SHOKO SCIENTIFIC Shodex CD-200 User manual

121056

READ

this operation manual

CAREFULLY

before using

Shodex® CD-200 Electric Conductivity Detector.

Electric Conductivity Detecto

r

Operation Manual

®CD-200

Copyright C 2011-2012, SHOKO SCIENTIFIC CO.,LTD. Printed in Japan.

All rights reserved. Contents of this publication may not be reproduced in any form or by

any means (including electronic storage and retrieval or translation into a foreign language)

without prior agreement and written consent from the copyright owner.

Notice

Users of Shodex®

CD-200

Electric Conductivity Detector (hereinafter Shodex

CD-200

) are requested to use it in strict accordance with the instructions in this manual.

Nothing contained in this manual shall be construed as giving any guarantee on

Shodex

CD-200

or granting or implying any license or immunity under any patent

or other rights.

Shodex

CD-200

must be used on the user's own responsibility and in strict

compliance with all applicable laws and regulations.

The information contained in this operation manual was obtained from sources

that we believe are reliable, but no warranty or representation is hereby given

as to its accuracy or completeness.

This operation manual does not expect Shodex

CD-200

to be used for clinical or

medical purposes. Shodex

CD-200

must not be used for such purposes.

The content of this operation manual is subject to change without notice.

Notice that the parts supply period for this product is 7 years from the end of

production. Please be aware that replacement parts may not be available beyond the

parts supply period.

Warranty

Except for a written warranty signed by its duly authorized representative and

specifically issued, SHOKO SCIENTIFIC CO.,LTD. makes no warranty,

express or implied,

written or oral, statutory or otherwise, as to the quality, performance,

workmanship,

fitness for a particular purpose, or merchantability of Shodex

CD-200

.

Precautions

Thank you for your continued patronage. Observe the following precautions

in order to make safe and stable use of the detector.

Precautions are divided into three groups in this operation manual,

depending on the degree of danger. The three groups are

: This sign is used where failure to follow strictly the instructions

and procedures indicated by this sign may cause injury or

damage to health.

: This sign is used where failure to follow strictly the instructions

and procedures indicated by this sign may cause this detector

and the peripheral apparatus to deteriorate or break down.

: This sign is used wherever information is given to ensure optimal

performance of the detector.

Precautions listed below are those of particular importance extracted

from

this operation manual :

Do not use the detector in places where combustible gas or any

source of fire or spark exists or might exist.

Prior to connection, make sure that the voltage of the power

socket into which the detector power cable is plugged is the

same as the power supply voltage indicated on the detector.

The power socket into which the detector power cable is

plugged should be of a 3P type with a grounding terminal.

Other types of power sockets should not be used.

When using organic solvent, wear safety goggles.

It is recommended that a sink or equipment for washing the eyes

be installed nearby in case the organic solvent in use comes into

contact with the eye(s) or skin.

When any abnormality, such as liquid leakage, is observed, immediately

turn off the power and unplug the detector from the main power

source.

!

Warning

Caution

Note

!

Warning

!

Warning

!

Warning

!

Warning

[ Important

! ]

!

Warning

Do not use the detector with the cover open; always unplug the

detector from the main power source before opening the cover.

If the detector is used in a manner not specified by this operation

manual, the protection provided by the detector may be impaired.

When using flammable organic solvent as mobile phase, be sure

to make necessary arrangement to prevent accidental ignition

(fire) by static electricity.

If the fuse blows after being replaced, power off the detector

immediately and disconnect the power cord. Please consult

our local representative in your area or SHOKO SCIENTIFIC.

As this detector is readily affected by the ambient temperature, use

it in places where there is little wind or change in the ambient

temperature. Do not use the detector near any source of vibration,

electrical noise, or in places where corrosive gas and a lot of dust

are present.

External input/output terminals are for contact closure.

Never apply voltage to them.

Do not connect any tube other than the provided "OUT tube"

to the eluent outlet joint of the detector. Put the exit end of

the "OUT tube" in the waste liquid bottle and do not apply back

pressure.

When connecting this detector to other detectors in series, put

it at the end.

Make sure that no back pressure is applied to the outlet of the

detector. Connect the tip of the Teflon tube on the cell outlet of the

detector to a receptacle for waste liquid.

If eluent freezes inside the detector, the flow line might break,

damaging the detector. If there is any chance of eluent freezing

during stoppage or storage of the detector, withdraw the eluent

completely from the flow line of the detector.

When using any eluent containing a salt at high concentration, make

sure that the flow line is washed with water thoroughly after use

.

Failure to do so may result in plugging of the line, causing the

detector to cease operation.

If the detector is not to be used for more than one week, prior

to storage, wash the flow line with pure water or acetone, and dry

the line by allowing nitrogen gas to flow through it.

Do not use any eluent which might corrode the material, such as

stainless steel, that it comes into contact with. Use of such eluent

might cause a base line drift and damage the detector.

Caution

Caution

Caution

Caution

Caution

Caution

Caution

Caution

!

Warning

!

Warning

!

Warning

!

Warning

Caution

Use a thoroughly degassed eluent. It is recommended that a degassing

device be used to degas the eluent, as it is easy to use and permits

continuous degassing.

If an eluent is replaced with another eluent, replace all channels of the ion

chromatograph with new eluent. When eluent replacement is not sufficient,

it may become the cause of an unstabilized baseline.

When high voltage caused by static electricity is applied to the instrument,

some incorrect actions may be observed. Please take note of static

electricity.

Please do not set other equipment on this detector, in order to avoid

enlarging the baseline drift and losing control of the temperature.

