Important

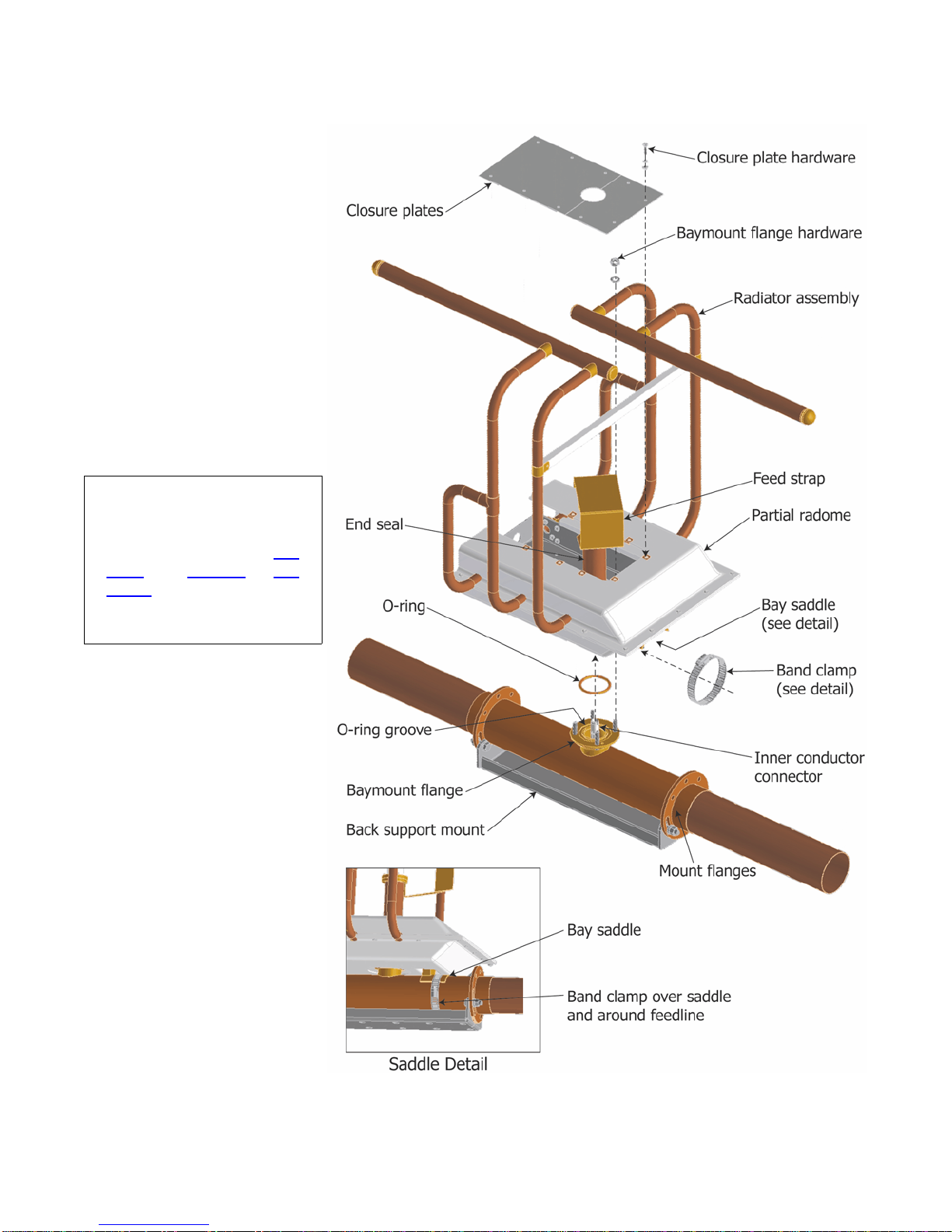

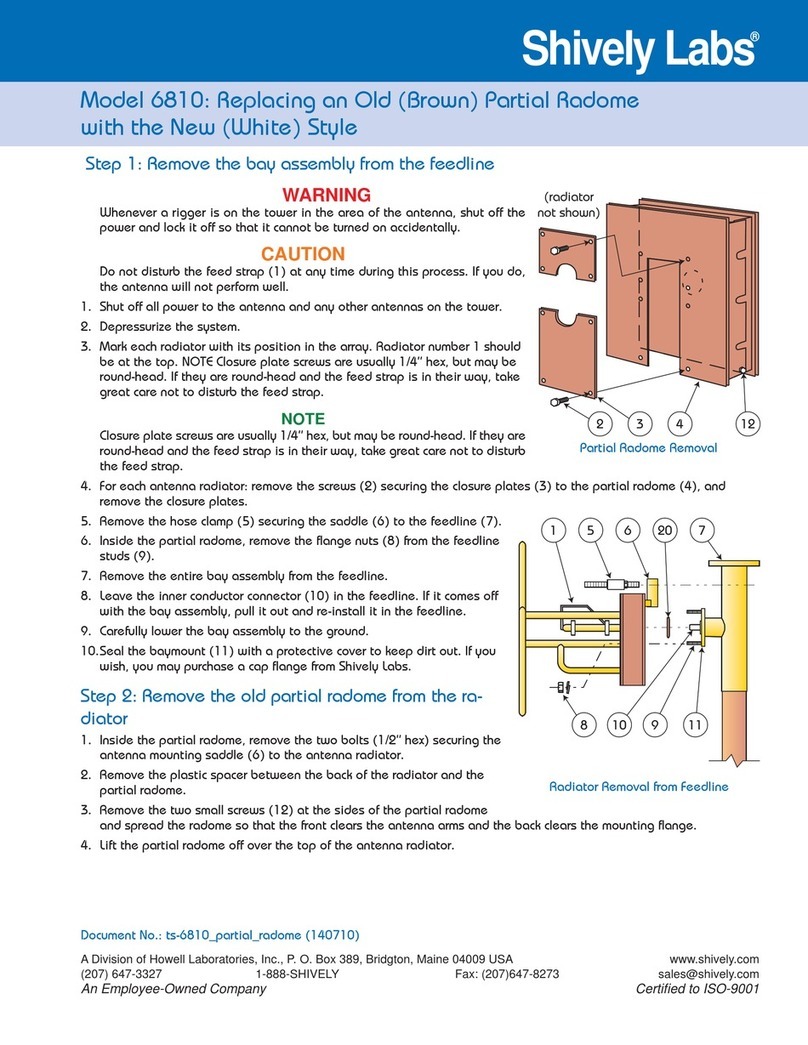

Be very careful to seal the radome completely. If water enters the

radome, the antenna will not perform as expected, and may cause dam-

age to your entire system.

g. Seal the closure plates and the joints where the radome meets the backplate

with the silicone sealant supplied with the antenna.

h. Install the tower mounts (20) onto the backplate, using the box bolts (21).

Manufacturer instructions for the box bolts are included.

