Shopsmith Mark V 520 User manual

Alignment Mark V Model 520

Page 1

Also, remember that your Mark V could possibly go

out of alignment if it is moved to an area with

varying floor levelness. Remember to recheck align-

ment and make needed adjustments after moving

your Mark V, if needed.

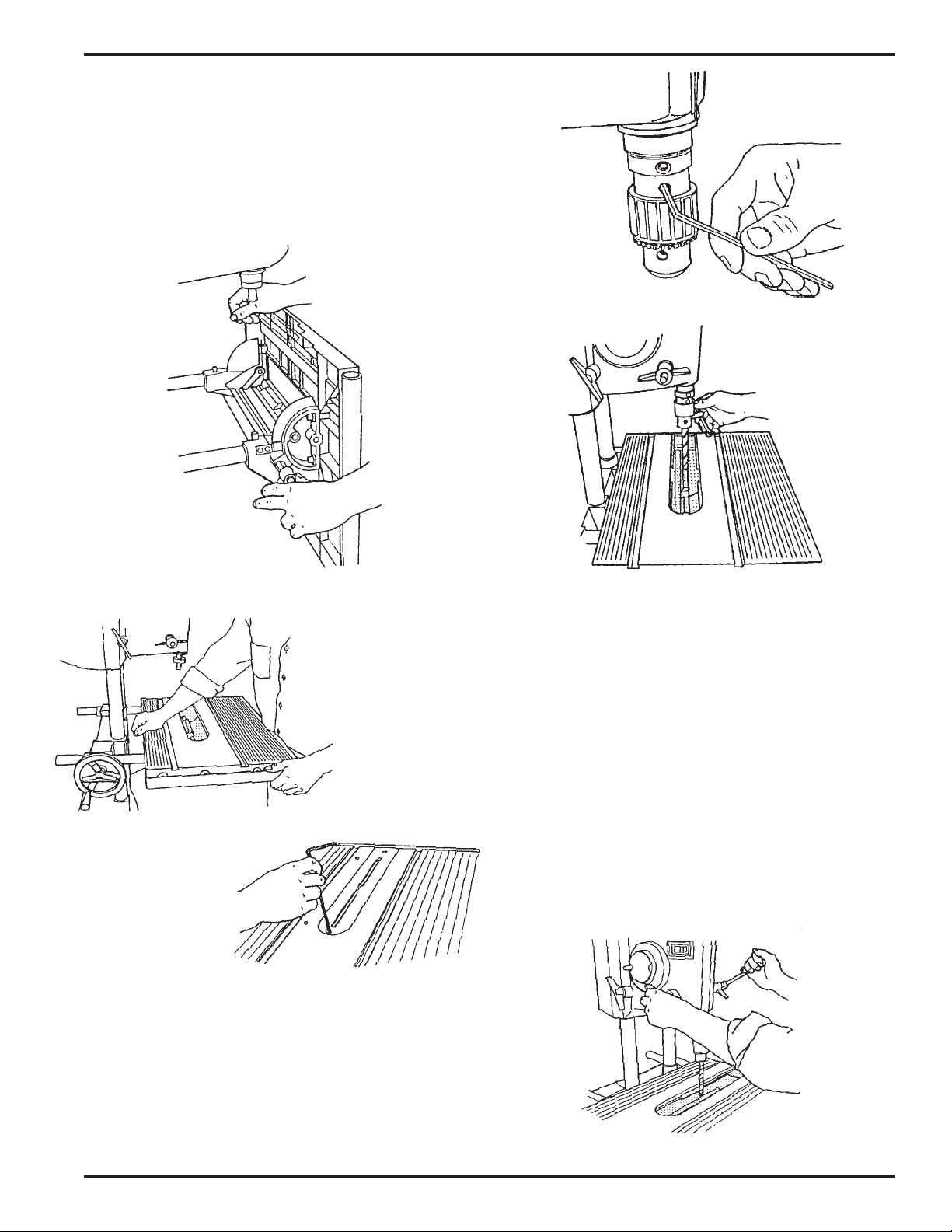

ADJUST THE HEADREST LOCK

1. To check the headrest lock (15), grasp the way

tubes near the tie bar (25) and pull up, as

demonstrated by the right hand in Figure B-

44.

2. If there is "give" in the lock, unlock the handle

and use a medium Phillips screwdriver to

turn the lock shaft (6) clockwise, as done by

the left hand in Figure B-44. If the lock is

difficult to operate, the shaft is too tight. To

loosen, unlock the handle and turn the shaft

counterclockwise.

SAFETY

WARNING

Make sure the speed dial is set to "Slow", then

turn off and unplug the Mark V before performing

any ALIGNMENT procedure.

1. Complete ALL of the following procedures–

and then recheck them at regular intervals.

You MUST use an accurate combination

square for alignment and adjustment. To

check that your square is accurate, select a

board with at least one straight and true edge.

Place the square against the good edge and

draw a line across the width. Flop the square

over and hold it against the same edge and

draw another line next to the first one. If the

lines are parallel, your square is accurate.

2. All the parts and accessories which support or

guide the stock MUST be aligned parallel

with or perpendicular to the main spindle's

plane of rotation. During the following align-

ment procedures the saw blade (provided in

the accessories box) will represent the main

spindle's plane of rotation.

NOTE

If you have installed casters (optional) on your

Mark V, make sure they are retracted and the legs

on the Mark V sit firmly on a level floor. Do this

now.