Note

Note

Note

Note

Contents

1 . Accessories ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 1

2 . Features ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 2

3 . Specifications ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 3

4 . Measuring mechanism ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 4

4-1 Detecting System ・・・・・・・・・・・・・・・・・・・・・・ 4

4-2 Electric System ・・・・・・・・・・・・・・・・・・・・・・ 5

5 . Nomenclature and Functions ・・・・・・・・・・・・・・・・・・・・・・ 6

5-1 Front Panel ・・・・・・・・・・・・・・・・・・・・・・・・・・ 6

5-2 Side Panel ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 7

5-3 Back Panel ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 8

5-4 Display ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 10

6 . Installation and Connections ・・・・・・・・・・・・・・・・・・・・・・ 13

6-1 Power Connection and Grounding ・・・・・・・ 13

6-2 Signal cable Connections ・・・・・・・・・・・・・・・・ 14

6-3 Tube Connections ・・・・・・・・・・・・・・・・・・・・・・ 15

6-4 Operation Procedures ・・・・・・・・・・・・・・・・・・・・ 16

7 . Maintenance ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 18

7-1 Flow Line Cleaning ・・・・・・・・・・・・・・・・・・・・・・ 18

7-2 Replacing Fuse ・・・・・・・・・・・・・・・・・・・・・・・・ 18

7-3 Cleaning of detector

exterior ・・・・・・・・・・・・・ 18

8 . Troubleshooting ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 19

9 . WEEE Instructions ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 20

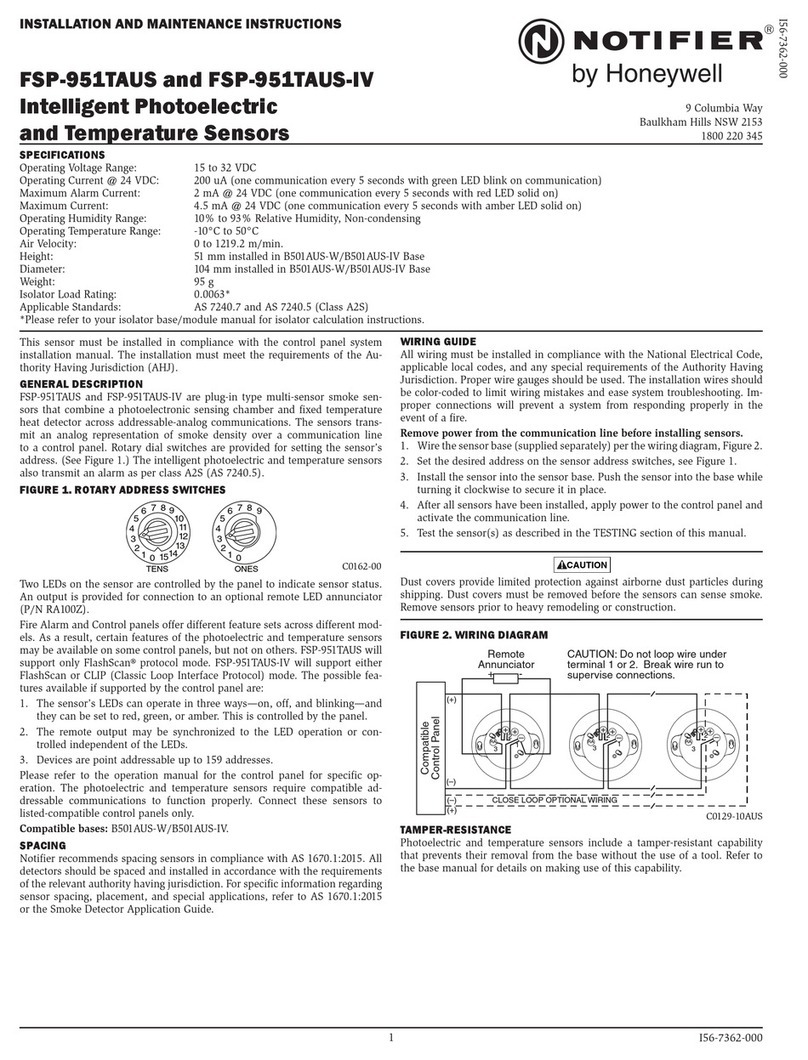

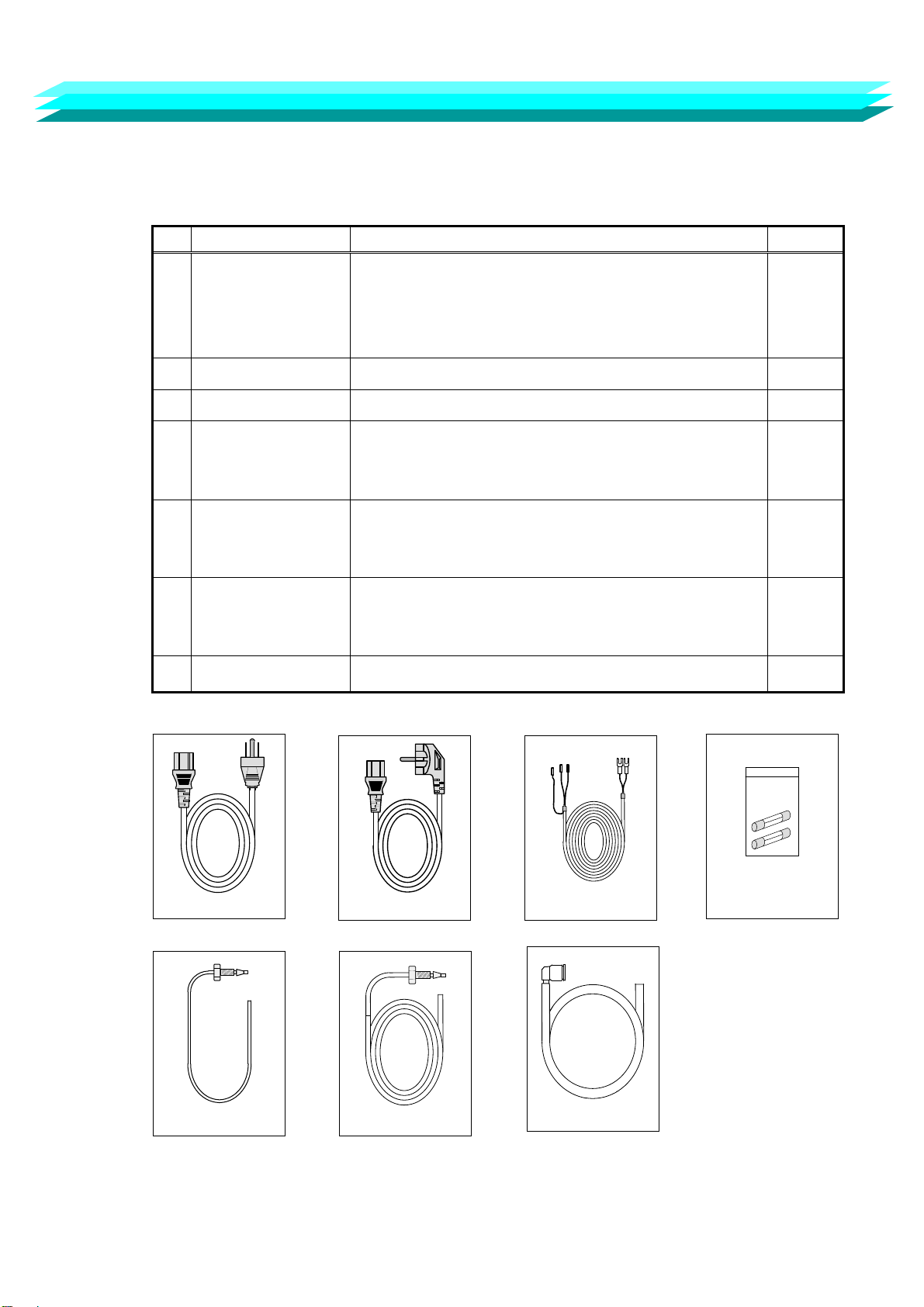

1. Standard accessories

When unpacking, please verify that all the following accessories are included:

【 Details of Accessories 】

No. Name Specification Quantity

1 Power cable

3-core cord with a grounding electrode (100V)

(1) For voltage of 100 or 120 VAC

Power supply cable set (125 V)

(2) For voltage of 220 or 240 VAC

Power supply cable set (250 V)

1*

2 Signal cable 2-core shield cable (approx. 2 m) 1

3 Fuse Time-lag type 500 mA (T500 mA L/250 V)

4 IN tube set

Teflon tube of 1.6 mm outer dia. x 0.25 mm inner dia.

x 1000 mm length

(PEEK setscrew with ferrule attached)

1

5 OUT tube set

Teflon tube of 2.5 mm outer dia. x 1.5 mm inner dia.

x 2000 mm length

(connecting tube, setscrew, and ferrule attached)

1

6 Discharge

tube set

Silicone rubber tube of 10 mm outer dia. x 7 mm

inner dia. x 2000 mm length

(connection joint attached)

1

7 Operation manual 1

