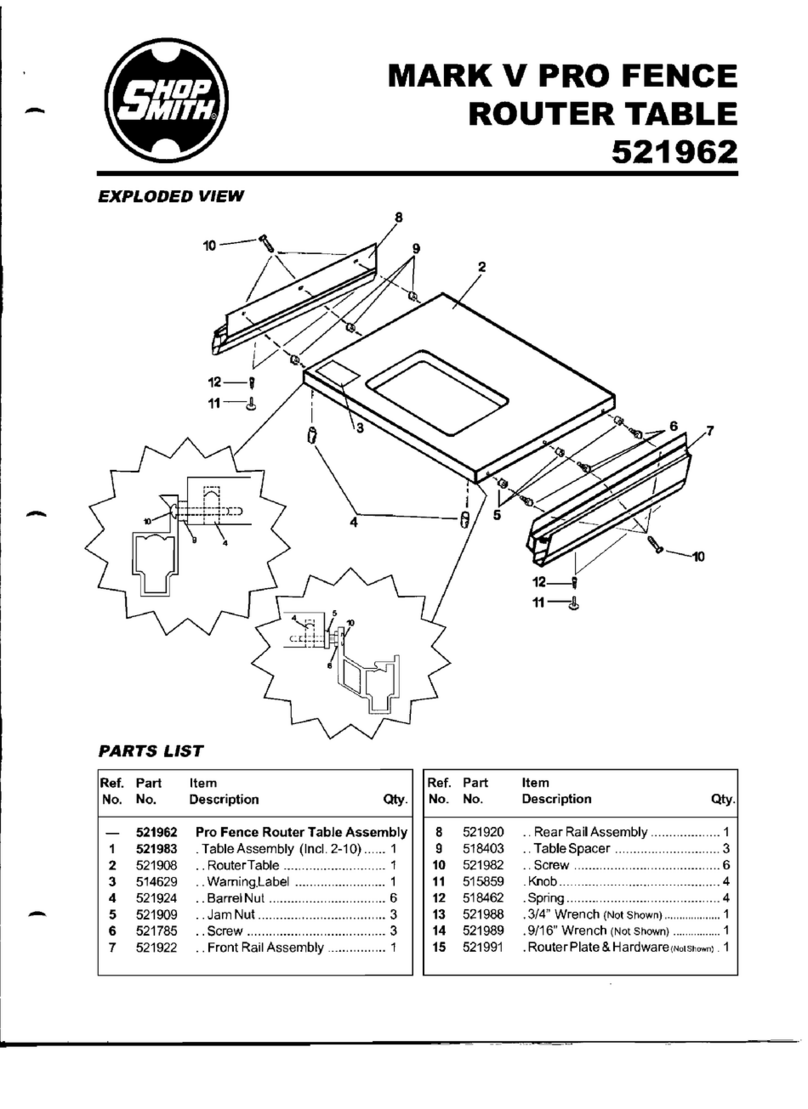

Shopsmith MARK V Instructions for use

MARK V

ALIGNMENT & MAINTENANCE

SHOPSMITH MARK V 845180

Page 2

NOMENCLATURE

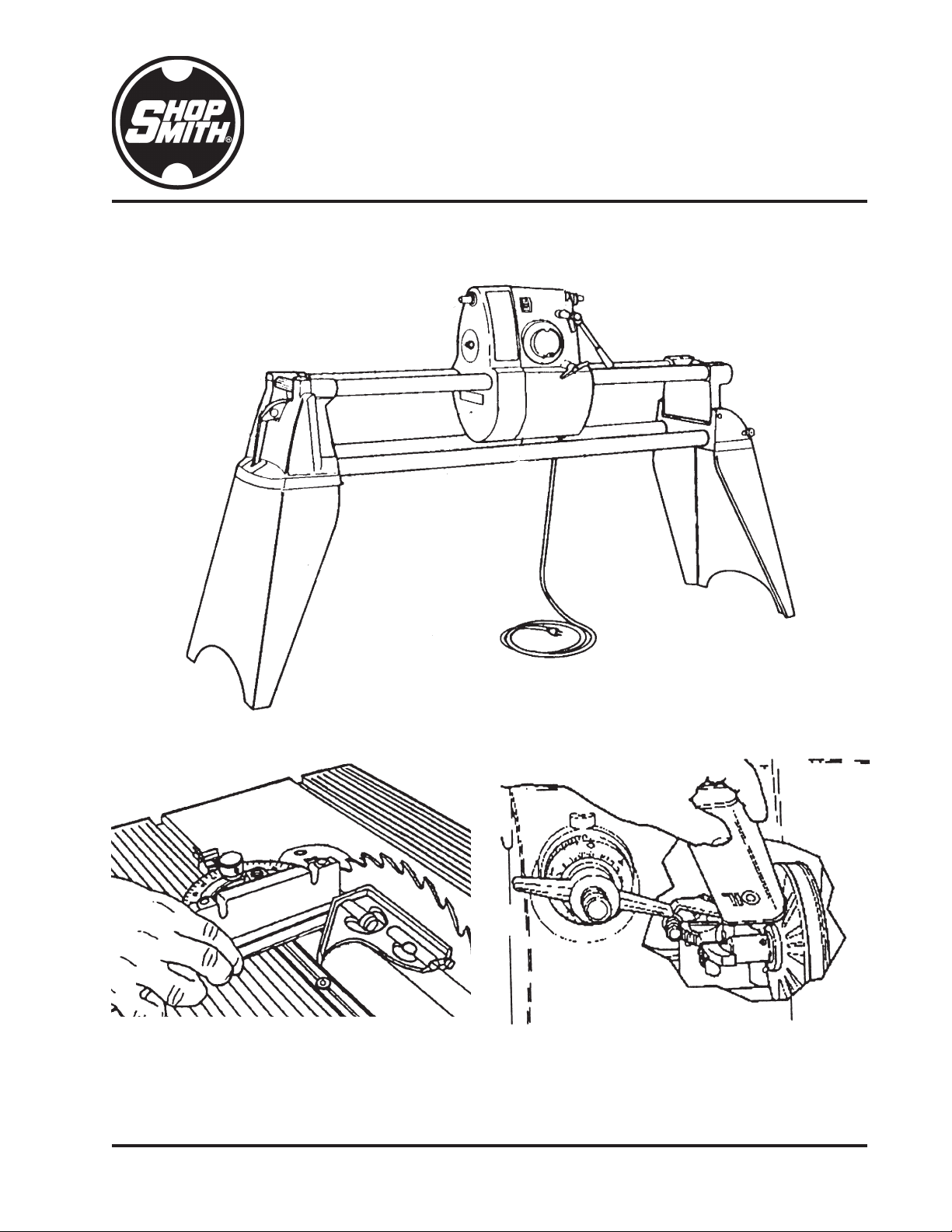

The Shopsmith MARK V will perform all the

functions of a Table Saw, Disc Sander, Drill

Press, Horizontal Boring Machine, and Wood

Lathe.

Basically, the MARK V is a rigid Bench that

holds the Headstock and a Worktable System.

The upper part of this Bench can be positioned

horizontally or vertically. The Headstock and

the Worktable slide independently and are

positioned along the Upper or Way Tubes.

You can mount Accessories to the Headstock

and operate them at different speeds. The

Worktable can be positioned over, under or

beside these accessories to hold stock at vari-

ous angles. In this way, the Bench, Headstock,

Worktable, and Accessories combine to make

a unique, capable and versatile Woodwork-

ing System.

Before you proceed, familiarize yourself with

the MARK V's basic parts:

1. Legs - SupporttheWayTubesandBench

Tubes.

2. Headrest Lock - Secures the MARK V in

the horizontal position.

3. Accessory Mount Locks - Secures the

Extension Table, Major Accessories, and

the Lathe Tailstock.

4. Power Mount - Holds the Extension

Table and the Major Accessories.

5. Way Tube Tie Bar - Holds the free end of

