6H15-019 Rev.3

Issued : Jul. 2015

Revised : Apr. 2019

Calibration material JIS SCM440 flat surface 1. Calibration material

MODEL FK-602F Transducers are calibrated for JIS SCM440 flat

surface (more than 54 mm dia.).

If the measured target is other than JIS SCM440 flat surface, it will

present a different characteristics. In such a case, calibration by the

connected equipment (e.g. monitor) side should be required for

system operation.

2. Shield wire connection

Connect shield wire of signal cable (3-wire shielded cable between

driver and monitor) to driver’s “COM” terminal (Spring lock terminal:

“Shield” terminal) and monitor’s “COM” terminal.

If this is not adhered to, noise may be caused.

3. Connector isolation, etc.

The connector connecting the sensor cable and the extension cable

shall be insulated with the attached insulation sleeve (transparent

shrink tube) or fluoro resin insulation tape.

The vinyl-insulating tape shall not be used.

4. Megger test of signal cable

If megger test is made on the signal cable (3-wire shielded cable), be

sure to discharge the charged electric load before connecting the

cable to driver.

If this caution is not adhered the driver could be dameged.

5. Sensor installation

Not available for rain water at out door use.

It may cause the sensitivity change and insulation down.

6. Calibrated as a system

The sensor, extension cable and driver, which are calibrated as a

system, shall be connected with each serial No. as specified in the

inspection test report. If this is not adhered the output characteristics

may be out of specification.

7. Linearity

The linearity margin provides for examination result in our factory. This

regulated value is not applied to the examination result in the site.

8. The instructions manual contains important information such as

conditions necessary for safe handling of the system.

Such information and conditions are important and indispensable for

ensuring safety. Therefore, be sure to read the instructions manual

thoroughly before handling the system.

9. Cable length 5.0m sensor is designed for 5m system only.

Can not use for 9m system.

Measuring range 0.5 mm to 6.5 mm from sensor tip

Sensitivit

*1 2.5 V/mm

Sensitivit

erro

*1 Within ±4 %

Linearit

*1 Within ±70

m of 2.5 V/mm straight line :

(if calibrated as a system)

Within ±90

m of 2.5 V/mm straight line :

(including interchangeability errors)

Linear range : 6 mm

Frequency responce*1 DC to 10 kHz or more (-3 dB)

Max. output voltage*1 Approx. -23 VDC

Sensor abnormal output

volta

e*1 Approx. -0.6 VDC (Sensor OPEN/Sensor SHORT)

Output impedance*1 50 ΩCurrent 5 mA (max.)

Current consumption

10 kΩload

Max. -15 mA

Output noise*1 Approx. 20 mVpk-pk + power supply noise

Sensor tip diamete

Approx. 18 mm dia.

Cable diamete

Approx. 3.6 mm dia.

Connector diamete

Approx. 7.1 mm dia.

System cable length 5 m or 9 m

Sensor cable color Blue

Extension cable color Black

Operating temperature

range

Senso

: -40 to +125 °C

Extension cable : -40 to +125 °C

Driver : -40 to +80 °C

Temperature characteristic

(Temperature drift)

Senso

: Less than ±3 % of F.S.

Extension cable : Less than ±3 % of F.S.

Condition : Gap=5 mm, Target : JIS SCM440

0 to 80 °C (at 20 °C standard)

Driver : Less than ±3 % of F.S.

Loop : Less than ±4 % of F.S.

Condition : Gap=5 mm, Target : JIS SCM440

0 to 60 °C (at 20 °C standard)

Operating humidity range 30 to 95 % RH (non-condensing, non-submerged)

(Sensor body : 100 % RH)

Power suppl

-24 VDC ±10 %

Dielectric strength of drive

Between each terminal and mounting plate :

1 mA or less at 500 VAC for one minute

Insulation resistance of

drive

Between each terminal and mounting plate :

100 MΩor more at 500 VDC

Applicable wire Screw type terminal block (M4) : 0.75 to 2mm2

Size Spring lock terminal : 0.2 to 1.5mm2

Driver mass Approx. 200 g

Oil leakage reduction

performance*2

Even if oil is poured in to the cable with the

pressure of 0.05MPa. Oil does not leak from

opposite the cable for 7 days.

(cable length : 4m, at 25 °C)

*1 The above specification apply at 25 °C with -24 VDC power supply and

load resistance 10 kΩand JIS SCM440 target (thickness≥5 mm).

