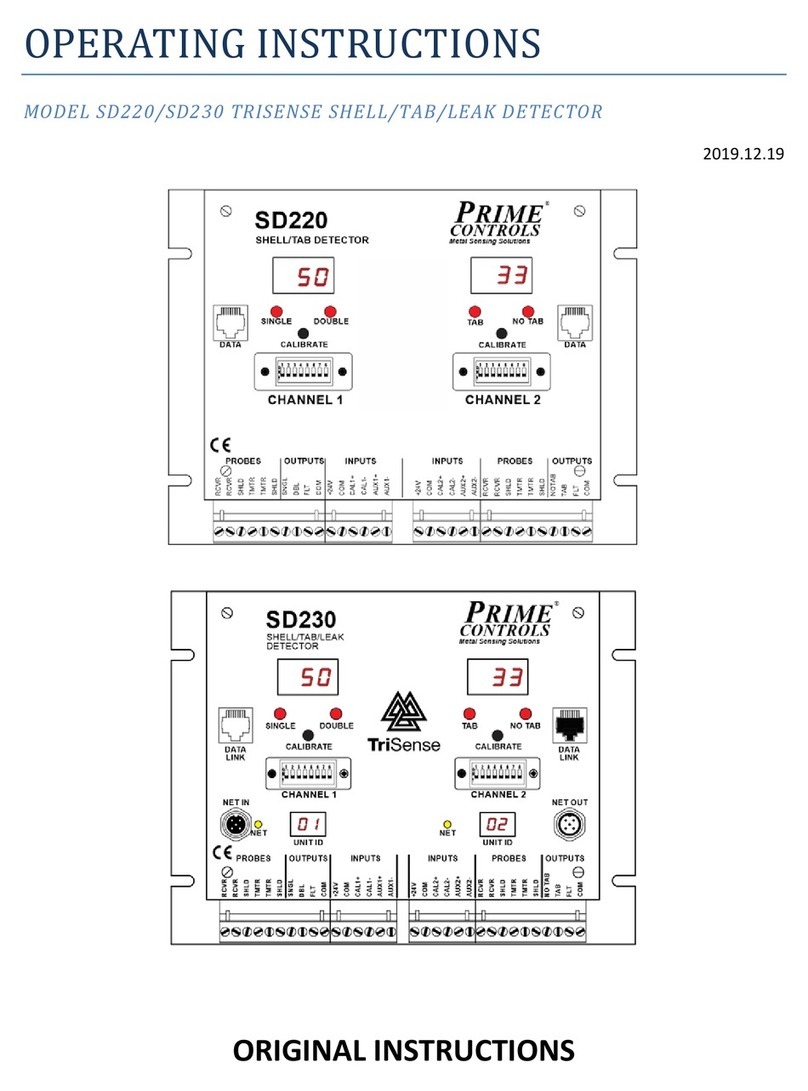

Prime Controls SD220 User manual

OPERATING INSTRUCTIONS

MODEL SD220 SHELL/TAB DETECTOR

DESCRIPTION

The Model SD220 Shell Detector for conversion press applications is a rugged but

sensitive dual channel instrument designed specifically to detect and report missing

blanks or double blanks at the infeed to a conversion press and to detect and report

ends that exit the press without tabs.

A complete system for one lane of a press comprises a control module housed in an

aluminum enclosure and four probes. One transmitting and receiving probe pair

senses doubles at the press input while the second transmitting and receiving pair

senses the presence or absence of tabs at the press output.

March 13, 2019

SNGL

COM

COM

COM

COM

+24V

+24V

CAL1+

NOTAB

CAL2+

2

TABLE OF CONTENTS

DESCRIPTION

Control Module………………………………………………….………...Page 3

Calibrate Pushbutton Operation………………………………………...Page 3

Probes………………………………………………………………….…. Page 4

OPERATION

Calibration …………………………………………………………….…..Page 4

Fault Message Interpretation ……………………………………….…..Page 5

INSTALLATION

Installing the Probes ……………………………………………….….…Page 5

Mounting the Control Module ………………………….………….…….Page 6

Wiring the Control Module ………………………………………..……..Page 6

Setting Switch Options ………………………………………….……….Page 7

Sensing Aluminum Ends ……………………………………….. Page 8

Sensing Steel Shells ……………………………………………. Page 8

Sensing Al Tabs on Al Ends ……………………………….……Page 8

Sensing Al Tabs on Steel Ends ………………………………...Page 8

Sensing Steel Tabs on Steel Ends ………………………….…Page 8

Set Sinking or Sourcing Outputs ……………………………….Page 8

Set Outputs for Failsafe or Compatibility ……………………..Page 8

Enable or Disable Tab Profiling ………………………………...Page 9

Setting Options Through the Front Panel…………………………..….Page 9

Adjusting the Tolerance……………………………………….…Page 9

Set Display Direction………………………………………….….Page 10

Parameter Value Ranges………………………………………..Page 11

Special Functions…………………………………………………………Page 11

Remote Calibration…………………………………………….…Page 11

Quick Calibration Changeover…………………………………..Page 11

Determining Firmware Version…………………………………. Page 12

DOCUMENT APPLICABILITY…………………………………………….…….Page 12

ELECTRICAL SPECIFICATIONS………………………………………………Page 13

CONTROL MODULE DIMENSIONS…………………………………………...Page 14

WIRING RECOMMENDATIONS………………………………………………..Page 15

OUTPUT SIGNAL DIAGRAMS………………………………………………….Page 16

SUMMARY OF DIFFERNCES BETWEEN SD200 AND SD220……………Page 17

SD200 TO SD220 MIGRATION…………………………………………………Page 18

LIMITATION AND EXCLUSION OF WARRANTIES………………………….Page 19

3

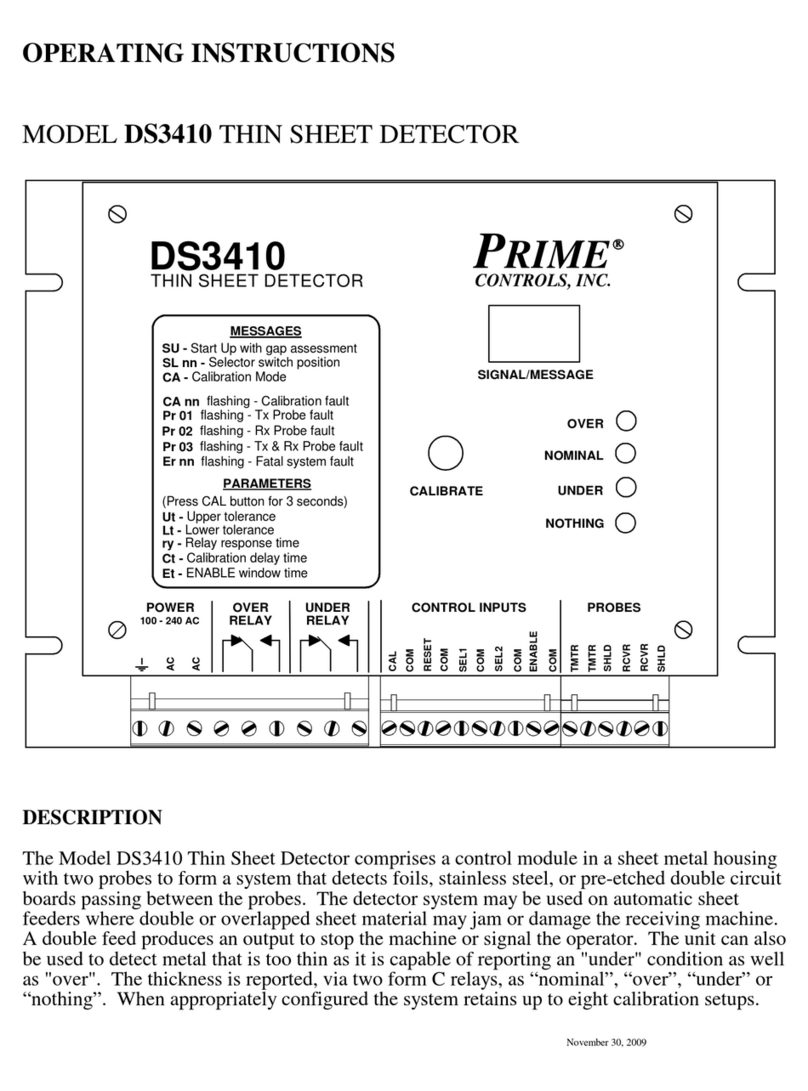

Control Module

The control module allows for fast and easy setup and for quick diagnosis of system

errors or problems. Setup is achieved through the simple press of a push-button switch

or an external contact closure. Faults are reported on digital displays on the control

module and through FAULT outputs that may be connected to a PLC or system

controller.