Tools Needed:

• 3/16" Allen wrench

• 5/32" Allen wrench, long handle (provided)

• 5/32" Allen wrench, short handle (provided)

• 5/16" Allen wrench (provided)

• 9/16" wrench

• Arbor wrench (provided)

• 1/2" wrench

• Adjustable wrench (optional)

• 1/2" socket and ratchet wrench with short extension

• 3/8" to 1/2" drill bit

• Small Straightblade screwdriver

• Medium Straightblade screwdriver

• Medium Phillips screwdriver

• High quality combination square

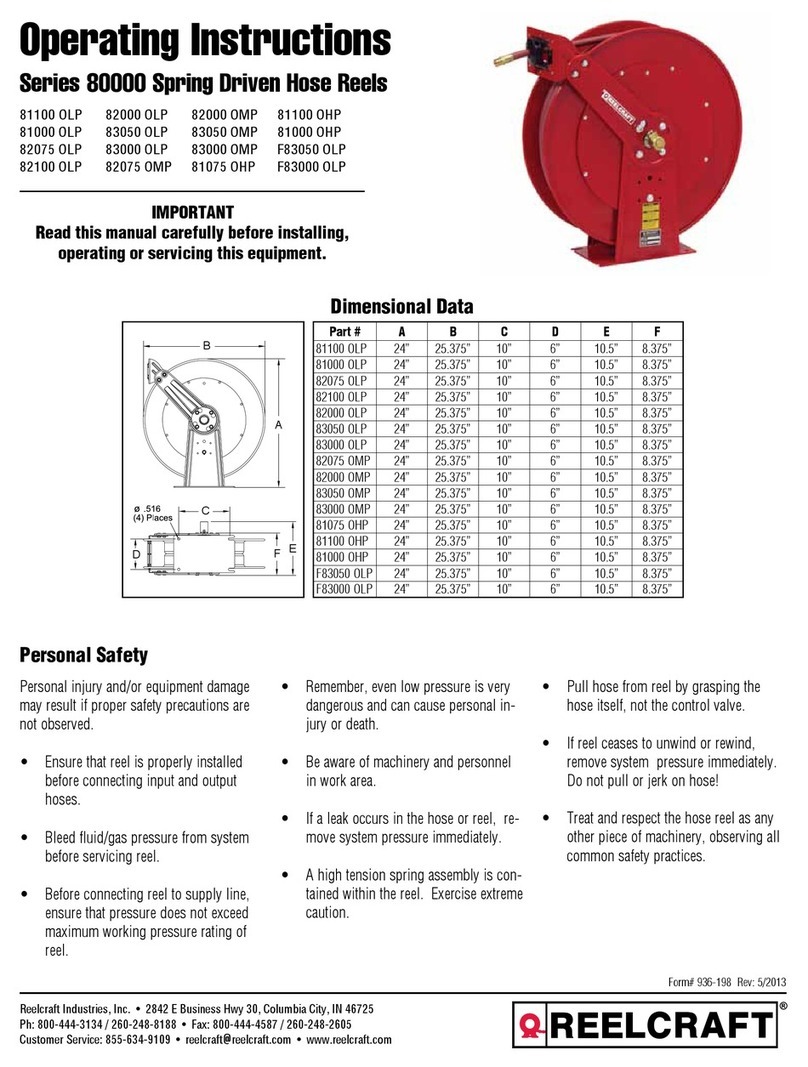

Alignment of Model 520

Figure B-44

Mark V Model 520 Alignment

Page 2

ADJUST THE CARRIAGE LOCK

3. If the carriage lock handle (187) does not lock

into the horizontal position or the carriage

moves out of position, the lock needs adjust-

ing. To adjust the lock, use a 1/2" socket with

an extension and ratchet handle to tighten or

loosen the nut located at the back of the

carriage assembly, as shown in Figure B-45.

Figure B-45

4. When the carriage lock handle locks into the

horizontal position and the carriage no longer

moves when the handle is in the horizontal

position, tighten the nut a final 1/4 turn.

WARNING

The carriage lock handle MUST lock into the

horizontal position, otherwise the carriage lock

may vibrate loose.

SET THE WORKTABLE'S 90° LEFT STOP

WARNING

Always make sure the Mark V headstock and

carriage are locked and all casters are raised off

the floor before lifting the Mark V into the vertical

drill press position.

5. Unlock the carriage and headstock. Move the

headstock to the middle of the way tubes.

Then move the carriage between the head-

stock and base mount (right side).

6. Tightentheheadstockandcarriagelocks. Place

the Mark V in the vertical position by loosen-

ing the headrest handle (15), firmly grasping

the way tubes (20) near the headrest end, and

lifting the tubes into the 90° position, as dem-

onstrated in Figure B-46.

Figure B-46

Figure B-47

Figure B-48

7. See Figure B-47. Use your fingers to screw in

the base lock (2). Note the base lock is slightly

off center to the countersink found in the

bench base, as shown in Figure B-48. This

offset allows the base lock to more firmly hold

the base in place.

Alignment Mark V Model 520

Page 3

8. Move the worktable into the 90° position by

loosening the table tilt lock (165), as seen in

Figure B-49, then putting the worktable in the

horizontal 90° position, as shown in Figure B-

50. Retighten the table tilt lock only enough to

allow movement with firm pressure.

9. Use a 5/32" Allen wrench to remove the table

insert, as demonstrated in Figure B-51.

Figure B-52

Figure B-54

Figure B-51

Figure B-53

Figure B-49

Figure B-50

10. To install the drill chuck, mount the chuck on

the spindle and align the chuck's set screw

with the spindle knob's set screw, as shown in

Figure B-52. This allows the chuck's set screw

to set on the flat part of the spindle. Use a 5/

32" Allen wrench to securely tighten the drill

chuck's set screw.

11. Install a 3/8" to 1/2" straight drill bit in the

drill chuck and use the chuck key to lock it

place. See Figure B-53.

NOTE

Check the straightness of the drill bit by rolling it on

a flat surface. You can also hand-rotate the drill

chuck while holding the combination square against

the drill bit and the table. If the bit is not straight

DO NOT use it for these alignment instructions.

12. With the drill bit above the table opening, use

the quill feed to extend the bit 1/2" into the

table opening, as in Figure B-54.

Mark V Model 520 Alignment

Page 4

15. Recheck the setting by loosening the tilt lock,

moving the table, and then repeating Steps 13

and 14. (Rechecking the settings is very im-

portant!)

SET THE WORKTABLE'S 0° STOPSET THE WORKTABLE'S 0° STOP

SET THE WORKTABLE'S 0° STOPSET THE WORKTABLE'S 0° STOP

SET THE WORKTABLE'S 0° STOP

16. Remove the drill bit and drill chuck from the

spindle.

17. Loosen the base lock (2). Firmly grasp the way

tubes and lower the headstock into the hori-

zontal position, then engage the head rest.

18. Loosen the table tilt lock and place the table in

the horizontal "0" position. Retighten the table

tilt lock only enough to allow movement with

firm pressure.

