䊚Shindaiwa Inc. 1998

4

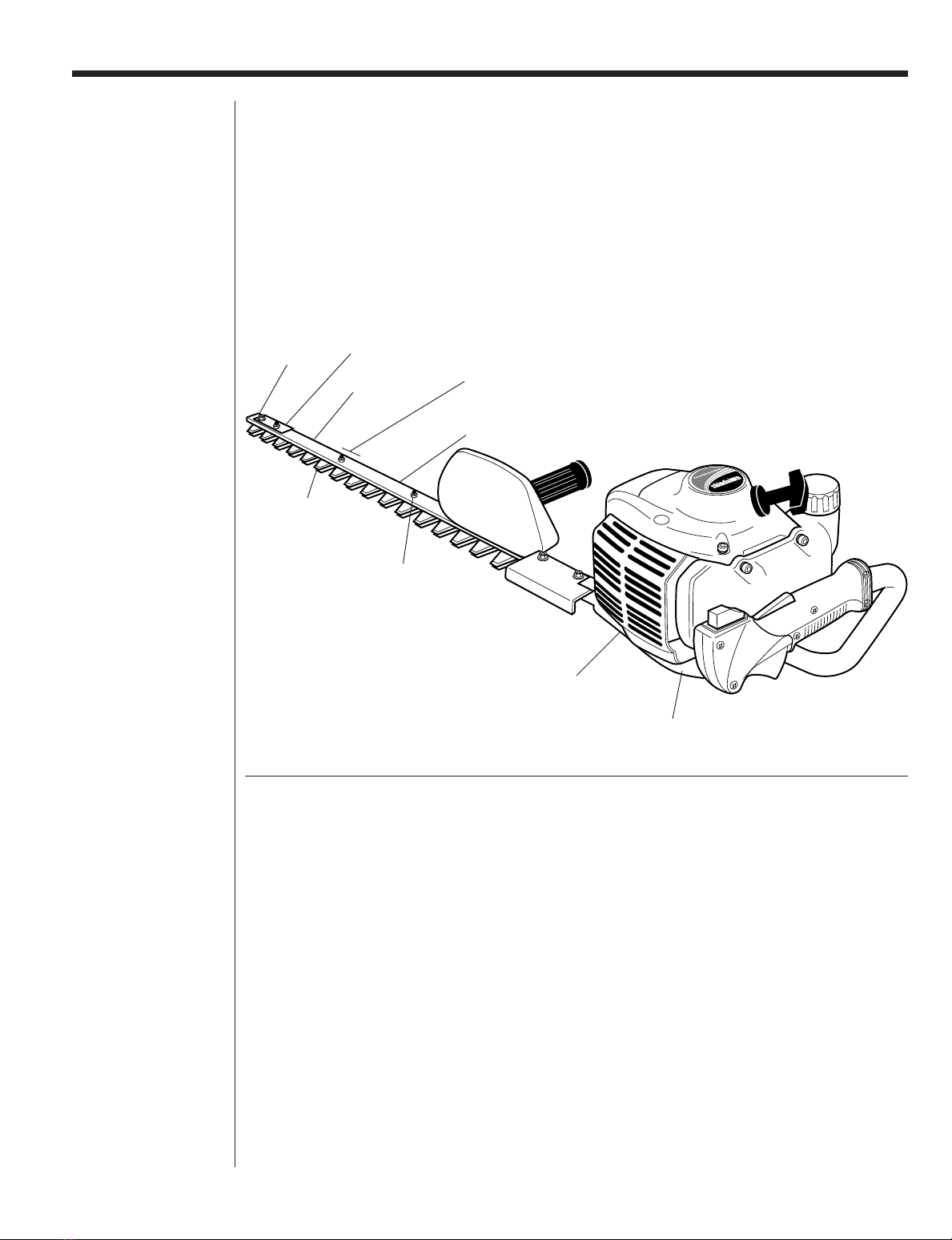

Section 1 Specifications

Specifications are subject to change without notice.