The DOUBLE, SINGLE, NO TAB, TAB and FLT outputs may be switch selected as

sinking or sourcing drivers. An eight position DIP switch, accessible on the front panel,

allows the installer to select a number of operational options as described in the

installation section of this document.

The AUX inputs provide a means to switch between two different setups, such as

sensing steel shells and sensing aluminum shells, without recalibrating or changing the

DIP switch settings.

When the unit first powers up, if probes are properly connected, the digital displays

indicate the operational mode of the unit, i.e. whether set up for sensing Aluminum,

Steel, or Aluminum on Steel by displaying the characters "Al", "St" or “AS” for a period

of approximately two seconds. Which mode comes up is determined by the setup of

the unit through the DIP switches and the state of the AUX input. See setup later in this

document.

Calibrate Pushbutton Operation

The push-button switches on the front panel of the control module serve to initiate the

calibration process and to make adjustments for system setup. The pushbuttons may

be used to adjust the gauge tolerances (tL) and set the display option to invert the

digital display (do).

To initiate calibration, simply press the appropriate pushbutton and release it within 3

seconds.

To view the current value of a parameter, press the pushbutton and hold it for more

than 3 seconds until the appropriate parameter identifier (tL or do) appears on the

digital display. After the parameter identifier appears, release the pushbutton and the

current value of the parameter displays for 5 seconds. To retain the current value of

the parameter, simply allow the 5 second display interval to elapse. The display

reverts to displaying the gauge signal.

To change the value of a parameter, press the pushbutton and hold it for more than 3

seconds until the appropriate parameter identifier appears on the digital display. After

the parameter identifier appears, release the pushbutton and the current value of the

parameter displays. Press the pushbutton while the parameter is displaying and the

value increments, first slowly then more rapidly. For more precise control of the value

adjustment, simply tap the pushbutton repeatedly until the desired value is displayed.

All parameters roll back to their minimum values after reaching the maximum value.

To retain the adjusted value of the parameter, simply allow the 5 second display

interval to elapse. The display reverts to displaying signal strength.

4

Probes

The SD220 may be used with any P15 or P70 series two wire probes or with older

model three wire probes including AV, AY, AZ, AZA, and CB probes. When used with

older 3 wire probes, the white wire in the probe cable is not used and must remain

disconnected.

OPERATION

Operation of the SD220 Shell/Tab Detector involves only two processes, calibration and

fault message interpretation. These processes are described below.

Calibration

Calibration requires the following steps:

1. Stop the press in the dwell portion of the cycle with a single end between the

infeed probes and a good tabbed end between the discharge probes.

2. Observe that no error conditions are being reported on either display of the

SD220 control module.

3. Press and release the CALIBRATE pushbutton on channel 1 of the SD220

control module and observe the SINGLE and DOUBLE LEDs flashing alternately

and “CAL” on the digital display. If the calibration is successful, the LED flashing

stops in less than three seconds and the digital display shows a number between

48 and 52.

If the display flashes alternately “CAL” and “Lo”, the calibration was

unsuccessful due to insufficient signal at the receiving probe. This can be an

indication that the probes are too far apart or that the unit is not set to the

appropriate frequency for the material being sensed, e.g. frequency set to

aluminum when steel ends are present. If the display flashes alternately “CAL”

and “Hi”, the receiver signal is too strong indicating nothing between the probes.

If the calibration problem is not resolved and the calibration switch is not pressed

again within 30 seconds, calibration mode is aborted and the previous calibration

values are reinstated.

4. Press the CALIBRATE pushbutton on channel 2 of the SD220 control module

and observe the TAB and NO TAB LEDs flashing alternately and ”CAL” on the

digital display. If the calibration is successful, the LED flashing stops in less than

3 seconds and a number between 28 and 33 is displayed.

If the display begins to alternately flash “CAL” and “Lo”, the calibration was

unsuccessful due to insufficient signal at the receiving probe. This can be an

indication that the probes are too far apart or that the unit is not set to the

appropriate frequency for the material being sensed e.g. frequency set to

aluminum when steel ends are present.

5

If the calibration problem is not resolved and the calibration switch pressed again

within 30 seconds, calibration mode is aborted and the previous calibration

values are reinstated.

If both channels calibrate successfully, calibration is complete. The calibration process

may also be initiated through an external switch or signal controlling the CAL+ and

CAL- inputs to the SD220. Activation of this input performs the same function as

pressing the CALIBRATE push-button switch for the corresponding channel.

Fault Message Interpretation

The SD220 monitors the probe connections on a continuous basis and reports what it

detects to be disconnected or malfunctioning probes. The probe faults are reported as

follows:

Alternately flashing "PR" and "1" - transmitter probe disconnected or failing.

Alternately flashing "PR" and "2" - receiver probe disconnected or failing.

Alternately flashing "PR" and "3" - both probes disconnected or failing

During calibration:

Alternately flashing “CAL” and “Lo” indicates a low signal at the receiving probe.

Alternately flashing “CAL” and “Hi” indicates the signal at the receiver is too

strong, likely no end between the probes.

The SD220 performs extensive self diagnostics at power up and more limited

diagnostics while running. Most fatal faults, if not involving the display subsystem, are

reported on the digital displays through the alternate flashing of "Err" and "nnn" where

"nnn" is a one to three digit number indicating the source of the fault. These faults are

not field repairable and require the change-out of the control module.

Any detected fault causes the FLT output to be turned OFF until the fault is cleared.

INSTALLATION

Installation comprises four basic steps: 1) Installing the probes, 2) Mounting the

control module, 3) Wiring the unit, and 4) Setting system options. Each of these steps

is further expanded below.

Installing the Probes

1. Mount the double detecting infeed probes, one above and one below the

centerline of the track carrying the ends into the press. The probes must be

positioned such that they are centered on the can end during the dwell portion of

the press cycle. In the vertical, the track should run midway through a gap of

approximately 5/8 inch (16mm) between the probes.

6

2. Positioning of the tab detecting probes is more critical than the positioning of the

infeed probes. For most tabbed ends, the optimum position for the probes is

above and below the ring of the tab, not centered on the rivet. Centering on the

rivet only works on some older tab designs where the tab formed a ring around

the rivet. If positioning of the tab sensing probes is uncertain, contact Prime

Controls for help.

Mount the tab detecting probes, one above and one below the tabbed ends as

they are carried on the track from the press. The probes must be positioned

such that they are centered on the tab ring during the dwell portion of the press

cycle. In the vertical, the track should run midway through a gap of

approximately 5/8 inch (16mm) between the probes.

3. Run the probe cabling through conduit back to the cabinet housing the control

module. Do not run the sensor cables through conduit carrying high level or

noisy signals.