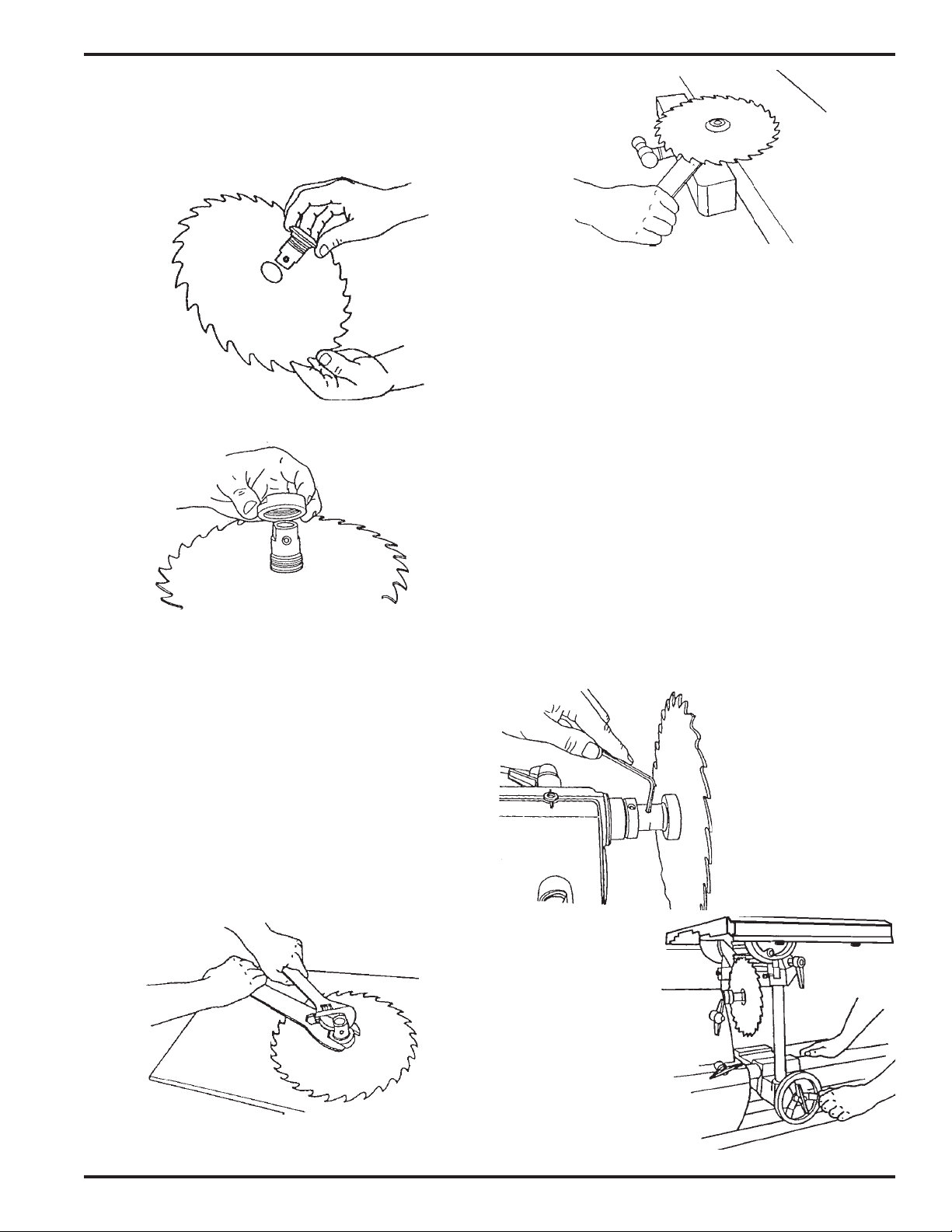

19. Mount the saw blade on the arbor:

a. Remove the arbor nut by turning it clock-

wise, as seen in Figure B-59a. Hold the

arbor with the threaded part pointing to

the left.

13. Set the combination square against the bit and

table, as shown in Figure B-55. The square

should contact the bit along its entire length.

When the table is exactly perpendicular to the

drill bit, lock the table, as seen in Figure B-56.

Figure B-56

Figure B-55

14. Both 90° stops (shown in Figs. B-57 and B-58)

should contact the underside of the table. If

they don't, use a 1/2" wrench to adjust the

stops.

Figure B-59a

Figure B-58

Figure B-57

Alignment Mark V Model 520

Page 5

b. Hold the blade with the teeth pointing

toward you, as shown in Figure B-59b,

then insert the arbor through the hole.

Replace the nut and finger tighten it, as in

Figure B-59c.

Figure B-59e

Figure B-59d

Figure B-59c

Figure B-59b

c. Place the blade and arbor on your work-

bench with the nut pointing up.

d. Hold the arbor with an adjustable wrench

and tighten the arbor nut with the arbor

wrench, as demonstrated in Figure B-59d.

Another way to tighten the arbor nut is to

clamp the arbor in a bench vise, as illus-

trated in Figure B-59e, and tighten the nut

with the arbor wrench.

NOTE

The only time the saw blade is used without the

upper or lower saw guards is during alignment and

only after the Mark V is turned off and unplugged.

20. Mount the saw blade on the spindle and align

the arbor set screw with the spindle knob's set

screw,thenuse a 5/32"Allen wrench to tighten

the arbor set screw, as seen in Figure B-60.

21. Reinstall the table insert (138) in the work-

table.

22. Raise the worktable so that it clears the top of

the saw blade.

23. Loosen the carriage lock and slide the carriage

so the saw blade is directly beneath the slot in

the table insert. See Figure B-61.