the Way Tubes.

6. Way Tubes - Supports the Headstock

and Carriage and allows them to slide.

7. Auxiliary Spindles - The Upper Spindle

provides power to the Bandsaw, Belt

Sander, Strip Sander and Thickness

Planer. The Lower Spindle provides

power to the Jointer and Scroll Saw.

8. Logo Cover - Provides access to the wir-

ing and Speed Changer Mechanism.

Used for maintenance access. (Hidden

from view)

9. Power Switch - Turns the MARK V on

and off. Has a removable Safety Key on

newer MARK V’s or is a Toggle Switch

on older units.

10. Quill Lock - Secures the Quill in posi-

tion.

11. Quill Feed Stop - Stops the Quill at

predetermined distances out from the

1

2

3

4

5

20

19

7

89

18

17

16

15

14

13

10 11

12

21

6

22

RIGHT

SIDE

LEFT

SIDE

Page 3

845180 SHOPSMITH MARK V

Headstock. (Hidden from view)

12. Quill - Contains the Main Spindle &

Spindle Bearings.

13. Main Spindle - Mounts the Saw Blades,

Sanding Discs, and other Accessories.

14. Quill Feed Lever - Extends the Quill out

from the Headstock.

15. Base Mount - Holds the Extension Table

and Lathe Tailstock.

16. Base - Allows the Way Tubes to pivot to

either a horizontal or vertical position.

17. Base Lock - Secures the MARK V in the

vertical position.

18. Headstock Lock - Secures the Head-

stock on the Way Tubes.

