Shimadzu EI-D1003M User manual

263-13228I

Read the instruction manual thoroughly before you use the product.

Keep this instruction manual for future reference.

Semiconductor Equipment Division

Power Supply Unit for Turbo Molecular Pump

Model:EI-D1003M

Model:EI-D1103M

Model:EI-D1303M

Model:EI-D2003M

Model:EI-D2203M

Model:EI-D2303M

Model:EI-D3203M

Model:EI-D3403M

Model:EI-D4203M

INSTRUCTION MANUAL

Introduction

i

Power Supply Unit

INSTRUCTION MANUAL

Introduction

Thank you for choosing the EI-Dxx03M Power Supply Unit for Turbo Molecular Pump

(hereafter referred to as "power supply unit" or "EI-Dxx03M"). Please read the instruction

manual carefully before using the power supply unit, and save the instruction manual for

future reference.

This instruction manual explains detailed operations of the power supply unit and cables.

For instructions regarding the pump unit, please refer to the instruction manual for the pump

unit to be used.

Standard type is explained in this manual. For special order type, please refer to the out-

lines and constructions of each specification.

Copyrights and Disclaimers

This document is copyrighted by Shimadzu Corporation. Please refrain from reproducing

or copying part or all of this document without permission from Shimadzu.

In an effort to improve the product, this document may be revised in the future without

notice.

Every effort has been made to prepare an accurate and complete manual, but if an error

or omission should be discovered, revisions might not be possible immediately.

Shimadzu does not take responsibility for any effects that may result from the use of this

manual.

Copyright 2003-2006 Shimadzu Corporation.All rights reserved.

©

Precautions for Safe Operation

ii 263-13228

Precautions for Safe Operation

The instruction manual's nomenclature for warnings and precautions complies with

the following safety warning symbols.

WARNING

CAUTION

NOTICE

WARNING

Turbo molecular pump repair and/or power supply repair can be very hazardous.

Only trained technicians who are authorized by Shimadzu may do service of

products.

WARNING

Neither overhaul nor modify the pump proper and power supply unit without

admission. Doing so would impair safety of the pump proper.

WARNING

Decisions on system compatibility should be made by the system designer or the person

deciding the specifications after conducting tests as necessary.The responsibility for

guaranteeing the expected performance and safety of the system lies with the person who

decides system compatibility.

Indicates a potentially hazardous situation whitch, if not avoided, could result

in serious injuly or possibly death.

Indicates a potentially hazardous situation whitch, if not avoided, may result in

minor to moderate injuly or equipment damage.

Emphasizes additional information that is provided to ensure the proper use of

this product.

Introduction

iii

Power Supply Unit

INSTRUCTION MANUAL

CAUTION

The standard power input voltage of the power supply unit EI-Dxx03M (the "xx" number

indicates the model of the corresponding pump) is AC 200 - 240 V ±10%. Connect the power

supply unit to the voltage indicated on the rear panel label only.Connection of the power supply

unit to the incorrect input voltage can cause damage to the equipment. Supply the power via a

breaker (rating 15A).Please provide PE(Protective Earth) connection to the terminal of a "PE"

marked wire in final application.

CAUTION

If an EI-Dxx03M power supply unit is used in combination with an existing pump that was

operated in combination with a power supply unit not having the variable speed function (EI-

xx03MD), the variable speed function cannot be used. (the "xx" number indicates the model of

the corresponding pump.)

If the power supply unit is to be combined with an existing pump, modification and operational

inspections are necessary. Please contact Shimadzu for detailed information.

CAUTION

The following "CAUTIONS" are to prevent operation anomalies.

1.Do not interrupt the electrical power operating the turbo molecular pump while the turbo

molecular pump is in operation.

2.Do not connect or disconnect the turbo molecular pump control cable during the time the

power supply is "ON".

3.Do not operate any equipment (i.e. drill motor, welding machine, etc.) that produces electro-

magnetic pollution, noise, etc., in the immediate proximity of an operating turbo molecular

pumping system (pump, power supply, cables, etc).

