and

requirements adopted by the ACTA. A compliant telephone cord and modular plug must be used. It is designed to be connected to a compatible modular

jack that is also compliant. See installation instructions for details.

This product’s REN is 0,0. The REN is used to determine the number of devices that may be connected to a telephone line. Excessive RENs on a

telephone line may result in the devices not ringing in response to an incoming call. In most but not all areas, the sum of RENs should not exceed five

(5.0). To be certain of the number of devices that may be connected to a line, as determined by the total RENs, contact the local telephone company. The

REN for this product is part of the product identifier that has the format US:AAAEQ##TXXXX. The digits represented by ## are the REN without a

decimal point (e.g., 03 is a REN of 0.3). The REN is separately shown on the door label.

If the terminal equipment Fire Alarm Control Panel causes harm to the telephone network., the telephone company will notify you in advance that

temporary discontinuance of service may be required. But if advance notice is not practical. the telephone company will notify the customer as soon as

possible. Also, you will be advised of your right to file a complaint with the FCC if you believe it is necessary.

The telephone company may make changes in it's facilities. equipment, operations or procedures that could affect the operation of the equipment. If this

happens the telephone company will provide advance notice in order for you to make necessary modifications to maintain uninterrupted service.

If trouble is experienced with this equipment Fire Alarm Control Panel, for repairs or warranty information, please contact Shield Fire, Safety and

Security Ltd 29th Floor, Reg us Suite, One Canada Square Canary Wharf, London, E14 5DY, UK Tel:+44 0 2077121610. If the equipment is causing

harm to the telephone network., the telephone company may request that you disconnect the equipment until the problem is resolved.

Reference Section 5, Maintenance and Repair of this manual for details describing standby battery and fuse replacement. No other user serviceable

components are contained within this assembly. Contact Shield Fire, Safety and Security Ltd technical support for diagnostic assistance when

necessary. Reference Section 1, Introduction of this manual for details describing technical support, Return Material Authorization (RMA), Warranty

Returns, Advanced Replacements and the Product Return Address.

Connection to party line service is subject to state tariffs. Contact the state public utility commission, public service commission or corporation

commission for information.

If your home has specially wired alarm equipment connected to the telephone line, ensure the installation of this Fire Alarm Control Panel does not

disable your alarm equipment. If you have questions about what will disable alarm equipment, consult your telephone company or a qualified installer.

Reference the Loop Explorer Configuration Manual, Section 4, Programming, page 10 for details describing the programming of this assembly.

Shield Fire, Safety and Security Ltd.

Shield Omega - X Panel Installation Manual

SH3514-00, Revision E03.04

Issue Date: 1 April 2014

NFPA

Shield Fire, Safety and Security Ltd

Install this product in accordance with NFPA 13, NFPA 72 and NEC 70 and all local codes.

Short Circuit Isolator Modules protect SLC loop devices from single-loop-shorts. SLC loops must be wired with Short Circuit Isolator Modules to comply

with NFPA 72, Class A Style 7. SLC loop connections must include closed nippling and conduit nippling to maintain compliance with individual

enclosures under NFPA 72, Class A, Style 7 requirements. Closed nippling encloses individual devices on SLC loops and conduit nippling encloses

wiring between these individual enclosures. For Class A, Style 6 compliance, the Short Circuit Isolator Modules may be located at strategic locations

based on the discretion of the designer or installer.

The NFPA requires that two dedicated and independent TELCO lines feed communication features such as the Integrated Dialer.

Install SLC detectors with spacing as specified in section 90.19 of UL 864, 9th edition where units employing the multiple detector operation shall include

guidelines for installing of a minimum of two detectors in each protected space and to reduce the detector installation spacing to 0.7 times the linear

spacing in accordance with National Fire Alarm Code, NFPA 72. Also reference 55.3.1 and 55.3.2 of UL 864, 9th edition for these detector spacing

requirements.

All field wiring should be installed using fire rated cables according to the NFPA 72. Riser conductors shall be installed in accordance with the

survivability from attack by fire requirements in National Fire Alarm Code, NFPA 72, Sections 6.8.6.3, and 6.9.4. Riser conductors shall employ either a 2

hour rated cable system, or meet requirements approved by the AHJ, or installation of the Supervised Output Module using NFPA Style 7 configuration.”

FM Global Technologies LLC (FM APPROVALS)

Shield Fire, Safety and Security Ltd

Shield Fire, Safety and Security Ltd.

Shield Omega - X Panel Installation Manual

SH3514-00, Revision E03.04

Issue Date: 1 April 2014

Shield

is a registered trademark of Shield

Fire, Safety and Security Ltd. All other product or service names are the

property of their respective owners.

Copyright © 2013 by Shield Fire, Safety and

Security Ltd All rights reserved.

