i

Table of Contents

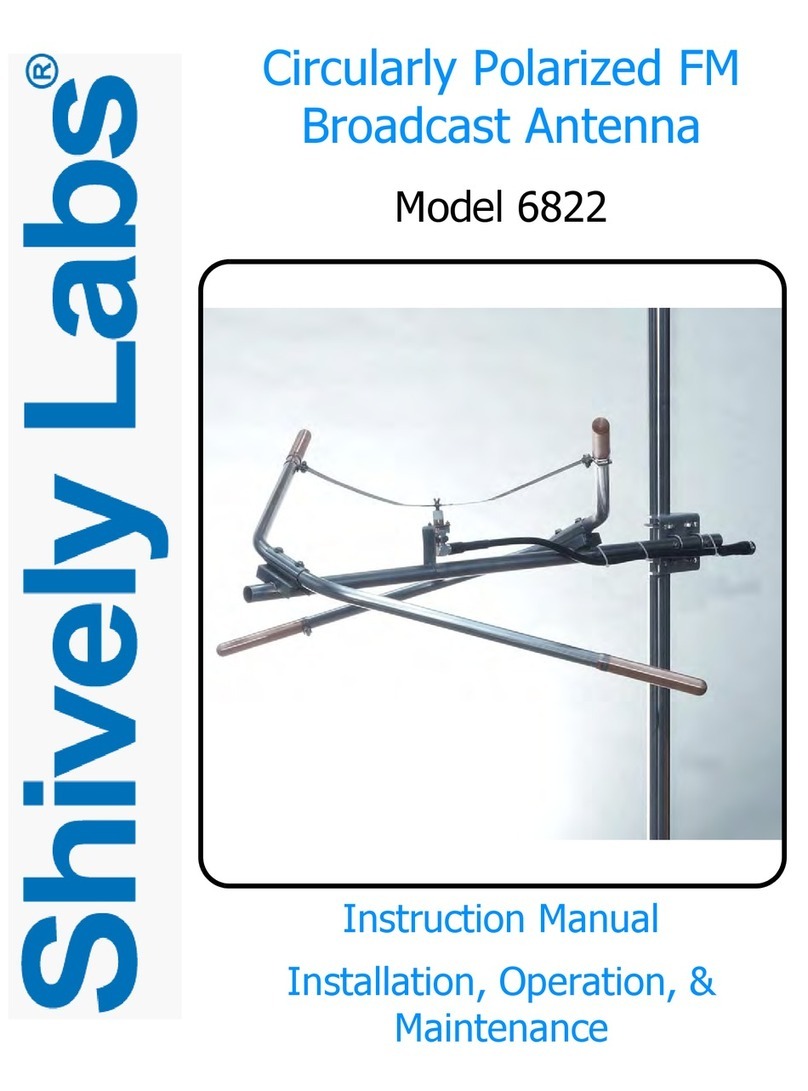

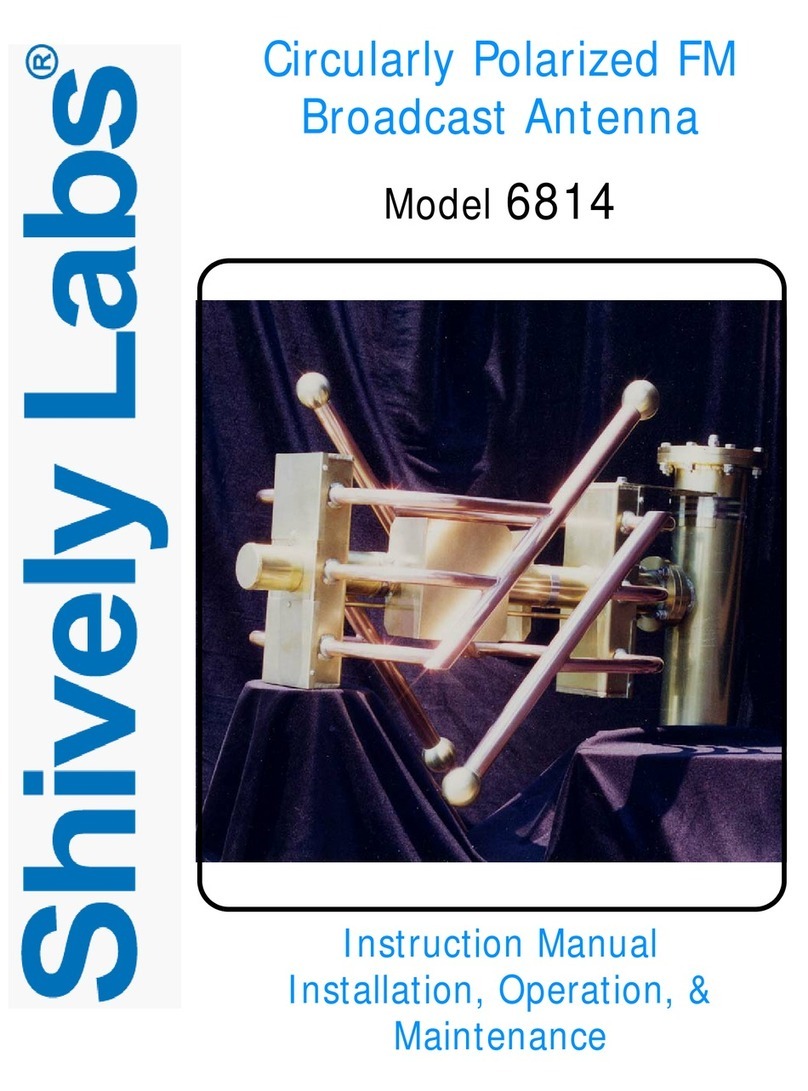