Figure B-60

Figure B-61

Mark V Model 520 Alignment

Page 6

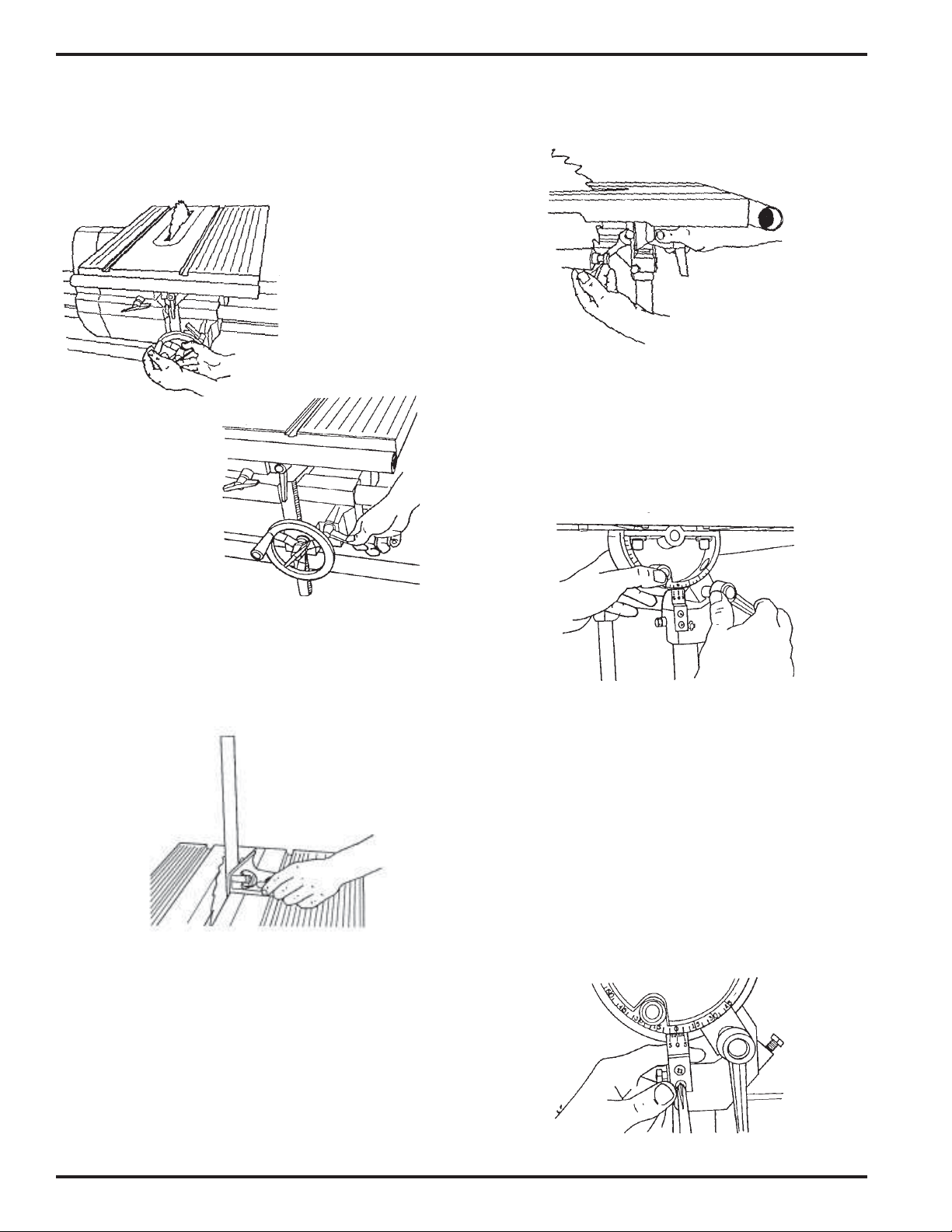

24. Lower the worktable (but not all the way

down) so the saw blade comes through the

slot. Lock the table height, as seen in Figure B-

62.

25. Tighten the carriage lock, as shown in Figure

B-63.

Figure B-62

Figure B-63

Figure B-66

Figure B-65

Figure B-67

26. Place the combination square against both the

saw blade and worktable, as seen in Figure B-

64. Make sure the square's blade does not

touch a saw tooth and does rest in a gullet

between teeth.

bolt is adjusted, the stop pin will "lock" back

when the tilt lock is tightened. See Figure B-

65.

29. Loosen the tilt lock, move the worktable, then

depress the 0° stop pin until the stop bolt

contacts it. Tighten the tilt lock, and recheck

the setting by repeating Steps 26 through 28.

See Figure B-66. (It is very important to re-

check the setting!)

ADJUST THE TABLE TILT INDICATOR

30. Tighten the table tilt lock and check that the "0"

mark on the indicator aligns with the "0" mark

on the trunnion ((149).

31. To adjust the scale, use a medium Phillips

screwdriver to loosen the two screws which

hold the indicator to the tie bar. See Figure B-

67. Then while holding the indicator in posi-

tion so the "0"s are aligned, retighten the

screws.

Figure B-64

27. If the worktable is not exactly perpendicular

to the saw blade, adjust the worktable so it is

perpendicular to the saw blade, then tighten

the tilt lock.