General Specifications HT230 & DH230

Dimensions (L x W x H)

HT230-30 ..................... 990 x 210 x 210 mm

HT230-40 ................... 1330 x 210 x 210 mm

DH230-24 .................. 1080 x 250 x 210 mm

DH230-30 .................. 1220 x 250 x 210 mm

Weight; engine and Cutter (less fuel)

HT230-30 .................... 5.5 kg (12.2 pounds)

HT230-40 .................... 6.0 kg (13.2 pounds)

DH230-24 .................. 5.7 kg (12.5 pounds)

DH230-30 ................... 5.9 kg (13.9 pounds)

Engine Specifications

Engine Model ....................................... SHT230

Type ..... 2-cycle, horizontal cylinder, air cooled

Bore x Stroke .......................... 32 mm x 28 mm

Displacement ........................................ 22.5 cc

Dry Weight ...................... 2.6 kg (5.73 pounds)

Max. Output ....... 1.1 hp (0.81 kW) @ 8000 rpm

Fuel ................................. Gasoline-oil Mixture–

40:1 with Shindaiwa

Premium 2-cycle Engine Oil

Fuel Tank Cap., (HT230) ..... 0.7 liter/24 ounces

Fuel Tank Cap., (DH230) .... 0.6 liter/21 ounces

Carburetor ........ Walbro WYJ (diaphragm type)