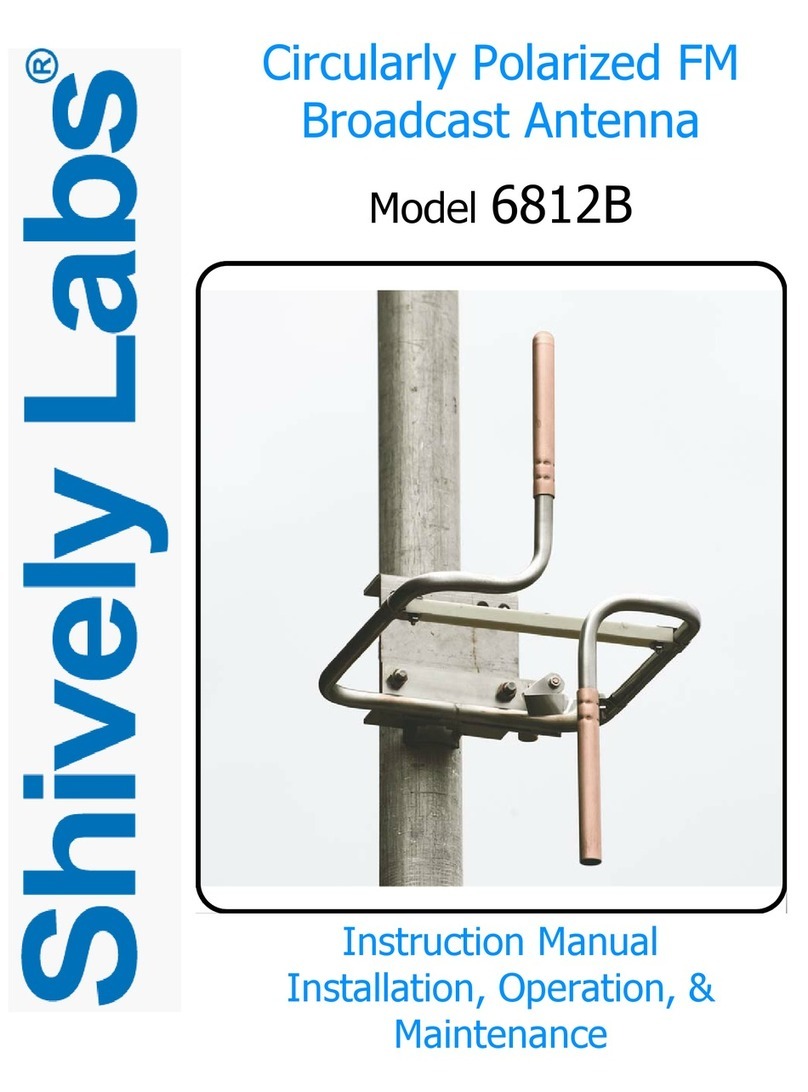

Chapter 1 Preparing for Installation..................................................1