4.When using the variable speed function to change the pump rotation rate, use a rotation rate

that does not cause resonance with other devices installed at the site.

iv 263-13228

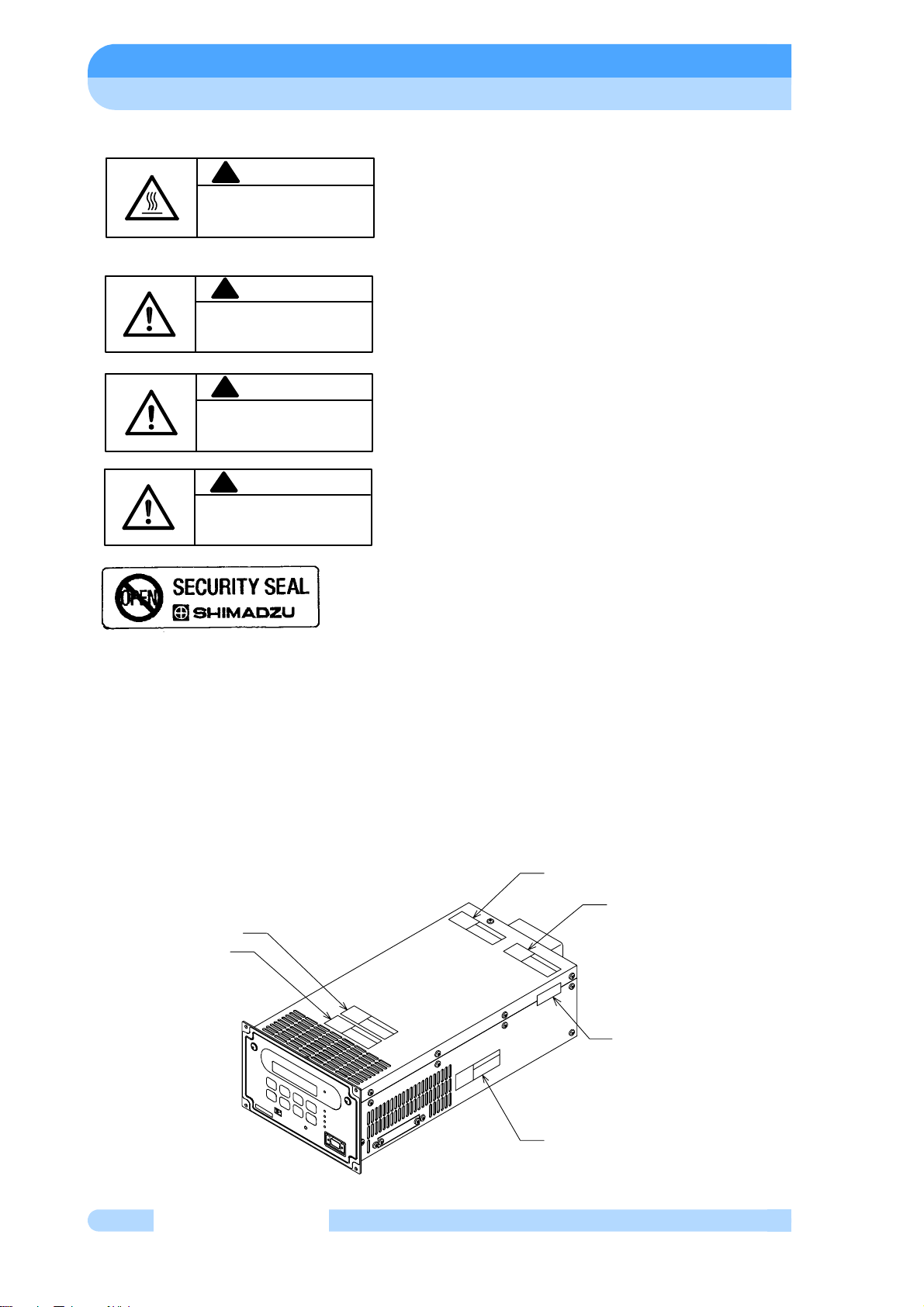

○Explanation of label (1) HOT SURFACE : Risk of burn. (Notes 1)

・Keep off from touching surface of the pump as it is

heated.

・Keep off from touching upper side surface of the

power supply while the pump is in deceleration as it is

heated.

(2) Do not remove cover, or else it may cause some

changes inside and it is failed.

(3) Do not shut off ventilation, or else the inside of

power supply get heated and it is failed.

(4)Besureto usespecifiedcableforthispowersupply.

If not, it may cause connector be broken and power

supply itself failed.

(5) SECURITY seal

This label certificates that the product was made or

maintenanced by Shimadzu or by Shimadzu

authorized facility.

In case "this label is removed" or "there is a mark

showing once this label has been removed",

Shimadzu warranty shall not be applied to the

product.

(Notes 1) The power supply units for some production lots come with a single nameplate, on

which the name is indicated in both English and Japanese, whereas the power supply units

for other production lots come with two nameplates, one in English and one in Japanese.

