4

CONTENTS

1. INTRODUCTION..............................................................6

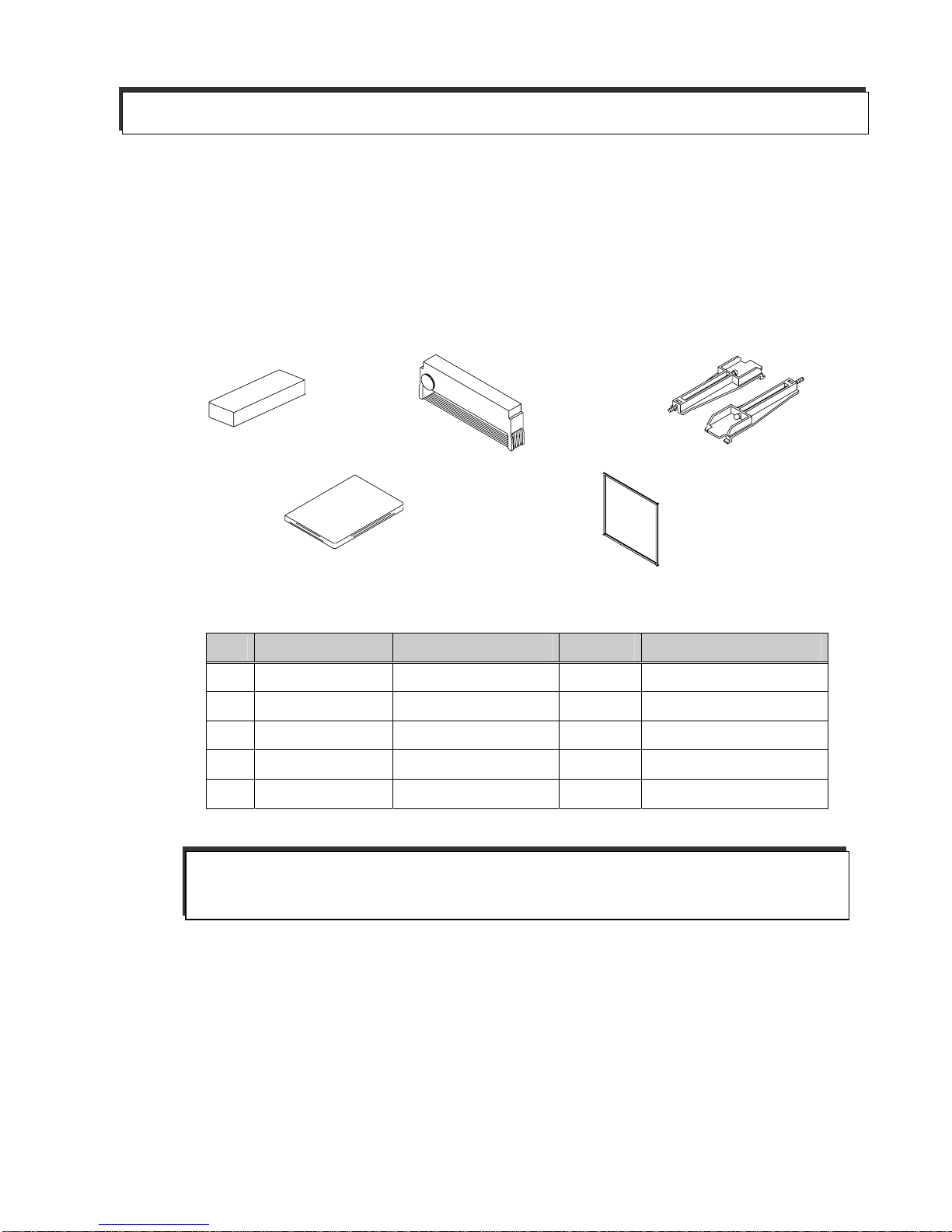

1.1 Checking theAccessories....................................................... 6

1.2 Checking the Model Type and Specifications........................ 7

1.3 Temporary Storage.................................................................. 8

1.4 Indication Card........................................................................ 8

2. CONSTRUCTION............................................................9

2.1 Appearance............................................................................. 9

2.2 Display Screen and Operation Keys.................................... 10

2.2.1 Display Screen ................................................................ 10

2.2.2 Operation Keys.................................................................11

3. INSTALLATION..............................................................12

3.1 External dimensions

and panel cutout....................................................................12

