Emcotec PowerCube HBS User manual

HBS Operating Instructions Version 1.0

Page 2 of 36

HBS Operating Instructions Version 1.0

Page 3 of 36

Contents

1. Preface .............................................................................................4

2. Safety Instructions..........................................................................5

3. What does HBS stand for?.............................................................6

4. HBS Connection Scheme...............................................................7

5. Characteristics ................................................................................8

5.1. Usage in an Electrical Motor Powered Model..........................8

5.2. Usage in a Combustion Engine Powered Model...................11

6. Recommended Accessories ........................................................ 15

7. Mounting........................................................................................16

8. Connecting the Supply Batteries.................................................16

9. Connecting the Receiver Battery.................................................17

10. External Status-LED....................................................................19

11. Mounting Examples ....................................................................19

11.1. Electrical Powered Model....................................................20

11.2. Electrical Powered Model with Dual Supply ........................20

11.3. Combustion Engine Powered Model ...................................21

11.4. Combustion Engine Powered Model with Dual Supply........22

12. Operating .....................................................................................23

13. Storage-Mode ..............................................................................25

14. Summarizing the HBS-Functions ..............................................27

15. LED-Codes (Error- and Status Indications)..............................28

15.1. Ext. LED at "Status Output".................................................29

15.2. Internal LED "Status"...........................................................30

15.3. Summary Table ...................................................................30

16. HBS Block Diagram ....................................................................32

17. Technical Data of the HBS .........................................................33

18. Warranty.......................................................................................35

19. Declaration of Conformity..........................................................36

20. Disposal of Equipment ...............................................................36

21. Legal Instructions .......................................................................36

HBS Operating Instructions Version 1.0

Page 4 of 36

1. Preface

With this PowerCube ® HBS (Hybrid Battery Supply) you purchased

a high grade, modern and secure power supply system. We appreciate

your trust and assure you that you made the right choice!

More than 25 years of experience in development and manufacturing

of electronically systems, knowledge of the world’s best model airplane

pilots as well as the experience in UAV's has influenced the

development of EMCOTEC products. All products are manufactured at

EMCOTEC GmbH in Germany on our own production line. Extensive

optically and electronically end tests for every system, which leaves

our house, assure that you, our customer acquire an absolute reliable

product, which considerably increases the reliability of your valuable

RC-Model.

Of course, the products not only have been tested extensively in the

laboratory, but also went through intensive flight-testing. Like done in

the automobile industry an FMEA (Failure Mode and Effect Analysis)

reduce the possibility of damage and malfunction on operating errors to

a minimum.

We kindly ask you to read these operating instructions carefully and to

observe the installation hints. Thus, errors can be avoided in advance.

We are all ears for your wishes and questions. Challenge us!

Wehringen, May 2013

The Staff of EMCOTEC GmbH

HBS Operating Instructions Version 1.0

Page 5 of 36

2. Safety Instructions

In general, all connecting lines should be run so that they do not

come into contact with moving or hot parts of the model (such as

servos, gears or mufflers).

The HBS (20V…75V) can be driven by high voltages but must be

according to IEC 60449 rules. This partial range of low voltage is

generally known as low tension current or light current. The limits

for direct current (DC) are ≤120 V. These values correspond to

continuously permissible effective touch voltages for adults and

are considered not life-threatening under normal circumstances.

For voltages greater than 60 volts DC all current leading cables

should be isolated and protected against touching.

The HBS must be protected from humidity and moisture.

The HBS must have sufficient distance to neighboring areas, in

order to allow for good heat dissipation.

Improper handling of the HBS can result in serious damage/injury

to property or persons!

Carry out a general inspection of all connections in your model

before each use! All plugs must be correctly polarized and have

clean contacts (i.e. fit tightly). Loose cables present a potential

hazard!

Under no circumstances may power sources be used that do not

meet the specified voltages.

The current-conducting contacts of the connector plugs may not

be short-circuited. If you fail to observe this warning, the short-

circuited cables may overheat and even melt.

The HBS may not be taken apart or technically altered under any

circumstances.

Never use the HBS for purposes other than for RC model making

as a hobby. Above all, their use in passenger-carrying equipment

is strictly prohibited.

Operate the HBS only with components provided for model

making (or UAS).

HBS Operating Instructions Version 1.0

Page 6 of 36

Always ensure that you have fully charged batteries when

operating your model. Empty batteries inevitably lead to failure of

the RC components, which cause the model to crash.

Do not expose the HBS to any extremely hot or extremely cold

temperatures, moisture or humidity. This would lead to danger of

malfunction, damage or decreased efficiency.

