TP-70BS (Rev 3.0)

TALON TECH CO. LTD.

6-1-6-1. ID Setting………………….………………………………………………………………………………………………………...

6-1-6-2. Maint Mode, Run Mode, Pump Reset Setting……….………………………………………………………….

6-1-7. Calibration………………………………………………………………………………………………………………………………….

6-1-8. Counter……………...……………………………………………………………………………………………………………………….

6-2. Example………………….………………………………………………………………………………………………………………………….

6-2-1. Dispense Test….………………………………………………………………………………………………………………………….

6-2-2. Recipe Setting……………………………………………………………………………………………………………………………

6-2-3. ID Setting………………………………………………………………………………………………………………………….............

6-2-4. Name Setting………………………………………………………………………………………………………………………….....

6-3. Cycle Purge Method…………………………...……………………………………………………………………………………………

6-4. Reset on Pump Error…………………………..…………………………………………………………………………………………….

6-5. Log Data………..…………………………………………………………………………………………….................................................

6-5-1. Log Data Analysis ………..……………………………………………………………………………………………...................

6-6. Touch Pad Menu Tree……………………………………………………………………………………………………………………….

6-7. Notice……...………………………………………………………………………………………………………………………………………..

6-7-1. Dispense Cycle………………………..…..……………………………………………………………………………………………..

6-7-2. Pump ID Setting……………..…………………………………………………………………………………………………………

6-7-3. Recipe Setting………………………………………………………………………………………………….………………………...

6-8. Notice on Pump Operation.………….………………………………………………………………………………………….………

7. Maintenance……………………………………………...……………………………………………………………………………………………

7-1. Purge Method……………….………………………………………………………………………………………………………………….

7-2. Pump Parts Dis/Assembly.…..………..………………………………………………………………………………………………….

7-2-1. Pump Cover Dis/Assembly..…..…………………….……..……………………………………………………………………..

7-2-2. Driving Shaft Condition Check & Grease up on Ball Screw……...……………………………………………..

7-3. Suck-Back Setting………….………………………………………………………………………………………………………………….

8. Recommended Spares/Mechanical Dimensions…………..……………………………………………………………………..

8-1. TP-70BS Spare Parts…………………………..……………………………………………………………………………………………..

8-2. Pump Dimensions………………….…………………………………………………………………………………………………………

8-2-1. Front View…………………….………………………………………………………………………………….………………………...

8-2-2. Side View………...………….……………………………………………………………………………………………………………...