19. Speed Dial - Controls the speed of the

MainandAuxiliarySpindles.ONLY turn

the speed dial when the MARK V is

running. Otherwise, you will damage

the speed changing mechanism. Turn

the speed dial to "Slow" after every op-

eration and then turn MARK V off.

20. Bench Tubes - Holds the MARK V rigid.

21. Headrest - Holds the Way Tube Tie Bar.

22. Belt Cover - Allows access to the Belts

and Sheaves.

MARK V MODEL 500

23. Extension Table - Mounts in either the

34

35

23

25

24 27

26

28 29

30

31

32

33

36

Power Mount or the Base Mount to pro-

vide extra support for the stock.

24. Rip Fence - Mounts to the Table and is

used as a guide, support or stop. It auto-

matically aligns itself parallel to the

Blade. Holes in the Fence are used to

mount fixtures and fence extensions.

25. Miter Gauge Slots - Guide and secure

the Miter Gauge.

26. Table Insert - Used for sawing, sanding,

drilling and boring. It can be replaced

with inserts for dadoing, molding, drum

sanding and shaping.

27. 10" Saw Blade - Mounts to the 1-1/4"

Arbor which then mounts to the Main

Spindle. This Saw Blade is use for both

crosscutting and ripping.

28. Upper Saw Guard - Provides a physical

barrier between you and the part of the

Blade above the Table. An anti-kickback

mechanism helps control kickbacks.

29. Miter Gauge with Safety Grip - Holds

stock firmly at various angles. It slides

freely or locks in the Miter Gauge Slots.

30. Worktable - Holds the stock and pro-

vides a working surface.

31. Lower Saw Guard - Protects you from

the part of the Blade or cutter below the

Table.

32. TableSupport Tubes -Supportthe Table

above the Bench. Each tube has racks

that mesh with Pinions in the Carriage to

raise and lower the Table.

33. Carriage - Slides along the Way Tubes

and holds the Table Support Tubes and

the Lathe Tool Rest.

34. Carriage Lock - Secures the Carriage on

the Way Tubes.

35. Table Height Handle - Turns the Pin-

ions in the Carriage which raise and

lower the Table.

SHOPSMITH MARK V 845180

Page 4

36. Table Height Lock - Secures the Table at

any height.