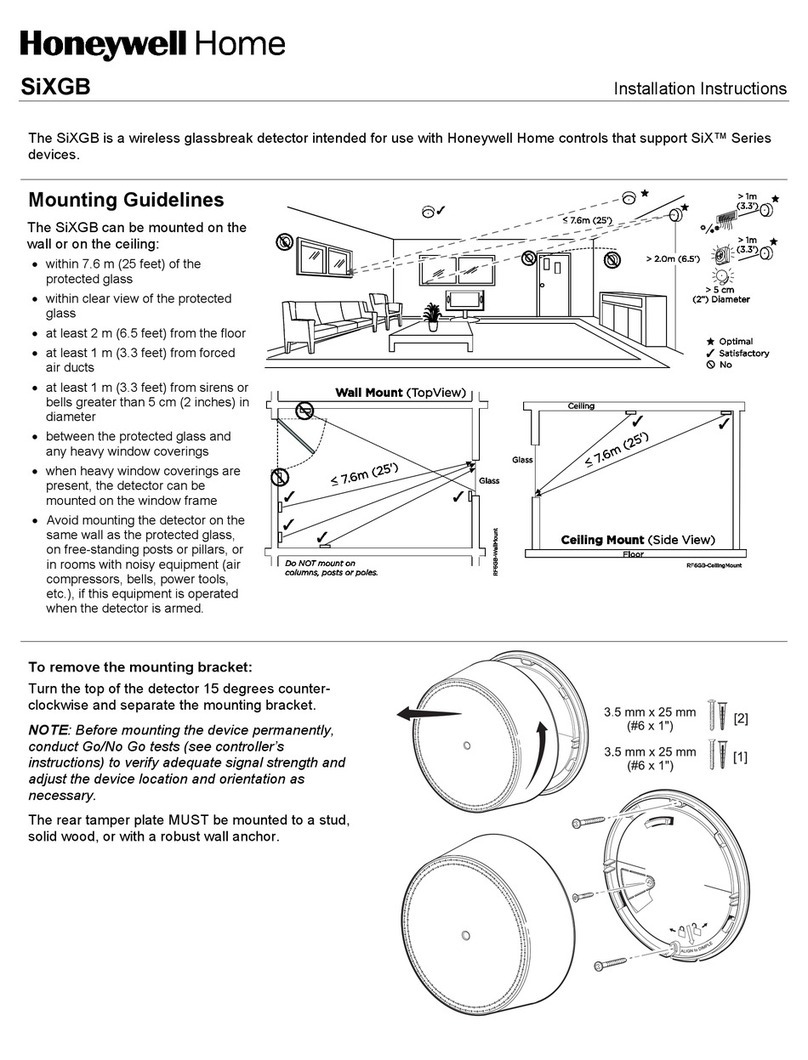

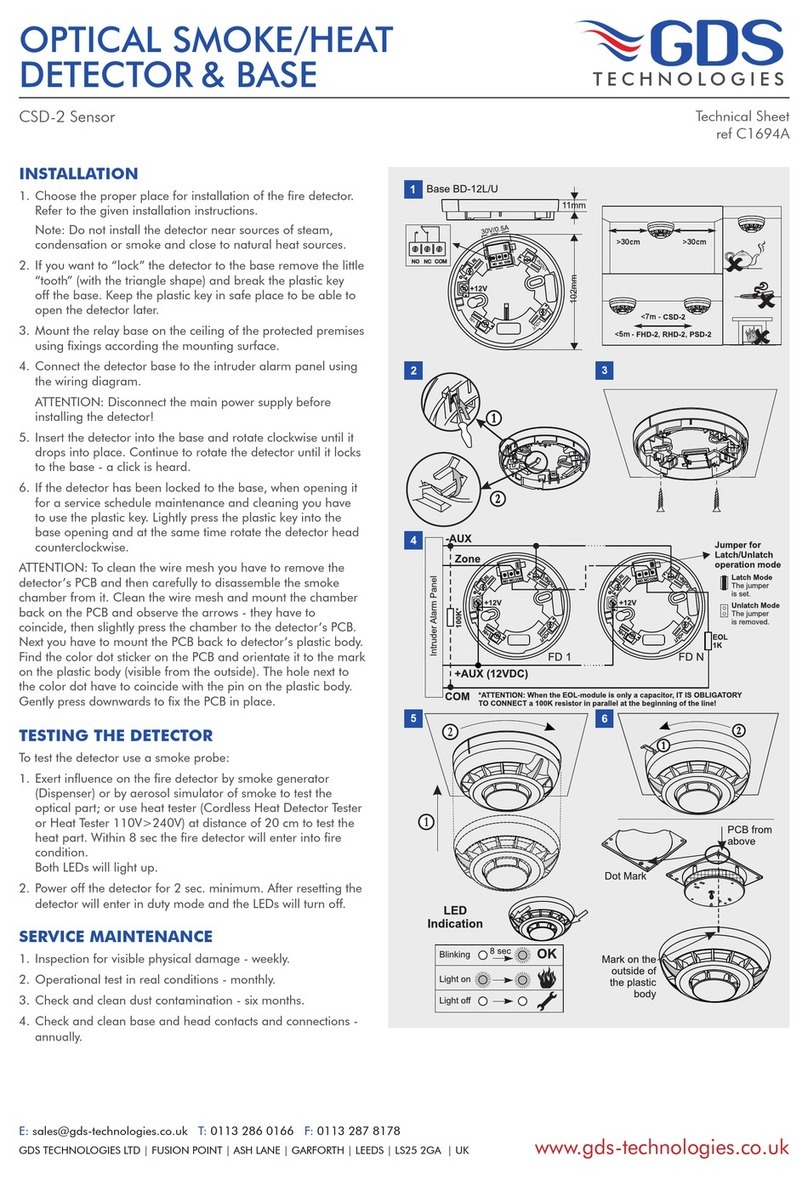

Mounting the Control Module

Mount the control module on the back panel of an industrial enclosure. The footprint is

8.25 inches (210 mm) by 6.25 inches (159 mm) with mounting slot locations on a

rectangle 7.625 inches (194 mm) in the horizontal and 4.0 inches (102 mm) in the

vertical. Insure that the mounting screws make good electrical contact between the

module housing and the control enclosure back panel. See drawing at the end of this

document.

Wiring the Control Module

1. Connect 24 volt dc power between both sets of the +24V and COM terminals of

the control module. The left and right side modules are electrically independent

and must be powered independently. The two +24V terminals are NOT

internally connected. The supply must be capable of delivering 0.250 amps

continuously with a startup surge of 0.5 amps for 2 milliseconds.

2. Connect the double detecting transmitter probe wires to the two TMTR terminals

on the channel 1 side of the control module and the double detecting receiving

probe wires to the two RCVR terminals on the channel 1 side of the control

module. The probe connections are not polarized Connect the shield wires to

the terminal labeled SHLD.

Though both the transmitting and receiving probes are identical, it is preferred

practice to choose the transmitting probe as the one that will remain farthest

from the track as it moves and stretches.

Note: Prime Controls assures compatibility with PN: CBL101-XX cables and the

cabling pre-attached to certain probes. Other types of cabling, and also, cable

lengths above 30 meters (approx 100 ft) are not advised.

On retrofit installations where older three wire probes are installed, cut back and

do not connect the third (white) wire. If in doubt about which wires to use,

measure the resistance between the wires in pairs, and then use the pair that

produces the highest resistance reading (typically 24 ohms).

7

3. Connect the tab detecting transmitter probe wires to the TMTR terminals on the

channel 2 side of the control module and the tab detecting receiving probe wires

to the two RCVR terminals on the channel 2 side of the control module. Connect

the shield wires to the terminals labeled SHLD.

The precautions regarding choice of transmitter probe are the same for the

discharge side as for the infeed. See above.

4. Connect the SNGL, DBL, NO TAB, TAB, and FLT outputs to the system

controller and/or interlocking circuitry as required. These outputs may be sinking

or sourcing as determined by the setting of SW 5. See switch settings later in

this document.

The FLT outputs are always ON for no fault. The active states of the other

outputs may be affected by the setting of the compatibility DIP switch as

described later in this document.

5. If calibration is to be activated remotely, connect the CAL+ and CAL- inputs

appropriately. Connect a sinking driver or contact to the CAL- terminal and

connect CAL+ to the 24 volt power source. Connect a sourcing driver to the

CAL+ terminal and connect CAL- to COM.

6. If the application may involve switching between steel and aluminum blanks, the

AUX inputs may be wired to provide external control of the sensing mode of the

SD220. Connect a sinking driver or contact to the AUX- terminal and connect

the AUX+ terminal to the 24 volt supply. Connect a sourcing driver to the AUX+

terminal and connect the AUX- terminal to COM.