Shield Fire, Safety and Security Ltd.

Shield Omega - X Panel Installation Manual

SH3514-00, Revision E03.04

Issue Date: 1 April 2014

Contents

i

Section 1

Introduction

Using This Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Related Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Document Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Part Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Writing styles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

If You Need Help . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Contacting Shield Tech Support . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

RMA Returns Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Warranty Returns . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Advanced Replacements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Suspect-Product Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Product Return Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Section 2

Overview

Points and Addresses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Contact ID Address Restrictions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Hardware Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Panel Controls and Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Device Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Terminal Strip X1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Terminal Strip X2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4 Amp OEM 1 Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Section 3

Installation

General Installation Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Determining System Current Draw . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Standby-Battery Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Operating Constraints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Wiring the 4 Amp OEM 1 Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Connecting Standby-Batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Connecting 24VDC Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Shield Fire, Safety and Security Ltd.

Shield Omega - X Panel Installation Manual

SH3514-00, Revision E03.04

Issue Date: 1 April 2014

Contents

ii

Connecting Class A Loops. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

NFPA 72, Style 7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

NFPA 72, Style 6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Connecting Class B Loops . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Installing SLC Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Detector Spacing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Addressable Notification Appliances and Output Modules . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Silencing Notification Appliances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Connecting NAC Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Connecting Output Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Fire Routing and Trouble Routing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Programmable Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Auxiliary 24 VDC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Relay Contacts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Connecting Remote Control And Aux. Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Mounting the Omega - X Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Marking the Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Preparing for Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Anchoring the Omega - X Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Wiring AC Power and TELCO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Testing the Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Confirming a Successful Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Testing the Panel Lamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Trouble-Silence Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

4 Amp OEM 1 Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Front-Panel Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Shield Fire, Safety and Security Ltd.

Shield Omega - X Panel Installation Manual

SH3514-00, Revision E03.04

Issue Date: 1 April 2014

Contents

iii

Section 4

Front-Panel Menu

Access Level 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Disablements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

View Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Test Zones . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Set System Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Sensor Maintenance Early Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Events and Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Access Level 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Front-Panel Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Section 5

Maintenance and Repair

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Inspecting Batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Replacing Standby-Batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Replacing Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

10 Amp Battery Fuse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

3 Amp Power-Supply Fuse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Replacing Internal Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Replacing Cabinet Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Shield Fire, Safety and Security Ltd.

Shield Omega - X Panel Installation Manual

SH3514-00, Revision E03.04

Issue Date: 1 April 2014

Contents

iv

Appendix A

Specifications

Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Standby and Alarm Current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Earth Fault Indication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

SLC Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Programmable Relay Contact Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Programmable Special Application NAC Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Power Output Circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Unsupervised Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

RS485 Serial Bus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Auxiliary 24 VDC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Omega - N Terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . 73

4 Amp OEM 1 Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

AC Line Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Cabling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Operating Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Physical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Appendix B

Equipment List

Shield Omega - X Panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Loop Devices and Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Compatible Notification Appliance Circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Authorized Special Application Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Compatible Devices for Auxiliary 24V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .95

Shield Fire, Safety and Security Ltd.

Shield Omega - X Panel Installation Manual

SH3514-00, Revision E03.04

Issue Date: 1 April 2014

Contents

v

Appendix C

Calculations

Current-Loading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Determining the Standby-Battery Rating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Battery Rating Equation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

NAC Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Auxiliary Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Tabulating Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

NAC Wiring Length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Sample Lmax Calculation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Appendix D

Door Label

Appendix E

Operating Instructions

Glossary

Shield Fire, Safety and Security Ltd.

Shield Omega - X Panel Installation Manual

SH3514-00, Revision E03.04

Issue Date: 1 April 2014

Introduction 1

Notice to Users, Installers, Authorities Having Jurisdiction, and other involved parties. This product incorporates

field-programmable software. In order for the product to comply with the requirements in the Standard for Control

Units and Accessories for Fire Alarm Systems, UL 864 9th Edition, certain programming features or options must be

limited to specific values or not used at all as indicated below.