*: Either 1-(1) or 1-(2) is attached according to the power supply voltage at the first destination.

When unpacking, please verify that all the following accessories are included:

- 1 -

1-(1) 1-(2)

4

3

5

2

6

2. Features

Shodex CD-200 is an Electric Conductivity Detector for HPLC and has the following features:

1) Stability

The double temperature control system provides for a very fast start up time

and excellent stable baseline performance.

2) Safety

Solvent leak sensor generates an output signal that stops pump flow in case of

an eluent leak within the detector.

3) Integration

Well-organized Output signal terminals and USB communication port guarantee

high-level integration and automation in conjunction with your HPLC system.

- 2 -

3. Specifications

1) Measuring method : Two-electrode system

2) Measuring limits : 0-600 mS/m

3) Measuring range : 0.0025-5.12/0.025-51.2/0.25-512 mS/m (12 steps)

4) Linearity range : 0-600 mS/m

5)

Noise

:

< 0.0005 mS/m (response; 1 sec) or less

(2.5 mM phthalic acid ; pH 4.0 ; 1.5 ml/min.)

6) Response : 0.1, 0.25, 0.5, 1.0, 1.5, 2, 3, 6 seconds

7) Zero adjustment : Automatic zeroing

8) Base line shift : Limit; 0-2 mS/m, Resolution; 0.01mS/m

9) Integrator output : 0-1 V (Sensitivity; 2/20/200 mV/mS/m)

10) Recorder output : 0-10 mV (for each range)

11) External contact input : ZERO IN/MARKER IN

12)

External contact output

:

・READY (Temperature control stabilized)/LEAK/

・ERROR (ROM/RAM/PARAMETER/LEAKAGE/ SENSOR

ERROR/OVER HEAT/ZERO OVER/ COMUNICATION)/

・MARKER OUT

(Contact capacity : 24 VDC, 0.1 A )

13)

Temperature control

:

OFF, 30-50℃ in increments of 1℃ (with a 77℃ thermal

fuse)

(Note) External cylinder is adjusted to a temperature

that is 5℃ lower than setting temperature.

14) External communication : USB

15) Cell volume : approx. 2.5 μl

16) Pressure rating : 1 MPa

17) Wetted part material SUS316, PTFE, PEEK

18)

Dead volume

:

Inlet → Cell ; approx. 75 μl

Cell → Outlet ; approx. 25 μl

Total dead volume ; approx. 103 μl

19) Power supply : 100-240 VAC ± 10% , 50/60 Hz

20) Demand : approx. 50 VA

21) Outside dimensions : approx. 260W x 400D x 150H mm (excluding rubber footing)

22) Weight : 8 kg

- 3 -

(OUT)

ElectrodeⅠ

Electrode Ⅱ

Heat exchangers

Internal cylinder (adjusted to the

setting temperature)

External cylinder (adjusted to the

temperature of 5°C lower than the

setting temperature)