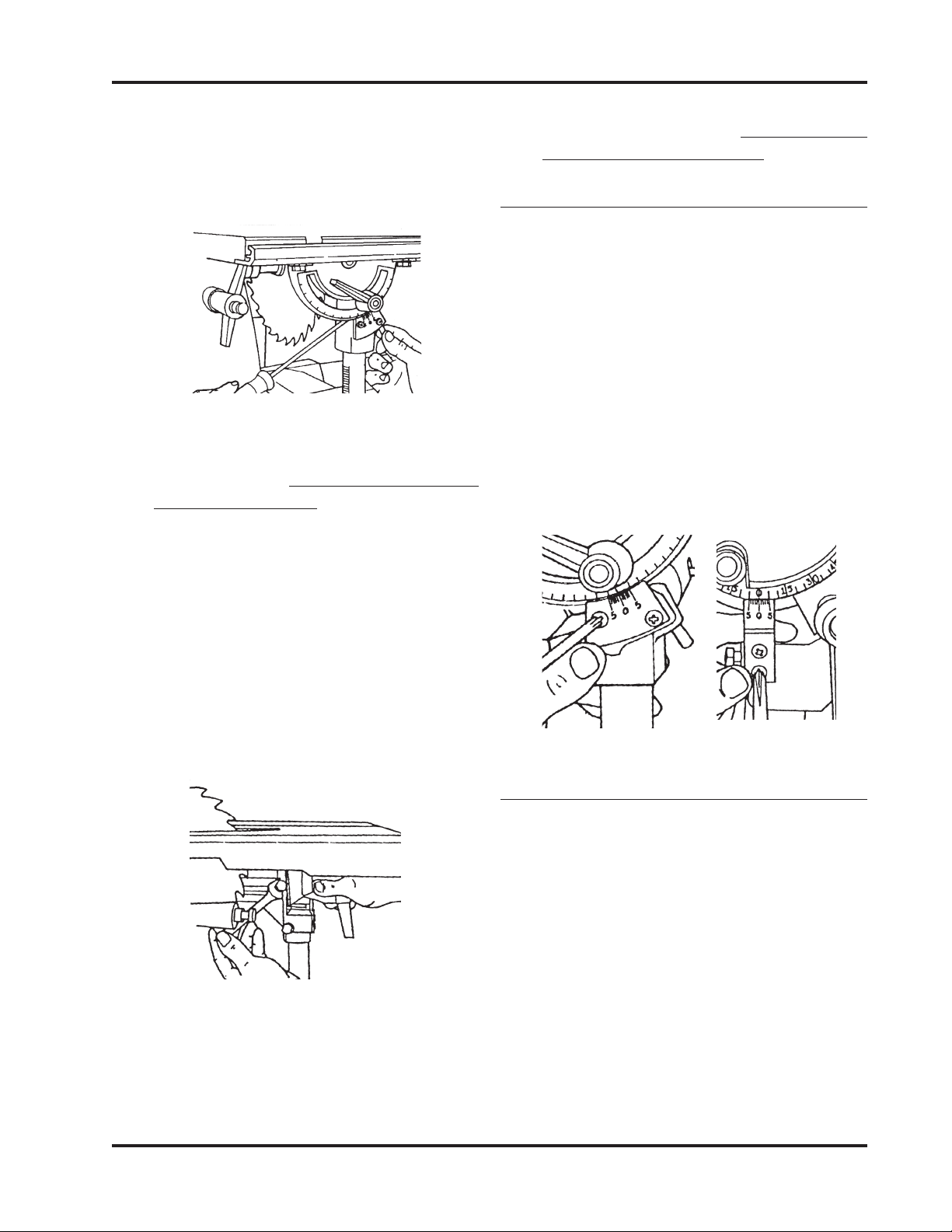

37. Trunnions - Allows the Table to tilt up to

90° Left and 45° Right.

38. Table Tilt Indicator - This Vernier Scale

indicates the Table angle.

39. Table Tilt Lock - Secures the Table at

any angle, up to 90° Left and 45° Right.

40. Table Tie Bar - Supports the Table Sup-

port Tubes and the Trunnions.

41. Table Stops - When properly adjusted,

they stop the Table at 90° Left, 45° Right

and 0°. (Note: one of the two 90° Table

Stop Bolts is shown.)

MARK V MODELS 510 & 520

37

40

38

39

41

42 43 44

54 53

45

52

51

50

46 48

47

49

42. Extension Table - Mounts in either the

Power Mount or the Base Mount to pro-

vide extra support for the stock.

43. Miter Gauge Slots - Guide and secure

the Miter Gauge.

44. Rip Fence - Mounts to the Table and is

used as a guide, support or stop. It auto-

matically aligns itself parallel to the

Blade. Holes in the Fence are used to

mount fixtures and fence extensions.

45. Table Insert - Used for sawing, sanding,

drilling and boring. It can be replaced

with inserts for dadoing, molding, drum

sanding and shaping.

46. 10" Saw Blade - Mounts to the 1-1/4"

Arbor which then mounts to the Main

Spindle. This Saw Blade is use for both

crosscutting and ripping.

47. Upper Saw Guard - Provides a physical

barrier between you and the part of the

Blade above the Table. An anti-kickback

mechanism helps control kickbacks.

48. Miter Gauge with Safety Grip - Holds

stock firmly at various angles. It slides

freely or locks in the Miter Gauge Slots.

49. Worktable - Holds the stock and pro-

vides a working surface.

50. Lower Saw Guard - Protects you from

the part of the Blade or cutter below the

Table. The Saw Guard has a Dust Chute.

The Lower Saw Guard is also used with

the Sanding Disc.

51. TableSupport Tubes -Supportthe Table

above the Bench. Each tube has racks

that mesh with Pinions in the Carriage to

raise and lower the Table.

52. Carriage - Slides along the Way Tubes

and holds the Table Support Tubes and

the Lathe Tool Rest.

53. Carriage Lock - Secures the Carriage on

the Way Tubes.

54. Table Height Lock - Secures the Table at

any height.

Page 5

845180 SHOPSMITH MARK V

Place the Square against the good edge and

draw a line across the width. Flop the Square

over and hold it against the same edge and

draw another line next to the first one. If the

lines are parallel, your Square is accurate.

TOOLS NEEDED:

This list covers all tools required for all mod-

els. Some tools listed may not be necessary for

your Model MARK V.

3/16" Allen Wrench

5/32" Allen Wrench, Long Handle

5/32" Allen Wrench, Short Handle

5/16" Allen Wrench

9/16" Wrench

Arbor Wrench

1/2" Wrench

Adjustable Wrench

1/2" Socket

Socket Wrench with Short Extension

1/2" Drill Bit

Small Straight Blade Screwdriver

Medium Straight Blade Screwdriver

Medium #12 Phillips Screwdriver

Large #3 Phillips Screwdriver

High Quality Combination Square

All the parts and accessories which support or

guide the stock MUST be aligned parallel

with or perpendicular to the Main Spindle's

plane of rotation. During the following align-

ment procedures the Saw Blade will represent

the Main Spindle's plane of rotation. This is

the only time the Saw Blade is used without

the Upper or Lower Saw Guards and then

only after the MARK V is turned off and

unplugged.