Setting Switch Options

To access the DIP switches in the middle of the front panel, swing the hinged plastic

window to the side. The left-most switch is SW1, the right-most is SW8. The switches are

on when in the up position.

Channel 1 Switch Options

Switch OFF ON

======================================================

SW1 Sense aluminum ends Sense steel ends

SW2 On-press sensing Off-press sensing (high speed)

SW3 Select fail-safe mode Select compatibility mode

SW4 Fixed thresholds Adjustable thresholds

SW5 Sourcing outputs Sinking outputs

SW6 No overlap allowed Overlap allowed if SW2 ON

SW7 Not used

SW8 Not used

8

Channel 2 Switch Options

Switch OFF ON

======================================================

SW1 Sense aluminum ends Sense steel ends

SW2 Sense aluminum tabs Sense steel tabs

SW3 Select fail-safe mode Select compatibility mode

SW4 Fixed thresholds Adjustable thresholds

SW5 Sourcing outputs Sinking outputs

SW6 Enable tab profiling Disable tab profiling

SW7 Not used

SW8 Not used

NOTE: The DIP switches are read only upon power-up of the unit. After changing

switch setting, power the unit down and back up again to activate the change.

Sensing Aluminum Ends

When sensing aluminum shells, insure that SW1 is off for both channels.

Sensing Steel Ends

When sensing steel shells, insure that SW1 is on for both channels.

Sensing Aluminum Tabs on Aluminum Ends

When sensing aluminum tabs on aluminum ends, insure SW1 and SW2 are off for both

channels.

Sensing Aluminum Tabs on Steel Ends

When sensing aluminum tabs on steel ends, set SW1 on and SW2 off for channel 1.

Set SW1 on and SW2 off for channel 2.

Sensing Steel Tabs on Steel Ends

When sensing steel tabs on steel ends, set SW1 on and SW2 off for channel 1 and set

both SW1 and SW2 on for channel 2.

Set Sinking or Sourcing Outputs

The setting of SW5 determines whether the output drivers are sinking or sourcing.

SW5 off selects sourcing, SW5 on selects sinking.

9

Set Outputs for Failsafe or Compatibility

When SW3 is on, the sourcing outputs of the SD220 provide the same logic levels as

the outputs of older double sheet units such as the DS33 and DS35, allowing for quick

and easy retrofit installations. When SW3 is off, the output states are defined to

provide maximum protection against loss of connection between the shell detector and

the controlling PLC. The loss of connection is sensed as the fault condition.

The table below defines the output states for all combinations of SW3 and the possible

sensing states. Also, see the output signal drawings at the end of this document.

OUTPUT STATES

Switch In Gap SNGL DBL NOTAB TAB

===================================================================

OFF missing OFF ON ON OFF

OFF single ON ON OFF OFF

OFF double/tab ON OFF ON ON

ON missing ON OFF ON OFF

ON single OFF OFF OFF OFF

ON double/tab OFF ON ON ON

Enable or Disable Tab Profiling

The SD220 uses two different methods for determining the absence or presence of

tabs. The most basic method is simple thresholding of the sensor signals. As the

shape of the beverage ends and tabs evolved and the speed of presses increased, it

became necessary to implement a redundant test that recognizes the profile of a tab

as it moves through the machine. This feature, however, is not compatible with larger

and steel ends or with machines that have stainless steel belts. The stainless steel

belts can change the sensor signal sufficiently to interfere with the tab profiling

algorithm and cause the system to report self check errors. Profiling is most effective

in the detection of aluminum tabs on aluminum ends on high speed presses. SW6

enables and disables tab profiling.

Setting Options Through the Front Panel

Adjusting the Tolerance

Adjust the double shell tolerance as follows:

1) Insure that SW4 is on. If necessary, change the switch position and power the unit

down and back up..

2) Press and hold the channel 1 calibrate pushbutton for at least 3 seconds until tL

appears on the display.

10

3) Release the pushbutton and observe the current value of the threshold (in percent).

4) If the current value is ok (typically 35), wait 5 seconds and the display reverts to

displaying the gauge value and retains the current tolerance.

5) To change the value, press and hold or tap the calibration pushbutton until the

desired value is displayed. After the value reaches 90, it rolls over to 10 and

increases.

6) When the desired value is on the display, wait 5 seconds and the display reverts to

displaying the gauge value and retains the last displayed tolerance value.

Adjust the missing tab tolerance as follows:

1) Insure that SW4 is on. If necessary, change the switch position and power the unit

down and back up.

2) Press and hold the channel 2 calibrate pushbutton for at least 3 seconds until tL

appears on the display.

3) Release the pushbutton and observe the current value of the threshold (in percent).

4) If the current value is ok (typically 15), wait 5 seconds and the display reverts to

displaying the gauge value and retains the current tolerance.

5) To change the value, press and hold or tap the calibration pushbutton until the

desired value is displayed. After the value reaches 90, it rolls over to 10 and

increases.

6) When the desired value is on the display, wait 5 seconds and the display reverts to

displaying the gauge value and retains the last displayed tolerance value.

Set Display Direction

By default, the digital display values follow the strength of the receiver signal, increasing

for stronger signal and decreasing for weaker signal. In this mode, the signal increases

for thinner materials between the probes and decreases for thicker materials. The

display may be inverted so that the values are proportional to material thickness rather

than signal strength. To invert the display:

1) Press and hold the calibrate pushbutton until do appears on the display.

2) Release the pushbutton and the display changes to 0or 1.

3) At this point, with each press of the pushbutton the display toggles between 0and

1. The 0selects normal display mode, 1selects inverted mode..

4) When the desired value is on the display, wait 5 seconds and the display reverts to

displaying the signal value in the selected mode.

The range of values available for the SD220 adjustable parameters are as follows:

11

Parameter Value Ranges

ID Function Range of Values___________________________

tL double tolerance 10% to 90% for double (default is 35%)

tL tab tolerance 10% to 90% for tab (default is 15%)

do display direction 0for signal strength (default), 1relative thickness

oL overlap percentage 0% to 90% for off-press sensing only (SW2 On)

Special Functions

The SD220 offers two sets of optically isolated inputs on each channel that provide

added control over the unit. These are the remote calibration input terminals labeled

CAL+ and CAL- and the sensing mode inputs labeled AUX+, AUX-.

.

Remote Calibration

The remote calibration inputs perform the same function as the CALIBRATE push-

button switches on the front panel of the control module.

Quick Calibration Changeover

The AUX input works in conjunction with SW1 (both channels) and SW2 (channel 2

only) to select the target tab and shell material combinations as presented in the table

below.

When the AUX input is activated or deactivated, the SD220 changes to accommodate

the new material combination and displays, for approximately 2 seconds, a two-

character abbreviation indicating the selected targeted materials. The display

interpretation is as follows:

Al – aluminum tab on aluminum shell

St – steel tab on steel shell

AS- aluminum tab on steel shell

The two-character indication also displays at power-up indicating the current selection.

12

Channel 1 Material Selection

SW1 AUX Shell Material

OFF OFF Aluminum

OFF ON Steel

ON OFF Steel

ON ON Aluminum

Channel 2 Material Selection

SW1 SW2 AUX Material Combination

OFF OFF OFF Aluminum tab on aluminum end

OFF OFF ON Aluminum tab on steel end

OFF ON OFF Aluminum tab on aluminum end

OFF ON ON Steel tab on steel end

ON OFF OFF Aluminum tab on steel end

ON OFF ON Aluminum tab on aluminum end

ON ON OFF Steel tab on steel end

ON ON ON Aluminum tab on aluminum end

If quick calibration changeover is to be activated remotely, connect the AUX+ and AUX-

inputs appropriately. Connect sinking drivers or contacts to the AUX- terminal and

connect AUX+ to the 24 volt power source. Connect sourcing drivers to the AUX+

terminal and connect AUX- to COM.