AC

oscillator

I/V

converter

Synchronous

rectifier

Conductivity

signal

Signal

processor

Eluent

IN

Spacer

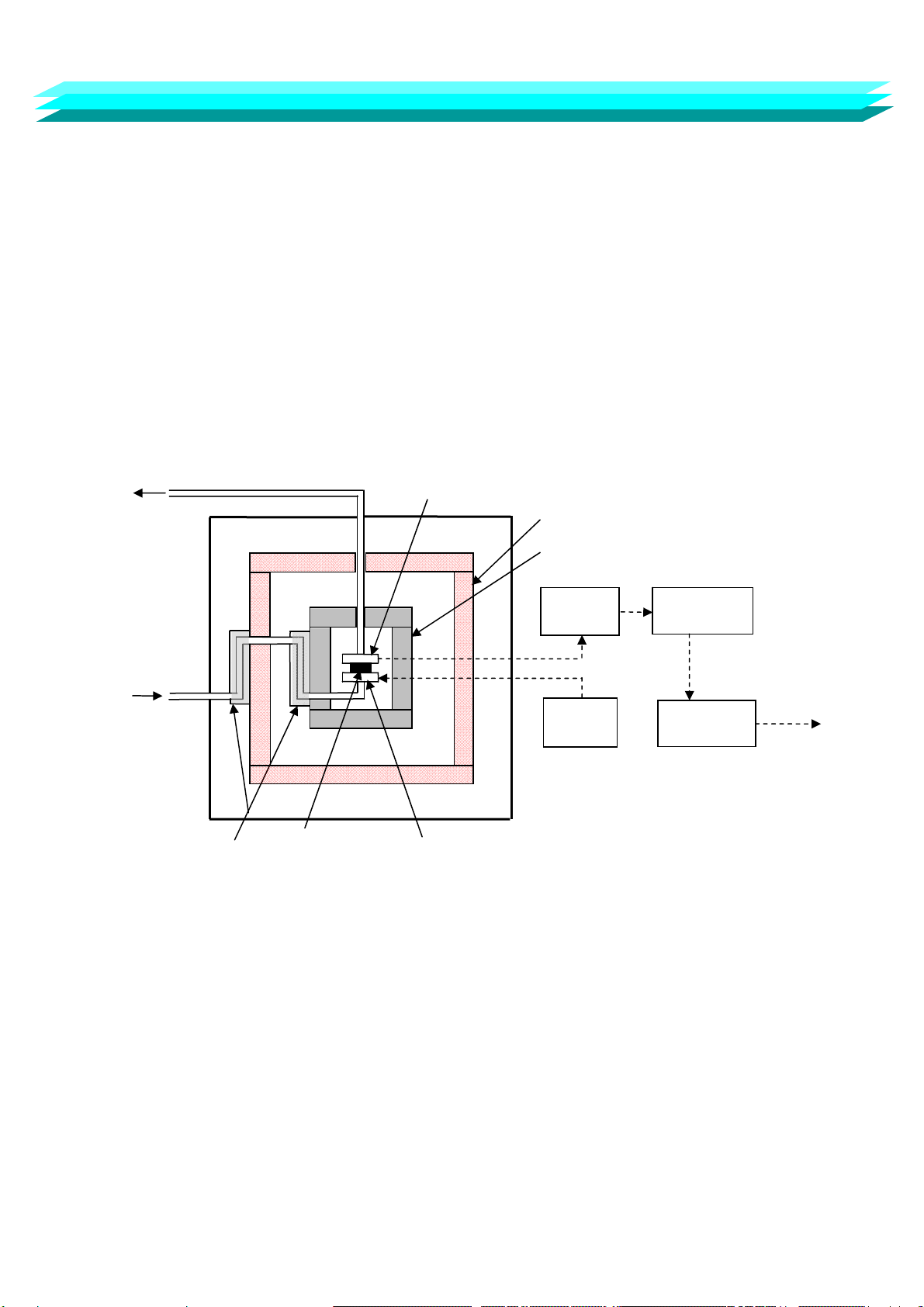

4. Measuring mechanism

4-1 Detecting system

This detector has adopted a two-electrode system, and the detection cell and flow line are as shown

in Fig. 4-1.

In Fig. 4-1, a current proportional to the electrical conductivity of eluent is output from electrode I

when an ac voltage is applied to electrode II. This current signal is output as the electrical

conductivity signal through an I/V converter, a synchronous rectifier, and a signal processing circuit.

In addition, the temperature dependence of eluent is large, and in order for the electric conductivity

of eluent to minimize this effect, the detection cell is contained in an inner cylinder which is adjusted

to the setting temperature, and the inner cylinder is contained in an outer cylinder which is adjusted

to a temperature that is 5℃ lower than the setting temperature.

In addition, two heat exchangers are prepared in the inner cylinder and the outer cylinder,

respectively, so that the temperature of eluent may attain the setting temperature.

Fig. 4-1 Measuring system

- 4 -

Cell

I/V converter

Synchronous rectifier

AC oscillator A/D converter for display

Coarse zero circuit

Sensitivit

y

settin

g

circuit

Precision A/D converter

Digital signal processing circuit

Display/keyboard

Integrator output circuit

Recorder output circuit

Communication port

External input/output circuit

Internal cylinder temperature

sensor/heater

External cylinder temperature

sensor/heater

Internal cylinder

Temperature controller

External cylinder

Temperature controller

4-2 Electric system

The electric system of Shodex CD-200 consists of an oscillator (generating AC voltage),

a signal processing circuit, a display/keyboard circuit, and two temperature control circuits.

Fig 4-2 shows a block diagram of the electric system.

The oscillator applies AC voltage to the cell, generating an electric AC current proportional to

the electrical conductivity of the eluent, in the cell electrode. The current is converted into

a voltage signal by the I/V converter. Then the voltage signals are converted by the synchronous

rectifier into DC voltage signals which depend on electrical conductivity of the eluent.

This DC voltage signal is displayed as electrical conductivity of eluent, and converted to a precision

digital signal after passing through the coarse zeroing circuit and the integrator range setting circuit.

This precision digital signal is transferred to the digital signal processing circuit.

This precision digital signal is processed for response setting, automatic zeroing, polarity setting,

base line shift, marker summation, and output for Integrator output, recorder output, and

communication port output as a differential electrical conductivity voltage signal.

The temperature control circuit for the internal cylinder is kept at a private temperature, and the

temperature control circuit for external cylinder is kept at a temperature which is 5 degrees

lower than private temperature.