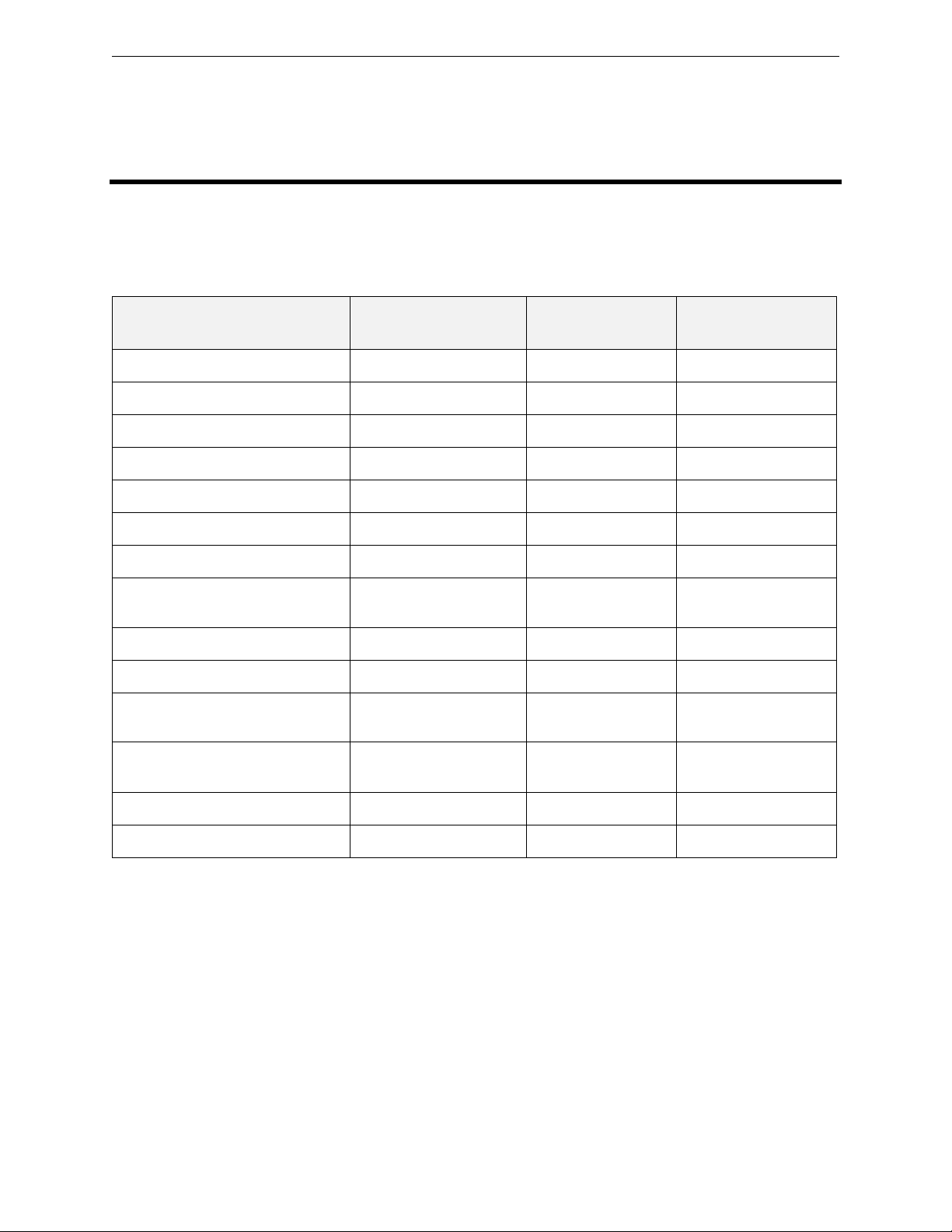

Reference Appendix B, “Equipment List” for model designations of the devices contained in this table.

Program Feature or Option Permitted in UL 864 ?

(Y / N)

Possible Settings Settings Permitted

In UL 864

AC Fail Delay Yes 0 - 24 hours 1 - 3 hours

Alarm Verification Yes 5 - 60 seconds 60 second

Disable Buzzer Yes Enable / Disable Enable

Disable Ground Trouble Yes Enable / Disable Enable

Set Buzzer Silence Access Level Yes 1 or 2 2

NAC Output Delay Stage 1 No 0 - 5 minutes 0 minutes

NAC Output Delay Stage 2 No 0 - 5 minutes 0 minutes

Photoelectric Smoke Sensor

Delay

No 0 -120 seconds 0 seconds

Ionization Smoke Sensor Delay Yes 0 -120 seconds 0 seconds

Duct Detector Yes 0 -120 seconds 0 seconds

Duct Detector with Relay Yes 0 -120 seconds,

0 - 5 seconds

0 seconds

Contact Module Delay

(All models)

Yes 0 -120 seconds 0 seconds

Relay Module Delay Yes 0 - 5 seconds 0 seconds

Supervised Output Module Delay Yes 0 - 5 seconds 0 seconds

Section 1

Introduction

Shield Fire, Safety and Security Ltd.

Shield Omega - X Panel Installation Manual

SH3514-00, Revision E03.04

Issue Date: 1 April 2014

Page 1 of 118

Introduction 1

This manual describes 2 loop and 4 loop models of the Shield Omega - X Panel. Two loop models include the No

Communication SA-P20, the Network Interface Card (Omega - N) SA-P2E. Four loop models include the No

Communication with Loop Expansion SA-P4L, the Network Interface Card (Omega - N)with Loop Expansion

SA-P4E.