28. To adjust the 0° stop, simultaneously depress

the table stop pin and use a 1/2" wrench to

adjust the stop bolt. The stop bolt should just

contact the side of the stop pin. Once the stop

Alignment Mark V Model 520

Page 7

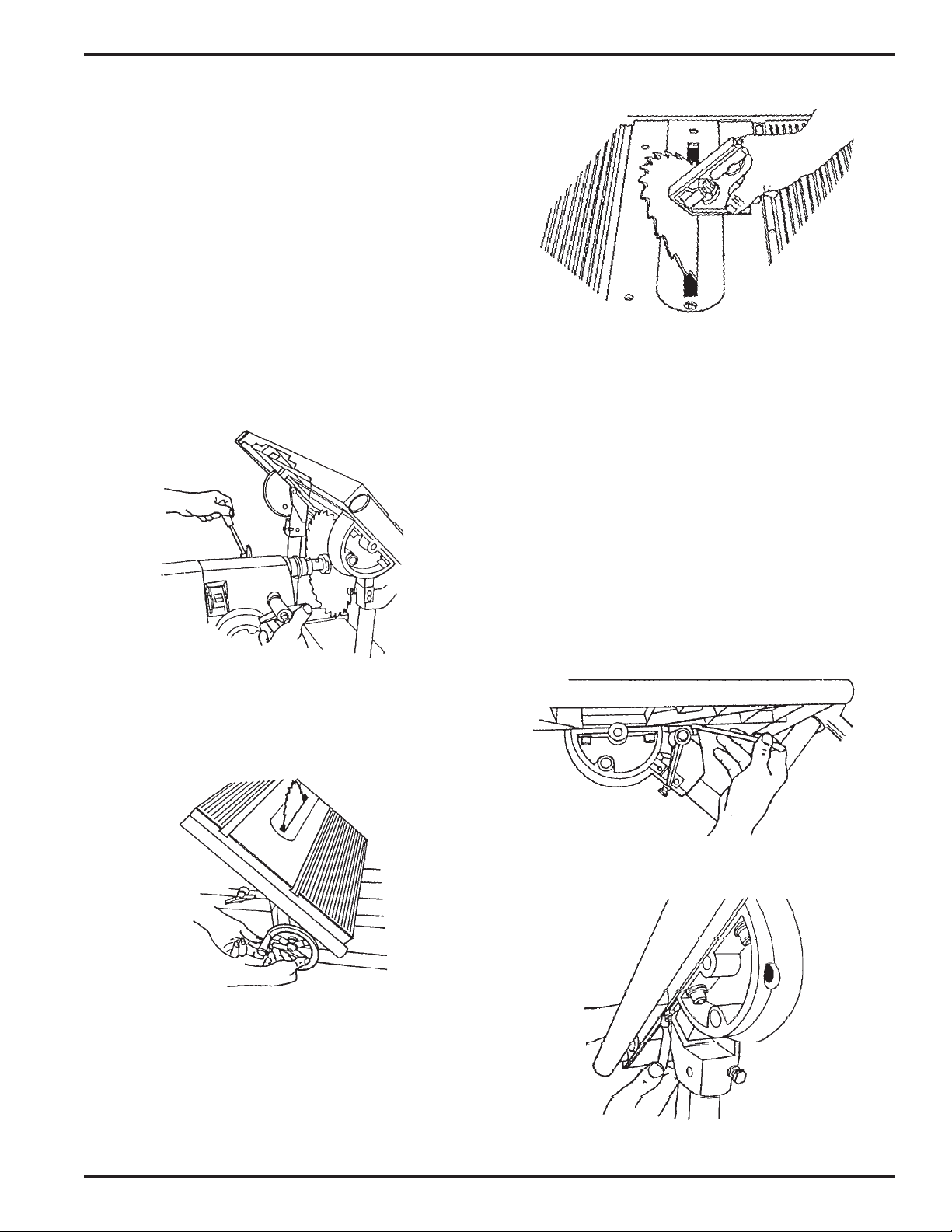

ADJUST THE WORKTABLE'S 45°

STOPS

32. Loosen the table height lock and raise the table

until it clears the saw blade. Tighten the

height lock.

33. Loosen the tilt lock and tilt the worktable to

the right until it makes contact with the two

45° stop bolts (158).

34. Tighten the tilt lock only enough to allow

movement with firm pressure.

35. Loosen the quill feed (shown in Figure B-68)

and extend the quill so the saw blade is cen-

tered beneath the slot in the table insert. When

it is centered, lock the quill feed.

36. Lower the worktable so the saw blade extends

through the slot. See Figure B-69. Lock the

table height.

38. If the worktable is not exactly 45° to the saw

blade, adjust the worktable so it is.

39. Tighten the tilt lock, then use a 1/2" wrench to

adjust the 45° stop on the front side of the

worktable (shown in Figure B-71) and the

back side of the worktable (shown in Figure B-

72). The stops should just contact the under-

side of the table.

40. Loosen the tilt lock and move the table. To

recheck the 45° stops, repeat Steps 35 through

39. (It is very important to recheck the set-

ting!)

Figure B-68

Figure B-70

Figure B-69

Figure B-71

Figure B-72

37. Removethebladefromthecombinationsquare

and place the square against the saw blade

and the worktable, as shown in Figure B-70.

Make sure the combination square doesn't

rest on the table insert.

Mark V Model 520 Alignment

Page 8

ALIGN THE MITER GAUGE SLOTS

41. Return the worktable to the horizontal "0"

stop and tighten the tilt lock. The carriage lock

and headstock lock should also be tightened.

Remove the table insert.

42. Place the miter gauge in the right miter gauge

slot, and use a 5/32" Allen wrench to remove

the quick clamp from the safety grip, as shown

in Figure B-73.

45. If the miter slots need to be aligned, do the

following:

a. Tilt the table to 45° and tighten the tilt lock.

b. Use a 5/16" Allen wrench to loosen all four

bolts (147) which hold the worktable to the

trunnions, as pointed out in Figure B-77.

Loosen the bolts only enough to allow

movement with firm pressure. See Figure

B-78.

Figure B-74

Figure B-73

43. Insert the long 5/32" Allen wrench through

the miter gauge. Borrow a set screw from the

lathe tool rest and use the short 5/32" Allen

wrench to install it in either top miter gauge

hole, as seen in Figure B-74. Place the tip of the

long wrench against the front side of the saw

blade and tighten the set screw.

44. Move the miter gauge from front to back

along the saw blade, as shown in Figs. B-75

and B-76. If it hangs up on the blade or a gap

develops, the miter gauge slots need to be

aligned. Make sure the Allen wrench does not

contact a saw blade tooth, because the tooth

"set" will cause misalignment.

Figure B-76

Figure B-78

Figure B-75

Figure B-77

NOTE

If you find it difficult to loosen the bolts, consider

using a T-handle Allen wrench, or use a boxed

wrench for extra torque. Another alternative is to

use the hanging hole in an adjustable wrench, as

demonstrated in Figure B-78a.

Alignment Mark V Model 520

Page 9

47. First tighten the rear screw. Then the front of

the insert will be sprung slightly above the

table. Level the insert by placing your hand on

the front of the insert, as in Figure B-79, and

slowly turning the front screw until it draws

the front of the insert flush with the worktable

surface.