Fig. 4-2 Electrical System

- 5 -

5. Names and functions of parts

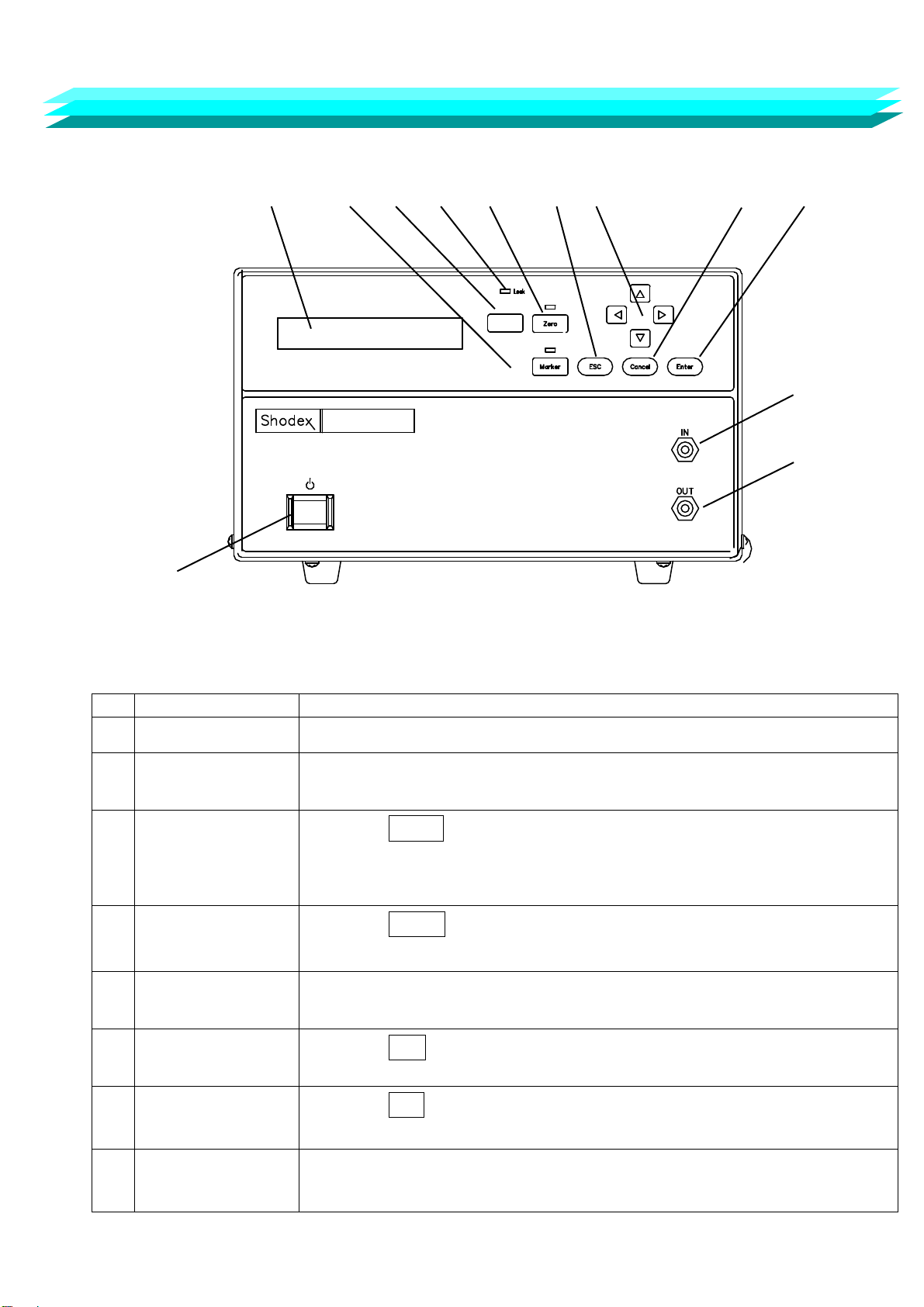

5-1 Front Panel

□

2 □

3

□

4

□

5

□

6 □

7

□

8

□

9 □

10

□

11

□

12

□

1

Fig. 5-1 Front Panel of Shodex CD-200

No. Name of part Function

□

1 Power Switch Press this key once to turn the unit on or off.

□

2 LCD Display A 24-digit 2-row character display panel. This is used for

displaying or setting various parameters.

□

3 Marker key

[Marker]

Press the Marker key to generate an event marker signal and add it

to the recorder output. While this function is active, the LED above the

key will be lit.

□

4 Display change key

[Display]

Press the Display key to toggle between S display and ΔS.

□

5 Leak LED

[Leak]

Illuminated when solvent leak is detected.

□

6 Auto Zero Key

[Zero]

Press the Zero key to activate “Auto-Zero”. While this

Function is active

,

the LED above

t

he ke

y

will be lit.

□

7 ESC Key

[ESC]

Press the ESC key to cancel an operation and return to the

normal screen.

□

8 Arrow Keys

[▲▼

▲

▼

]

Press the Arrow keys to move cursor or to edit values.