NOTE

If there are Casters installed on your MARK V,

make sure they are retracted and the Legs on the

MARK V sit firmly on a level floor. Check this

58

60

59

55

56

57

55. Trunnions - Allows the Table to tilt up to

90° Left and 45° Right.

56. Table Tilt Indicator - This Vernier Scale

indicates the Table angle.

57. Table Tilt Lock - Secures the Table at

any angle, up to 90° Left and 45° Right.

58. Table Height Crank - Turns the Pinions

in the Carriage which raise and lower

the Table.

59. Table Tie Bar - Supports the Table Sup-

port Tubes and the Trunnions.

60. Table Stops - When properly adjusted,

these Bolts stop the Table at 90° Left, 45°

Right and 0°. (Note: Only the two 90°

Table Stop Bolts are shown.)

WARNING

Make sure the Speed Dial is set to

"Slow", then turn off and unplug the

MARKVbeforeperforminganyALIGN-

MENT procedure.

Complete ALL of the following procedures -

and then recheck them at regular intervals.

You MUST use an accurate Combination

Square for alignment and adjustment. To

check that your Square is accurate, select a

board with at least one straight and true edge.

SHOPSMITH MARK V 845180

Page 6

now.

Also, remember that your MARK V could possibly

go out of alignment if it is moved to an area with

varying floor levelness. Remember to recheck

alignment and make needed adjustments after

moving your MARK V, if needed.