A list of Documentation Updates will be displayed.

This section describes:

• Using This Manual

• Related Documentation

• Document Conventions

• If You Need Help

•Contacting Shield For Repair

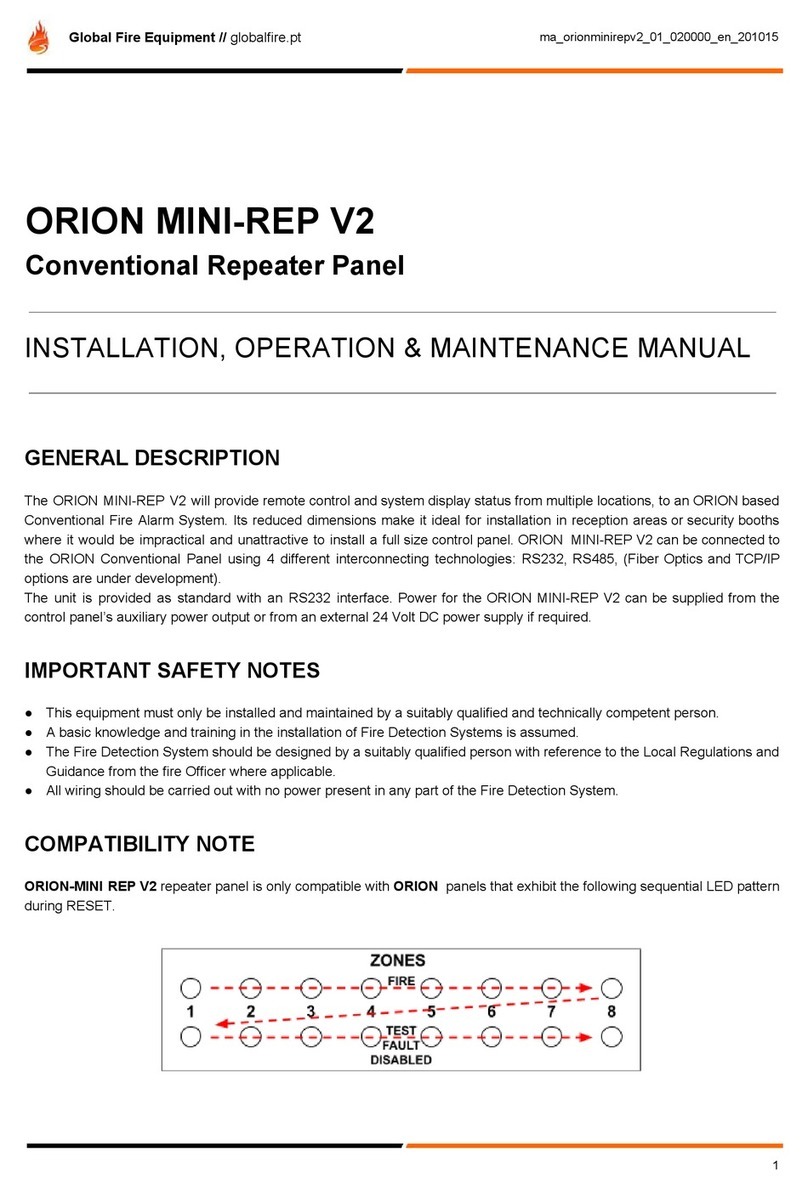

The figure below illustrates the Omega - X

Panel: Figure 1-1

Omega - X Panel

Shield Fire, Safety and Security Ltd.

Shield Omega - X Panel Installation Manual

SH3514-00, Revision E03.04

Issue Date: 1 April 2014

Page 2 of 118

Introduction 1

Using This Manual

The following sections provide instructions for installing, testing and troubleshooting the Omega - Xpanel.

Related Documentation

The following documents shall be used to provide additional information for installing the Omega - X Panel:

•16 Channel I/O Interface Installation Manual, SH3512-00

•Omega - R Installation Manual, SH3510-00

•Omega - M Installation Manual, SH3513-00

•Omega - N Installation Manual, SH3511-00

Introduction provides document conventions, the technical help-line, repair and return

information.

Section 2 Overview provides a summary features of the Omega - X Panel.

Section 3 Installation describes how to setup, install and test the Omega - X Panel.

Section 4 Front-Panel Menu describes how to operate the Omega - X Panel from its front-panel.

Section 5 Maintenance and Repair describes how to perform routine service and repair on the Omega - X Panel.

Appendix A Specifications provides characteristics of the Omega - X Panel.

Appendix B Equipment List provides model numbers for Shield Omega - X Panels, loop

replacement parts and compatible Notification Appliances.

Appendix C Current Draw Worksheet provides an example for recording and calculating the current draw of

the Omega - X Panel and its Signaling Line Circuits, Initiation Devices and Notification Appliances.