Determining Firmware Version

From time to time, as improvements are made to Prime Controls products, the firmware

controlling the units is revised. When setting a unit up or troubleshooting it may be

necessary to determine the version number for the firmware installed in your unit. The

version numbers are of the form 1.00 and are incremented either by tenths (1.01, 1.02,

etc.) for small revisions or by the integer digit (1.00, 2.00, etc.) for more significant

revisions.

To determine the version of the firmware running in your unit, hold the calibration

pushbutton in as power is applied to the unit. The revision number is displayed directly

on the digital display.

The two channels of the SD220 are independent and may be running different versions

of firmware. Each must be checked separately.

DOCUMENT APPLICABILITY

This document applies to SD220 units running firmware Version 1.01 through 1.11

13

ELECTRICAL SPECIFICATIONS

Supply Voltage: 24 volts DC plus or minus 10%

Supply Current per Channel: 130 mA plus sourcing output load

Inrush Current at Startup: 500 mA for 3 milliseconds per channel

AUX and CAL Max Input Voltage: 30V

AUX and CAL input impedance: 3300 ohms

Sourcing Outputs: On voltage: Supply Voltage – 1.0 volt

Off voltage: 0 volts

Max current: 50 mA

Sinking Outputs: On voltage: 0 volts

Off voltage: Load pullup dependent

Max current: 50 mA

Output Overload Protection: Self-resetting thermal fuse

Input and Output Transient Protection: 30 volt transient absorber.

Probe Cabling: Prime Controls PN: CBL101-XX, Belden 8761,

or exact equivalent.

14

SD220 CONTROL MODULE DIMENSIONS

SNGL

COM

COM

COM

COM

+24V

+24V

CAL1+

NOTAB

CAL2+

7.94

(.313)

210

(8.25) 194

(7.63)

159

(6.25)

101.6

(4.00)

20.6

4.76

(.188)

(1.125)

28.6

15

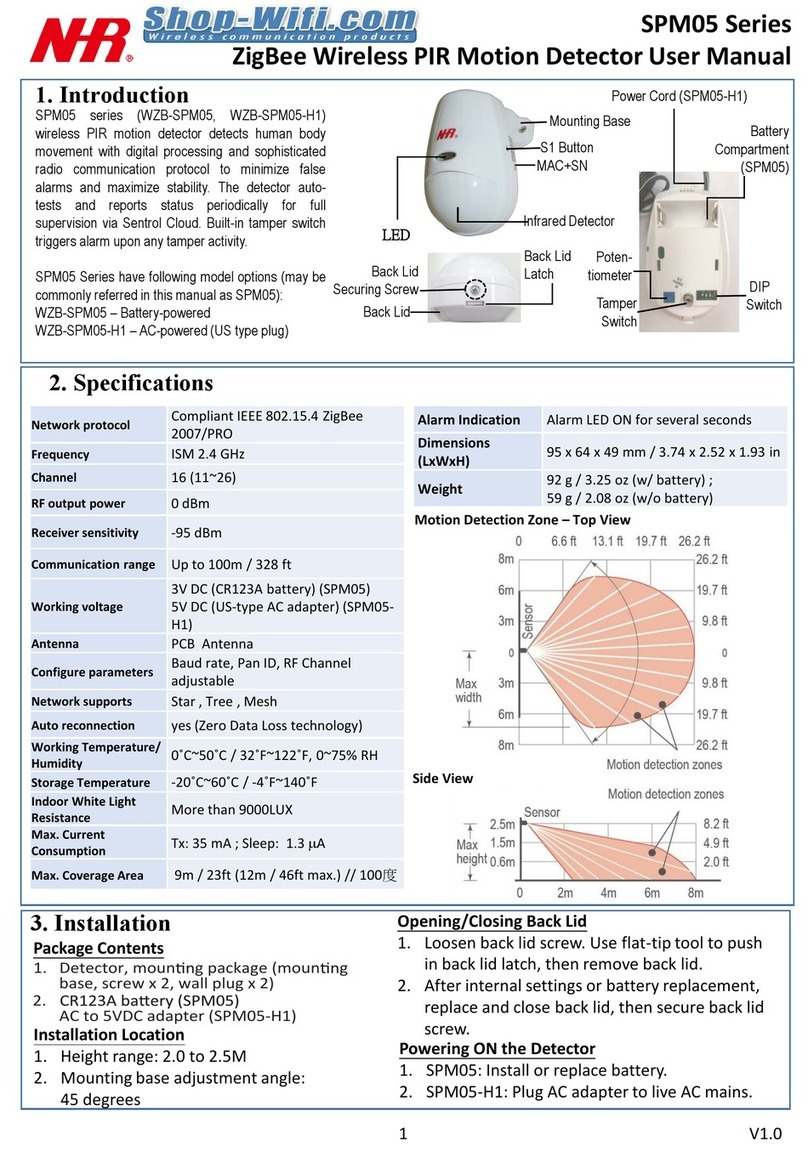

SD220 WIRING RECOMMENDATIONS

For maximum noise immunity, splice or terminate cables only when absolutely necessary. Where

extension is necessary, use Belden 8761 or equivalent shielded twisted pair cable. The SD22x family

of products is designed to provide high common mode noise rejection. Common mode rejection is

realized most effectively with twisted pair cabling.

Total cable lengths greater than 30 M (approx. 100 ft.)

are not advised. Use of excessively long cables, or cables not specified by Prime Controls, may

cause issues within the receiver and/or probe detection circuits of the controller.

3. Maintain independent shields

4. Position shield terminals between

transmitter and receiver signal terminals

1. Minimize unshielded lengths.

2. Twist signal wires together where

unshielded.

TRANSMITTER TRANSMITTER

FLT

TMTR

TMTR

SNGL

COM

COM

AUX1+

AUX1-

+24V

FLT

CAL+

CAL-

NOTE: When extending three wire probes with

2 wire twisted pair cabling (8761), connect

black to black and probe red to 8761 clear.

the clear conductorDO NOT CONNECT

of the probe cable.

