Shield M10U User manual

Safety Precautions

Shield M10U user manual I

Safety Precautions

This manual contains information concerning the installation and operation of Modular UPS. Please carefully read this

manual prior to installation.

The Modular UPS cannot be put into operation until it is commissioned by engineers approved by the manufacturer (or

its agent). Not doing so could result in personnel safety risk, equipment malfunction and invalidation of warranty.

The UPS has been designed for commercial or industrial use only, and is not intended for use in any life support

application. This is a CLASS C Uninterruptible Power Supply (UPS) product. In a domestic environment, this product may

cause radio interference, in which case, the user may be required to take additional measures.

Conformity and standards

This product complies with CE73/23 & 93/68 (low voltage safety) and 89/336 (EMC), and the following UPS product

standards:

*IEC62040-1-1-General and safety requirements for use in operator access area

*IEC/EN62040-2 EMC requirements CLASS C

*IEC62040-3 Performance requirements and test methods

For more details, refer to Chapter 9 . Continued compliance requires installation in accordance with these

instructions and the use of manufacturer approved accessories only.

WARNING: high earth leakage current

Earth connection is critical before connecting the input supply (include both utility supply and battery).

"Earth leakage current introduced by the UPS, in any configuration from 10kW to 150kW, exceeds 3.5 mA and is less

than 1000 mA and complies with the requirements of IEC/EN 62040-1 / IEC/EN 60950-1" Transient and steady-state

earth leakage currents, which may occur when starting the equipment, should be taken into account when selecting

instantaneous RCCB or RCD devices.

Residual Current Circuit Breakers ( RCCBs) must be selected sensitive to DC unidirectional pulses (class A) and

insensitive to transient current pulses.

Note also that the earth leakage currents of the load will be carried by this RCCB or RCD.

This equipment must be earthed in accordance with local electrical authority codes of practice.

WARNING: backfeeding protection

This system has a control signal available for use with an automatic device, externally located, to protect against

backfeeding voltage through the mains Static Bypass circuit. If this protection is not used with the switchgear that

is used to isolate the bypass circuit, a label must be added to the switchgear to advise service personnel that the

circuit is connected to a UPS system.

The text has the following meaning or is equivalent to: Isolate the UPS before working on the circuit of this UPS.

Components that can be maintained by user

All the equipment maintenance and servicing procedures involving internal access need special tools and should be

carried out only by trained personnel. The components that can only be accessed by opening the protective cover

with tools cannot be maintained by user.

This UPS full complies with “IEC62040-1-1-General and safety requirements for use in operator access area UPS”.

Dangerous voltages are present within the battery box. However, the risk of contactor with these high voltages is

minimized for non-service personnel. Since the component with dangerous voltage can only be touched by opening

the protective cover with a tool, the possibility of touching high voltage component is minimized. No risk exists to

any personnel when operating the equipment in the normal manner, following the recommended operating

procedures in this manual.

警告

危险

警告

危险

警告

危险

警告

危险

Safety Precautions

II Rack Modular UPS System 10-90kVA User Manual

Battery voltage higher than 400Vdc

All the battery maintenance and servicing procedures involving internal access need special tools or keys and should

be carried out only by trained personnel.

SPECIAL CARE SHOULD BE TAKEN WHEN WORKING WITH THE BATTERIES ASSOCIATED WITH THIS EQUIPMENT.

WHEN CONNECTED TOGETHER, THE BATTERY TERMINAL VOLTAGE WILL EXCEED 400Vdc AND IS POTENTIALLY

LEATHAL.

Battery manufacturers supply details of the necessary precautions to be observed when working on, or in the vicinity

of, a large bank of battery cells. These precautions should be followed implicitly at all times. Particular attention

should be paid to the recommendations concerning local environmental conditions and the provision of protective

clothing, first aid and fire-fighting facilities.

警告

危险

Contents

Shield M10U user manual III

Contents

Safety Precautions.................................................................................................................................

Chapter 1 Installation..........................................................................................................................1

1.1 Introduction............................................................................................................................1

1.2 Initial Checking.......................................................................................................................1

1.3 Location...................................................................................................................................1

1.3.1 UPS Location ...............................................................................................................1

1.3.2 External Battery Room..............................................................................................2

1.3.3 Storing..........................................................................................................................2

1.4 Positioning..............................................................................................................................2

1.4.1 System Cabinet...........................................................................................................2

1.4.2 Moving the Cabinets..................................................................................................3

1.4.3 Clearances Required for Operating ........................................................................3

1.4.4 Front Access ................................................................................................................3

1.4.5 Final Positioning .........................................................................................................3

1.4.6 Installation of Adjustable Feet.................................................................................3

1.4.7 UPS Composition........................................................................................................3

1.4.8 Installing Power Modules .........................................................................................5

1.4.9 Cable Entry ..................................................................................................................7

1.5 External Protective Devices.................................................................................................8

1.5.1 Rectifier and Bypass Input Supply of the UPS.......................................................8

1.5.2 External Battery .........................................................................................................9

1.5.3 UPS Output..................................................................................................................9

1.6 Power Cables..........................................................................................................................9

1.6.1 Cable Connections ...................................................................................................10

1.7 Control Cabling and Communication ...............................................................................11

1.7.1 UPS Dry Contactor and Monitoring Board Features ..........................................11

1.7.2 Dry Contactor Interface of Battery and Environmental Temperature Detection

...............................................................................................................................................12

1.7.3 Remote EPO Input Port...........................................................................................12

1.7.4 Generator Input Dry Contactor..............................................................................13

1.7.5 BCB Input Port..........................................................................................................14

1.7.6 Battery Warning Output Dry Contactor Interface..............................................14

1.7.7 Integrated Warning Output Dry Contactor Interface........................................15

1.7.8 Mains Failure Warning Output Dry Contactor Interface....................................15

Chapter 2 Battery Installation and Maintenance .........................................................................17

2.1 General Recommendations ...............................................................................................17

2.2 Battery Typologies..............................................................................................................18

2.2.1 Traditional Battery Installation..............................................................................18

2.3 Battery Maintenance ..........................................................................................................19

Chapter 3 Installation of UPS Rack System ...................................................................................20

3.1 Overview...............................................................................................................................20

3.2 UPS Rack Modules in Parallel System ..............................................................................21

3.2.1 Installation of Cabinet.............................................................................................21