Appendix D Front Door Label is a copy of the Omega - X Panel front door label.

Appendix E Operating Instructions provides an overview of Omega - X Panel status and control instructions.

Glossary Glossary contains definitions for terminology used in the Omega - X Panel Installation Manual.

Document Conventions

This document contains conventions for part numbers and writing style.

Part Numbers

Part numbers are provided in Section 1, Appendix B and Appendix D of this manual. Refer to Appendix D,

Door Label for diagram summary of information contained in this manual. Refer to Appendix B, Equipment List for a

complete list of part numbers required for completing this installation.

Writing styles

Before you begin using the Omega - X Panel, familiarize yourself with the stylistic conventions used in this manual:

Bold type

Italic type

Indicates text that you must type exactly as it appears or indicates a default value.

Denotes a displayed variable, a variable that you must type, or is used for emphasis.

Courier font Indicates text displayed on a computer screen.

Section 1

Shield Fire, Safety and Security Ltd.

Shield Omega - X Panel Installation Manual

SH3514-00, Revision E03.04

Issue Date: 1 April 2014

Page 3 of 118

Introduction 1

If You Need Help

If you need technical support contact Shield at +44 1708 377731 or e-mail [email protected].

Shield technical support is available Monday through Friday, 8:00 AM to 5:00 PM.

Limited Returns and Repairs Policy

In-Warranty Items

All equipment supplied by Shield is provided with a warranty, these warranties are between Shield (the Seller) and the

company that placed the order upon the seller (the Buyer). The warranty Period is valid for 36 months from the

delivery date and is non-transferable.

Damaged Goods

In the event of damage to equipment during transit or any defect in the quality of goods, the Buyer shall Notify Shield

within seven days of delivery.The goods may then be returned to the Customer Service Department of Shield for

repair, or replacement parts may be supplied (by arrangement).

Component Failure

In the event of a defect of the supplied equipment during the warranty period, due to defective materials or

workmanship, then replacement parts shall be supplied to the Buyer using the Service Replacement Item (SRI)

scheme.

Service Replacement Items

The Buyer shall request the replacement part(s) required from the Customer Service Department. This Request

shall be made by fax to +44 1708 347637 or e-mail to [email protected] and shall include the Parts required

the panel Works Order (W/O) Number and the required delivery address.

If the Buyer is not aware of the required replacement part(s), additional advice may be obtained from the Technical

Support Department. Once the SRI has been approved, items are normally dispatched for next day delivery subject to

stock availability.

SRI parts are supplied on the following terms and conditions:

• SRI parts are loan items and are not available for resale.

• All SRI parts must be returned to the Customer Service department of Shield within 14 days of delivery.

• Any SRI parts that have not been returned within 28 days of delivery will be invoiced at the price given in the

Shield Price List, less discount.

• Any returned items that are found to have failed due to fair wear and tear, willful damage, negligence, abnormal

working conditions, misuse or alteration or repair without the Suppliers approval or failure to follow the sellers

instructions will be subjected to a repair fee of up to the price given in the Shield Price List, less discount.

• Any returned items that are not part of the original equipment or are not in warranty will be invoiced at the price

given in the Shield Price List, less discount where applicable.

• All SRI parts shall be returned in the same packaging as the replacement parts were supplied in. Failure to ensure

that adequate anti-static precautions are taken during the replacement of parts, or in the return of SRI parts may

result in an invoice of up to the price given in the Shield Price List, less discount.

• Any SRI parts returned without the completed SRI delivery report or any SRI reference documentation will be

invoiced at the price given in the Shield Price List, less discount. The right to receive Service Replacement Items

is regularly reviewed and may be withdrawn from persistent abusers of this facility. Shield reserve the right not to

supply SRI items without prior notice.

Shield Fire, Safety and Security Ltd.

Shield Omega - X Panel Installation Manual

SH3514-00, Revision E03.04

Issue Date: 1 April 2014

Page 4 of 118

Introduction 1

Out Of Warranty Items

Shield provides a test and repair facility for most standard and special build products. This facility can also recondition

control panels, subject to availability of components.

Customer Repairs

Items for repair shall be returned to the Customer Service Department of Shield. Any items returned for repair must be

accompanied with the following:

• A request for repair work to be undertaken.

• A customer contact name.

• Details of the company requesting the repair.

Failure to supply the required information will result in the returned items being quarantined for a period not

exceeding 60 days. If the items are not identified within 60 days of receipt, then Shield reserves the right to

dispose of these items or return them.

A written quotation will be provided for all items to be repaired that are not included in the repair prices section of the

Shield Price list. No repairs or refurbishment will be undertaken without prior authorisation from the customer and a

written order for the repair work. Returned equipment will be held awaiting authorisation for a period not exceeding

60 days from the date of quotation. After this period, Shield reserves the right to dispose of these items or return them.