Only use accessories approved by EMCOTEC with the HBS.

3. What does HBS stand for?

HBS stands for Hybrid Battery Supply. Hybrid means "bundled,

interbred or mixed". In this case, it relates to the voltage supply of the

receiver equipment or other components in a RC model or UAS

(Unmanned Aerial System).

The supply voltage of the HBS is generated by the flight battery of an

electrical powered model or another power source (e.g. generator). It is

actually a kind of BEC (Battery Elimination Circuit). Additionally, this

supply voltage is "interlaced" with a regular 2-cell Lithium-Polymer

battery. This additional battery serves as a buffer; it provides for high

current peaks and makes sure, that there is enough energy in case the

flight battery is empty or breaks.

Of course, the usage of the HBS is not limited to electrically powered

models. Stay tuned for more later on.

HBS Operating Instructions Version 1.0

Page 7 of 36

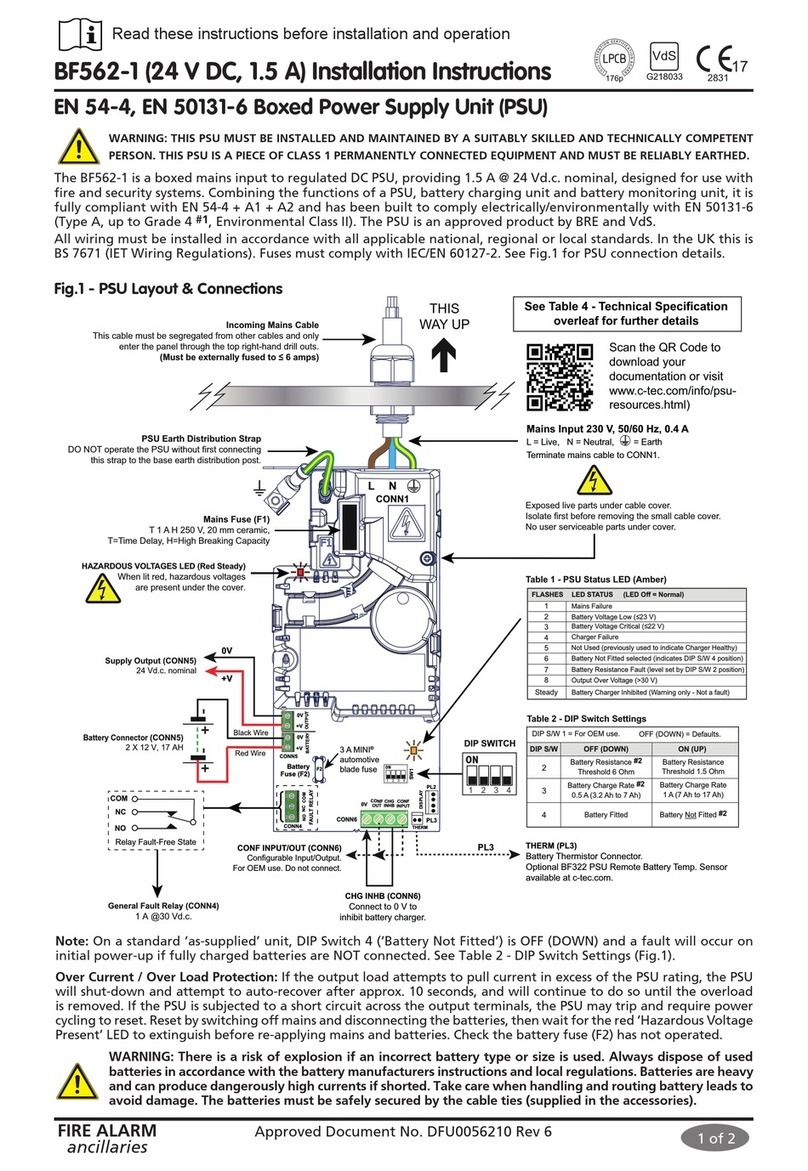

4. HBS Connection Scheme

Rear:

Hint:

The HBS can get very hot depending on withdrawn power. Therefore, the total

aluminum housing is used as heat sink.

HBS Operating Instructions Version 1.0

Page 8 of 36

5. Characteristics

The HBS is available in two versions mend for different usages. Both

systems differ only in their input voltage range.

Version 1: HBS with 10V … 36V input voltage

•Intelligent energy management system for combustion

powered models.