3.2.2 External Protective Devices ...................................................................................21

3.2.3 Power Cables.............................................................................................................21

3.2.4 Parallel Signal Board................................................................................................21

3.2.5 Control Cables ..........................................................................................................21

Chapter 4 Installation Drawing........................................................................................................23

Chapter 5 Operations........................................................................................................................30

5.1 Introduction..........................................................................................................................30

Contents

IV Rack Modular UPS System 10-90kVA User Manual

5.1.1 Split-Bypass Input.....................................................................................................31

5.1.2 Static Transfer Switch..............................................................................................31

5.2 1+1 Parallel System.............................................................................................................31

5.2.1 Features of Parallel System....................................................................................31

5.2.2 Parallel Requirements of UPS Modules................................................................31

5.3 Operating Mode ..................................................................................................................32

5.3.1 Normal Mode ............................................................................................................32

5.3.2 Battery Mode............................................................................................................32

5.3.3 Auto-Restart Mode ..................................................................................................32

5.3.4 Bypass Mode .............................................................................................................32

5.3.5 Maintenance Mode (Manual Bypass)....................................................................32

5.3.6 Parallel Redundancy Mode (System Expansion) .................................................32

5.3.7 Eco Mode ...................................................................................................................32

5.4 Battery Management—Set During Commissioning ......................................................33

5.4.1 Normal Function.......................................................................................................33

5.4.2 Advanced Functions (Software Settings Performed by the Commissioning

Engineer) .............................................................................................................................33

5.5 Battery Protection (Settings by Commissioning Engineer)..........................................33

Chapter 6 Operating Instructions...................................................................................................34

6.1 Introduction..........................................................................................................................34

6.1.1 Power Switches.........................................................................................................34

6.2 UPS Startup ..........................................................................................................................34

6.2.1 Start-Up Procedure ..................................................................................................34

6.2.2 Procedures for Switching Between Operation Modes ......................................35

6.3 Procedure for Switching the UPS between Maintenance Bypass and Normal Mode

......................................................................................................................................................36

6.3.1 Procedure for Switching from Normal Mode to Maintenance Bypass Mode 36

6.3.2 Procedure for Switching from Maintenance Mode to Normal Mode..............36

6.4 Procedure for Completely Powering Down a UPS.........................................................37

6.5 EPO Procedure.....................................................................................................................37

6.6 Auto Start .............................................................................................................................38

6.7 UPS Reset Procedure..........................................................................................................38

6.8 Operation Instruction for Power Module Maintenance ...............................................38

6.9 Language Selection.............................................................................................................39

6.10 Changing the Current Date and Time ............................................................................39

6.11 Control Password 1...........................................................................................................39

Chapter 7 Operator Control and Display Panel ............................................................................40

7.1 Introduction..........................................................................................................................40

7.1.1 Mimic Current Path ..................................................................................................41

7.1.2 Audible Alarm (buzzer)............................................................................................41

7.1.3 Functional Keys.........................................................................................................41

7.1.4 Battery Pack Indicator.............................................................................................42

7.2 LCD Display Type .................................................................................................................42

7.3 Detailed Description of Menu Items................................................................................43

7.4 UPS Event Log ......................................................................................................................49

Chapter 8 Optional Parts..................................................................................................................55

8.1 Install SNMP card.................................................................................................................55

Chapter 9 Product Specification .....................................................................................................56

9.1 Applicable Standards..........................................................................................................56

9.2 Environmental Characteristics ..........................................................................................56

9.3 Mechanical Characteristics ................................................................................................56

9.4 Electrical Characteristics (Input Rectifier).......................................................................57

9.5 Electrical Characteristics (Intermediate DC Link) ..........................................................57

Contents

Shield M10U user manual V

9.6 Electrical Characteristics (Inverter Output)....................................................................57

9.7 Electrical Characteristics (Bypass Input) .........................................................................58

9.8 Efficiency...............................................................................................................................59

Appendix A. Power Connection of Modular System....................................................................60