Repair Warranties

Repaired items are not covered by the normal Warranties and Liability conditions. Subsequent failures of repaired

items will only be covered if the failure is due to a material or workmanship defect directly associated with the repair

and for a period not exceeding three months from the date of the repair. Shield are under no liability if the repaired or

replaced components are found to have failed due to fair wear and tear, willful damage, negligence, abnormal working

conditions, misuse or alteration or repair without approval or failure to follow the sellers instructions.

Items Returned For Credit

Items shall only be accepted for credit by written approval with the Operation Manager of Shield. Items will only be

eligible for credit in the first 3 months from the supply date.

Before any items are returned for credit, an RMA reference number must be obtained from the Sales / Operations

Department. This number must be used for any correspondence relating to the goods. All goods Returned for credit

must be approved before receipt.Written approval will then be issued using a Goods Return Application Form. A copy

of this form must be supplied with the returned goods. The RMA reference number must be clearly marked on the outer

packaging when returning goods to the company. Goods must be returned to Shield within 30 days of the issue of the

Goods Return Application Form. Only items listed on this from must be returned under the RMA reference. Items

returned without prior request for an RMA reference may be returned to the customer.

Failure to supply the required information will result in the returned items being quarantined for a period not

exceeding 60 days. If the items are not identified within 60 days of receipt, then Shield reserves the right to dispose of

these items.

Any items returned for credit will be tested and returned to a production release condition. Any material and labour

costs associated with this process shall be deducted from the credit amount in accordance with the Returned Goods

Policy in the Shield price list and at the discretion of the Managing Director.

Shield Fire, Safety and Security Ltd.

Redburn House, 2A Tonbridge Road,

Romford, Essex – RM3 8QE, United Kingdom

Tel: +44 1708 377731, Fax: +44 1708 347637,

E-mail: [email protected]

Shield Fire, Safety and Security Ltd.

Shield Omega - X Panel Installation Manual

SH3514-00, Revision E03.04

Issue Date: 1 April 2014

Page 5 of 118

Overview 2

Models of the Shield Omega - X Panel operate SLC devices using Apollo protocol.

The Omega - X Panel accepts a variety of industry standard devices for FACP monitoring and reporting.

Link the Omega - X Panel with other panels using the proprietary Omega - N to monitor conditions between

panels. Provide reports concerning these conditions to monitoring-centers using a standard TELCO line.

Points and Addresses

Points and addresses are fundamental to the operation of Omega - X monitoring and reporting. Devices are

identified as points when connected to the Omega - X Panel. Device points are assigned addresses when

configured on the Omega - X Panel using the Loop Explorer application. Each Omega - X Panel supports a

maximum of 126points per loop without subpoints or 381 points per loop when utilizing subpoints.

Omega - X Panels support a point and subpoint maximum of 800 addresses per panel.

Do not exceed this 800 address maximum when assigning subpoints to points on Omega - X Panels.

Contact ID Address Restrictions

Address restrictions effect all models of the Omega - X Panel when using the Contact ID format for

monitoring-center communication.

The Contact ID format limits reporting to an address of 99. Configuration features in the eSP Discovery application

restrict the use of the Contact ID format when selecting addresses above 99. The Contact ID format can be used for

devices other than analog-sounder-bases as long as the device address and sub address are below 99.

FACP reporting can be changed from point reporting to zone reporting when the limit of 99 addresses per loop

cannot be avoided. Zone reporting can be used to resolve address assignments in excess of 99 but doing so reduces

overall reporting granularity.

Models of the Omega - X Panel can be programmed for the SIA or Contact ID digital communication format. The

SIA and Contact ID format provides status monitoring and reporting to industry-standard receivers at the

monitoring-center.

Both ofthese digital communication formats provide a range of addressing for device-points and sub-points on the

Omega - X Panel. The SIA format allows full reporting from all device-points and sub-points. The Contact ID

format provides a limited range of reporting from device-points. The eSP Discovery application uses an open

protocol to assign device addresses to the Omega - X Panel.

Reference Appendix B, “Equipment List” for all models effected by restrictions of the Contact ID format.

Section 2

Overview

Shield Fire, Safety and Security Ltd.