*2 Oil leaka

e reduction performance is applied to the extension cable part.

Specifications Notice

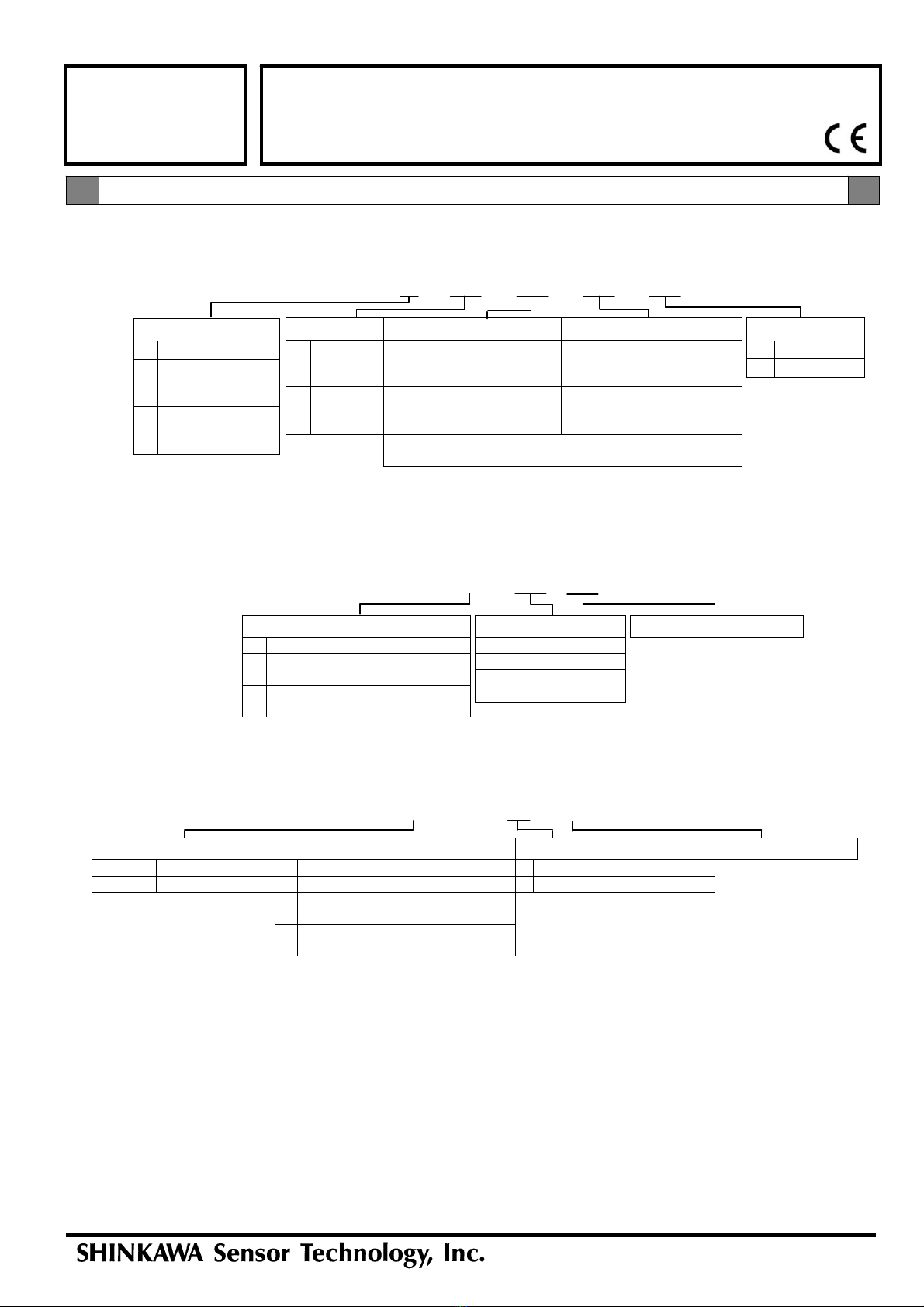

Configuration

FK-602F Transducer

Oil leakage reduction extension cable option

Page 1 of 2

FK Series

Transducer

Specifications

Connector

Sensor Extension cable*2

(Oil leakage reduction)

Driver

System cable length

FK-602F1 : 5m

FK-602F2 : 9m