Receiving..............................................................................................1

Unpacking ............................................................................................1

Check the System .................................................................................1

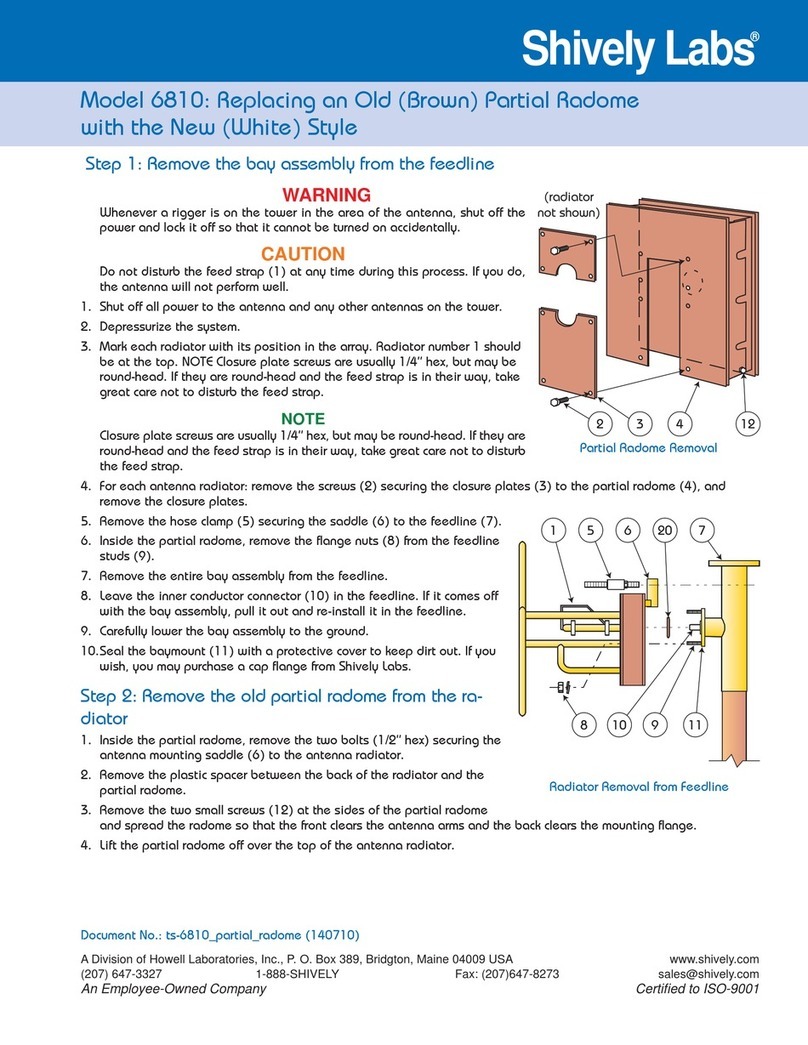

Chapter 2 Installing the Radiators.....................................................3

Before Beginning Radiator Installation:...................................................3

Installation Procedure............................................................................3

Figure 1 Baymount Detail................................................................ 4

Figure 2 Radiator Installation, exploded view.................................... 4

Figure 3 Flange Bolt Tightening Sequences ...................................... 5

Table 1 Torque Specifications, Flange Bolts...................................... 5

Chapter 3 Installing the Radomes (if applicable)..............................7

Before Beginning Radome Installation: ...................................................7

Installation of Radomes.........................................................................7

Figure 4 Radome Installation........................................................... 7

Chapter 4 Installing Feedline and Transformer ................................9

Before Beginning Feedline and Transformer Installation:..........................9