Table of Figures

VI Rack Modular UPS System 10-90kVA User Manual

Table of Figures

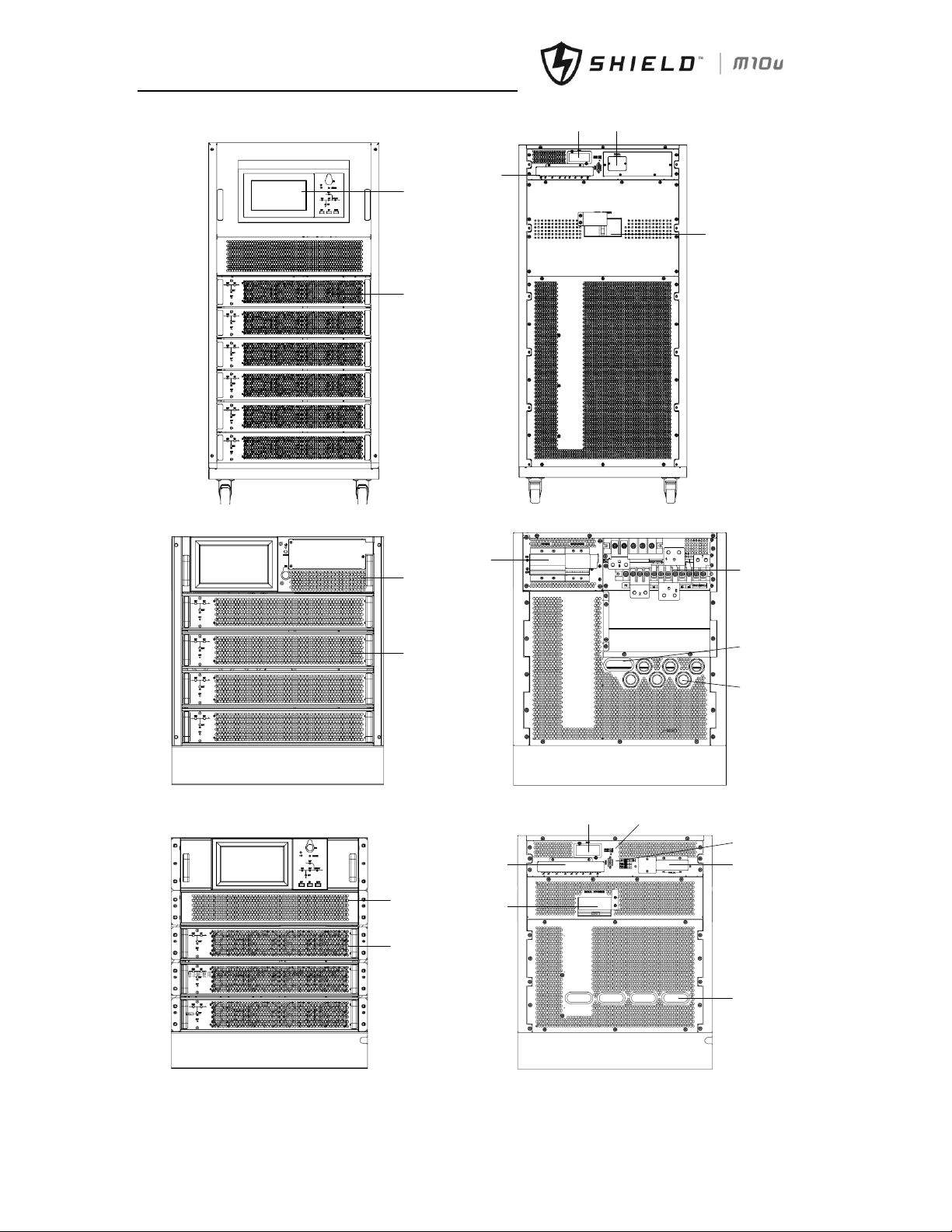

Fig.1- 1: UPS Structure ................................................................................................................5

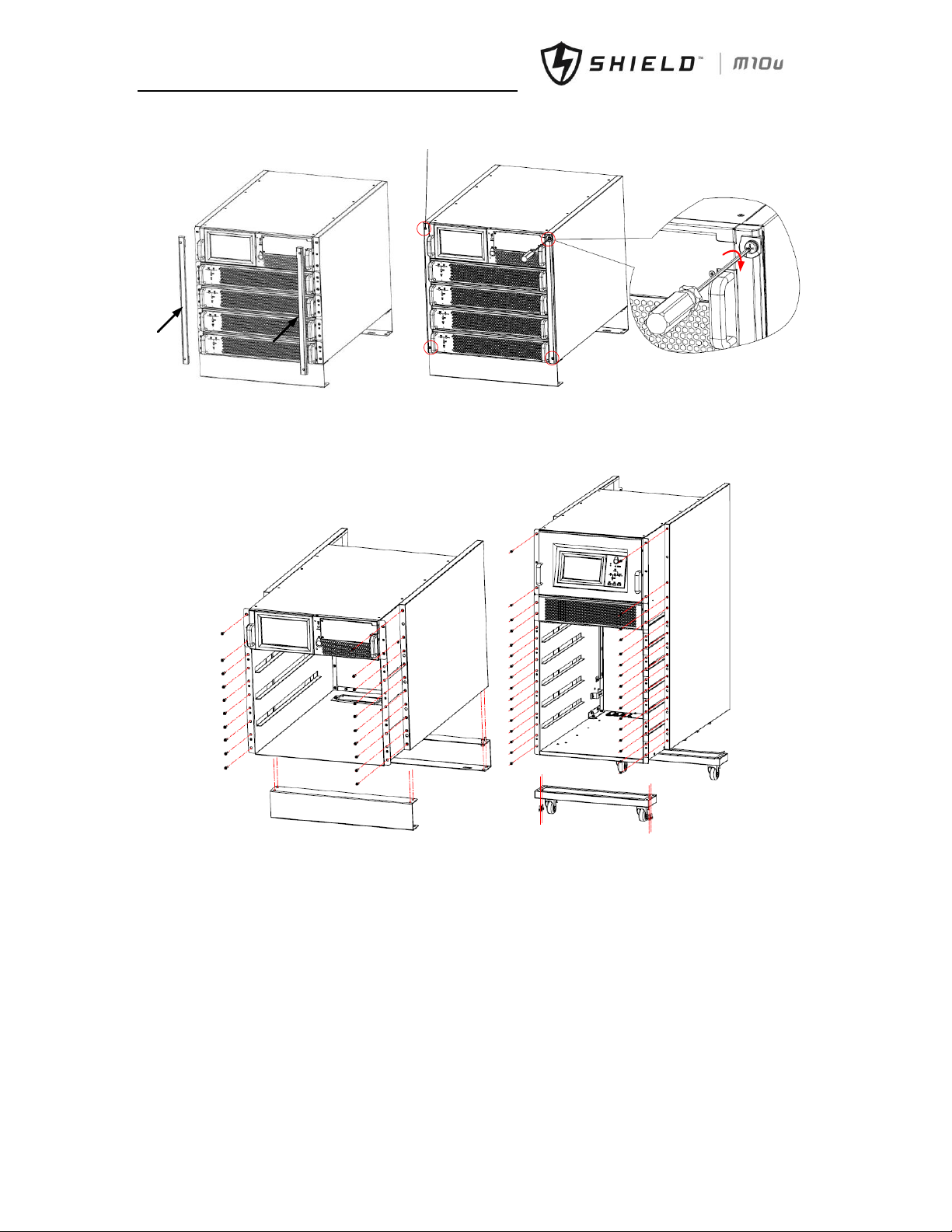

Fig.1- 2: Power Module Installation ..........................................................................................6

Fig.1- 3: rack mounted installation............................................................................................7