Shield Omega - X Panel Installation Manual

SH3514-00, Revision E03.04

Issue Date: 1 April 2014

Page 6 of 118

Overview 2

Hardware Features

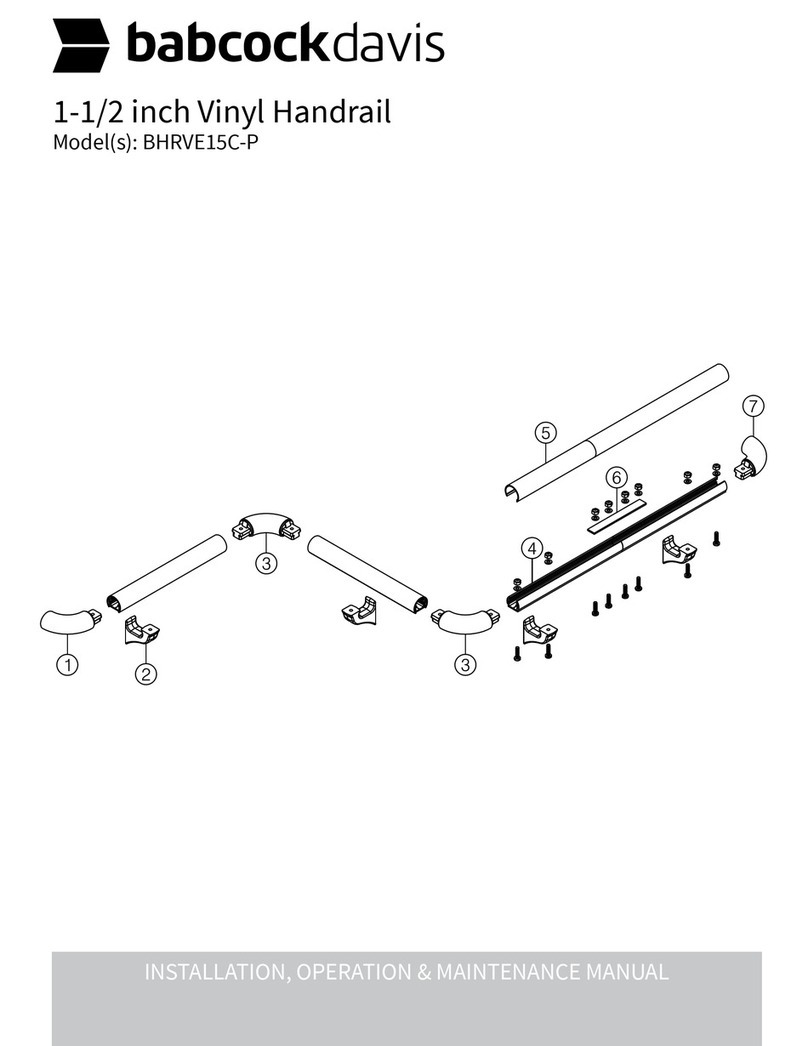

All Omega - X Panels contain a 4 Amp OEM 1Power Supply, Control Unit Board, Batteries and Panel Annunciator Board.

The figure below illustrates internal components of the Omega - X Panel:

Figure 2-1

Internal Components

Key Description

1

Modem-DACT

2Control Unit Board

34 Amp OEM 1 Power Supply

4Panel Annunciator Board

5Batteries

HANDLING PROCEDURES AT ALL TIMES.

WHILST B OARD IS POWERED.

DO NOT PLUG OR UNPLUG RIBBON CABLES

STATIC SENSITIVE CIRCUITS, OBSERVE STATIC

WARNING

PN: HW-000012 REV C

FCC REG. NO.: VESAL00BVF10xx-xx

PRI

TELCO

Line 1

JACK TYPE: RJ11C

REN = 00B

Line 2

SEC

Comm A ct iv e

610-992-0400

PANEL -D I AL ER

THIS DEVICE COMPLIES WITH PART 68 RULES

TESTED TO COMPLY WITH FCC STANDARDS

(2) THIS DEVIC E MUST ACCEPT ANY INTER FERENC E RECEIVE D,

OPERATION IS SUBJECT TO THE FOLLOWING TWO CONDITIONS:

(1) THIS DEVIC E MAY NOT CAUSE HARMFU L INTERFERE NCE, AND

INCLUDIN G INT ERFE RENCE THAT MAY CA USE UN DESIRE D OP ERATIO N.

THIS DEVICE COMPLIES WITH PART 15 OF THE FCC RULES.

Industry Canada Elec tromagnetic Compatibili ty, ICES-003 :

THIS CLASS A DIGITAL APPARATUS COMPLIES WITH CANADIAN ICES-003.

CET APPAREIL NUMERI QUE D E LA CLA SSE A EST CONF ORM E A LA NORME

MODEL NO.: PLASY-000004

POWER REQUIREMENETS: 24VDC @ 200mA ( MAX)

NMB-003 DU CAN ADA.