- 6 -

CD-200

Conductivity Detector

Display

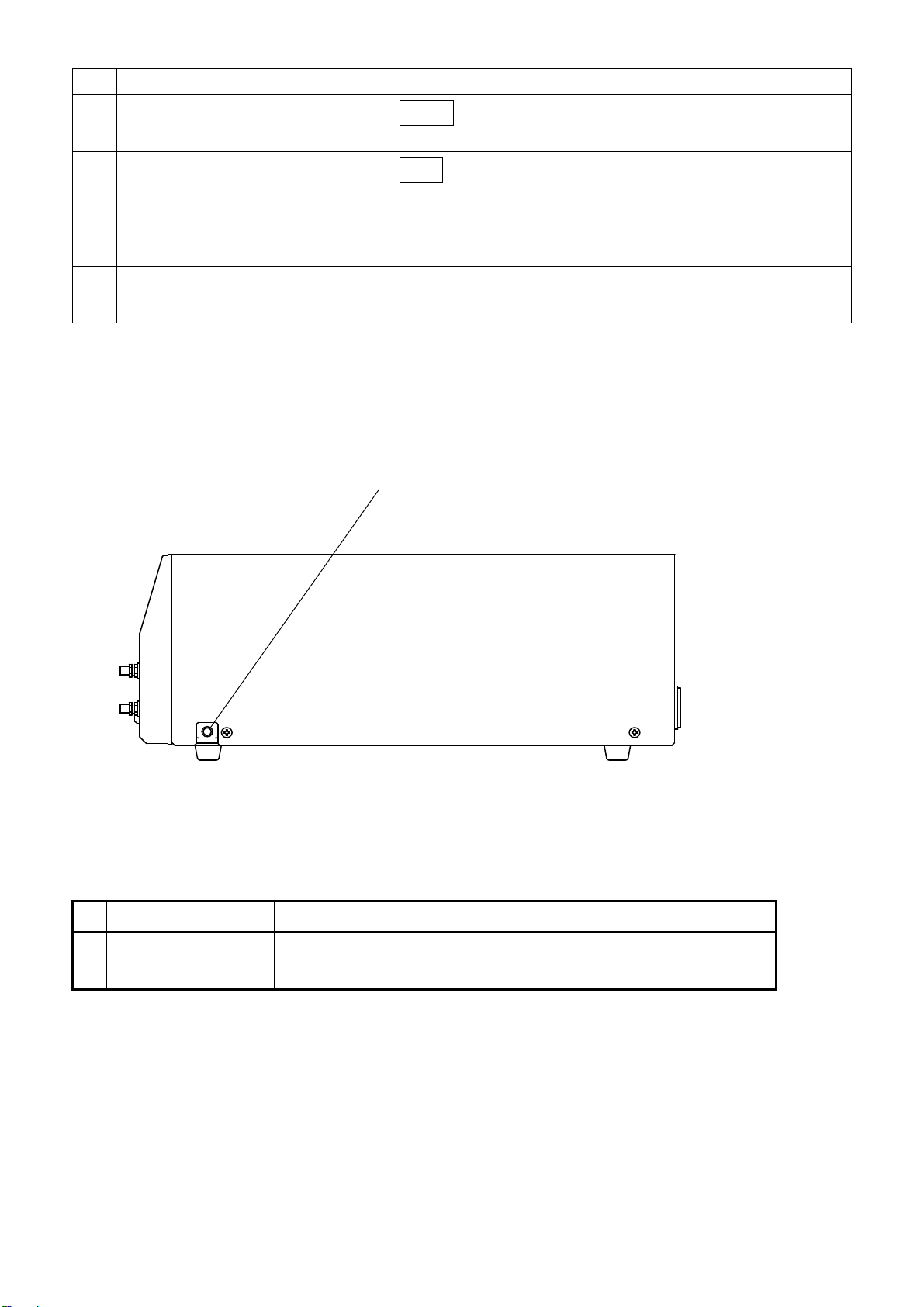

5-2 Side Panel

□

13

Fig. 5.2 Side panel of Shodex CD-200

No. Name of part Function

□

13 Drain Port In case of internal eluent leak, the eluent will be discharged from

this port. Connect the attached tubing as necessary.

- 7 -

No. Name of part Function

□

9 Cancel Key

[Cancel]

Press the Cancel key to cancel change and to stop beeping.

□

10 Enter Key

[Enter]

Press the Enter key to finalize operations or settings.

□

11 Inlet Port

[IN]

Connects tubing from separation column outlet.

□

12 Outlet Port

[OUT]

Eluent passing through the flow path is discharged from this port.

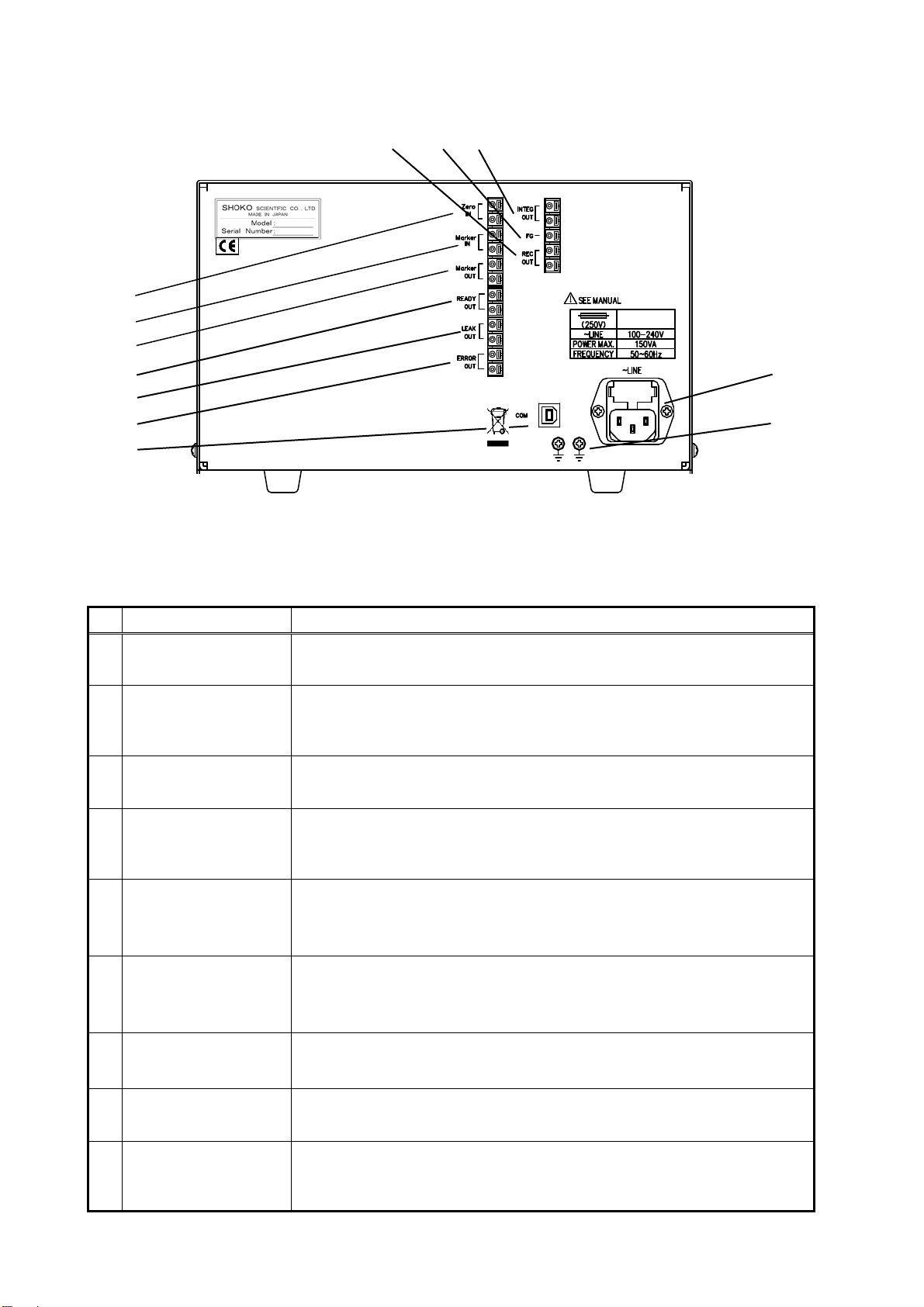

5-3 Back Panel

□

21 □

22 □

23

□

20

□

19

□

18

□

17 □

24

□

16

□

15 □

25

□

14

Fig. 5.3 Back panel of Shodex CD-200

No. Name of part Function

□

14 Communication port

[COM] USB communication port

□

15 Error out terminals

[ERROR OUT]

A contact signal is sent out through these terminals when

an error occurs.