16

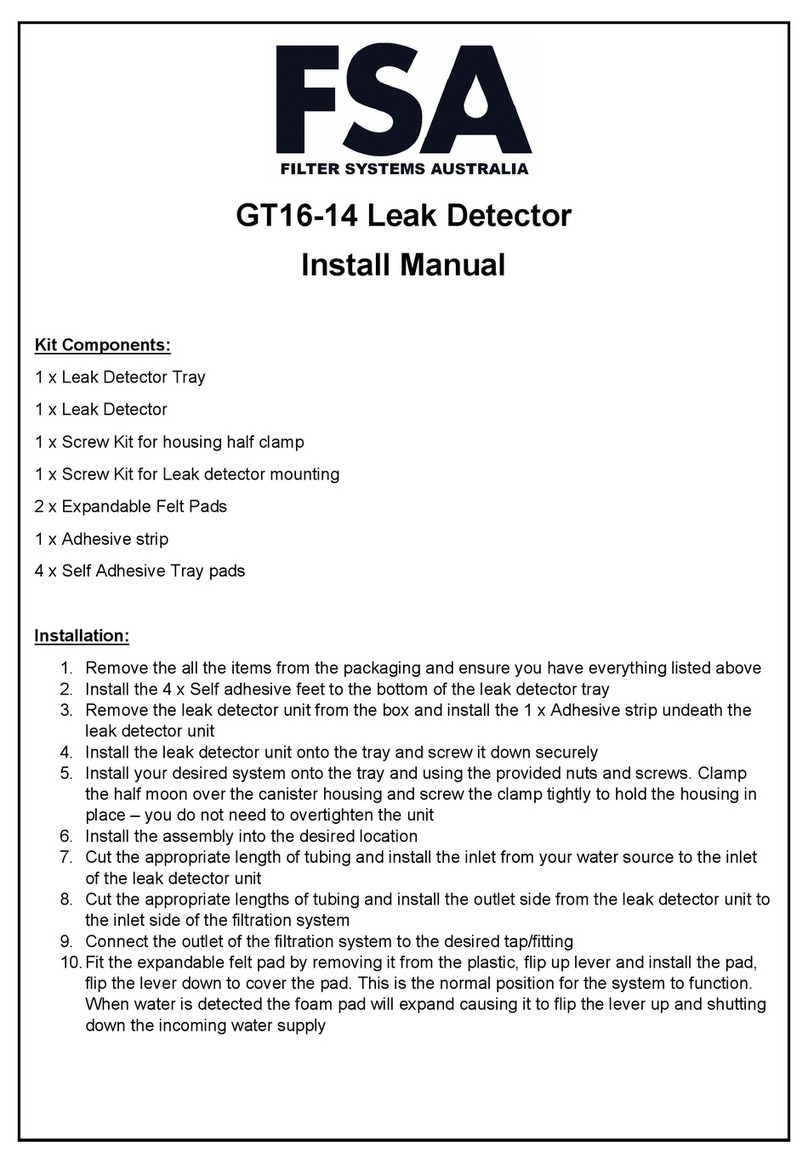

SD220 OUTPUT SIGNALS

No Tab/Tab Outputs - Failsafe Mode

CHANNEL 2 - DISCHARGE

CHANNEL 1 - INFEED

NO TAB

no end no end

NO TAB

no end no end

NO TAB

no end no end

NO TAB

no end no end

17

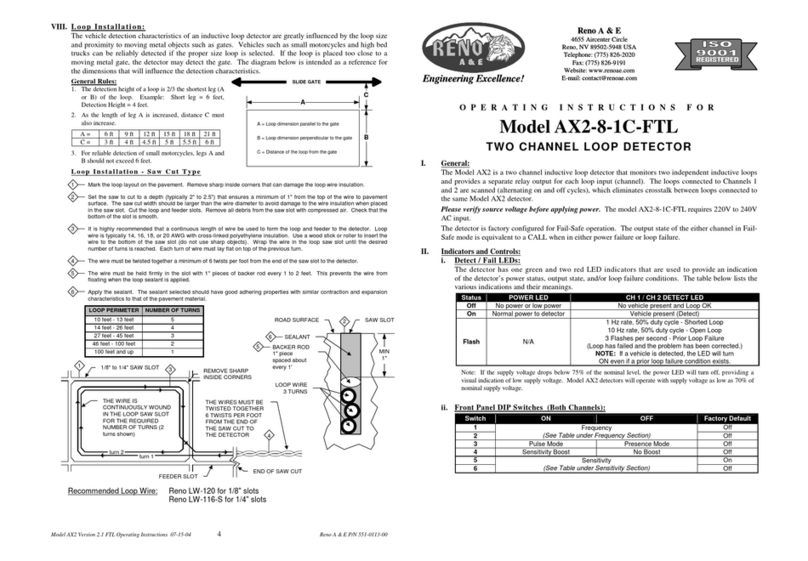

SUMMARY OF DIFFERENCES BETWEEN SD200 AND SD220

FEATURE

SD200

SD220

Wiring

Power connection

+24V and COM to left or right

channel

+24V and COM to both channels

Fault signal

Fault signals are slaved

internally

Fault signals must be monitored

independently

AUX input frequency change

AUX inputs are slaved internally

Both AUX inputs must be driven

externally

Configuration

DIP switch access

Remove cover

Window on front panel

Number of configuration switches

Four for both channels

Eight for each channel

Sink/Source select

Jumpers beneath cover

Switch Select

Al tab on steel end sensing

SU parameter set through front

panel

Switch Select

Profiling enable/disable

Pd parameter set through front

panel

Switch Select

Display inversion

Switch select

Parameter selected

Data Collection

Serial port

Not available

Serial port on each channel

SD200 TO SD220 MIGRATION

Replacement of installed SD200 units by SD220s requires the following wiring changes:

1. +24V and COM must be connected to both channels of the SD220.

2. SD200 faults for either channel are reported on both fault outputs. The fault

signals on the two channels of the SD220 are totally independent.

3. If your installation uses the AUX input to quickly change between calibrations on

different shell materials, it is necessary with the SD220 to activate the AUX input

on both channels independently. The AUX inputs are not slaved together as in

the SD200.

18

Configuration of the SD220 has been simplified as compared to the SD200. It is no

longer necessary to remove the cover to change options. These changes include:

1. The DIP switches, now eight per channel instead of four per unit, are accessible

through a window on the front panel.

2. Where the SD200 requires jumper changes under the front panel to select

sinking or sourcing outputs, the selection on the SD220 is made through the

setting of DIP switch 5. Set SW5 off for sourcing and on for sinking.

The method of setting some options has changed. The list below shows which settings

remain the same and which have changed:

CHANNEL 1 Configuration Switches

1. SW1 – (no change) – configures the unit for aluminum or steel ends.

2. SW2 – (change) – no longer inverts display, must be off on SD220.

3. SW3 – (no change) – selects output failsafe or compatibility mode.

4. SW4 – (no change) – selects fixed thresholds or adjustable thresholds.

5. SW5 – (new) – selects sourcing or sinking outputs.

6. SW6 – (new) – allows or disallows overlap – not used on SD220

7. SW7 – not used

8. SW8 – not used

CHANNEL 2 Configuration Switches

1. SW1 – (no change) – configures the unit for aluminum or steel ends.

2. SW2 – (change) – selects tab material, off for aluminum, on for steel

3. SW3 – (no change) – selects output failsafe or compatibility mode.

4. SW4 – (no change) – selects fixed thresholds or adjustable thresholds.

5. SW5 – (new) – selects sourcing or sinking outputs.

6. SW6 – (new) – enables or disables tab profiling.

7. SW7 – not used

8. SW8 – not used

Setup parameter SU not available on SD220; use SW2.

Setup parameter Pd not available on SD220; use SW6.

SW2 no longer inverts the display as on the SD220; use setup parameter do (display

option) on the SD220

19

LIMITATION AND EXCLUSION OF WARRANTIES

All goods purchased form PRIME CONTROLS, INC. shall be free from defects in

materials, design and workmanship under normal conditions of use for one year from

the date of shipment. THIS WARRANTY IS THE SOLE WARRANTY AND IS

EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED,

INCLUDING BUT NOT LIMITED TO ANY IMPLIED, WARRANTY OF

MERCHANTABILITY OF FITNESS FOR A PARTICULAR PURPOSE. THE LIABILITY

OF PRIME CONTROLS TO ANY PURCHASER SHALL BE LIMITED EXCLUSIVELY

TO THE COST OF REPLACEMENT OR REPAIR OF DEFECTIVE PARTS, AND

SHALL NOT INCLUDE LIABILITY FOR ANY DIRECT, CONSEQUENTIAL OR

INCIDENTAL DAMAGES WHATSOEVER, WHETHER FORESEEN OR

UNFORESEEN, INCLUDING BUT NOT LIMITED TO LOST PROFITS, LOST SALES,

OR INJURY TO PERSONS OR PROPERTY.