620 ALLENDALE ROAD, SUITE 175

KING OF PRUSSIA , PA 19406

Comm Fau lt

DATA

J7

Heartbeat

POWER

J8

VNet B

VNet A

000AFD0002FB

REFER TO PANEL-DIALER INSTALLATION

MANUAL VF1523-00 Rev. E01.XX AND

PANEL -C ONFIGU RATI ON A ND R EP A IR

MANUAL VF1524-00 Rev. E01.XX

VIKING ELECTRONIC SERVICES LLC

FUSE:

3A 250V

SB 5x20mm

PN: HW-000 106

REV B

VIKING ELECTRONIC SERVICES

620 ALLENDALE RD, SUITE 175

KING OF PRUSSIA, PA 19406

WARNIN G

HIGH VOLTAGE

DISCONNECT POWER

BEFORE REMOVING

INSTALLATION INSTRUCTIONS

PN:VF1537-00

`

1

2

3

4

5

Shield Fire, Safety and Security Ltd.

Shield Omega - X Panel Installation Manual

SH3514-00, Revision E03.04

Issue Date: 1 April 2014

Page 7 of 118

Overview 2

Panel Controls and Indicators

The Omega - X front-panel contains the following controls and indicators:

• LCD display

• Upper-control-pad

• Lower-control-pad

• Left-panel-indicators

• Right-panel-indicators

The figure below illustrates the Omega - X front-panel:

Figure 2-2

Controls and Indicators

Key Description

1LCD display

2Left-panel-indicators

3Upper-control-pad

4Lower-control-pad

5Right-panel-indicators

24513

Shield Fire, Safety and Security Ltd.

Shield Omega - X Panel Installation Manual

SH3514-00, Revision E03.04

Issue Date: 1 April 2014

Page 8 of 118

Overview 2

Controls

The Omega - X contains upper-panel and lower-panel control-pads.

Upper-Control-Pad

The figure below illustrates the Omega - X upper-control-pad:

Figure 2-1

Upper-Control-Pad

Key Name Description

1Central keypad number four Navigates menu selections to the left.

2More Fire Events Displays the number of alarms present on the

Omega - X Panel and overrides the display provided by menu navigation.

3Exit Cancels the current menu selection.

4Central keypad question mark Provides a “help screen” for the current menu display and also

displays status. For example, recommendations are displayed

during alarm or fault conditions. If a menu function is accessed then

help relating to that function will be displayed.

5Central keypad number three Navigates menu selections down.

6Enter Enables the menu selection.

7More Events Displays the number of events present and overrides menu

navigation. Provides event status for Fire, Pre-Alarm, Trouble,

Disablements and Other.

8Central keypad number two Navigates menu selections to the right.

9Central keypad number one Navigates menu selections up.

Shield Fire, Safety and Security Ltd.

Shield Omega - X Panel Installation Manual

SH3514-00, Revision E03.04

Issue Date: 1 April 2014

Page 9 of 118

Overview 2

Lower-Control-Pad

The figure below illustrates the Omega - X lower-control-pad:

Figure 2-4

Lower-Control-Pad

Key Name Description

1Re-Sound Alarm Re-sounds the alarm when sounders are muted using the Alarm Silence

button.

2Alarm Silence Silences NACs connected to the Omega - X Panel after receiving

authorization through Access Level 2.

3Panel Sounder

Silence

Mutes the internal buzzer of the Omega - X Panel. No other sounder

outputs are affected by this operation.

4Lamp Test Tests front-panel indicators and the internal buzzer by illuminating all LEDs

while darkening the front-panel display and sounding the buzzer.

5Reset Resets latching inputs such as fire and pre-alarm events after receiving

authorization through Access Level 2. Fault events are non-latching inputs

and cannot be cleared by the Reset button. Non-latching inputs are cleared

when faults are cleared.

6Fire Drill Provides a fire drill for the Omega - X Panel after receiving authorization

through Access Level 2. During the drill:

• The “On Test” LED illuminates continuously

• The “Fire” LEDs blink

• The internal buzzer sounds intermittently

• The display provides the message,

“FIRE DRILL:FIRE DRILL ZONE 00*

To stop the fire drill:

1 Press 4 to display the “SET ACCESS LEVEL 2 MENU”.

2 Provide Access Level 2 authorization.

3 Press Reset or Fire Drill on the lower-control-pad.

7Programmable

Function

Activates inputs, outputs or actions defined in the configuration by the

customer.

Shield Fire, Safety and Security Ltd.

Shield Omega - X Panel Installation Manual

SH3514-00, Revision E03.04

Issue Date: 1 April 2014

Page 10 of 118

Table of contents

Popular Firefighting Equipment manuals by other brands

Emerson

Emerson 2400 instruction manual

Cooper Lighting Solutions

Cooper Lighting Solutions 4125 Series instructions

Bentel Security

Bentel Security FireClass FC500-MFI installation manual

Tyco Fire Protection Products

Tyco Fire Protection Products TY-B Series manual

STI

STI EZ-Path 44+ Series installation instructions

Zico

Zico QUIC-RELEASE QR-FEH-1 Series Parts and instruction manual