□

16 Leak out terminals

[LEAK OUT]

A contact signal is sent out through these terminals when

an eluent leak is detected.

□

17 Ready out terminals

[READY OUT]

A contact signal is sent out through these terminals when

10 minutes have passed since the temperature of the cell has

reached the designated value.

□

18

Marker output

terminals

(MARKER OUT)

A contact signal (approx. a quarter second in duration) is sent out

through these terminals when marker is in operation.

□

19

Marker input

terminals

(MARKER IN)

Shortcircuiting these terminals gives the same effect as pushing

the marker switch (□

3).

□

20 Zero terminals

(ZERO)

Shortcircuiting these terminals gives the same effect as pushing

the zero switch (□

6).

□

21 Recorder terminals

[REC. OUT]

Signals to the recorder are sent out through these terminals.

The sensitivity of the output signal is 10 mV/FS.

□

22

Ground terminal

for the signal cable

[FG]

The shield terminal of the signal cable should be connected to

this terminal.

- 8 -

CD-200

T2.0A

No. Name of part Function

Integrator terminals

[INTEG. OUT]

Signals to the data processing unit are sent out through these

terminals. The sensitivity of the output signal is 200, 20, or 2

mV/(mS/m) with the integrator range of 5.12, 51.2, or 512 mS/m/FS .

Power connector

[~LINE]

The included power cable should be plugged into this connector.

Ground terminals

[ ]

These are the terminals to ground the main body of the detector.

- 9 -

□

23

□

24

□

25

5-4 Display

The display shows a “Monitor screen” when the detector is started and can be switched

to a “Parameter setting screen” when the W key or the X key is pressed.

<Monitor screen> <Parameter setting screen>

X S 123.4 mS/m 45℃ X * PARAMETERS * X

W RD W * SETTING * W

<Monitor screen>

□

26 □

27 □

28 □

29 □

30

AA

XXX.X mS/m XX ゚C

AAAAAAAAAAAAAAAA AA

No. Function

□

26 When the nominal value of conductivity displayed in □

27 is the electrical

conductivity of a background, "S" is displayed, and when the displayed value is

differential conductivity, "ΔS" is displayed.

□

27 This indicates whether the displayed value is electrical conductivity of a background

or differential conductivity.

□

28 This indicates the temperature of the cell.

□

29

This indicates error or operation status.

If there are multiple messages to be displayed, the priority message is displayed.

(1) ROM : Is displayed when a ROM error has occurred.

(2) RAM : Is displayed when a RAM error has occurred.

(3) PARAMETER : Is displayed when a parameter memory error has occurred.

(4) LEAKAGE : Is displayed when eluent leakage has occurred.

(5) SENSOR ERROR : Is displayed when the temperature sensor has a problem.

(6) OVER HEAT : Is displayed when the temperature is excessively high.

(7) ZERO OVER: Is displayed when Auto Zero does not function correctly.

(8) COMMUNICATION : Is displayed when a communication error has occurred.

(9) TEMP. UNSTABLE : After the detector is started, this remains displayed

until the temperature remains within ± 1°C of the set

temperature for 10 minutes.

□

30

One of the following is displayed in response to the detector status.

(1) LK : Key Lock status

(2) ER : Error status

(3) RD : Stable temperature status

- 10 -

<Parameter setting screen>

To show the currently set parameters in order, press the ▼ key or the ▲ key

while the parameter setting screen is displayed.

▼ ▲

▼ ▲

▼ ▲

▼ ▲

▼ ▲

▼ ▲

▼ ▲

▼ ▲

▼ ▲

▼ ▲

▼ ▲

- 11 -

PARAMETERS

REC.RANGE XXX mS/m

PARAMETERS

TEMPERATURE XX ℃

PARAMETERS

TIME CONSTANT X.X sec

PARAMETERS

POLARITY A

PARAMETERS

BASELINE SHIFT XXX

PARAMETERS

LEAK SENSOR AA

PARAMETERS

KEY LOCK AAA

PARAMETERS

DEFAULT AAA

PARAMETERS

INTEG.RANGE XXX mS/m

* PARAMETERS *

* SETTING *

To change parameters, perform the following procedures:

(1) Display the relevant parameter.

(2) Press the Enter key. The underlined digits will flash and the parameter can be changed.

(3) Press the T key or the S key to change the parameter with reference to Table 5-1.

(4) Press the ENTER key to finalize the parameter.

(5) Press the ESC key to return to the monitor screen.