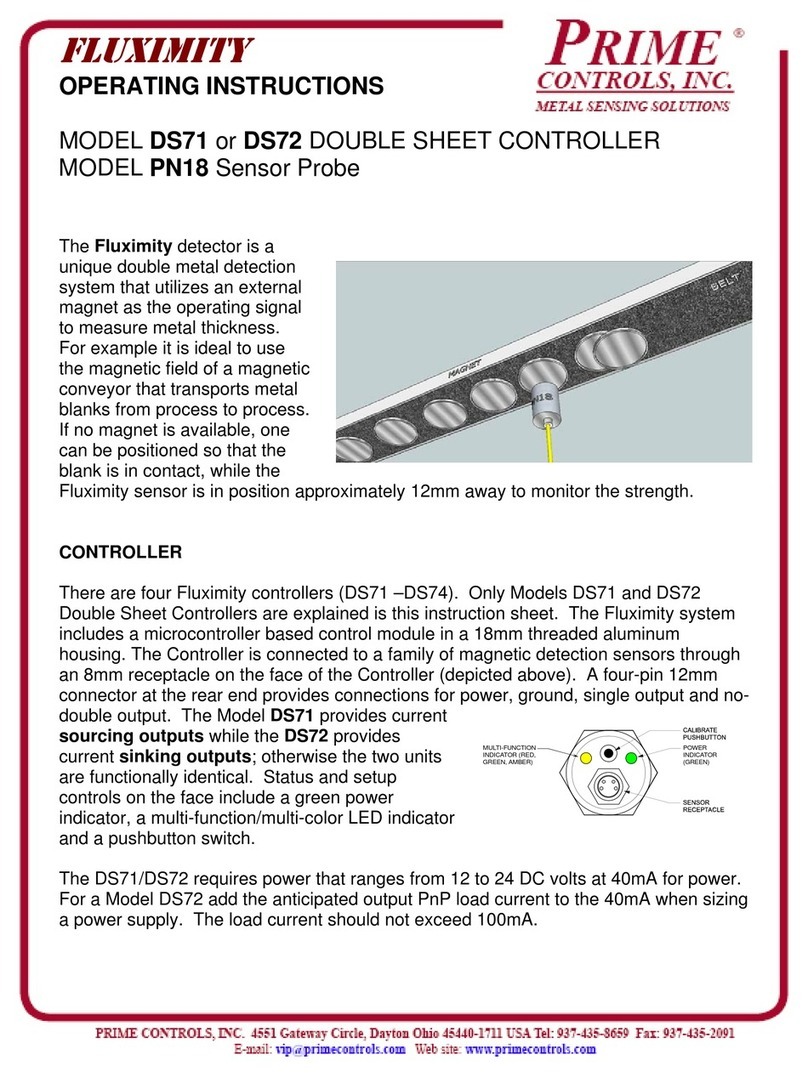

Other manuals for SD220

1

Table of contents

Other Prime Controls Security Sensor manuals

Prime Controls

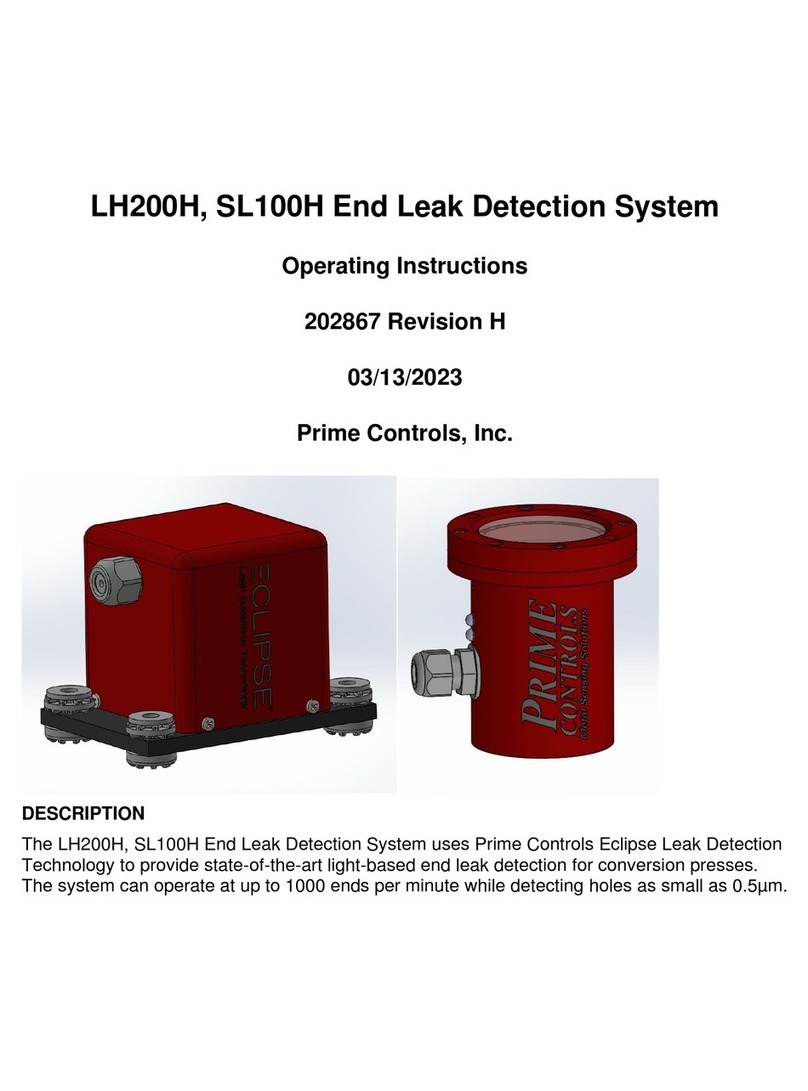

Prime Controls LH200H User manual

Prime Controls

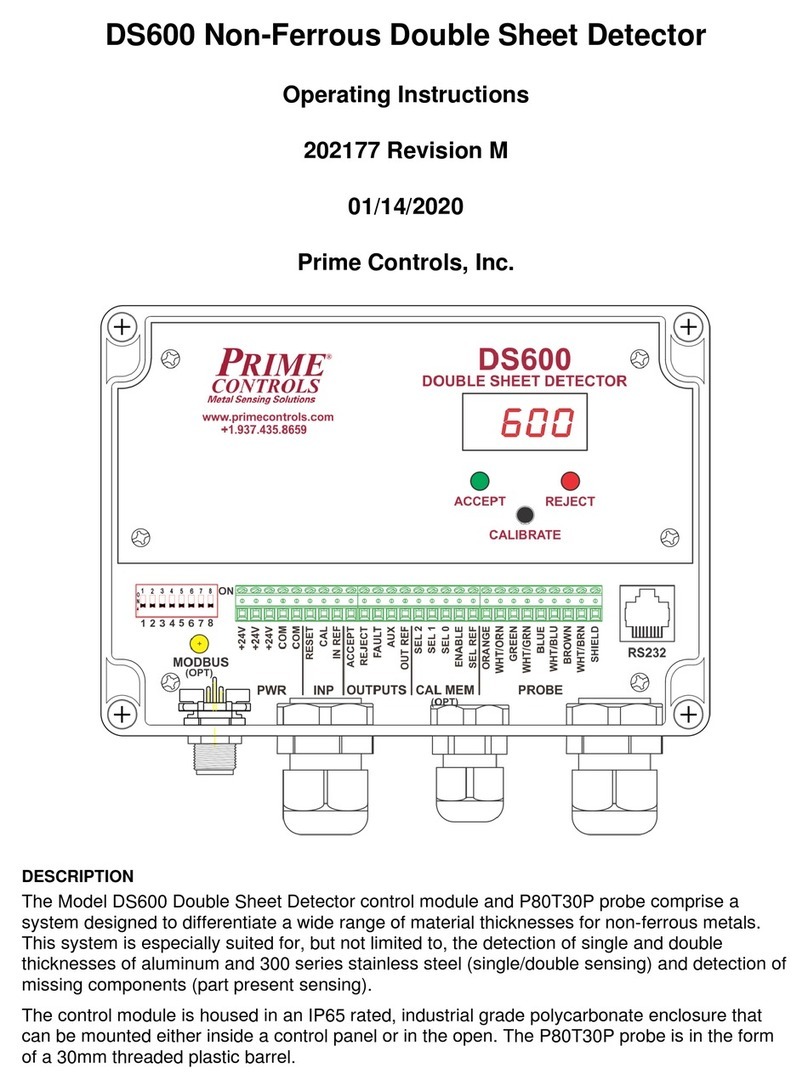

Prime Controls DS600 User manual

Prime Controls

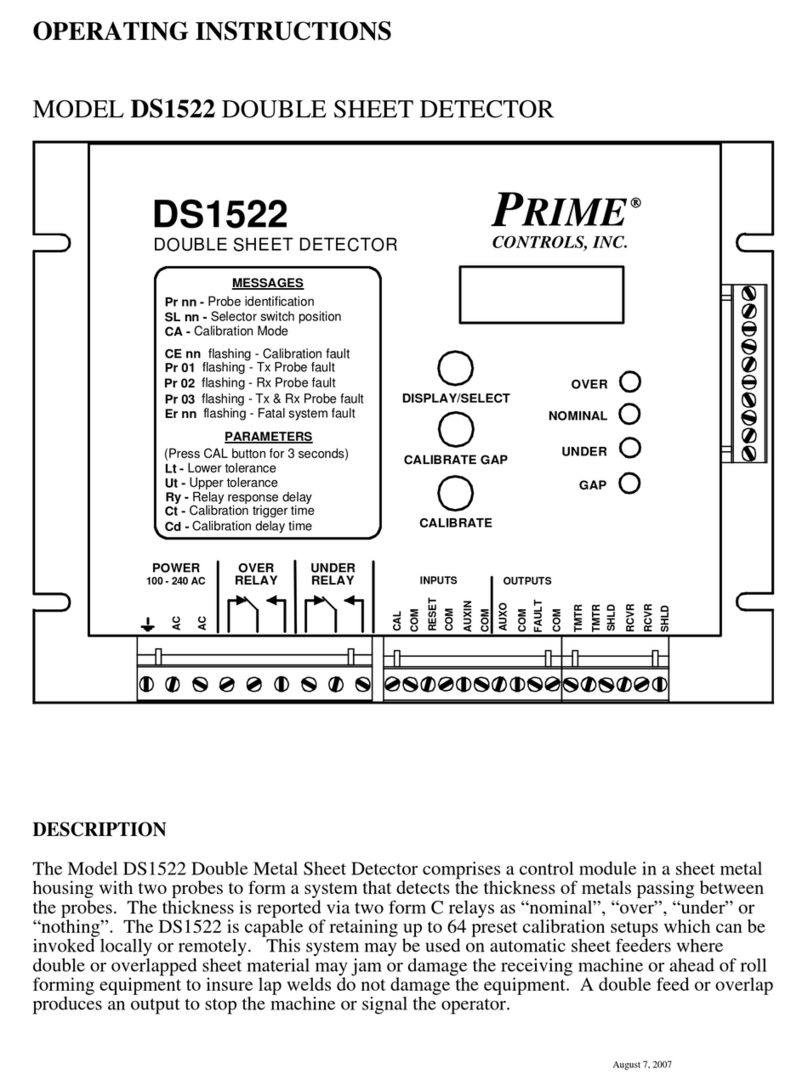

Prime Controls DS1522 User manual