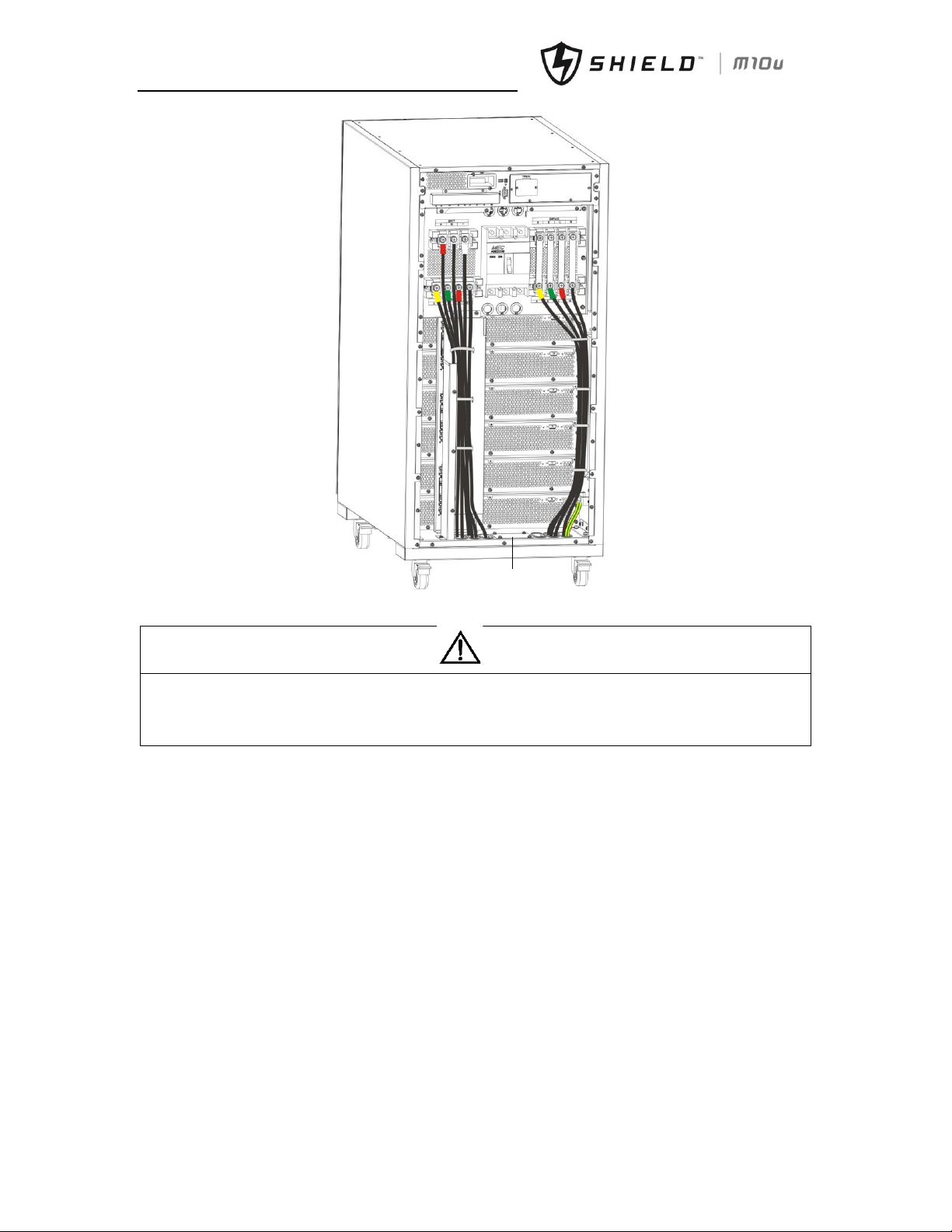

Fig.1- 4: cable entry .....................................................................................................................8

Fig.1- 5: The Symbols of RCCB ...................................................................................................9

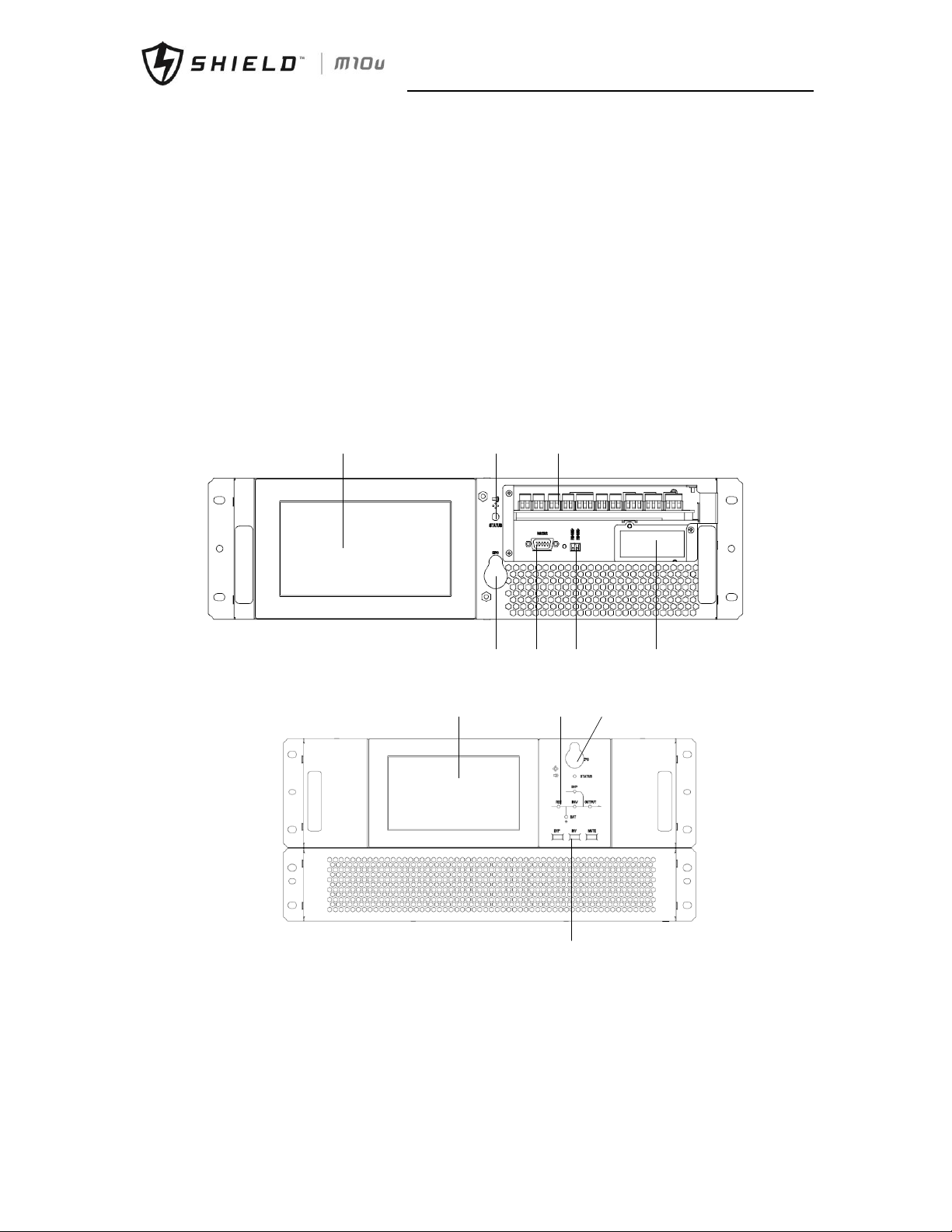

Fig.1- 6: Bypass Module (include bypass and monitoring) ..................................................12

Fig.1- 7: Diagram of J2 and J3 Dry Contactor of Temperature Detection .......................12

Fig.1- 8: Diagram of Input Dry Contactor for Remote EPO.................................................13

Fig.1- 9: Connection of Generator...........................................................................................13

Fig.1- 10: BCB Interface ............................................................................................................14

Fig.1- 11: Battery Low Warning Dry Contactor .....................................................................14

Fig.1- 12: Integrated warning dry contactor..........................................................................15

Fig.1- 13: Utility Failure Warning Dry Contactor ...................................................................15

Fig.2- 1: Diagram of Batteries Connection ............................................................................18

No table of figures entries found.