○Location of label

CAUTION

!

高温注意

HOT SURFACE

Risk of burn. Avoid contact.

やけどのおそれがあります。触らないで下さい。

!CAUTION

DO NOT REMOVE COVER.

ケースを分解しないでください。

!

262-76048

USE SPECIFIED CABLE ONLY.

指定のケーブルを使用してください。

CAUTION

!

262-76050

DO NOT SHUT OFF VENTILATION.

通風口をふさがないでください。

CAUTION

!

262-76049

(3)

(2)

(4)

(1)

(2)

(same on reverse side)

(5)

Introduction

v

Power Supply Unit

INSTRUCTION MANUAL

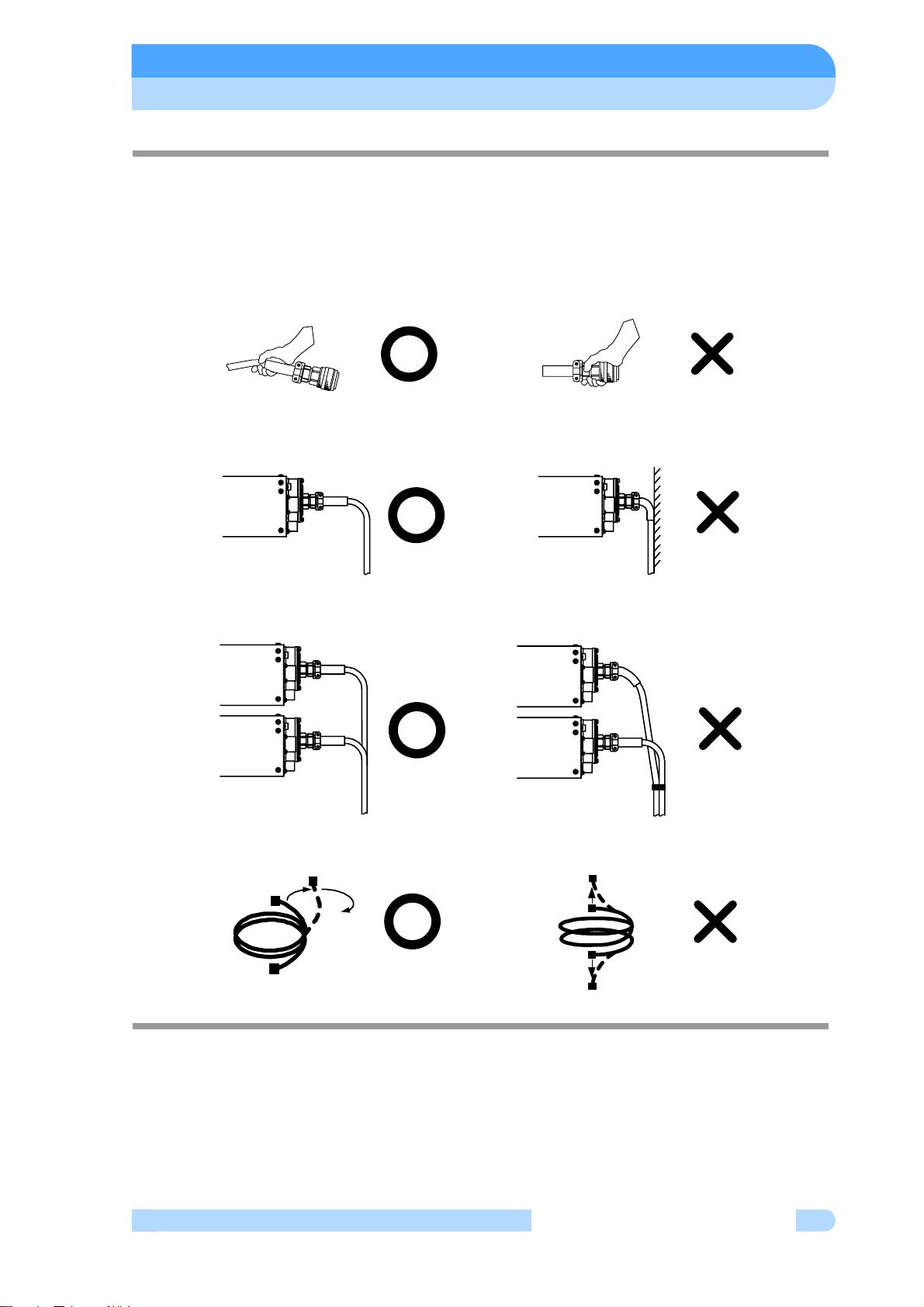

○Installation Precautions

Do not apply abnormal loads to the turbo molecular pump control cable plug and/or connector.