•Entire BEC substitute for electrical flight applications in

connection with a 2S LiPo buffer battery

Version 2: HBS with 20V … 75V input voltage

•Entire BEC substitute for electrical flight applications in

connection with a 2S LiPo buffer battery

Hint:

The HBS is a totally new system and therefore remains under legal protection of

registered designs at the German patent office (Nr. 20 2013 000 114.2)

First, the function for electrical flight (BEC substitute) will be shown for

better appreciation as follows.

5.1. Usage in an Electrical Motor Powered Model

Charging of all batteries in an electrical powered model

Background of the development of the HBS is the necessity to

additionally charge the receiver battery in electrical powered models. In

huge models with redundant supply (battery switching operation) even

two receiver batteries must be charged in order to charge all batteries.

This causes a lot of work and thoughtfulness.

HBS Operating Instructions Version 1.0

Page 9 of 36

Right here the HBS adds to it: It disburdens the pilot's everyday life

remarkably and makes sure there are less or even no errors during

charging of the batteries.

BEC was yesterday – HBS is today

The reason for the PowerCube ® HBS is to supply the receiver

equipment out of the flight battery similar to a BEC. Additionally, a

small receiver battery when mounted inside the model which actually

serves as buffer provides for high current peaks and serves for

reliability in case the flight battery is empty or malfunctions.

The receiver set is actually supplied by the HBS while the receiver

battery (2S Lithium-Polymer battery) serves for safety and is recharged

by the HBS at the same time. Manual charging of the receiver battery

is eliminated, as well as cell matching, which is done by the HBS, too.

The flight battery supplies the HBS. The DC/DC converter in the HBS

reduces the voltage of the flight battery to the charging voltage of the

2-cell LiPo battery which is directly connected to the balancing

connector of the HBS.

As soon as the flight battery is connected the HBS starts charging the

receiver battery – fully automatically. Charging current is 1.4 amps.

Simultaneously to charging, both cells of the receiver battery are

matched (equalizing function).

The receiver set gets its current via the receiver battery (when using a

battery switch via two receiver batteries with a HBS each) additionally

from the HBS (=> hybrid solution). Due to the HBS, the receiver

battery can be very small which practically leads to a weight neutral

solution. A 450mAh to 800mAh battery fully suffices – for huge models

2 batteries when using dual current supply operation.

HBS Operating Instructions Version 1.0

Page 10 of 36

The HBS constantly recharges the receiver battery, thus, the receiver

battery is rarely discharged. Only when the flight battery fails, the

receiver set is supplied by the receiver battery only.

Hint:

As long as the average of the withdrawn current is lower than 1.4 amps (average

current consumption of the receiver set) the system acts as an "unlimited" big

receiver battery. The disadvantages of separate charging and balancing of the

(receiver) battery are eliminated.

The charging end voltage is 8.2 volts instead of normally 8.4 volts. This

reduces the usable capacity slightly but increases life expectancy

(charging cycles) significantly – similar to the batteries in a hybrid

vehicle. Here too, the bandwidth of the battery is not fully utilized in

order to increase life duration.

Extremely high Currents

The difference to a regular BEC without receiver battery is that, due to

the usage of a 2S Lipo battery, high current peaks are possible which a

BEC can not deliver. An 800mAh / 30C LiPo battery delivers 24 amps

continuous current. No BEC can do that! Additionally, the circuitries of

the flight battery and the receiver set are totally electrically separated

by the HBS. The advantages of motor controllers with optically isolated

couplers fully remain. The biggest advantage of the HBS compared to

a BEC is, that the receiver set works totally normal should the flight

battery fail because it is then supplied by the receiver battery.

The HBS is available in two versions which differ in their input voltage

range. Both versions apply to electrical flight; the version with the

smaller input voltage range applies for applications without electrical

drive as well.

HBS Operating Instructions Version 1.0

Page 11 of 36

5.2. Usage in a Combustion Engine Powered Model

The HBS also works perfectly for motor models and jets – but is used

differently than in electrically powered models.

In a combustion engine powered model the HBS does not work as

hybrid supply but rather as a charger / equalizer which is constantly

mounted into the model. Charging of the receiver battery (or ignition /

turbine battery) is conducted by connecting an external voltage in the

range of 10 volts up to 36 volts (e.g. car battery, truck battery, solar

panel, 4S – 8S Li++ battery or any other voltage supply).

Integrated charging station in combustion engine powered model

Due to the circuitry design of the HBS a fully electrically isolation

(galvanic separation) of the input voltage (Input) and the output voltage

(Output) is accomplished.