Fig.3- 1: Circuit diagram of EPO...............................................................................................20

Fig.3- 2: Parallel Board ..............................................................................................................21

Fig.3- 3: Connection of Parallel Cables of "1+N" System ....................................................22

Fig.4- 1: Wiring Diagram............................................................................................................23

Fig.4- 2: External Battery Connection ....................................................................................23

Fig.4- 3: 90kVA UPS module System, Front View and Rear View without Door..............24

Fig.4- 4: 40KVA UPS Module System, Front View and Rear View without Door .............24

Fig.4- 5: 20KVA UPS Module System, Front View and Rear View without Door .............24

Fig.4- 6: 90KVA UPS External Dimensions .............................................................................25

Fig.4- 7: 40KVA UPS External Dimensions .............................................................................25

Fig.4- 8: 20KVA UPS External Dimensions .............................................................................26

Fig.4- 9: Power Connection of Module System UPS.............................................................27

Fig.4- 10: Power Module ...........................................................................................................27

Fig.4- 11: Monitoring and Bypass Module .............................................................................28

Fig.4- 12: cables routing (dry contactoror, RS485, SNMP) ..................................................29

Fig.5- 1: Single Unit Block Diagram.........................................................................................30

Fig.6- 1: External Maintenance Bypass...................................................................................36

Fig.7- 1: UPS operator control and display panel .................................................................40

Fig.7- 2: Main LCD Display.........................................................................................................42

Fig.7- 3: Menu Structure ...........................................................................................................43

Fig.7- 4: cabinet menu...............................................................................................................44

Fig.7- 5: main input and output information.........................................................................44

Fig.7- 6: load and battery information ...................................................................................45

Fig.7- 7: power module information .......................................................................................45

Fig.7- 8: module output and load information......................................................................46

Fig.7- 9: module information and S-code...............................................................................46

Fig.7- 10: Setting Menu .............................................................................................................46

Fig.7- 11: System Operate ........................................................................................................48

Fig.7- 12: output and bypass waveform .................................................................................49

Fig.8- 1: SNMP card....................................................................................................................55

Fig.B- 1: Power Connection of 2 slots and 4 slots ................................................................60

Fig.B- 2: Power Cables Connection of 6 slots cabinet..........................................................60

Table of Tables

Shield M10U user manual VII

Table of Tables

Table.1- 1: UPS Configuration List.............................................................................................5

Table.1- 2: Maximum Steady State AC and DC Current .........................................................9

Table.1- 3: Description of Input Dry Contactor.....................................................................12

Table.1- 4: Description of Input Dry Contactor for Remote EPO.......................................13

Table.1- 5: Description of Status Interface and Connection of Generator.......................13

Table.1- 6: Description of BCB Interface................................................................................14

Table.1- 7: Battery warning dry contactor interface description ......................................14

Table.1- 8: Integrated warning dry contactor interface description.................................15

Table.1- 9: Description of Mains failure warning dry contactor.........................................15

Table.7- 1: Description of UPS Operator Control and Display Panel.................................40

Table.7- 2: Status Description of Indicator ............................................................................41

Table.7- 3: Description of Audible Alarm ...............................................................................41

Table.7- 4: Functions of Functional Keys................................................................................41

Table.7- 5: Description of LCD Icons .......................................................................................42

Table.7- 6: Description of Items in UPS System Information Window ..............................43

Table.7- 7: description of details of submenu in setting.....................................................46

Table.7- 8: UPS Event List .........................................................................................................49

Table.9- 1: Compliance with European and International Standards ................................56

Table.9- 2: Environmental Properties.....................................................................................56

Table.9- 3: Mechanical Properties ...........................................................................................56

Table.9- 4: Rectifier AC Input (mains) .....................................................................................57

Table.9- 5: Battery Information ...............................................................................................57

Table.9- 6: Inverter Output (to Critical Load) ........................................................................57

Table.9- 7: Bypass Input ............................................................................................................58

Table.9- 8: Efficiency, Air Exchange ........................................................................................59

Chapter 1 Installation

Shield M10U user manual 1

Chapter 1 Installation

1.1 Introduction

This chapter introduces the relevant requirements for positioning and cabling of the Modular UPS and related equipment.

Because each site has its requirements, it is not the aim of this chapter to provide step-by-step installation instructions,

but to act as a guide for the general procedures and practices that should be observed by the installing engineer.

Warning: installation can only be done by authorized engineers

Do not apply electrical power to the UPS equipment before the commissioning engineer arrives at installation site.

The UPS should be installed by a qualified engineer in accordance with the information contained in this chapter. All

the equipment not referred to in this manual is shipped with details of its own mechanical and electrical installation

information.

Note: 3-Phase 4-Wire Input Power is required

The standard UPS system can be connected to TN, TT AC distribution system (IEC60364-3) of 3-phase 4-wire, and a 3-

wire to 4-wire conversion transformer is provided as an optional part. 1-phase 3-wires is also provided as an optional

part.

WARNING: battery hazards

SPECIAL CARE SHOULD BE TAKEN WHEN WORKING WITH THE BATTERIES ASSOCIATED WITH THIS EQUIPMENT.

When connecting the battery, the battery terminal voltage will exceed 400Vdc and is potentially lethal.

Eye protection should be worn to prevent injury from accidental electrical arcs.

Remove rings, watches and all metal objects.

Only use tools with insulated handles.

Wear rubber gloves.