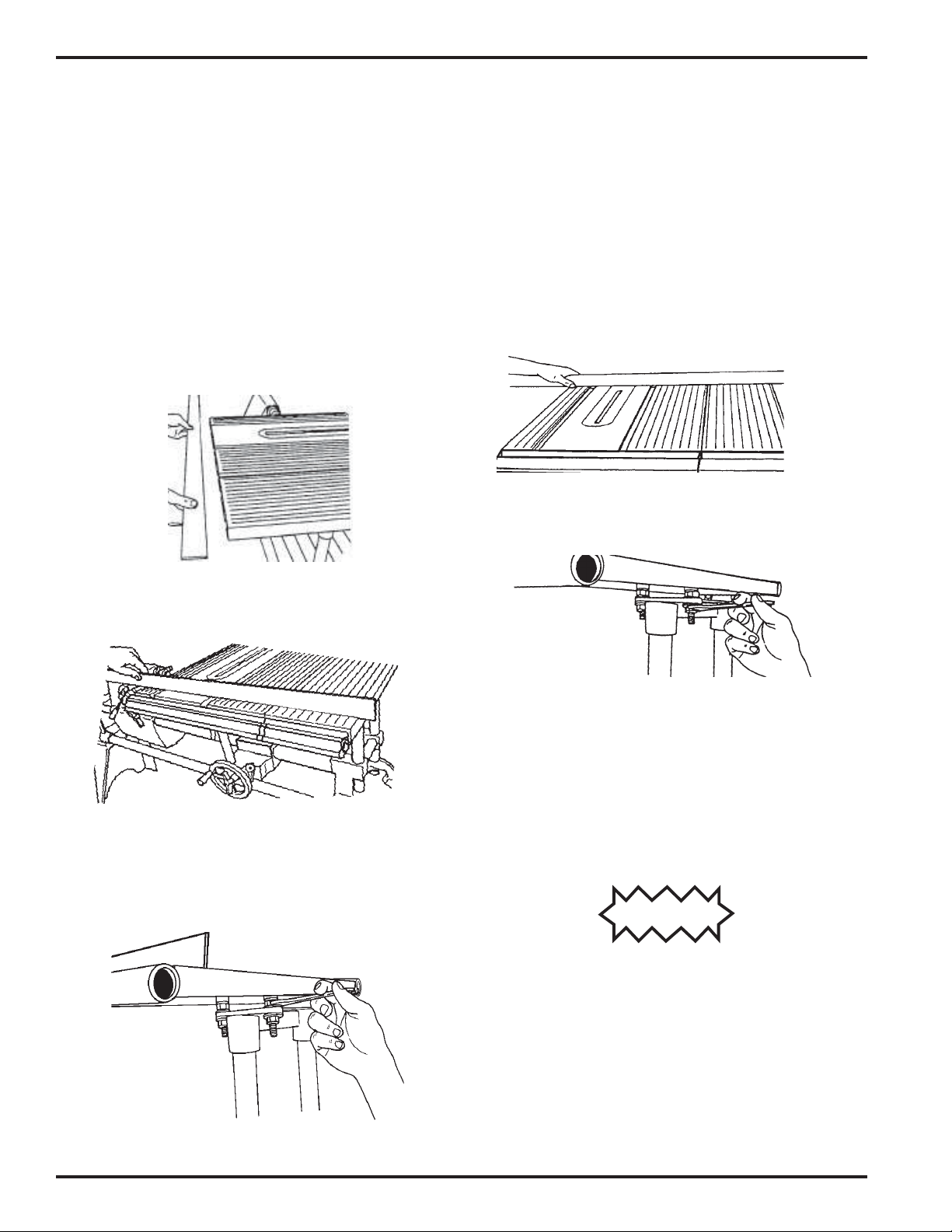

ADJUST THE MITER GAUGE GLIDES

48. Place the miter gauge in the worktable's miter

gauge slot. See Figure B-80.

Figure B-78a

c. Position the worktable back to the hori-

zontal "0" and tighten the tilt lock.

d. Adjust the worktable, then again move the

miter gauge and wrench along the face of

the saw blade until the wrench tip consis-

tently contacts the entire blade surface.

e. When the miter gauge slot is aligned, use

the 5/16" Allen wrench to retighten the

two trunnion bolts which are closer to the

headstock. Then loosen the table tilt lock,

tilt the worktable to 45°, and retighten the

table tilt lock. Use the 5/16" Allen wrench

to retighten the other two trunnion bolts.

f. Loosen the table tilt lock and move the

table, then return it to the horizontal "0"

position. Recheck the slot alignment. If it

is off, repeat Steps dand e.

NOTE

Tighten the bolts only after the table tilt lock is secured.

Otherwise the worktable will bow or bind the next time

the table tilt lock is tightened.

INSTALL THE TABLE INSERT IN THE

WORKTABLE

46. Place the table insert in the worktable recess.

Use a 5/32" Allen wrench to start both screws.

Figure B-79

Figure B-80

49. Check to see if the miter gauge wobbles side-

to-side. Also, slide it back and forth in the slot

to check if the miter gauge scrapes against the

table. If the miter gauge rocks or scrapes the

table, adjust the glides.

50. If the glides need to be adjusted, do the follow-

ing:

a. Remove the miter gauge from the slot and

turn it over.

b. Use a medium screwdriver to screw the

glides in or out, as illustrated in Figure B-

81, so that the glides hold the miter gauge

1/64" to 1/32" off the worktable and the

miter gauge does not rock in the slots.

Figure B-81

c. Return the miter gauge to the slot and

recheck and re-adjust it, if needed.

Mark V Model 520 Alignment

Page 10

ADJUST THE MITER GAUGE FACE

51. Remove the safety grip from the miter gauge.

Make sure you keep the small, thin washer.

52. Put the miter gauge in the right slot and place

the combination square against the saw blade

and miter gauge face, as seen in Figure B-82.

Figure B-83

Figure B-84

Figure B-82

53. If the miter gauge face is not perpendicular to

the saw blade, do the following:

a. Use a long Allen wrench to loosen the lock

knob (268) and adjust the miter gauge so it

is perpendicular to the saw blade, then

tighten the lock knob. See Figure B-83.

b. Use a medium screwdriver, loosen the

screw(273) whichholds the indicator plate

(275 ), and set its "0" to the miter gauge's

"90". Tighten the screw. See Figure B-84.

55. Depress the plunger, then turn the stop screw

until you feel it touch the plunger.

56. To re-check the stop setting, repeat Steps 52

through 55.

ADJUST BOTH 45° STOPS

57. Loosen the lock knob (268) and pull out the

plunger. Then, at the same time, rotate the

miter gauge and push in the plunger until it

hits the 45° stop (there is one on each side of

the 90° stop).

58. Use a combination square to set the miter

gauge face at 45° to the saw blade. If the 45°

stop needs adjustment, use a medium screw-

driver to back out the 45° screw 2 to 3 turns.

59. Depress the plunger, then turn the stop screw

until you feel it touch the plunger.

60. To recheck the stop setting, repeat Steps 54

through 59.

61. To adjust the other 45° stop, repeat Steps 57

through 60.

REMOVE THE SAW BLADE

62. Loosen the table height lock and raise the table

so that it clears the saw blade, then tighten the

lock. Unlock the carriage lock and move the

worktable to the right.

Figure B-85

Figure B-86

ADJUST THE 90° POSITIVE STOP

54 Use a small screwdriver to back out the 90°

stop screw 2 to 3 turns, as shown in Figure B-

85.