Hint:

The output voltage (Output) of the HBS is galvanic separated from the input

voltage (Input) (electrically isolated).

Fully automatically charging several batteries with one single connector

In a model with e.g. three LiPo batteries (two for the receiver set and

one battery for ignition or turbine) three HBS are to be built in (one

HBS for each battery). All Inputs (Input) of the HBS' are connected

together and put onto one single charging connector (e.g. EMCOTEC

Part No. PC4205).

Now one single car battery suffices to be connected and all three

batteries are charged simultaneously and automatically!

HBS Operating Instructions Version 1.0

Page 12 of 36

Because no charging program, no cell number and no charging current

must be selected and no balancer must be connected, charging is

simple as never before and can be conducted practically after every

flight. Simply connect a car battery after landing the model – ready.

Due to recharging after every flight, batteries can be much smaller as

usual. This leads to a weight neutral solution because the additional

weight of the HBS is compensated by the smaller batteries.

Battery State Indication

The charging state of the (receiver) battery which is connected to the

HBS is displayed by five LED's, operating state by 2 additional LED's.

In order to assess the remaining capacity of the battery pressing the

built in button of the HBS suffices. The charging state is displayed by

the LED's before the device automatically turns off after one minute. It

is possible to connect an external LED e.g. in the fuselage's sidewall. It

is an additional advantage of the HBS that the receiver battery can be

connected unlimited times because there is no current consumption

(without flight battery or any other input voltage)!

HBS Operating Instructions Version 1.0

Page 13 of 36

Storage-Function

A so called storage function rounds up the performance of the HBS. If

the (receiver) battery is to be unused for a longer period of time (e.g.

winter pause) a 5 second push onto the button activates the storage

mode. Both LiPo cells of the receiver battery are then discharged to

their optimal voltage which is best for storage, fully automatically. Due

to this function, the life performance of the battery is increased

tremendously.

Cooperation with DLR

The HBS (Hybrid Battery Supply) was developed in close cooperation

with the DLR (Deutsches Luft- und Raumfahrtzentrum / German Air

and Space Center) and finds its usage in unmanned flight systems

(UAS).

Highest Safety

Due to elaborate FMEA (Failure Mode and Effect Analysis) all risks

when using Lithium-Polymer batteries could be minimized or

eliminated. The combination of the HBS with the PowerCube LiPo

batteries (Part No. PC4100 up to PC4120) therefore is absolutely safe

and long living.

HBS Operating Instructions Version 1.0

Page 14 of 36

PowerCube batteries must not be removed from the model for

recharge and can remain built in. Just some other outstanding safety

features of the HBS are over-load protection, low-discharge protection,

equalizing, reverse polarity protection, shortcut protection, over

temperature cutoff and recognition of battery errors. The Hybrid Battery

Supply makes charging technique in a RC model as safe as never

before.

The HBS in head words

Wide input voltage range from 10-36 volts or 20-75 volts

Galvanic isolated charging system for 2S Lithium-Polymer

batteries

1.4A charging current, 8.20V charging end voltage

Integrated equalizer with storage function

Quiescent current lower than 1.5µA – Therefore no discharge of the

batteries during longer breaks

Unlimited number of parallel HBS possible. The outputs are

electrically isolated

Shortcut- and reverse polarity protected input

Shortcut protected output

Conservative Trickle-Charging for deep discharged batteries

Over-temperature cutoff

Different display modes of the charging- and battery state

Recognition and indication if battery errors

Simple control of charging state of the receiver battery with single

button press

Special ground concept for disturbance free operation and highest

safety

High grade housing milled out of a solid aluminum block which also

serves as heat sink at the same time

Perfectly suitable in combination with PowerCube LiPo batteries

Under legal protection of registered designs (German Patent Office

Nr. 20 2013 000 114.2)

HBS Operating Instructions Version 1.0

Page 15 of 36

6. Recommended Accessories

Part No. Product

PC4100 PowerCube 450 – 2S LiPo battery, 450mAh

PC4105 PowerCube 800 – 2S LiPo battery, 800mAh

PC4110 PowerCube 1300 – 2S LiPo battery, 1300mAh

PC4115 PowerCube 1800 – 2S LiPo battery, 1800mAh

PC4120 PowerCube 2400 – 2S LiPo battery, 2400mAh

PC4230 JR/UNI battery patch cable - Variant 30cm long

PC4230 JR/UNI battery patch cable - Variant 50cm long

PC4240 PowerCube battery charging / balancing cable - Variant 10cm

PC4240 PowerCube battery charging / balancing cable - Variant 20cm

PC4200 EMCOTEC Charging Socket

PC4205 EMCOTEC Charging Socket with Status LED's

PC4220 Charging Cable for Charging Socket - Variant 180cm

PC4220 Charging Cable for Charging Socket - Variant 250cm

PC4010 PowerCube HBS Status-LED, 5mm

A86200 Vibration Damper Set (4 pieces) - Variant “A”

HBS Operating Instructions Version 1.0

Page 16 of 36

7. Mounting

The HBS can be mounted onto a board using M3 screws. We

recommend mounting on vibration dampers (Part No. A86200). That

assures for good air flow and vibration damping.