If a battery leaks electrolyte, or is otherwise physically damaged, it must be replaced, stored in a container

resistant to sulfuric acid and disposed of in accordance with local regulations.

If electrolyte comes into contactor with the skin, the affected area should be washed immediately with water.

1.2 Initial Checking

Perform the following checking operations prior to the UPS installation.

1. Visually examine if there is any damage inside and outside the UPS rack and battery equipment due to the

transportation. Report any such damage to the shipper immediately.

2. Verify the product label and confirm the correctness of the equipment. The equipment label is attached on the back

of front door. The UPS model, capacity and main parameters are marked on the label.

1.3 Location

1.3.1 UPS Location

The UPS is intended for indoor installation and should be located in a cool, dry and clean environment with adequate

ventilation to keep the environmental parameters within the specified operating range (see Table.9-2).The Modular series

UPS uses forced convection cooling by internal fans. Cooling air enters the module through ventilation grills located at

the front part of the cabinet and exhausted through grills located in the rear part of the cabinet. Please do not block the

ventilation holes.

警告

危险

警告

危险

警告

危险

Chapter 1 Installation

2 Shield M10U user manual

If necessary, a system of extractor fans should be installed to aid cooling-air flow. An air filter should be used when the

UPS is to operate in a dirty environment and should be regularly cleaned to maintain airflow. The cooling capacity of air

conditioner should be selected according to the power loss data of UPS specified in Table.9-8: Normal mode (VFI SS 111

double-conversion UPS)

Note: The UPS should be installed on a cement surface or other surface that is not combustible.

1.3.2 External Battery Room

The battery will generate some amount of hydrogen and oxygen at the end of charging, so the fresh air volume of the

battery installation environment must meet EN50272-2001 requirements.

The ambient temperature of the battery must be stable. Ambient temperature is a major factor in determining the

battery capacity and life. The nominal operating temperature of battery is 20°C. Operating above this temperature will

reduce the battery life, and operation below this temperature will reduce the battery capacity. If the average operating

temperature of battery is increased from 20ºC to 30ºC, then the service life of the battery will be reduced by 50%. If the

operating temperature of the battery is above 40ºC, then the battery service life will be decreased in exponent rate. In

a normal installation, the battery temperature is maintained between 15°C and 25°C. Keep batteries away from heat

sources or air outlets.

If external batteries are to be used, the battery circuit breakers (or fuses) must be mounted as close as possible to the

batteries, and the connecting cables should be as short as possible.

1.3.3 Storing

Should the equipment not be installed immediately, it must be stored in a room so as to protect it against excessive

humidity and heat sources (see Table.9-2).The battery needs to be stored in dry and cool place with good ventilation. The

most suitable storage temperature is 20 ºC to 25ºC.

Preventing battery deep discharge

Should the UPS remains unpowered for a prolonged period of time while the battery are connected, the batteries

may deeply discharge and being so permanently damaged .In such cases it is therefore recommended to leave the

battery circuit breaker(s) open. During storage in any case, periodically charge the battery according to the battery

user manuals.

1.4 Positioning

When the equipment has been finally positioned, ensure the UPS will remain stationary and stable. To prolong the service

life, the place chosen must guarantee:

Space for easy operation on the UPS

Air sufficient enough to dispel heat produced by UPS

Against atmospheric agents

Against excessive humidity and heat sources

Against dust

With the current fire prevention requirements

The operating environment temperature is within +20°C to +25°C. The batteries are at maximum efficiency in this

temperature range (for information about the battery storage and transportation as well as the environment, refer

to Table.9-2 )

This equipment is of steel frame structure wrapped by removable panels. The top and side panels are fixed by

screws.

After opening the UPS rack door, the auxiliary connections for external low voltage interface and the maintenance

bypass can be accessed. The UPS rack has an operator and control panel located on its front door, which provides

the basic operating status and alarm information. Batteries are external. The UPS provides air inlet port in the front

and the air exhaust port in the rear part.

1.4.1 System Cabinet

A UPS system can comprise an UPS rack system, external battery cabinet, depending on the specific system requirement.

All the UPS system cabinets used in the same installation site are of the same height and should be positioned side-by-

警告

危险

Chapter 1 Installation

Shield M10U user manual 3

side to achieve an aesthetically appealing effect. Refer to Chapter 7 Installation Drawing for the positioning of UPS

cabinet.

1.4.2 Moving the Cabinets

Warning

Ensure that any lifting equipment used in moving the UPS cabinet has sufficient lifting capacity. The UPS is fitted with

castors – take care to prevent movement when unbolting the equipment from its shipping pallet. Ensure adequate

personnel and lifting aids are available when removing the shipping pallet.

Ensure that the UPS weight is within the weight loading capacity range of any hoisting equipment. See Table.9-3 for UPS

weight.

UPS and optional cabinets can be handled by means of a fork lift or similar equipment. The UPS cabinet can also be moved

by its castors when moving in a short distance.

Note: Care must be taken when handling units fitted with batteries. Keep such moves to a minimum.

1.4.3 Clearances Required for Operating

As rack module UPS has no ventilation grills at either sides, no clearances are required for the sides.

To enable routine tightening of power terminations within the UPS, it is recommended that clearance around the front

of the equipment should be sufficient to enable free passage of personnel with the doors fully opened. It is important

to leave a distance of 500mm in the rear side of the rack to permit adequate circulation of air coming out of the unit.

If the UPS make use of internal modular battery sufficient clearing shall be given at the back site to allow personnel to

operate the battery circuit breakers

1.4.4 Front Access

The component layout of the UPS rack system supports front access and repairing the UPS, thus reducing the space

requirement for side access.

1.4.5 Final Positioning

When the equipment has been finally positioned, ensure the adjustable feet are set so that the UPS will remain stationary

and stable.

1.4.6 Installation of Adjustable Feet

Installation diagrams in Chapter 4 of this manual identify the location of the holes in the base plate through which the

equipment can be bolted to the floor. If the UPS is to be located on a raised floor, it should be mounted on a pedestal

suitably designed to accept the UPS point loading (more than 150 kg).