63. Use the 5/32" Allen

wrench to loosen the

arbor set screw. Re-

move the saw blade.

See Figure B-86.

64. Unlock the table height

lockandlowerthe table

to a comfortable work-

ing height. Tighten the

lock.

Page 11

Alignment Mark V Model 520

Figure B-99

ALIGN THE EXTENSION TABLE

NOTE

These instructions are for aligning the exten-

sion table on the right side of the headstock. You

70. The worktable should already be mounted

in the carriage mount. Move the worktable

next to the extension table and adjust it to

about 1/4" above the extension table, as

seen in Figure B-100.

ALIGN THE PRO FENCE PARALLEL

WITH THE WORKTABLE

63. Place the miter gauge in the left slot of the

worktable on the infeed side. Place the Pro

Fence on the right side of the saw table.

64. Insert the long 5/32" Allen wrench through

the miter gauge and secure it using the short

5/32" Allen wrench and a set screw bor-

rowed from the tool rest.

65. Move the fence toward the Allen wrench

until it just touches it.

66. Lock the lower fence lock handle first, then

lock the upper fence lock handle to secure

both ends of the pro fence.

67. Slide the miter gauge back and forth in the

slot. The tip of the Allen wrench should

keep in slight contact with the fence. Watch

that you don't scratch the fence.

68. If the allen wrench pulls away from or binds

against the fence, the fence needs aligning. If

so, do the following:

a. Using the short 5/32” short Allen

wrench, loosen the four button head

cap screws (3), located on the top of the

fence, slightly. They should be just tight

enough to require firm pressure to align

the fence.

b. Raise the upper fence lock handle only

to unlock the rear of the fence.

c. Adjust the rear end of the fence so that

it just touches the allen wrench as the

miter guage slides along the fence.

d. When alignment is reached, lock the

upper fence lock handle. Slide the miter

gauge back and forth to double check

your alignment. Using the short 5/32”

Allen wrench, tighten the four button

head cap screws (3) completely.

can also follow these same procedures to align it

to the left side of the headstock.

For most projects, align the extension table on

the right side, since it can usually be used when

placed on the left side. However, once the exten-

sion table is aligned on the right side, it cannot

be transferred to the left side and still maintain

precise alignment.

If you wish precise alignment on the left side,

repeat the following instructions– but place the

extension table on the left side in the headstock.

69. Mount the extension table in the Mark V's

accessory base mount (on the right side) at a

comfortable height, as shown in Figure B-

99. Use a 1/2" wrench to loosen the bottom

nuts holding the table base to the table ap-

proximately 1/4" from the table. This will

allow you room for later adjustment.

Figure B-100

Page 12

Mark V Model 520 Alignment

71. Hold a straightedge against the infeed edge

of both the worktable and extension table

tubes, as in Figure B-101. Line up the exten-

sion table's infeed edge with the worktable's

infeed edge. The elongated holes in the ex-

tension table's base permit you to slide the

extension table forward and backward.

72. Hold a straightedge on the infeed top sur-

face of both the worktable and the extension

table, as shown in Figure B-102. As needed,

adjust the top nuts located on the infeed side

of the extension table, in order for the

straightedgetobelevelacross both the work-

table and the extension table infeed sides.

See Figure B-102a.

Figure 103a.

Figure B-102

Figure B-101

Figure B-103

Figure B-102a

73. Hold the straightedge on the outfeed top

surface of both the worktable and the exten-

siontable,asseeninFigureB-103. Asneeded,

adjust the top nuts located on the outfeed

side of the extension table, in order for the

straightedgetobe level across both thework-

table and the extension table outfeed sides.

74. Double check the levelness at the infeed and

outfeed sides of the table surfaces. All four

top nuts (those nearest the table) used in

levelingthe extension tableshould be touch-

ing the base.

75. When the tables are aligned on three sides–

infeed side edge (along the table tubes, as in

Figure B-101), infeed top surface (as in Fig-

ure B-102), and outfeed top surface (as in

Figure B-103) – securely tighten the bottom

nut on each of the four studs, as seen in

Figure 103a.

CAUTION

DO NOT overtighten the nuts. Tighten the nuts until

they bottom out, then no more than 1/8 additional turn.

Overtightening the nuts will stretch and damage the

threads.

NOTE

If you move the Mark V to another location–

especially one with an uneven floor– remember

to re-check the extension table alignment.