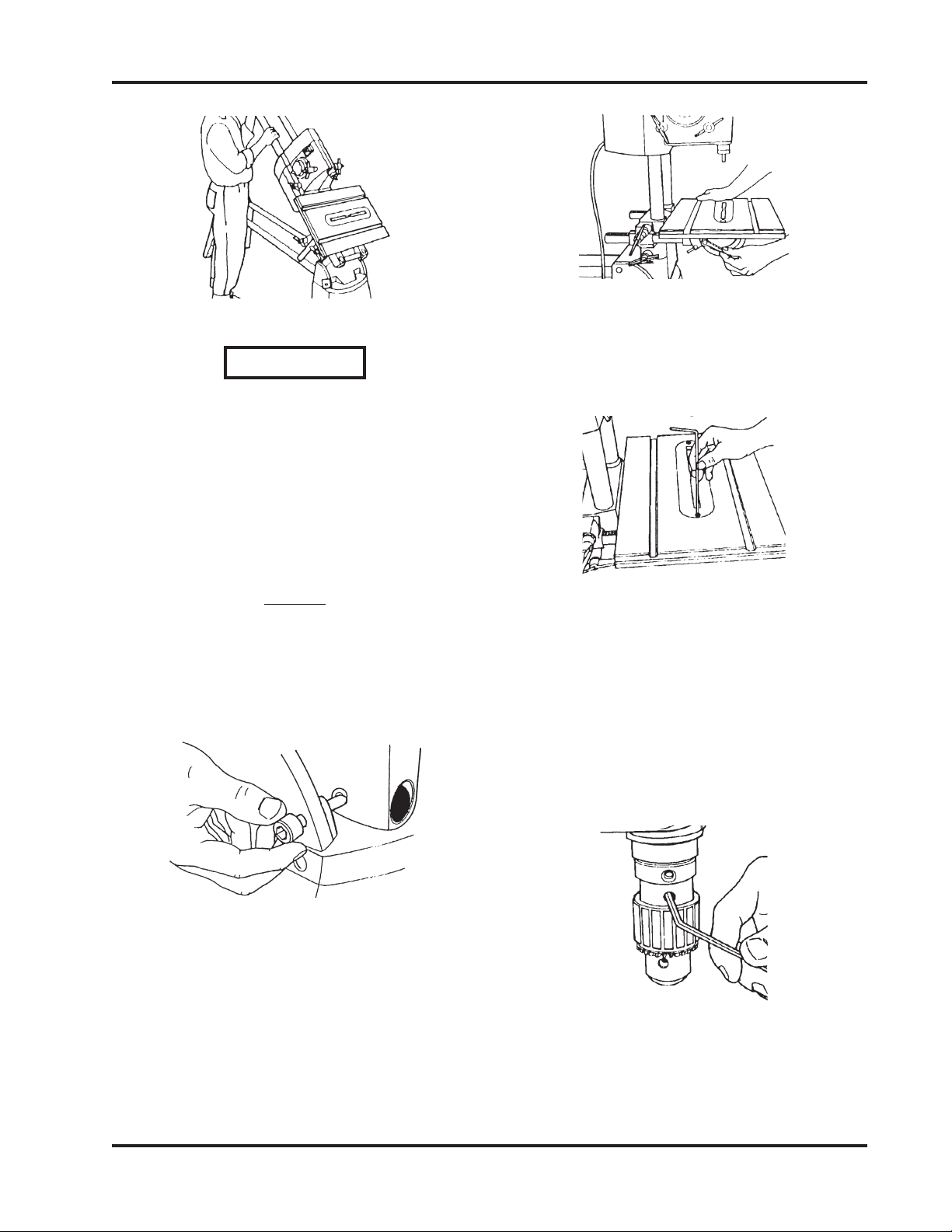

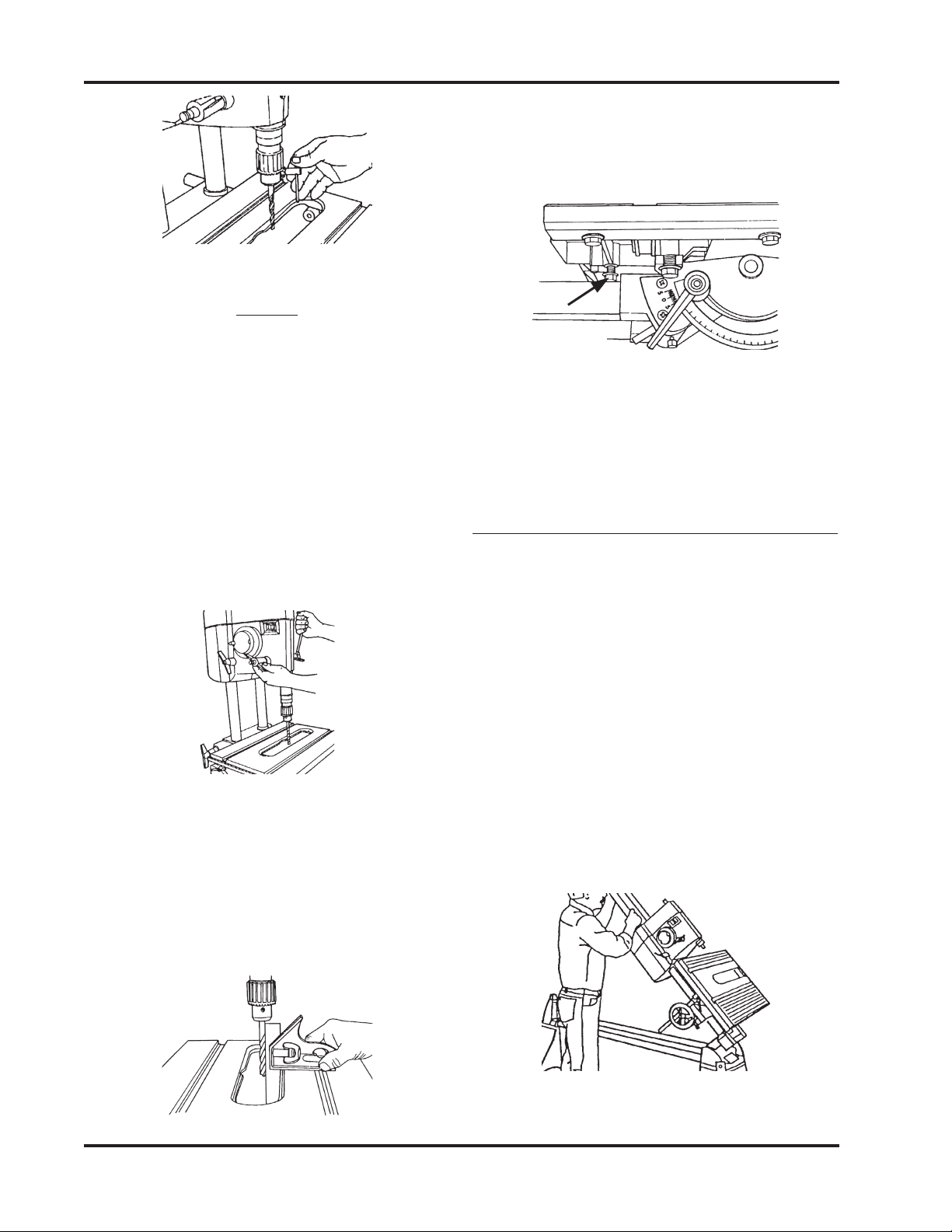

ADJUST THE HEADREST LOCK

(ALL MARK V MODELS)