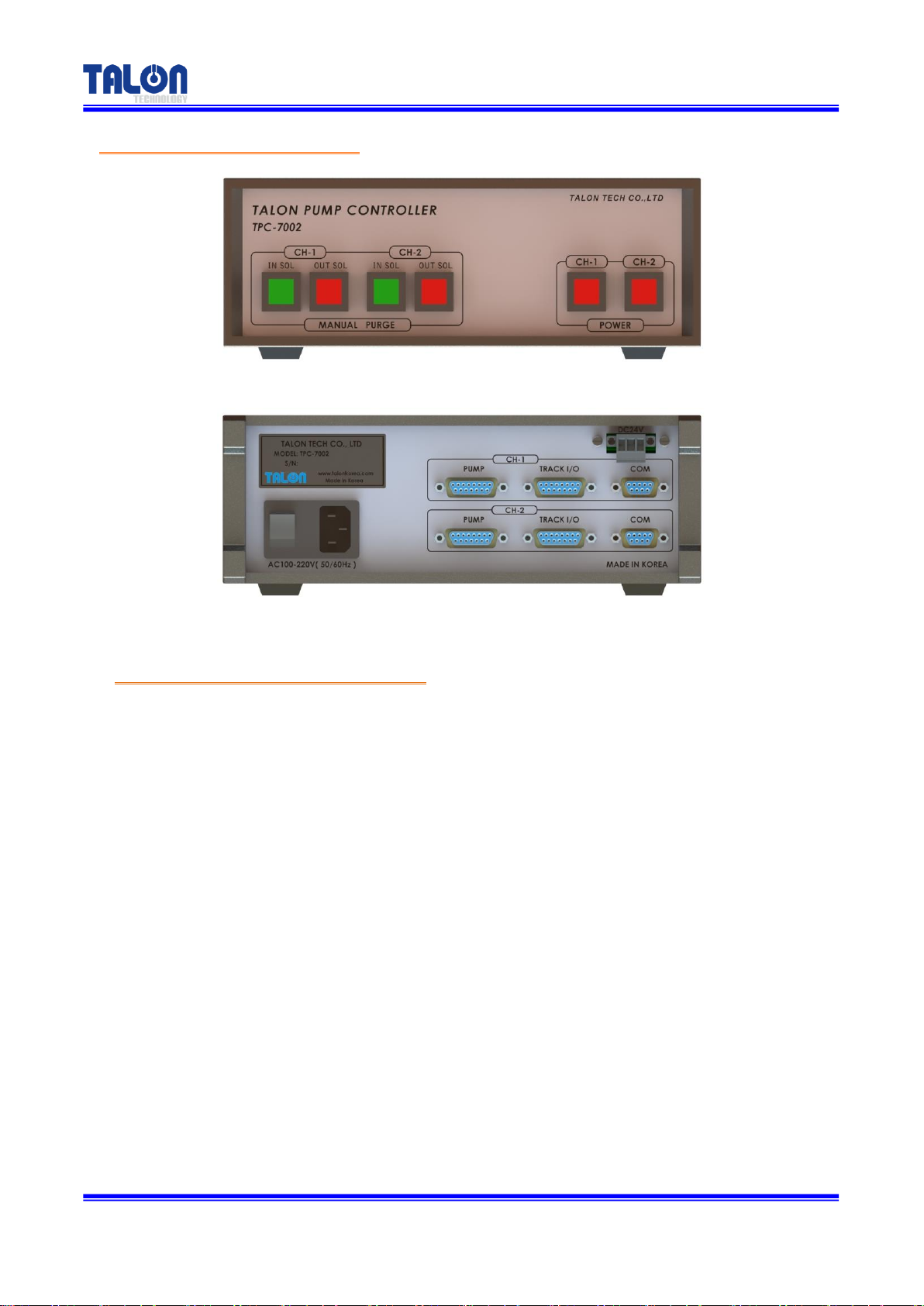

8-3. Controller Dimensions……..…………………………………………………………………………………….………………………...

8-3-1. Front View………………………….…………………………………………………………………………….………………………...

8-3-2. Rear View………………….…...……..……………………………………………………………………………………………………

8-3-3. Side View………………….……………………..………………………………….……………………………………………………...

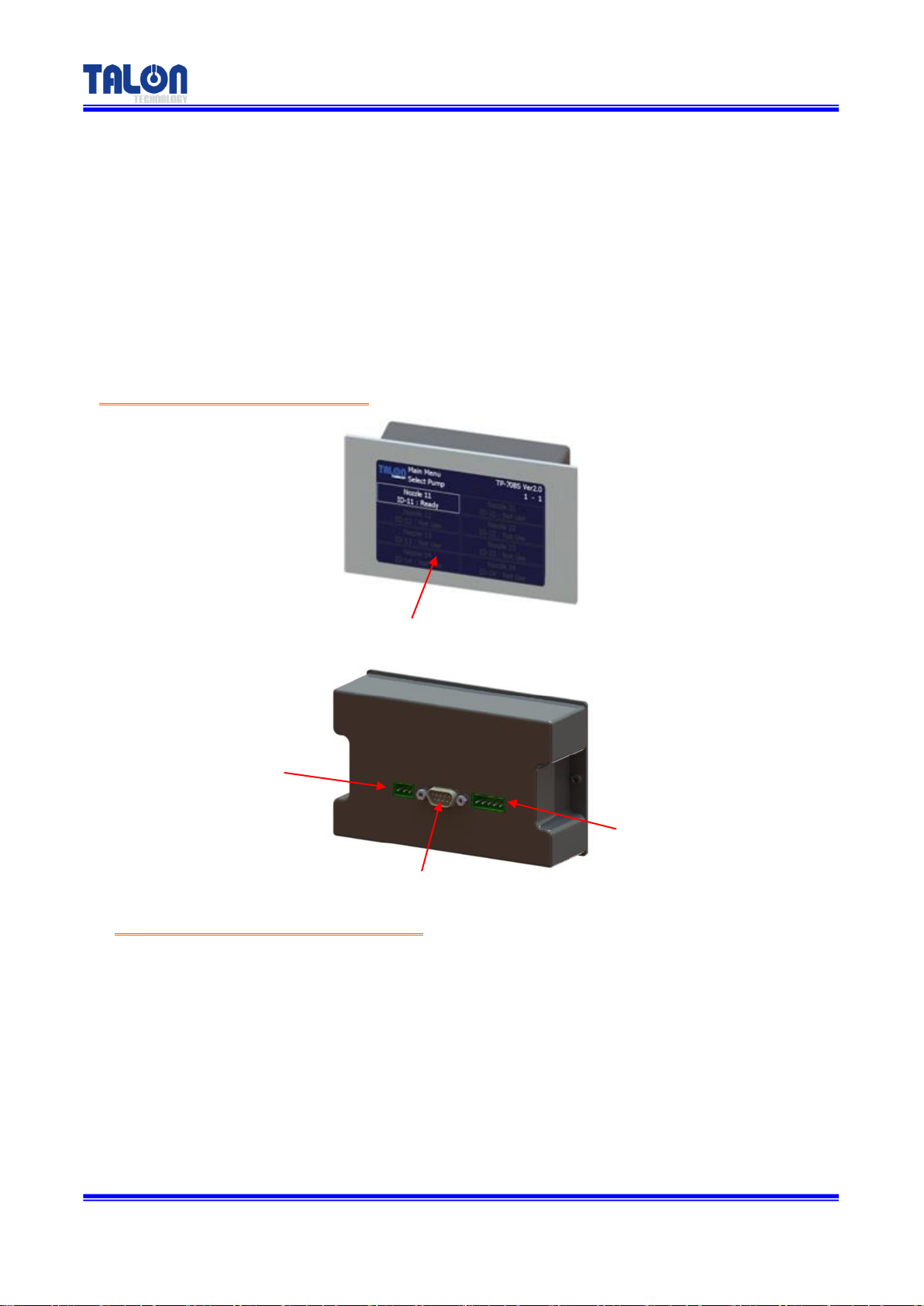

8-4. Touch Pad Dimensions…………………………..………………………………….……………………………………………………...

8-4-1. Front View……………………...…………………………………………………………………………………………………………..

8-4-2. Rear View…………………...………………………………………………………………………………………………………………

8-4-3. Side View………………..……………………..…………………………………………………………………….……………………..