Abnormal loads may cause cable disconnection.

(1) Do not pull the turbo molecular pump control cable by the connector or plug.

(2) When installing the power supply unit into equipment, do not allow any electrical cables to

be in tension or to have very tight bending radii.

(3) Do not bundle the turbo molecular pump control cable with any cables.

(4) Do not twist the turbo molecular pump control cable during connection.

vi 263-13228

○Part Replacement

The lifetime of parts are specified as below.

The request for changing parts exceeding the estimated lifetime should be made to Shimadzu

or an approved service company in order for safety and adequate performance of the pump and

power supply unit. Table 1 Estimated Part Life.

○Warranty period

12 months on new TMP's from the date of shipment from Shimadzu, or from any of its

worldwide sales offices.

○Conditional warranty

During the warranty period and under normal operation, if the TMP fails to meet its product

specification due to defects in material and/or workmanship, Shimadzu will, at its discretion,

either repair it or exchange it with a new one for free.

○Scope of the warranty

The warranty covers only TMPs, controllers and accessories sold by Shimadzu.

○Warranty of repaired or replacement parts

In-warranty repaired or replacement parts are warranted only for the remaining unexpired

portion of the original warranty period applicable to the parts thathave been repaired or replaced.

○Exemption from the warranty

During the warranty period, Shimadzu will charge for repair or exchange in the following cases:

1) Failure caused by natural disasters or fire.

2) Failure or functional deterioration due to the following:

a) Pumping of special gases and materials

b) Ingestion of foreign objects through the TMP's protective net

c) TMP is operated differently than what is prescribed in the instruction manual

d) When Shimadzu determines through failure analysis that the cause of failure was due to

abnormal operation or external circumstances. our engineers judge that the cause of the

trouble is an irregular operation

3) Warranty is voidedif the "Security Seal" on the product has been removed, hampered with,

or altered.

Parts List Estimated Part Life

Transformer 10 years

Electrolytic condenser 5 years

Cooling fan 5 years

Button-type battery 10 years

Introduction

vii

Power Supply Unit

INSTRUCTION MANUAL

○Disposal of Products and Parts

Please contact Shimadzu for proper disposal of its products or parts. There is a possibility to

pollute the environment with the material of the parts, when you dispose this product in an inap-

propriate way.

○LIMITATION OF LIABILITY

EXCEPT AS STATED HEREIN, SHIMADZU MAKES NO WARRANTY, EXPRESSED OR

IMPLIED (EITHER IN FACT OR BY OPERATION OF LAW), STATUTORY OR OTHERWISE:

AND, EXCEPT AS STATED HEREIN, SHIMADZU SHALL HAVE NO LIABILITY FOR

SPECIAL OR CONSEQUENTIAL DAMAGES OF ANY KIND OR FROM ANY CAUSE ARISING

OUT OF THE SALE, INSTALLATION, OR USE OF ANY OF ITS PRODUCTS.

viii 263-13228

This page is intentionally left blank.

Table of contents

ix

Power Supply Unit

INSTRUCTION MANUAL

Table of contents

Introduction

Copyrights and Disclaimers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . i

Precautions for Safe Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . ii

○Explanation of label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iv

○Location of label. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iv

○Installation Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

○Part Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vi

○Warranty period . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vi

○Conditional warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vi

○Scope of the warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vi

○Warranty of repaired or replacement parts . . . . . . . . . . . . . . . . . vi

○Exemption from the warranty. . . . . . . . . . . . . . . . . . . . . . . . . . . . vi

○Disposal of Products and Parts . . . . . . . . . . . . . . . . . . . . . . . . . . vii

○LIMITATION OF LIABILITY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

Table of contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

Section 1 OUTLINE AND DESCRIPTIONS

1.1 Outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.2 Descriptions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.2.1 Power Supply Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.2.2 Control Cable. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.2.3 Motor Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.2.4 Standard Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Section 2 IDENTIFICATION AND FUNCTION

2.1 Power Supply Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Table of contents

x263-13228

Section 3 CONSTRUCTION AND PRINCIPLE

3.1 Power Supply Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Section 4 SPECIFICATIONS

4.1 Power Supply Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.2 Standards Fulfilled . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Section 5 INSTALLATION