Ignition ....Fully electronic, transistor controlled

Spark Plug ................................ Champion CJ8

Air Cleaner ................. Semi-wet type, silenced

Starting Method .............................. Recoil type

Drive and Cutters Specifications

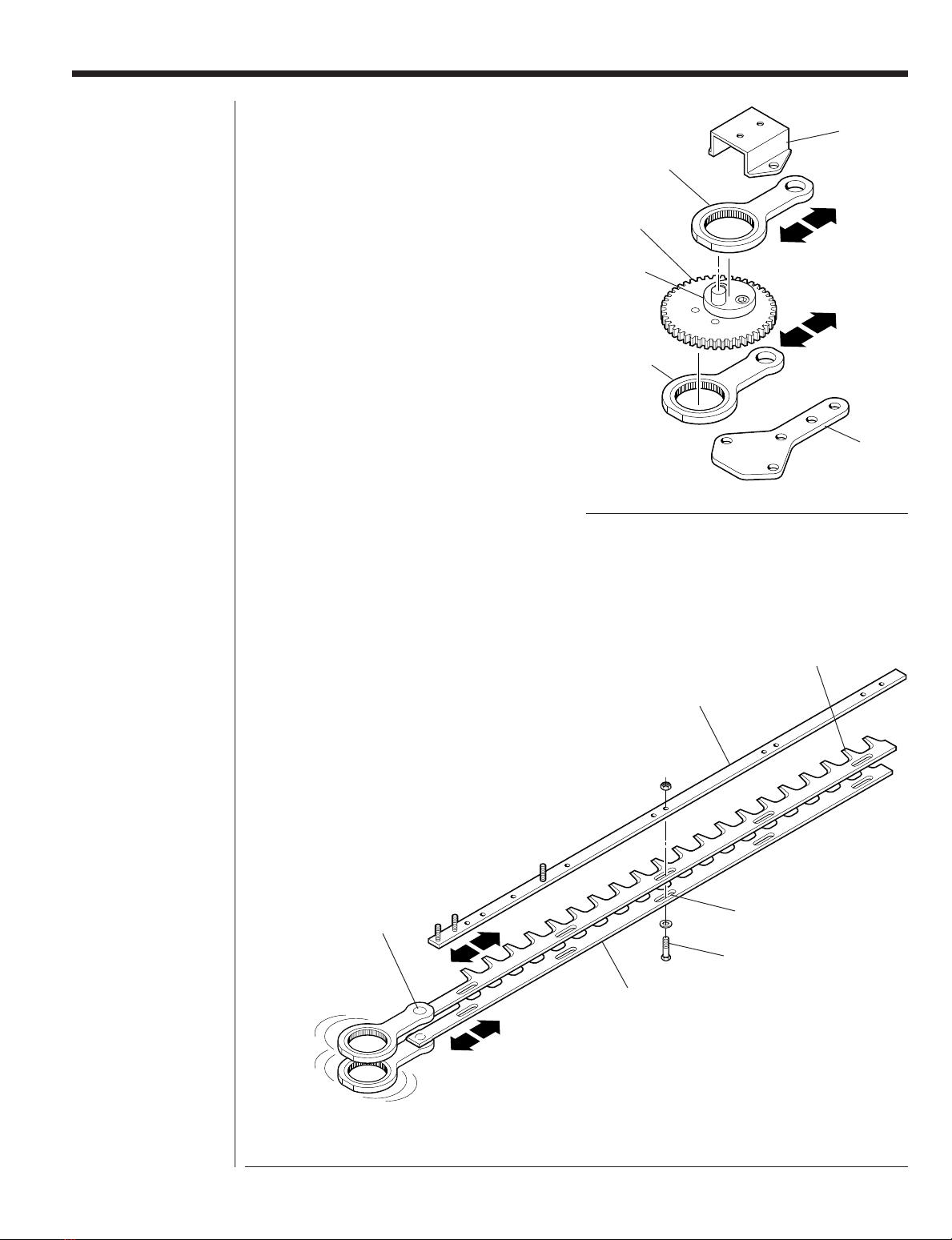

HT230 Blade ......... Double-action, single edge

DH230 Blade .......Double-action, double edge

Blade Length

HT230-30 ......................................... 740 mm

HT230-40 ....................................... 1080 mm

DH230-24 ........................................ 605 mm