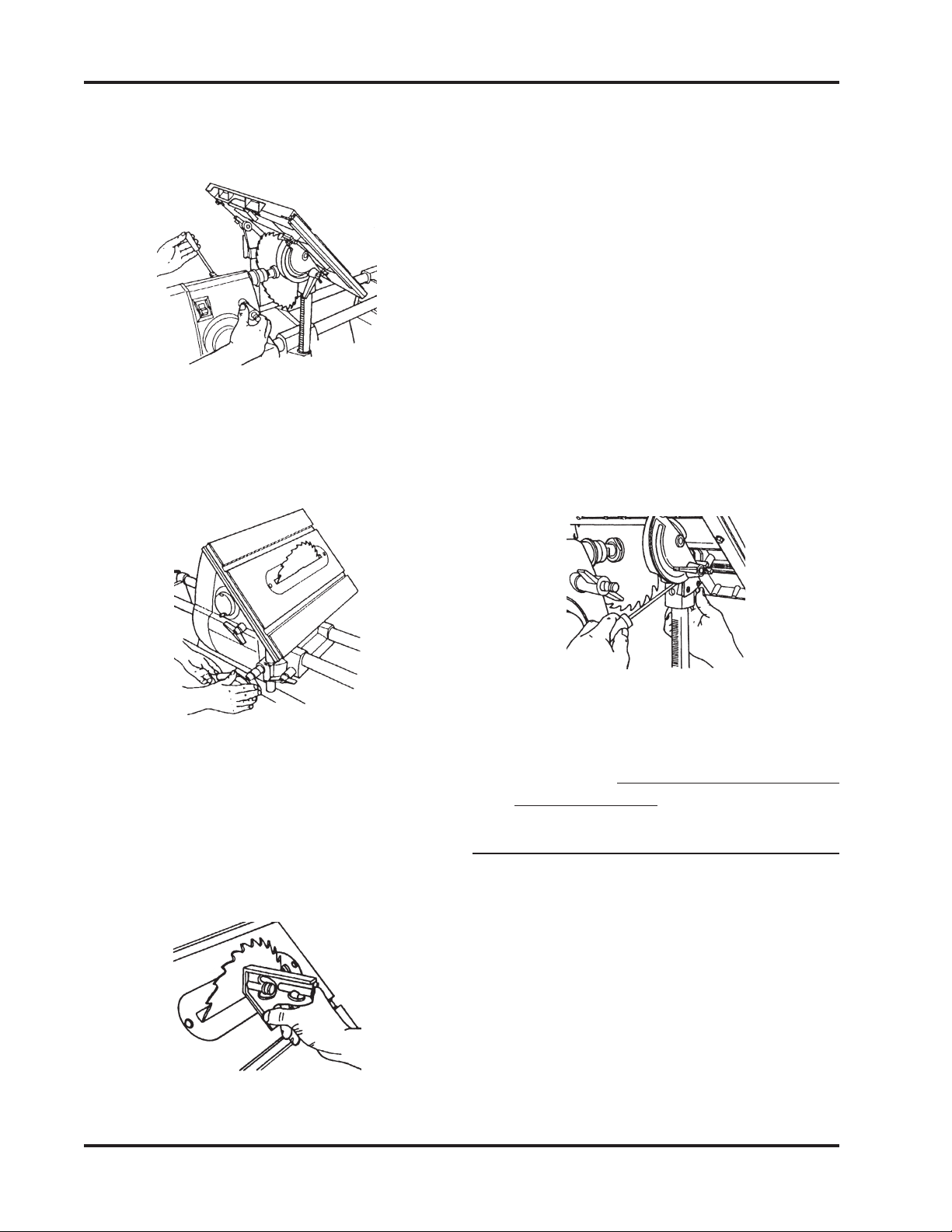

1. To check the Headrest Lock, grasp the

Way Tubes near the Tie Bar and pull up,

as demonstrated by the Right Hand in

Figure 1.

2. If there is "give" in the Lock, unlock the

Handle and use Medium Straight Blade

Screwdriver to turn the Lock Shaft clock-

wise, as done by the Left Hand in Figure

1. If the Lock is difficult to operate, the

Lock Shaft is too tight. To loosen, unlock

theHandleandturn the Lock Shaft coun-

terclockwise.

Figure 1

ADJUST THE CARRIAGE LOCK

(MARK V MODELS 510 & 520)

1. If the Carriage Lock Handle does not

lock past the horizontal position to four-

o’clock or the Carriage moves when the

lock handle is in this position, the Lock

needs adjusting. To adjust the Lock, use

a 1/2" Socket with an Extension and

Ratchet Handle to tighten or loosen the

Nut located at the back of the Carriage

Assembly, as shown in Figure 2.

Figure 2

2. When the Carriage Lock Handle locks

past the horizontal position to four-

o’clockand the Carriage nolonger moves

when the Handle is in this position,

tighten the Nut a final 1/4 turn.

WARNING

TheCarriageLockHandleMUSTlock

past the horizontal position to Four-

O’clock,otherwisetheCarriageLock

will vibrate loose.

SET WORKTABLE'S 90° LEFT STOP

(MARK V MODEL 500)

1. Unlock the Carriage and Headstock.

Move the Headstock to the middle of the

Way Tubes. Then move the Carriage

between the Headstock and Base Mount

(right side).