Page 13

Alignment Mark V Model 520

Figure B-104

Figure B-108

Figure B-106

Keps Nuts

Figure B-105

Figure B-107

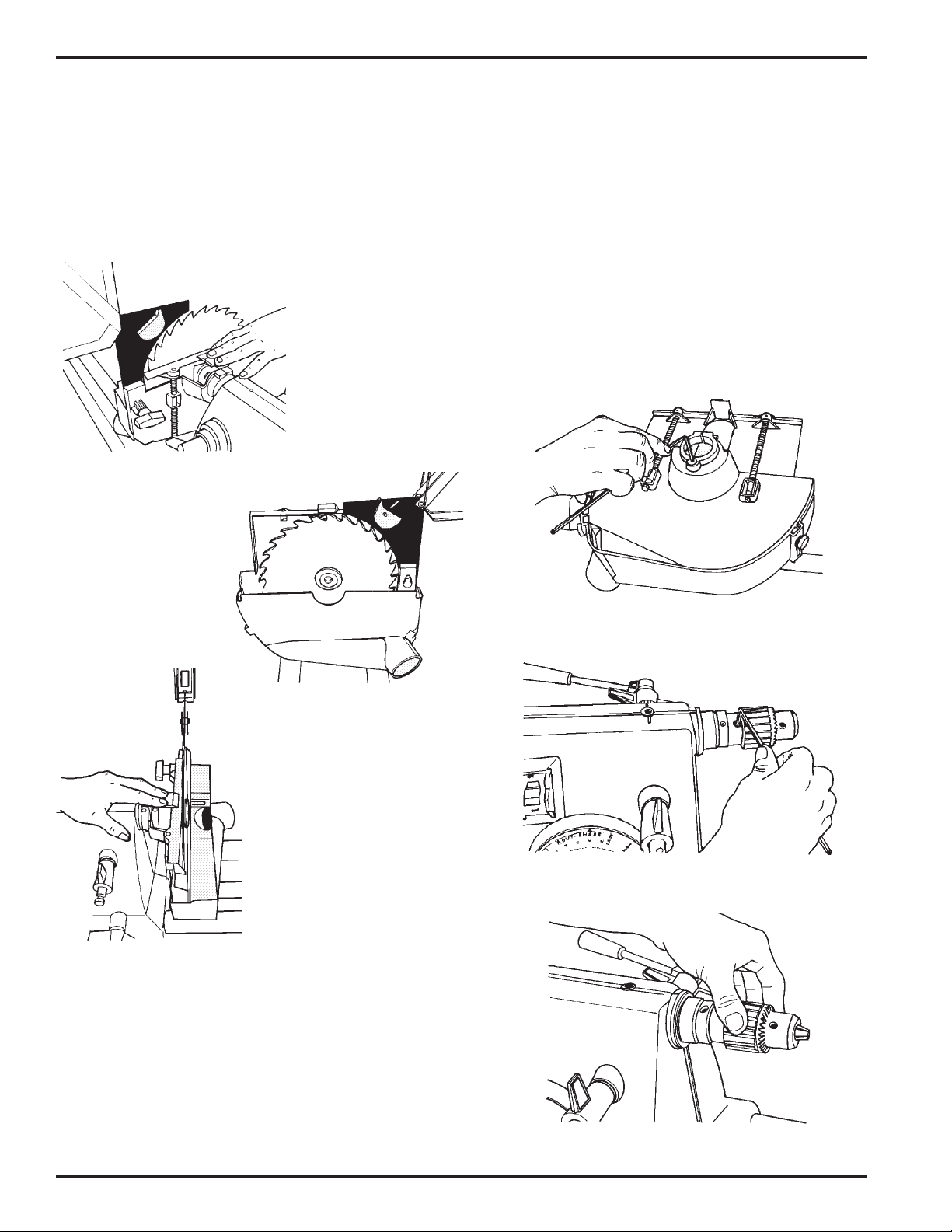

ALIGN THE EXTENSION

TABLE TUBES

76. Place the straightedge along the infeed-side

tops of both the worktable and extension

table tubes, as shown in Figure B-104.

77. If the extension table's tube is not aligned

withtheworktable'stube,usea7/16"wrench

to slightly loosen both keps nuts (248) at-

tachingthe tube tothe extension table. Make

the needed adjustments, then re-tighten the

nuts. See Figure B-105.

78. Repeat Steps 85 and 86 for the extension

table's tube located on the outfeed-side.

MOUNT THE SAW GUARD

79. Loosen the accessory mount lock and re-

move the extension table. Loosen the table

heightlock and removethe worktable. Place

the saw blade and arbor in the lower saw

guard cover (204).

80. Fit the lower saw guard's clamp on the

spindle quill (59). Line up the arbor set

screw with the spindle knob's set screw

(where the spindle flat is located). Use a 5/

32" Allen wrench to tighten the arbor set

screw, as shown in Figure B-106.

87. Use the 5/32" Allen wrench to tighten the

socket head screw (215) on the saw guard

collar, as seen in Figure B-107.

INSTALL THE RIVING KNIFE

82. Loosen the guard lock knob (210) and insert

the upper saw guard's riving knife (199)

between the guard (213) and the lock plate

(208), as demonstrated in Figure B-108.

Page 14

Mark V Model 520 Alignment

Figure B-112

Figure B-111

Figure B-113

Figure B-114

Figure B-110

Figure B-109

83. Make sure the riving knife is fully seated

between the guard and the lock plate, as in

Figure B-109. The curved portion of the

riving knife should be very close to the saw

blade teeth (about 1/8"), as illustrated in

Figure B-110. Tighten the guard lock knob

(210). Look to see if the riving knife is

centered with the saw blade, as shown in

Figure B-111.

84. If the riving knife is not centered with the

saw blade, follow these steps:

a. Notice which way the riving knife is

not centered with the saw blade.

b. Unclamp and remove the upper saw

guard, then remove the saw blade and

lower saw guard.

c. Use a 5/32" Allen wrench to adjust the

stopscrew(211) located below the lower

saw guard's collar, see Figure B-112.

• If the riving knife is to the left of the

saw blade, back out the stop screw

(counter-clockwise).

• If the riving knife is to the right of the

saw blade, screw in the stop screw

(clockwise).

d. Re-install the saw blade, lower saw

guard and riving knife, according to

Steps 88 through 92. If the riving knife

is still not centered on the saw blade,

repeat this Step 93.

Page 15

Alignment Mark V Model 520

Figure B-118

Figure B-117

Figure B-116

Figure B-115

ALIGN THE LATHE CENTERS

85. Remove the saw guards and the saw blade,

thenloosenthecarriage and headstock locks.

Move the headstock and carriage all the way

to the right and lock them in place.

86. Mount the drill chuck on the spindle, as

shown in Figure B-113. Completely close

the chuck jaws, as in Figure B-114.

87. Mount the cup center into the tailstock's

adjustable center, as seen in Figure B-115,

thenmount thetailstock into the base mount

(right side). Tighten the mount lock.

88. Loosen the quill lock. Extend the quill (seen

in Figure B-116), so the drill chuck almost

touches the cup center point and the center

point could fit into the chuck jaws.

89. If the center point does not "fit" into the

chuck jaws, determine whether you need to

adjustthecupcenter point horizontally and/

or vertically. Then do the following:

a. To adjust the cup center point horizon-

tally, loosen the set screw that locks the

adjustable center, as seen in Figure B-

117. Rotate the adjustable center as

needed to line up the cup center with

the drill chuck, then tighten the set

screw.

b. To adjust the cup center point verti-

cally, loosen the mount lock, then

loosen the tailstock stop collars. Raise

or lower the tailstock in the base mount

until the cup center point vertically

lines up with the drill chuck, then

tighten the mount lock. Press the stop

collars down firmly against the base

mountandtighten the collarsetscrews,

as shown in Figure B-118.

Popular Tools manuals by other brands

Gardena

Gardena 8022 operating instructions

SIXTOL

SIXTOL HOME PINK 120 BAG instruction manual

Beta

Beta 665 Operation manual and instructions

HOZAN

HOZAN C-438 quick start guide

Current Tools

Current Tools 509 Operating, Safety and Parts Manual

Pittsburgh Automotive

Pittsburgh Automotive 63984 Owner's manual & safety instructions