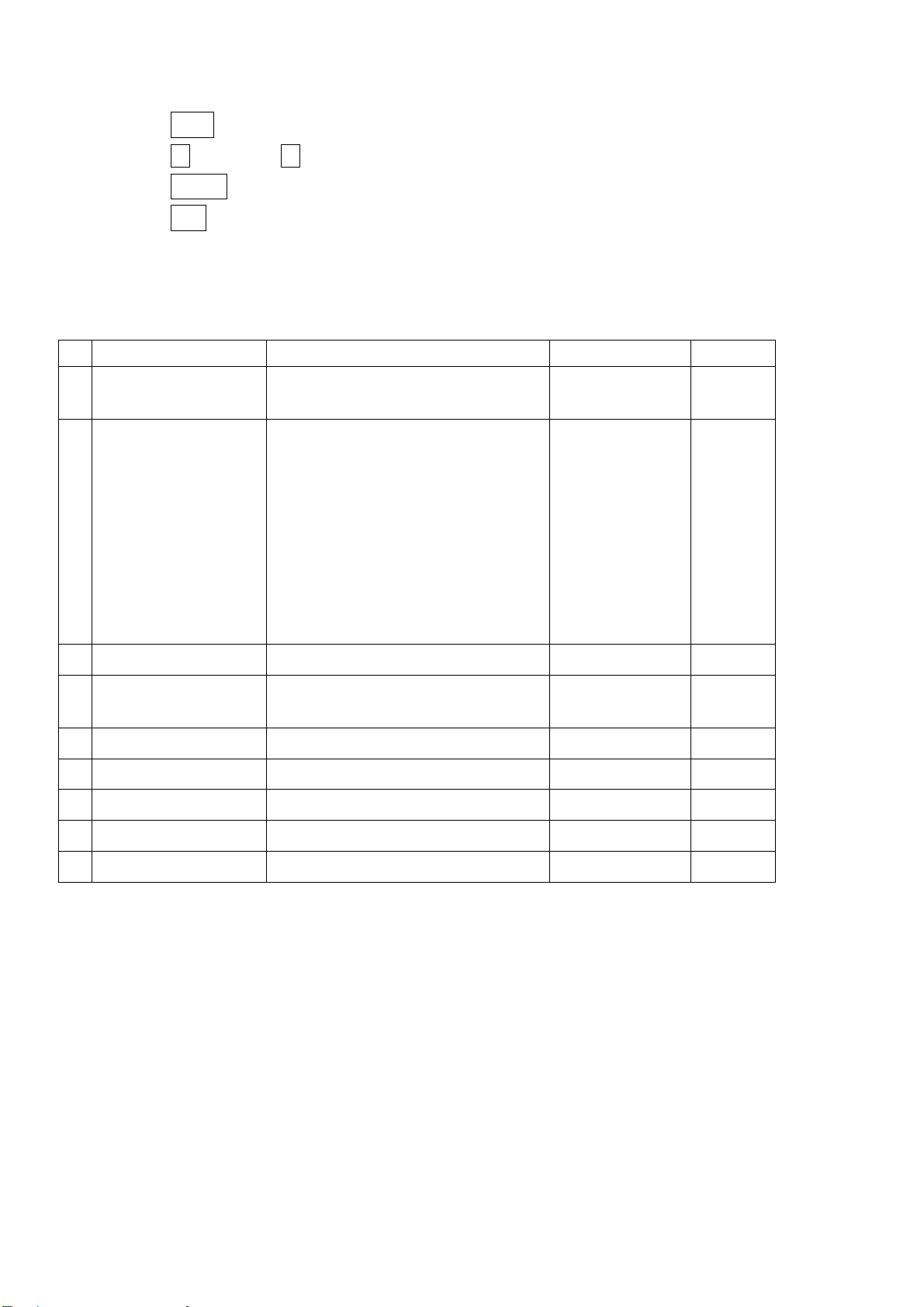

Table 5-1 Settable parameters

NParameter Selectable value Unit Default

1 INTEG. RANGE 5.12, 51.2, 512 mS/m/1024mV 512

2 REC. RANGE

(INTEG. RANGE;5.12)

0.0025,0.005,0.01,0.02,0.04,0.08,

0.16,0.32,0.64,1.28,2.56,5.12 (12

Steps)

(INTEG. RANGE;51.2)

0.025,0.05,0.1,0.2,0.4,0.8,1.6,

3.2,6.4,12.8,25.6,51.2 (12 Steps)

(INTEG. RANGE;512)

0.25,0.5,1,2,4,8,16,32,64,128,

256,512 (12 Steps)

mS/m/10mV 512

3 TEMPERATURE OFF,30-50 (1 Step) ℃ 45

4 TIME CONSTANT 0.1,0.25,0.5,1,1.5,2,3,6

(8 Steps) sec 1

5 POLARITY +,- - +

6 BASELINE SHIFT 0-200 (50 nRIU increment) - 0

7 LEAK SENSOR ON,OFF - ON

8 KEY LOCK YES,NO - NO

9 DEFAULT DATA YES,NO - NO

- 12 -

6. Installation and connections

6-1 Power Connection and Grounding

Connect the detector to the power source according to the following procedure:

1) Confirm that the power socket into which the detector power cable

is plugged is of a 3P type with a grounding terminal.

2) Confirm that the voltage of the power socket into which the detector power cable is

plugged is the same as the voltage indicated on the rear panel of the detector.

3) Turn off the power switch □

1 of the detector.

4) Connect the Power connector □

24 of the detector rear panel to the power source

using the accessory power cable.

Prior to connection, make sure that the voltage of the power socket into

which the detector power cable is plugged is the same as the power supply

voltage indicated on the detector.

The power socket into which the detector power cable is plugged

should be of a 3P type with a grounding terminal. Other types of power sockets

should not be used.

The accessory power cable should be used to connect the detector to the

power socket. Other cables should not be used.

Do not use the detector in places where combustible gas or any source of

fire or spark exists or might exist.

As the detector is readily affected by the ambient temperature, use it in

places where there is little wind or change in ambient temperature.

Do not use the detector near any source of vibration or electrical noise or in

places where corrosive gas and a lot of dust are present.

Please do not set other equipment on this detector, in order to

avoid enlarging the baseline drift and losing control of the temperature.

- 13 -

!

Warning

!

Warning

!

Warning

!

Warning

Caution

Notice

Table of contents

Popular Security Sensor manuals by other brands

Prime Controls

Prime Controls SD220 operating instructions

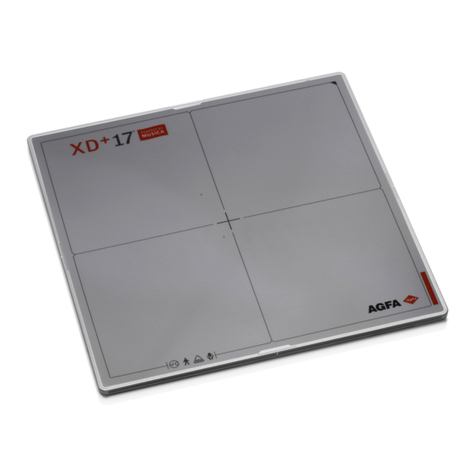

AGFA

AGFA XD 17 user manual

Inficon

Inficon Sensistor ISH2000 HySpeed operating instructions

Powerfix Profi

Powerfix Profi 278296 Operation and safety notes

THORLABS

THORLABS PDA10PT user guide

PCB Piezotronics

PCB Piezotronics HT352B01 Installation and operating manual