5.1 Installation of the Power Supply Unit . . . . . . . . . . . . . . . . . . . 18

5.1.1 Location of the Power Supply Unit. . . . . . . . . . . . . . . . . . . . . . . . . 18

5.1.2 Installation of the Power Supply Unit . . . . . . . . . . . . . . . . . . . . . . . 18

5.1.3 Compatibility with Previous Models . . . . . . . . . . . . . . . . . . . . . . . . 21

5.2 Connection of Power Cable . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.3 Connection of the Pump to the Power Supply Unit . . . . . . . . 24

Section 6 OPERATION

6.1 Outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

6.1.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

6.1.2 Operation Flowchart. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

6.2 Start-up Preparation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

6.2.1 Start-up Preparation Sequence in LOCAL Mode. . . . . . . . . . . . . . 35

6.2.2 Start-up Preparation Sequence in REMOTE Mode . . . . . . . . . . . . 35

6.3 Start-up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

6.3.1 Start-up Sequence in LOCAL Mode . . . . . . . . . . . . . . . . . . . . . . . 36

6.3.2 Start-up Sequence in REMOTE Mode. . . . . . . . . . . . . . . . . . . . . . 36

6.4 Shutting Down . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

6.4.1 Preparations Prior to Shutting Down Operation. . . . . . . . . . . . . . . 37

6.4.2 Shutting Down Sequence in LOCAL Mode . . . . . . . . . . . . . . . . . . 37

6.4.3 Shutting Down Sequence in REMOTE Mode . . . . . . . . . . . . . . . . 38

6.5 Variable Speed Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

6.5.1 Outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

6.5.2 Operation from Start-up to Low Speed Rotation . . . . . . . . . . . . . . 40

Table of contents

xi

Power Supply Unit

INSTRUCTION MANUAL

6.5.3 Operation from Rated Speed Rotation to Low Speed Rotation. . . 41

6.5.4 Operation from Low Speed Rotation to Rated Speed Rotation. . . 41

6.6 Software Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

6.7 Remote-Control Connector . . . . . . . . . . . . . . . . . . . . . . . . . . 58

6.7.1 Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

6.7.2 Compatibility with Previous Models . . . . . . . . . . . . . . . . . . . . . . . . 60

6.7.2.1 Replacing the EI-xx03M/MD Power Supply Unit . . . . . . . 60

6.7.2.2 Replacing EI-xx03MZ Power Supply Units. . . . . . . . . . . . 62

Section 7 TROUBLESHOOTING

7.1 Nothing Happens After an Operation is Made. . . . . . . . . . . . 66

7.2 Power Failures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

7.2.1 Power Failure Counter-Operation . . . . . . . . . . . . . . . . . . . . . . . . . 68

7.3 Vacuum Pressure Rise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

7.4 Abnormal Noise and/or Vibration. . . . . . . . . . . . . . . . . . . . . . 69

7.5 Alarm Detection Capabilities . . . . . . . . . . . . . . . . . . . . . . . . . 69

7.5.1 Movement in Alarm Detection Capabilities (ALARM) . . . . . . . . . . 69

7.5.2 Movement in Alarm Detection Capabilities (WARNING) . . . . . . . . 70

7.5.3 Reset Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Appendix A COMMUNICATIONS

A.1 GENERAL SPECIFICATION. . . . . . . . . . . . . . . . . . . . . . . . A-2

A.2 INTERFACE SPECIFICATION . . . . . . . . . . . . . . . . . . . . . . A-3

A.2.1 RS-232C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

A.2.1.1 Transmission Specification. . . . . . . . . . . . . . . . . . . . . . . . A-3

A.2.1.2 Communications Connector. . . . . . . . . . . . . . . . . . . . . . . A-3

A.2.1.3 CABLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

A.2.2 RS-485. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-5

A.2.2.1 Transmission Specification . . . . . . . . . . . . . . . . . . . . . . . A-5

A.2.2.2 Communications Connector. . . . . . . . . . . . . . . . . . . . . . . A-5

A.2.2.3 CABLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-5

A.3 POWER SUPPLY TO COMPUTER CONNECTION . . . . . . A-7

A.3.1 Communication Cable Connection . . . . . . . . . . . . . . . . . . . . . . . . A-7

A.3.2 Serial Communications Baud Rate Configuration . . . . . . . . . . . . . A-7

A.3.3 RS-485 Multi-drop Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-7

A.4 SERIAL COMMUNICATIONS PROTOCOL . . . . . . . . . . . . A-8

A.4.1 Basic Message Structure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-8