3.2 Mounting to the Panel...........................................................13

3.2.1 Procedure for Mounting to the Panel..............................13

3.2.2 Mounting to the Panel in compliance with the IP65.......14

4. WIRING ..........................................................................15

4.1 Terminal arrangement and Power Wiring.............................15

4.1.1 Terminal arrangement..................................................... 15

4.1.2 Power Wiring................................................................... 15

4.1.3 Wiring Procedure............................................................. 16

4.2 Input Wiring............................................................................17

4.2.1 Wiring Procedure............................................................. 18

4.3 DI function/Alarm Output Wiring (Option)............................. 20

4.3.1 DI function/Alarm Output Wiring Example .....................20

4.3.2Alarm Output Wiring Procedure......................................21

4.3.3 DI function Wiring Procedure..........................................21

4.4 Communication Wiring.......................................................... 22

4.4.1 RS-232C Wiring ..............................................................22

4.4.2 RS-485 Wiring.................................................................22

5. PREPARATIONS FOR OPERATION ...........................23

5.1 Setting the Chart Paper ........................................................23

5.2 Setting the Ribbon Cassette................................................. 29

6. RUNNING.......................................................................31

6.1 Running .................................................................................31

6.1.1 Status after Initial Screen ................................................ 31

6.2 Recording..............................................................................32

6.2.1 Recording Colors............................................................. 32

6.3 How to Record....................................................................... 32

6.3.1 Starting/Stopping Recording .........................................32

6.3.2 Feeding the Chart Paper.................................................32

6.3.3 Print Sample....................................................................33

6.4 Digital Print.............................................................................34

6.4.1 Manual Print.....................................................................34

6.4.2 List Print...........................................................................35

6.4.3 Engineering List Print......................................................37

6.5 Changing the Display ........................................................ 39

6.5.1Auto Display < >...............................................39

6.5.2 Manual Display < >..............................................39

6.5.3 Date Display < > .............................................. 39

6.5.4 Time Display < >.............................................. 39

6.5.5 Display Off < >...................................................... 39

7. DEVICE SETTING.......................................................40

7.1 Setting the Setup Mode.........................................................40

7.1.1 Setting the Range ............................................................43

(1) Setting method .................................................................43

(2) (Current/Voltage), (Thermocouple),

(Resistance Temperature Detector)..................44

(3) (Scaling)......................................................46

(4) (Square Root)..................................................48

(5) (Decade)......................................................50

(6) (Difference), (Sum),

(Average)........................................................52

(7) (Skip) ...............................................................53

7.1.2 Setting theAlarm..............................................................54

7.1.3 Setting the Unit.................................................................56

(1) Character Code Table......................................................57

7.1.4 Setting the Chart feed Speed..........................................58

7.1.5 Setting the Date and Time...............................................59

7.1.6 Copying the Setting Data.................................................60

7.1.7 Setting Other Functions...................................................61

(1) (Printing Cycle)............................................62

(2) (Zone Recording)............................................62

(3) (Partial Compression/Expansion)...................63

(4) (Digital Print)................................................64

(5) (Tag).....................................................................65

(6) (Comment Words)...........................................66

7.2 Setting the Engineering Mode...............................................67

7.2.1Alarm Hysteresis..............................................................70

7.2.2 Burnout ON/OFF..............................................................70

7.2.3 Channel Offset.................................................................70

7.2.4 Reference Junction Compensation.................................71

7.2.5 Changing the Printing Color ...........................................72

7.2.6 Settings Related to Recording.........................................73

(1) Trigger setting for recording start/stop.............................73

(2) Tag/channel print selection...............................................73

(3)Alarm print ON/OFF .........................................................74

(4) Logging print ON/OFF......................................................74

(5) Scale print ON/OFF..........................................................75

(6) Logging print Synchronous/Asynchronous .....................75

7.2.7 Setting the Communication Function..............................76

7.2.8 Initializing the Setup Data ..............................................76

7.2.9 DI functions.......................................................................77

7.2.10 Temperature Unit selection............................................77

7.2.11 Point Calibration.............................................................78

7.2.12 Data Calibration .............................................................79

7.3 Terminating the Engineering Mode.......................................81