DH230-30 ........................................ 745 mm

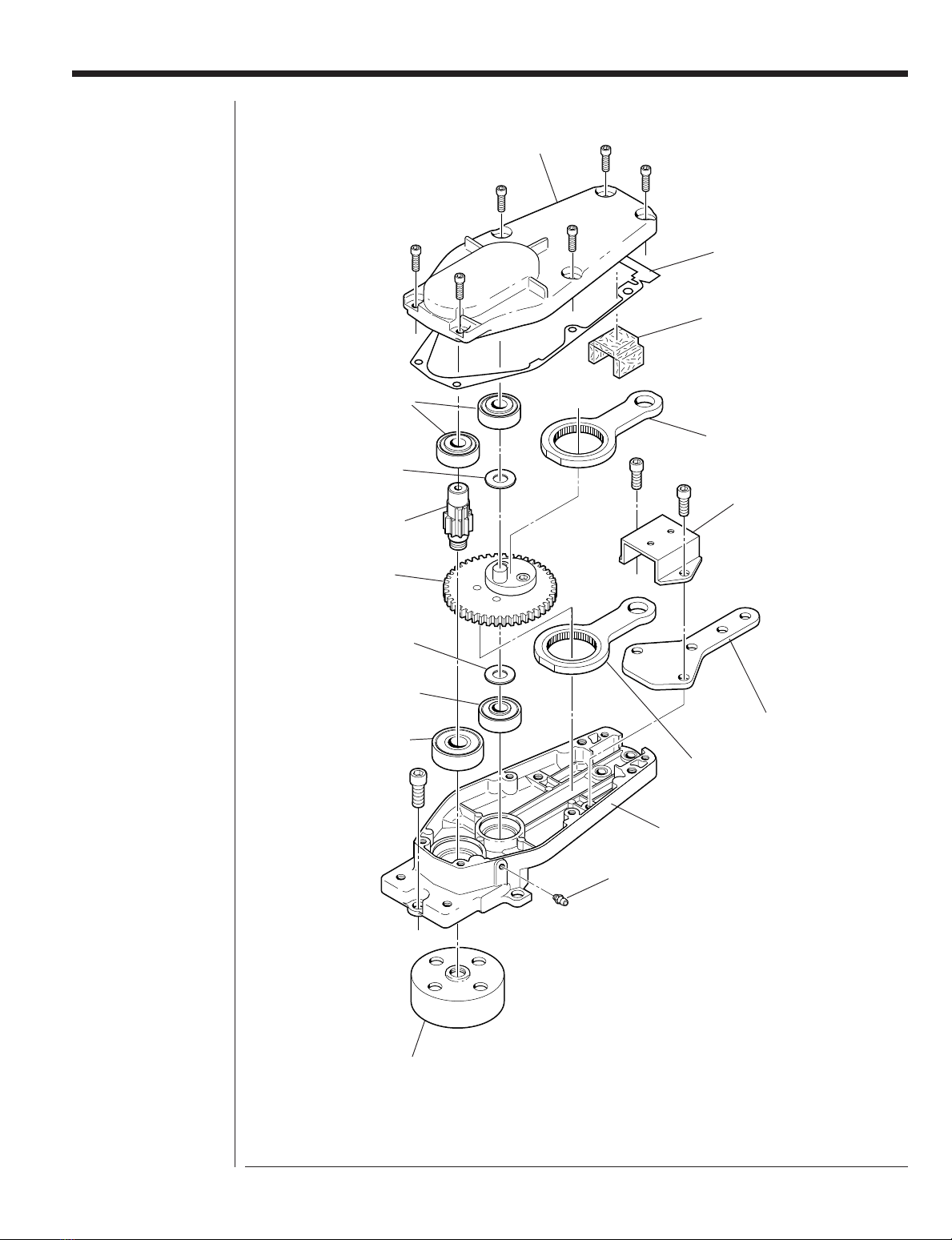

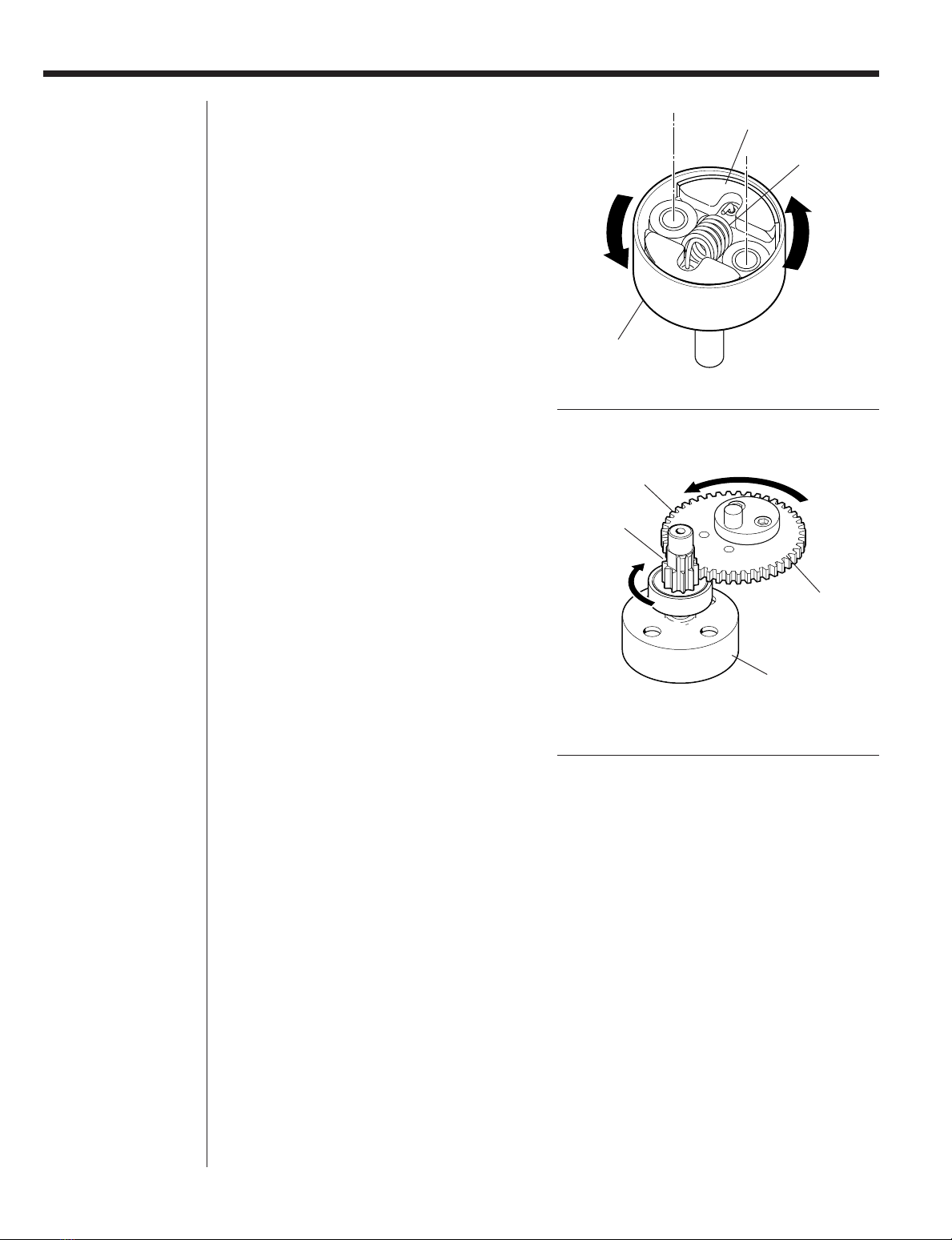

Clutch Type .............Fully automatic centrifugal

clutch, dry type

Gear Type ....................................... Spur gears

Gear Reduction ...................................... 1:4.98

Gear Lubrication ............ Lithium-based grease

Standard Equipment

Rear handle with integral controls, anti-vibe

mountings.

Front handle with guard.

Tool set and blade cover (scabbard).

Options

Deflector shield (HT230 only)