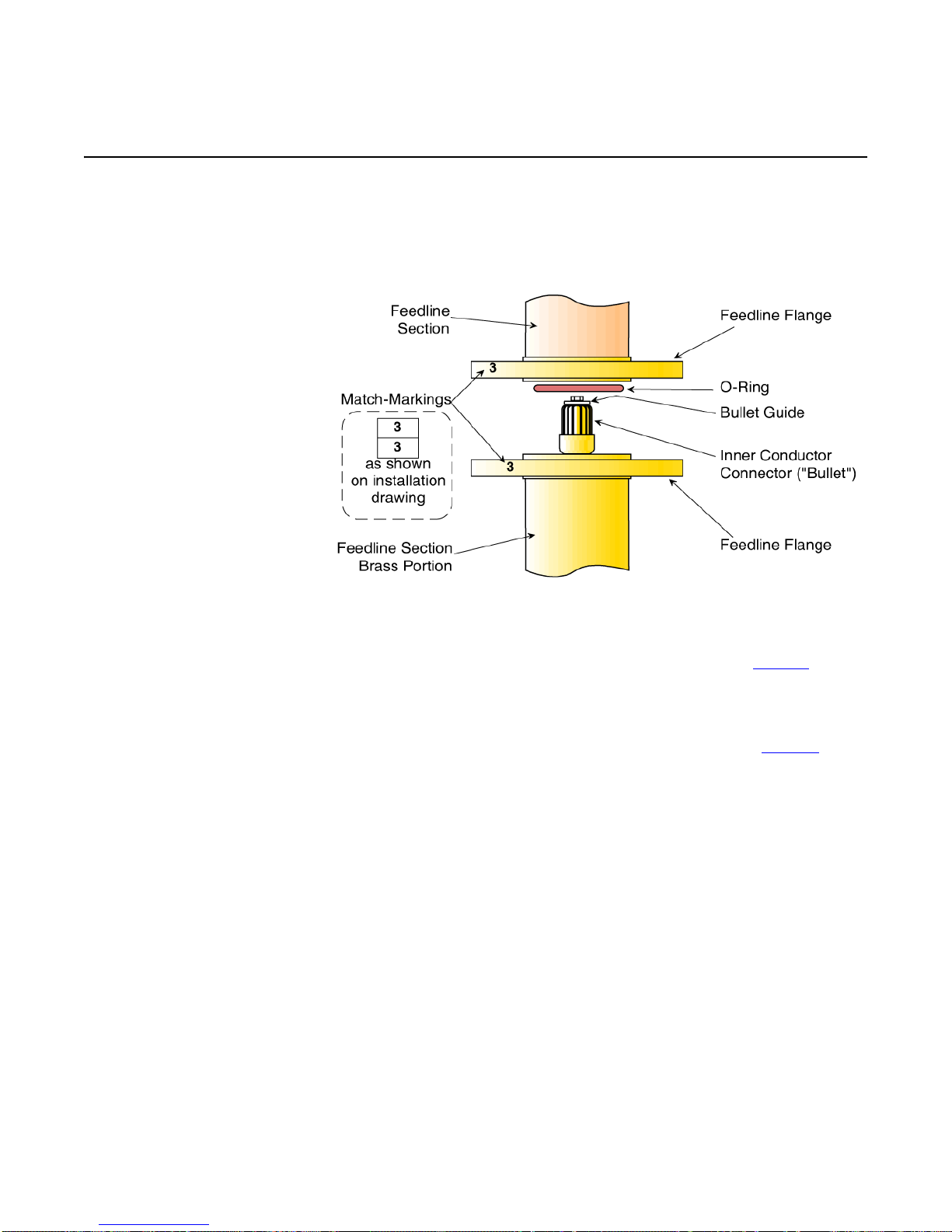

Figure 5 Feedline Flange Detail........................................................9

Installing the Feedline Mounts..............................................................10