Table of contents

xii 263-13228

A.4.2 Character to Character Time-out: 0.1 sec. . . . . . . . . . . . . . . . . . . A-8

A.4.3 Command to Answer Time-out: 1 sec.. . . . . . . . . . . . . . . . . . . . . . A-9

A.4.4 Power Supply Command Send Retry Cycles: 5 . . . . . . . . . . . . . . A-9

A.4.5 Command Transmission Specification. . . . . . . . . . . . . . . . . . . . . . A-9

A.4.6 Receiving Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-9

A.4.7 Using the Checksum Byte . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-9

A.4.8 Outline of Multi-drop Communications. . . . . . . . . . . . . . . . . . . . . A-10

A.5 TABLE OF COMMANDS . . . . . . . . . . . . . . . . . . . . . . . . . . A-11

A.6 COMMAND DESCRIPTION. . . . . . . . . . . . . . . . . . . . . . . . A-17

A.6.1 Operation Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-17

A.6.2 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-18

A.6.3 Run Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-19

A.6.4 Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-20

A.6.5 Events . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-20

A.6.6 Timer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-21

A.6.7 History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-21

A.6.8 Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-22

A.6.9 Shared Answer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-22

A.7 RS-232C COMMANDS / ANSWERS. . . . . . . . . . . . . . . . . A-23

A.8 RELATION OF LOCAL MODE TO REMOTE MODE

OPERATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-26

A.9 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-27

A.9.1 No Message can Transmit and Receive . . . . . . . . . . . . . . . . . . . A-27

A.9.2 Sending and Receiving are Done, But Receivable Messages are

Invalid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-27

A.9.3 Characters Get Disordered from Time to Time, Then Resulting in

CHECKSUM Error. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-27

1

1OUTLINE AND

DESCRIPTIONS

1.1 Outline

1.2 Descriptions

1.2.1 Power Supply Unit

1.2.2 Control Cable

1.2.3 Motor Cable

1.2.4 Standard Accessories

SECTION 1 OUTLINE AND DESCRIPTIONS

2263-13228

11.1 Outline

The turbo molecular pump is a vacuum pump. The turbo molecular pump is used with a

backing vacuum pump to create a high vacuum in a vacuum chamber.

Typical Applications ; Semiconductor equipments,

Industrial equipments,

R&D applications,

The other ultra high vacuum applications.

The turbo molecular pump (one standard set) consists of the following items.

・Pump 1

・Power Supply Unit 1

・Control Cable 1

・Motor Cable 1

・Standard Accessories 1 Set

The cable length must be specified for the magnetic bearing cable and motor cable. (Refer to

Sections 1.2.2 and 1.2.3.)