Installing the feedline

assemblies on the

tower

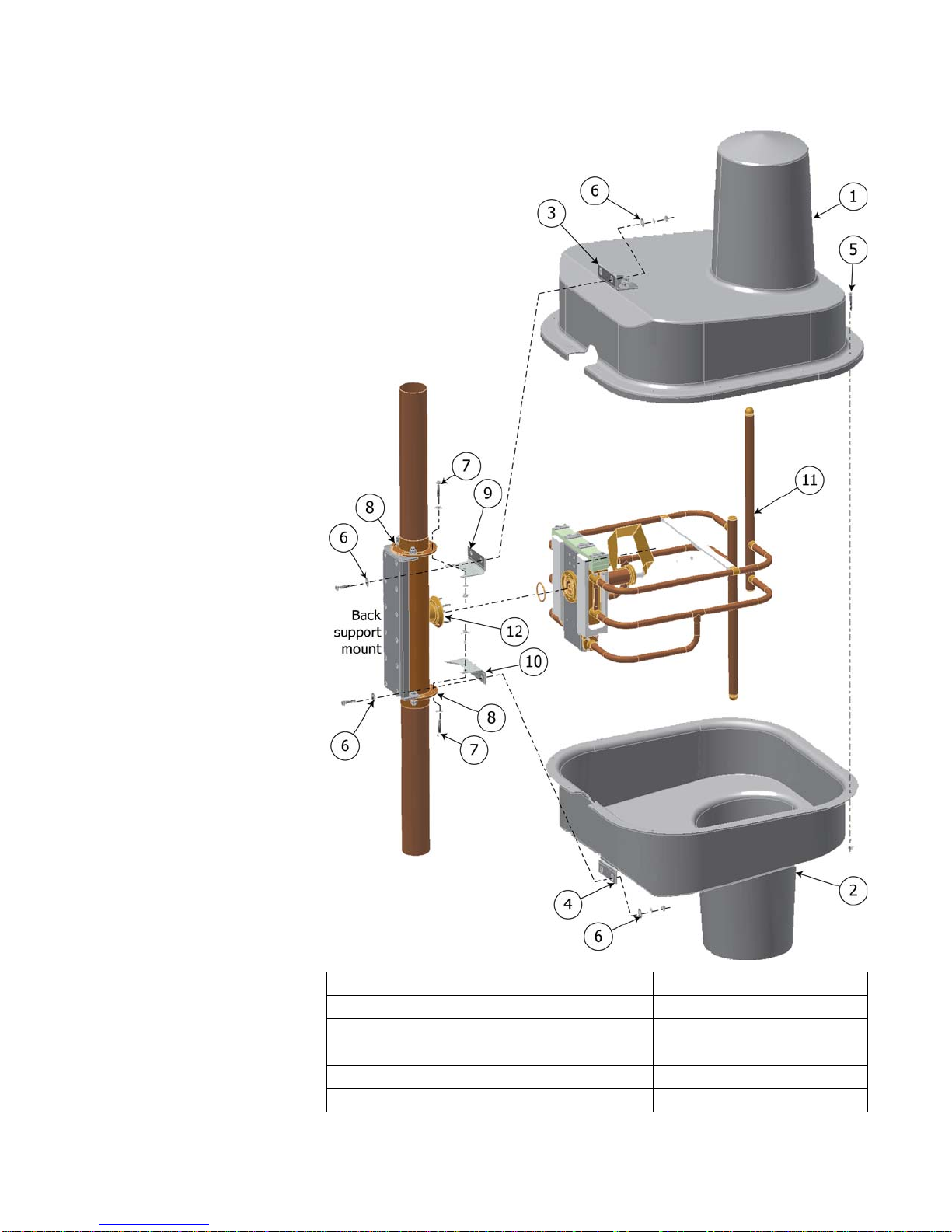

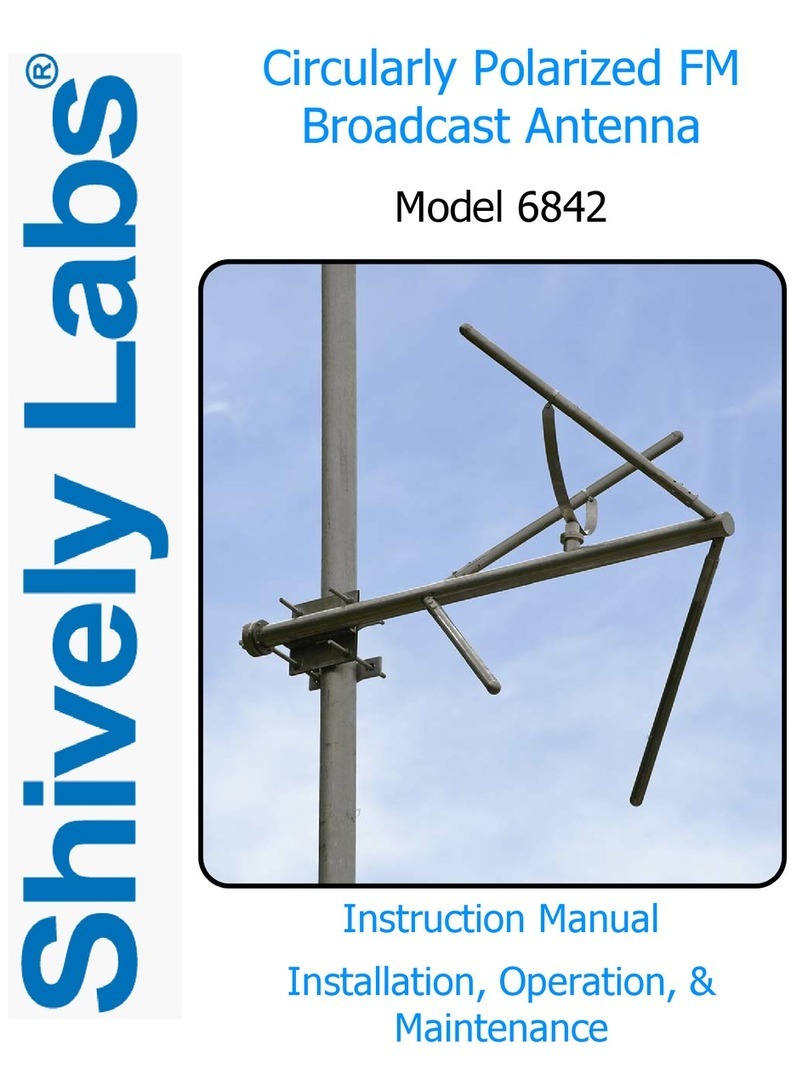

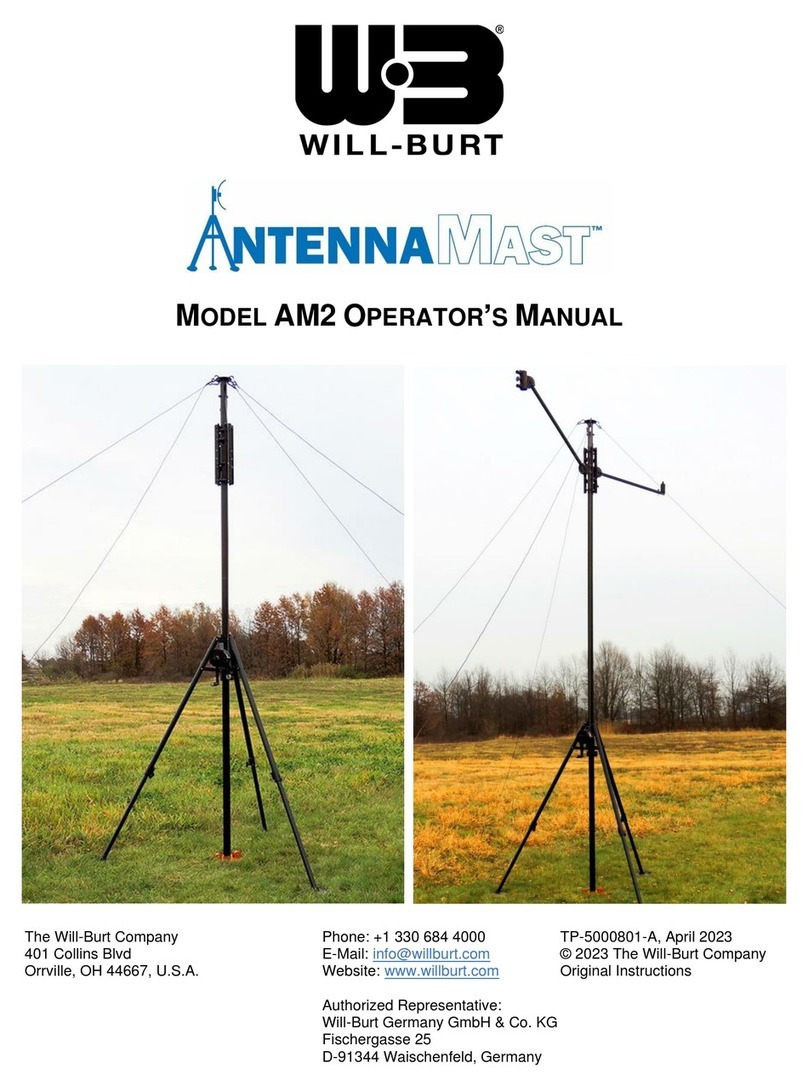

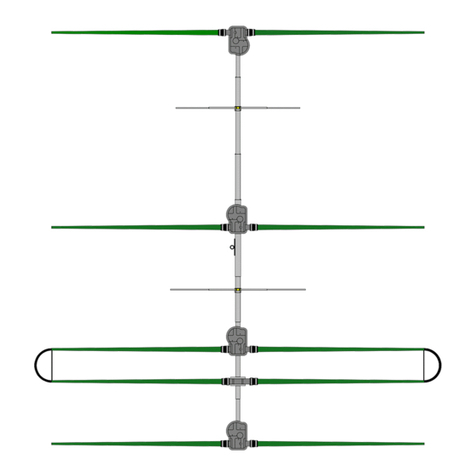

Feedline mounts vary from installation to installation, to accomodate various

tower and mounting pole requirements. Figure 8 shows several common con-

figurations. Your feedline mounts may be one of the common designs shown;

if they are not, they will be shown in detail on your installation drawing.

Before you begin installation, study the mounts, the mounting tower leg(s) or

pole, and your installation drawing carefully, to determine which mount(s) will

be used for each component.

a. Prepare the tower for mounts:

(1) On the tower, starting at the top, use a steel measuring tape to find the