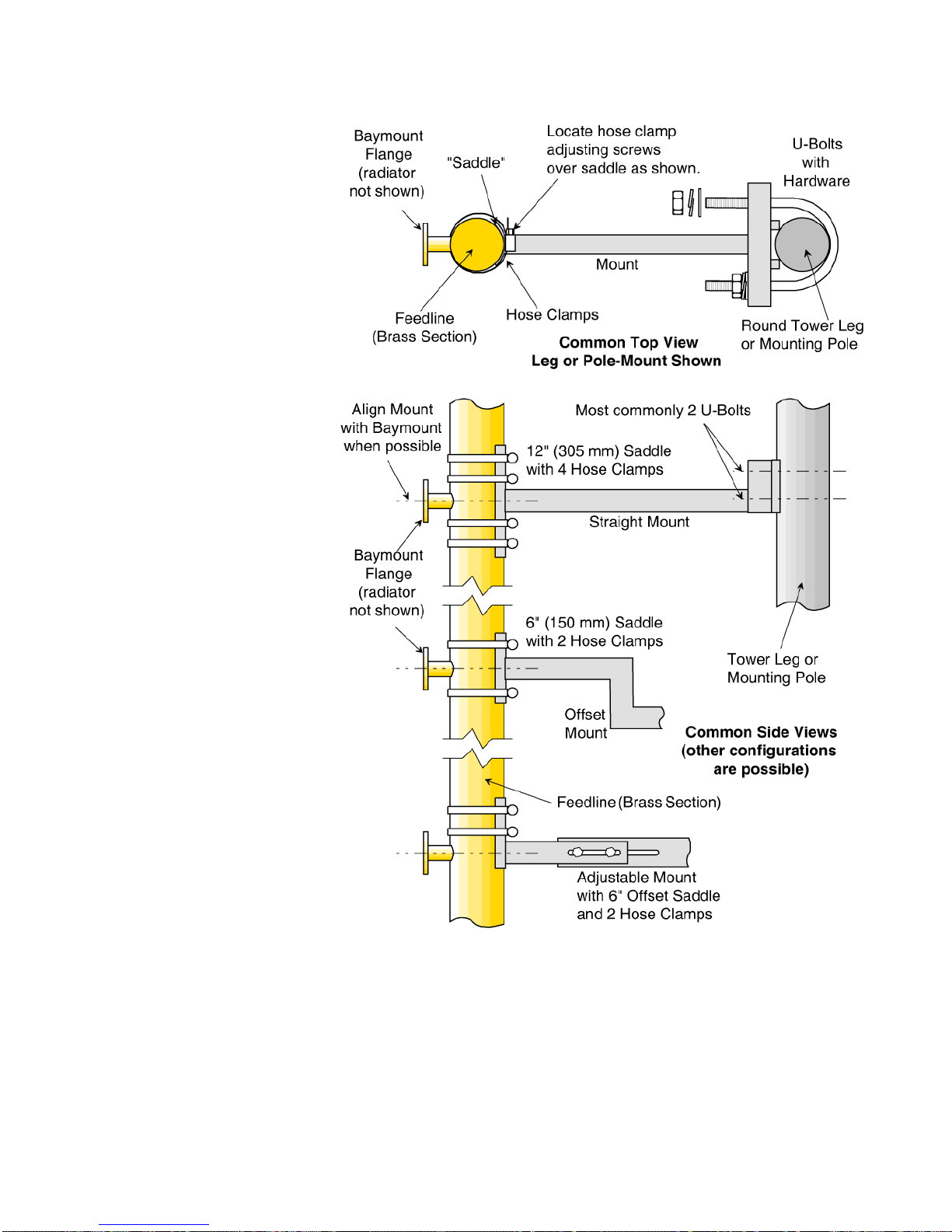

Figure 6 Common Mounting Styles................................................. 10

Installing the Feedline Sections............................................................11

Figure 7 Common Feedline Mount Configurations ........................... 12

Installing the Transformer ...................................................................13

Figure 8 Transformer Installation, top view .................................... 13

Chapter 5 Installing the De-Icer System (if applicable)..................15

Before Beginning De-Icer Installation: .................................................. 15

Installation Procedure.......................................................................... 15

Figure 9 De-Icer Electrical Schematic............................................. 16

Figure 10 Bay Junction Box Installation.......................................... 17

Figure 11 Mounting of Bottommost Bay Junction Box (as needed) ... 17

Figure 12 Shively De-Icer Control Box Layout................................. 18

Figure 13 De-Icer Control Box Electrical Schematic ......................... 19

Table 2 Single Thermostat Readings ............................................. 20

Table 3 Tandem Thermostat Readings .......................................... 20

Table 4 De-Icer Specifications ....................................................... 21

Chapter 6 Startup.............................................................................23

Before Beginning Startup:....................................................................23

Pressurization ..................................................................................... 24

Leak Testing .................................................................................24

Figure 14 Pressurized Gas Schematic............................................. 25

Purging the System....................................................................... 25

Table 5 Volume of Coax per 1000 Feet of Length............................ 26

Leaving the System Pressurized......................................................26