1.2 Descriptions

3

Power Supply Unit

INSTRUCTION MANUAL

1

1.2 Descriptions

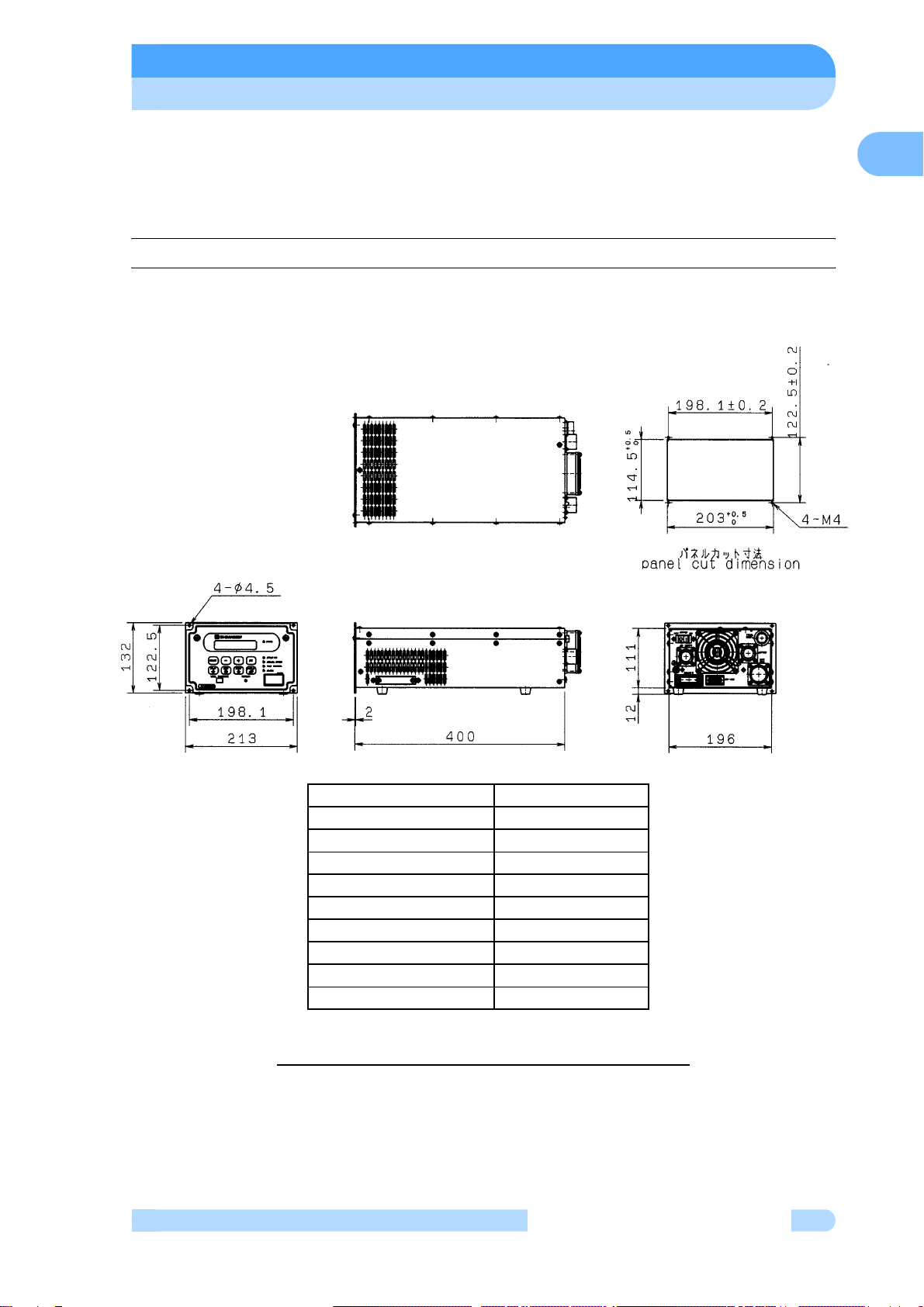

1.2.1 Power Supply Unit

Fig.1-1 Outside Dimensions of Power Supply Unit

Description Parts number

EI-D1003M 262-78689-02

EI-D1103M 262-78690-02

EI-D1303M 262-78688-02

EI-D2003M 262-78691-02

EI-D2203M 262-78692-02

EI-D2303M 262-78693-02

EI-D3203M 262-78685-02

EI-D3403M 262-78694-02

EI-D4203M 262-78696-02

SECTION 1 OUTLINE AND DESCRIPTIONS

4263-13228

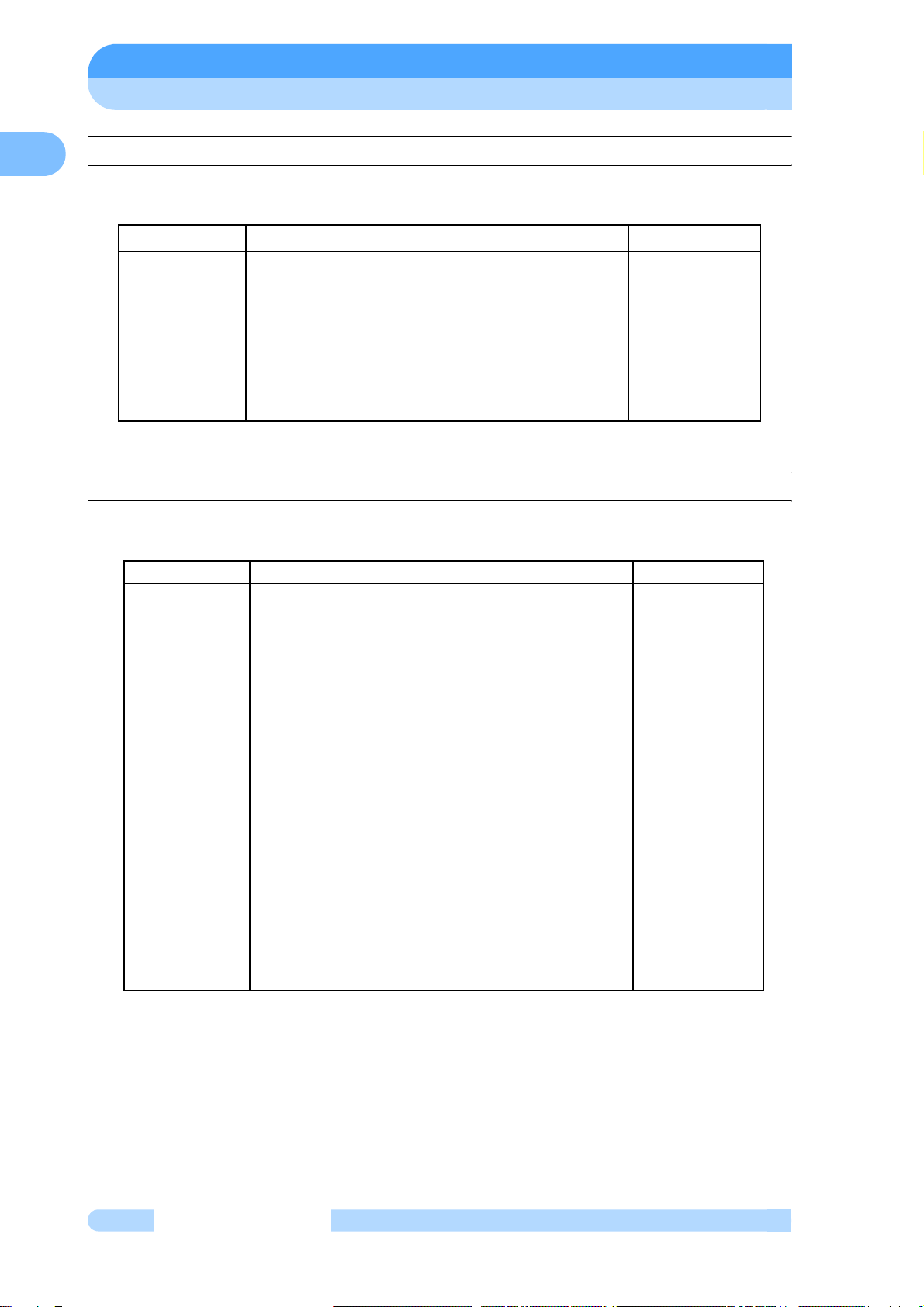

11.2.2 Control Cable

The cable can be selected from the following.

1.2.3 Motor Cable

The cable can be selected from the following

Description Note Parts number

Control Cable

3 meters length, straight plugs for both sides.

5 meters length, straight plugs for both sides.

7 meters length, straight plugs for both sides.

10 meters length, straight plugs for both sides.

15 meters length, straight plugs for both sides.

20 meters length, straight plugs for both sides.

30 meters length, straight plugs for both sides.

262-78187-03

262-78187-05

262-78187-07

262-78187-10

262-78187-15

262-78187-20

262-78187-30

Description Note Parts number

Motor Cable

(for Air cooled type and Air cooled chemical type)

3 meters length, straight plugs for both sides.

5 meters length, straight plugs for both sides.