Prime Controls

Prime Controls SD220 User manual

Prime Controls

Prime Controls FLUXIMITY DS71 User manual

Prime Controls

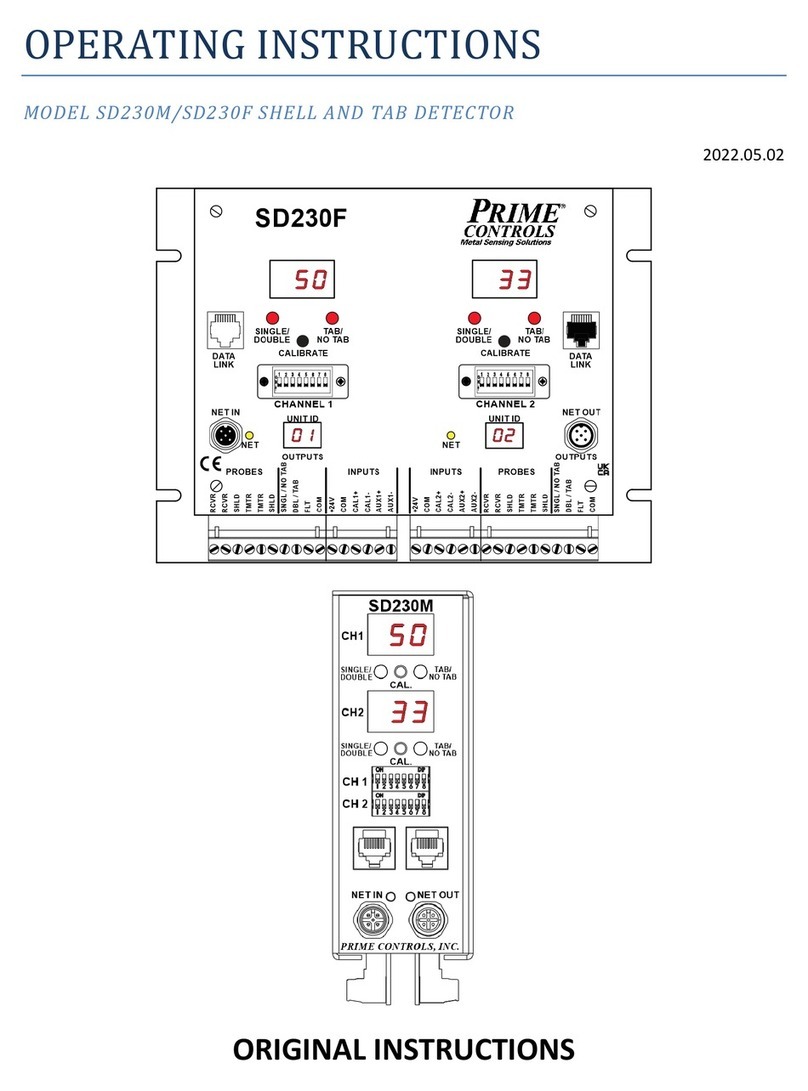

Prime Controls SD230M User manual

Prime Controls

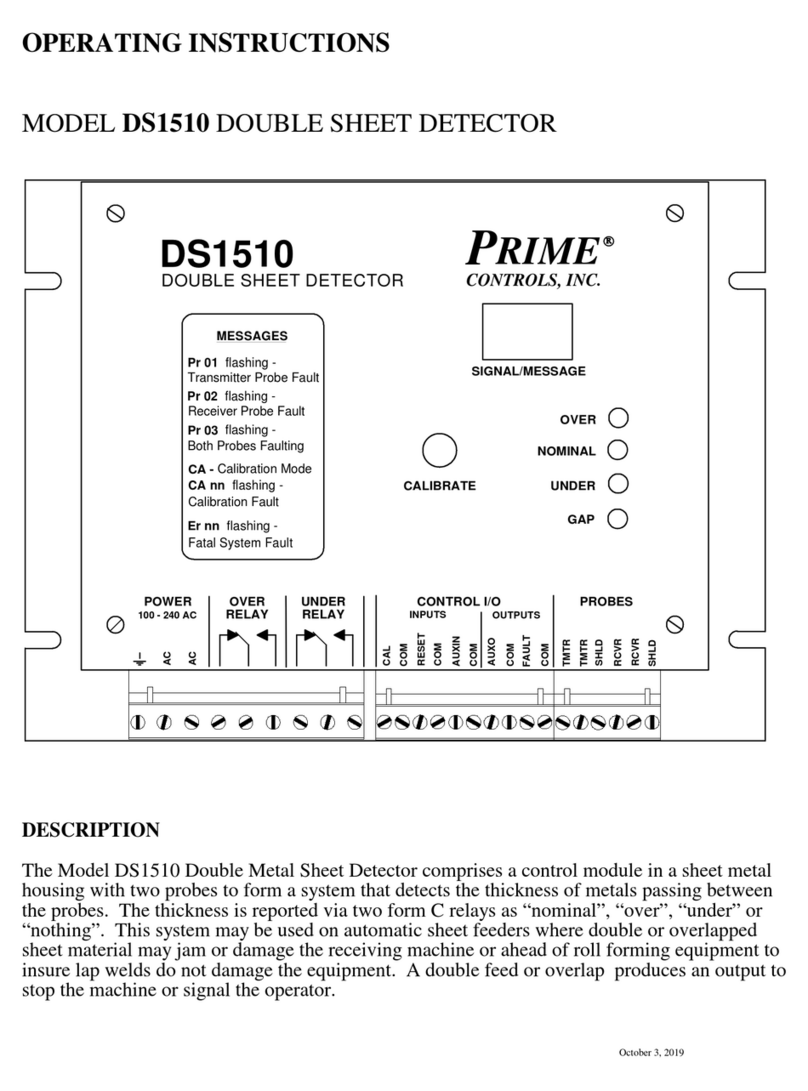

Prime Controls DS1510 User manual

Prime Controls

Prime Controls LH200 User manual

Prime Controls

Prime Controls DS3410 User manual