location of each bay in accordance with the installation drawing. Mark

the mount locations.

(2) Mark the specified location of any accessory mounts, such as for the

transformer or special coax input line sections, to make sure they will

fit as planned.

(3) Watch carefully for any interferences by tower members or guy wires

which were not accounted for in the design.

(4) Where the mounts will be in contact with the tower leg(s) or mounting

pole, scrape the tower paint away to ensure good electrical contact.

b. Install the feedline sections:

CAUTION

Feedline flanges are match-marked. Assemble components in accor-

dance with their match-markings (see Figure 9) and the installation

drawing. If you don’t, the antenna will not perform as expected.

CAUTION

Secure each feedline section to its mount before installing the next sec-

tion, tightening in accordance with Figure 3 and Table 1.

(1) Starting at the top of the antenna array, install the feedline and feedline

mounts carefully, in accordance with your installation drawing and the

illustrations in this chapter.

Important!

To avoid damage to the

antenna, always lift, posi-

tion, and attach each sec-

tion individually. Never try

to transport connected

feedline sections! Feedline

is not designed to support

multiple sections and

damage will occur.

Important!

Remove the tower paint

to ensure good electrical

contact between the

mounts and the tower. If

you don’t get good con-

tact, the antenna may not

perform as designed, and

may produce stray signals

that will interfere with

other services on the

tower.