1.4.7 UPS Composition

The UPS structure is shown in Fig. 1-1. The UPS configuration is provided in Table. 1-1

警告

危险

Chapter 1 Installation

4 Shield M10U user manual

panel

Power

module

SNMP parallel

Dry

contactor

Manual

breaker

(a) 6 modules cabinet

Bypass

module

Power

module

connector

breakers

Ellipse

cable entry

Round

cable entry

(b) 4 modules cabinet

Bypass module

Power module

Manual bypass

Dry contactor

SNMP RS485

RS232

Parallel

Ellipse cable

entry

(c) 3 modules cabinet

Chapter 1 Installation

Shield M10U user manual 5

Bypass

module

Power

module

breakers

connector

Ellipse

cable

entry

Round

cable

entry

(d) 2 modules cabinet

Fig.1- 1: UPS Structure

Table.1- 1: UPS Configuration List

Item

Component

Quantity

Remarks

1

System Display

1

Requisite, factory installed

2

Bypass module

1

Requisite, factory installed

3

Bypass/maintenance

bypass breakers

1

Requisite, factory installed

4

Power module

1 ≤n ≤6

Requisite

5

Decorative metal strip

2

Factory installed

1.4.8 Installing Power Modules

The number and possible installation positions of the Power Modules may vary according to the chosen factory

configuration. Please install the power modules from bottom to top, so as to avoid cabinet toppling due to high gravity

center.

Installation procedures of power modules

When installing power modules always work from the lower available space upwards to prevent from raising the center

of gravity. The default setting from the bottom space upwards is NO.1 to NO.2 (2 modules cabinet), NO.1 to NO.3 (3

modules cabinet), NO.1 to NO.4 (4 modules cabinet), NO.1 to NO.6 (6 modules cabinet).

Notes

If installed as standalone unit, it’s recommended that install power modules from upper available space downwards

to prevent from corrosion of the bottom module.

Recover decorative metal strips on the two side of front panel. Loose screws through holes on metal strips, pull

metal strips upwards then take away the strips as Fig.1-2(a).

Insert the module in the installation position, and push it into the cabinet.

Secure the module to the cabinet through the fixing holes on both sides of the front panel of the module.

Loose the upper and bottom 4 screws and fix two side decorative metal strips (as Fig.1-2) to cover the screws on

front side following Fig.1-2(c)(d).

警告

危险

Chapter 1 Installation

6 Shield M10U user manual

(a) Remove side decorative metal strips (b) insert power module

Screws*4

(c) recover the decorative metal strips (d) fasten the strips

Fig.1- 2: Power Module Installation

When using the UPS in a rack-mount configuration, the UPS must be supported by a slide kit, fixed rails or a shelf. Fasten

slide kit into the rack enclosure. Remove side panels and holders of UPS as Fig.1-3. Lay the UPS in rack-mounting position.

Fasten the UPS into the rack enclosure with (20)M6 screws

(a) Remove side panels and holders

Chapter 1 Installation

Shield M10U user manual 7

b. fasten cabinet into rack enclosure

Fig.1- 3: rack mounted installation

Warning

Servicer rack enclosure within side doors should be chosen to cover side panel of UPS cabinet, otherwise the

connector for power modules might be touched with tools like screwdriver.

1.4.9 Cable Entry

Cables can enter the module UPS rack system both from bottom and back. The recommended installation practice is to

connect cables through ellipse hole to prevent foreign material or vermin entering the cabinet. Use circular entry

protector if ellipse hole is not big enough. If connect cables through bottom entry, remove the cover and install a rubber

cable protector in the bottom entry hole firstly.

Cable entry is followed as fig.1-4.

(a) 2-module or 4-module cabinet cables entry

警告

危险

Chapter 1 Installation

8 Shield M10U user manual

Reserved

entry hole

(b) 6-module cabinet cables entry

Fig.1- 4: cable entry

Notes

Cables connection should be followed as diagram on rear panel or appendix B (2-module and 4-module cabinet)

Fix cables in 6-module cabinet as Fig.1-4(b) to make sure best ventilation.

Enter through reserved entry cover if ellipse holes are not big enough, and block the remained space to protect UPS

from rats.

1.5 External Protective Devices

For safety concerns, it is necessary to install external circuit breakers or other protective devices for the input AC supply

of the UPS system. This section provides generic practical information for qualified installation engineers. The

installation engineers should have the knowledge of the regulatory wiring standards, and of the equipment to be

installed.

1.5.1 Rectifier and Bypass Input Supply of the UPS

Over currents

Install suitable protective devices in the distribution unit of the incoming mains supply, considering the power cable

current-carrying capacity and overload capacity of the system (see Tab. 9-7). Generally, the magnetic circuit breaker with

IEC60947-2 tripping curve C (normal) at the 125% of the current listed in Tab. 9-7 is recommended. Split bypass: In case

a split bypass is used, separate protective devices should be installed for the rectifier input and bypass input in the

incoming mains distribution panel.

Note: The rectifier input and bypass input must use the same neutral line.

Protection against earth faults (RCD devices):

The RCD device installed upstream of the input supply should:

警告

危险

Chapter 1 Installation

Shield M10U user manual 9

Sensitive to DC unidirectional pulses (class A) in the network

Insensitive to transient current pulses

Have an average sensitivity that is adjustable between 0.3A and 1A.

Fig.1- 5: The Symbols of RCCB

When using the RCD in the split bypass system or parallel system, the RCD should be installed in the upstream of the

input distribution to avoid wrong alarm.

The residual current introduced by RFI filter in the UPS is between 3.5mA and 1000mA. It is recommended to confirm the

sensitivity of each RCD of upstream input distribution and downstream distribution (to load).

1.5.2 External Battery

The DC compatible circuit breaker provides over current protection for UPS system and battery, which is provided by the

external battery cabinet.

1.5.3 UPS Output

In the eventuality that an external distribution panel is used for load distribution, the selection of protective devices

must provide discrimination with those that are used at the input to the UPS (see Tab. 9-7).

1.6 Power Cables

Design the cables according to the descriptions in this section and local regulatory wiring standards, and the

environmental conditions (temperature and physical support media) should be taken into consideration. Refer to

IEC60950-1 Table 3B Cabling.

WARNING

FAILURE TO FOLLOW ADEQUATE EARTHING PROCEDURES CAN RESULT IN EMI, ELECTRIC SHOCK HAZARD, OR RISK

OF FIRE, SHOULD AN EARTH FAULT OCCUR.