7 meters length, straight plugs for both sides.

10 meters length, straight plugs for both sides.

15 meters length, straight plugs for both sides.

20 meters length, straight plugs for both sides.

30 meters length, straight plugs for both sides.

(for Wide range type and Wide range chemical

type)

3 meters length, straight plugs for both sides.

5 meters length, straight plugs for both sides.

7 meters length, straight plugs for both sides.

10 meters length, straight plugs for both sides.

15 meters length, straight plugs for both sides.

20 meters length, straight plugs for both sides.

30 meters length, straight plugs for both sides.

262-76410-03

262-76410-05

262-76410-07

262-76410-10

262-76410-15

262-76410-20

262-76410-30

262-76409-03

262-76409-05

262-76409-07

262-76409-10

262-76409-15

262-76409-20

262-76409-30

1.2 Descriptions

5

Power Supply Unit

INSTRUCTION MANUAL

1

1.2.4 Standard Accessories

Description Q'ty Notes Parts Number

1Power cable 15meters length 262-76773-05

2Remote Control

Connector 1MR-34MG

MR-34L4 (Pin type connector)

(Connector hood)

070-50791-63

070-50792-75

3 Instruction Manual 1 263-13228

SECTION 1 OUTLINE AND DESCRIPTIONS

6263-13228

1

This page is intentionally left blank.

2

2IDENTIFICATION AND

FUNCTION

2.1 Power Supply Unit

This manual suits for next models

8

Table of contents