8. Connecting the Supply Batteries

For connection of the supply voltage (= external charging voltage) on

the HBS a normal JR/Uni battery patch cable or a servo cable with

disconnected pulse line suffices. The wire cross section for low input

voltages should be up to 20 volts 0.5mm² (AWG21), for higher voltages

a cable with 0.25mm² (AWG24) suffices. The input of the HBS is

reverse polarity- and shortcut protected.

Hint:

A JR/Uni battery connection cable could be accidentally connected to the HBS

output because the spacing is nearly identical. This could lead to damage of the

HBS! Therefore always observe correct connection of the cable!

HBS Operating Instructions Version 1.0

Page 17 of 36

9. Connecting the Receiver Battery

All 2S Lithium-Polymer batteries are suitable as (receiver)-batteries for

charging. We recommend using PowerCube LiPo batteries. These are

equipped with today's highest grade available cells from KOKAM. This

assures for very long life performance. The capacity indication of the

HBS is calibrated to PowerCube LiPo batteries and shows the most

precise results for them.

Supply voltage 2S LiPo battery

(external charging voltage) (receiver battery)

The battery is connected to the output of the HBS with its balancing

connector (JST EHR connection system). Charging current of the HBS

is limited to 1.4 amps, charging end voltage is 8.2 volts.

HBS Operating Instructions Version 1.0

Page 18 of 36

Hint:

The charging end voltage of the HBS is 8.2 volts (although 8.4 volts are

permissible). This lowers the provided capacity of the battery by approx. 18%.

An 800mAh battery therefore has only effectively approx. 650mAh of capacity, a

battery with nominal 2400mAh just under 2Ah effective capacity.

These measuring results correspond to PowerCube batteries with KOKAM cells

at 23°C and 1C charging / discharging current.

Life performance of the batteries is tremendously increased by this lowered

charging end voltage because relevant values of the DOD (Depth of Discharge)

for life performance are far not reached.

Hint:

Only 2-cell Lithium-Polymer batteries must be connected to the HBS. Usage of

LiFePO4 batteries is impossible and not permissible!

Hint:

A receiver battery connected to the HBS is not protected against deep discharge!

Because the battery is directly connected to the consumer (e.g. battery switch or

receiver set) the HBS has no control. But a threatening low voltage is optically

indicated by LED's if the HBS is turned on.

HBS Operating Instructions Version 1.0

Page 19 of 36

10. External Status-LED

If free sight to the HBS in the model is not possible, an external LED

(Part No. PC4010) can be connected to the output ("Status Output").

The LED can be mounted into the fuselage's sidewall and indicate

important system states of the HBS optically. The open collector output

of "Status Output" switches 5 volts and can be loaded with a maximum

of 60mA.

The EMCOTEC charging socket with status LED (Part No. PC4205)

has two integrated LED's which illuminate the outer ring of the charging

socket. The charging socket is suitable for two HBS (e.g. for dual

current supplies) and can display the status of two HBS. Contact is

accomplished directly with the connection cables of the charging

socket.

11. Mounting Examples

The following mounting examples serve as recommendation for using

a HBS in an RC model. Of course, many other variants are

considerable.

HBS Operating Instructions Version 1.0

Page 20 of 36

11.1. Electrical Powered Model

In this example the receiver set is powered by a receiver battery.

Switches and so on are not shown.

11.2. Electrical Powered Model with Dual Supply

In this example the receiver set is powered by a dual current supply

with two receiver batteries.

Table of contents

Popular Power Supply manuals by other brands

MPL

MPL ZBX-12V/2A user manual

Satel

Satel APS-30 manual

Pepperl+Fuchs

Pepperl+Fuchs PS1000-A6-24.10.R technical information

VOLTCRAFT

VOLTCRAFT VSP Series operating instructions

Tactical Power Products

Tactical Power Products TP12VDC-5A-ILS installation manual

BGS technic

BGS technic 3383 Safety and operating instructions