Table.1- 2: Maximum Steady State AC and DC Current

UPS

power(KVA

)

Rated current (A)

Main input current at full load

battery charging1,2

Output current at full load2

Battery discharging current at

E.O.D=1.67V/cell, no overload

380V

400V

415V

380V

400V

415V

36

Batt./stri

ng

38

Batt./stri

ng

40

Batt./st

ring

60

120

120

120

92

87

83

175

166

157

40

80

80

80

61

58

56

117

111

105

30

60

60

60

46

44

42

88

83

79

20

40

40

40

31

29

28

59

56

53

Note:

1. Input current of common input configurations of rectifier and bypass

2. Take special care when determining the size of the output and bypass neutral cable, as the current circulating on the neutral

cable may be greater than nominal current in the case of non-linear loads, which is usually 1.732 times of rated currents.

3. The earth cable connecting the UPS to the main ground system must follow the most direct route possible. The earth

conductor should be sized according to the fault rating, cable lengths, type of protection, etc.

According to AS/IEC60950-1, the cross section area of the conductor is 16mm2/10mm2 (40 input/output), the cross section

area of the conductor is 10mm2/6mm2 (10/20KVA input/output), the cross section area of the conductor is 35mm2/25mm2

(60kVA input/output).

4. When sizing battery cables, a maximum volt drop of 4Vdc. is permissible at the current ratings given in Table.1-2. The load

警告

危险

Chapter 1 Installation

10 Shield M10U user manual

equipment is connected to a distribution network of individually protected busbars fed by the UPS output rather than

connected directly to the UPS. In parallel multi-module systems, the output cable of each ups rack unit should be kept at equal

length between the output of the ups rack output terminals and the parallel distribution busbars to avoid affecting the shared

current. When laying the power cables, do not form coils, so as to avoid the formation of electromagnetic interference.

5. See Chapter 4 Installation Drawing for the positions of wiring terminals.

WARNING

FAILURE TO FOLLOW ADEQUATE EARTHING PROCEDURES CAN RESULT IN EMI, ELECTRIC SHOCK HAZARD OR RISK

OF FIRE, SHOULD AN EARTH FAULT OCCUR.

1.6.1 Cable Connections

Note

The operations described in this section must be performed by authorized electricians or qualified technical

personnel. If you have any difficulties, do not hesitate to contactor our Customer Service & Support department.

After the equipment has been finally positioned and secured, refer to Chapter 4 Installation Drawing to connect the

power cables as described in the following procedures:

1. Verify that all the external input distribution switches of the UPS are completely opened and the UPS internal

maintenance bypass switch is opened. Attach necessary warning signs to these switches to prevent unauthorized

operation.

2. Open rear panel of the UPS, and then the power connection terminals are visible.

3. Connect the protective earth and any necessary grounding cables to the PE terminal. The cabinet for the UPS must be

connected to the user’s ground connection.

Note: The grounding cable and neutral cable must be connected in accordance with local and national codes practice.

Identify and make power connections for incoming cables according to one of the two procedures below, depending on the

type of installation:

Common Input Connections

4. For common bypass and rectifier inputs, connect the AC input supply cables to the UPS input terminals (input A-B-C-N)

Refer to Fig. 4-11 and tighten the connections to 5 Nm (M6 Bolt), 13Nm(M8 Bolt) or 25Nm (M10 Bolt). ENSURE CORRECT

PHASE ROTATION.

Split Bypass Connections(option)

5. If a 'split-bypass' configuration is used, connect the AC input supply cables to the rectifier input terminals (input A-B-

C-N) Refer to Fig.4-11 and the AC bypass supply cables to the bypass input terminals (bypass A-B-C-N) and tighten the

connections to 5 Nm (M6 Bolt) or 13Nm (M8 Bolt) or 25Nm (M10 Bolt). ENSURE CORRECT PHASE ROTATION.

Note: For split Bypass operation ensure that the busbars between Bypass and Rectifier inputs are removed. The neutral

line of bypass input must be connected to that of the rectifier input.

Frequency Converter Mode

If the frequency converter configuration is used, connect the AC input cables to the rectifier input terminals (input A-B-

C-N) Refer to Fig.4-11 and tighten the connections to 5Nm (M6 bolt), or to 13Nm (M8 bolt), or to 25Nm (M10 bolt).

ENSURE CORRECT PHASE ROTATION AND TIGHTEN CONNECTION TERMINALS. No need to connect the bypass input

cables to bypass input terminals (bA-bB-bC-bN).

Note: For the frequency converter operation mode, ensure that the busbars between Bypass and Rectifier inputs are

removed.

Output System Connections

6. Connect the system output cables between the UPS output busbars (output A-B-C-N) Refer to Fig.4-11 and the critical

load and tighten the connections to 5Nm (M6 Bolt) or to 13Nm (M8 Bolt) or to 25Nm(M10 Bolt). ENSURE CORRECT PHASE

ROTATION.

WARNING

If the load equipment will not be ready to accept power on the arrival of the commissioning engineer, then ensure

that the system output cables are safely isolated at their ends.

7. Re-install all the protective covers.

警告

危险

警告

危险

警告

危险

Chapter 1 Installation

Shield M10U user manual 11

1.7 Control Cabling and Communication

1.7.1 UPS Dry Contactor and Monitoring Board Features

According to the specific needs of the field, the UPS may need auxiliary connection to realize the management of the

battery system (including external battery switch and battery temperature sensor), communicate with PC, provide alarm

signal to external device, or realize remote EPO. These functions are realized through the UPS dry contactor board (GJ)

and monitoring board (JK) at the front of bypass module. The boards provide the following interfaces:

EPO

Environment and battery temperature input interface

Generator input dry contactor interface

Battery warning output dry contactor interface

Battery circuit breaker interface

Mains failure warning output dry contactor interface

Intellislots (TM) intelligent card interface

User communication interface

The UPS dry contactor board provides input dry contactors and output dry contactors.

LCD Indicator LED Dry

contactor

EPO RS232 RS485 SNMP

(a) 20kVA/40kVA bypass module

Functional button

LCD LED indicator EPO

(b) 30kVA/45kVA bypass module

Table of contents

Other Shield UPS manuals

Popular UPS manuals by other brands

CyberPower

CyberPower CyberShield CSN27U12V-NA3-G user manual

Power-all

Power-all Uninterruptible Power System user manual

Diablotek

Diablotek UDP-600 user manual

socomec

socomec MASTERYS BC+ 10 kVA Installation and operating manual

CyberPower

CyberPower AVR Series user manual

inform

inform Informer Compact Series user manual