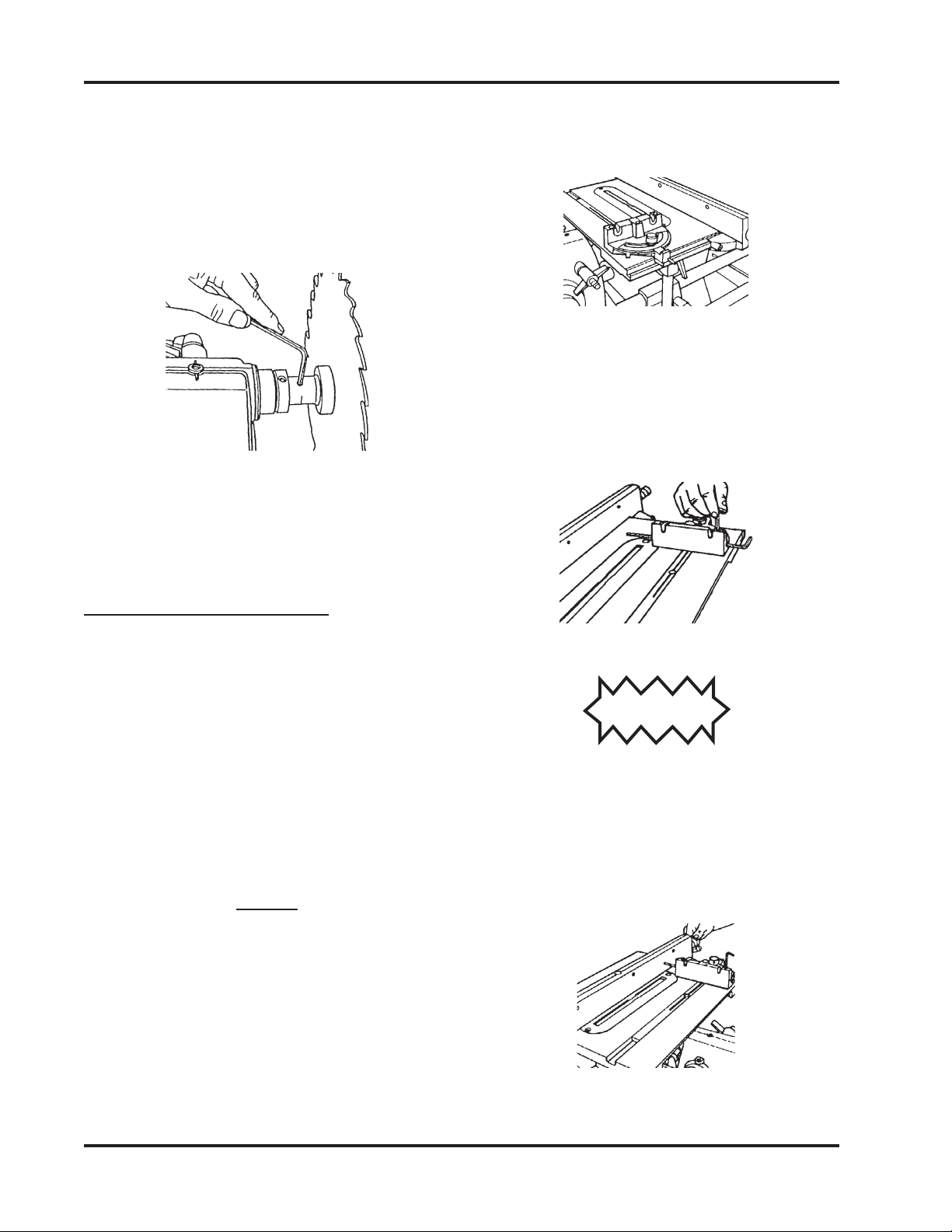

2. Tighten the Headstock and Carriage

Locks. Place the MARK V in the vertical

position by loosening the Headrest

Handle, firmly grasping the Way Tubes

near the Headrest end, and lifting the

Tubes into the 90° position, as demon-

strated in Figure 3.

Page 7

845180 SHOPSMITH MARK V

Figure 3

WARNING

AlwaysmakesuretheMARKVHead-

stockandCarriagearelockedandall

Castersareraisedoffthefloorbefore

lifting the MARK V into the vertical

Drill Press position.

3. Useyourfingers to tighten the Base Lock.

NOTE

The Base Lock is slightly off center to the counter-

sink found in the Base, as shown in Figure 4. This

offset allows the Base Lock to more firmly hold the

Base Arm in place.

Figure 4

4. Move the Worktable into the 90° posi-

tion by loosening the Table Tilt Lock,

then putting the Worktable in the hori-

zontal 90° position, as shown in Figure 5.

Retightenthe TableTilt Lockonly enough

to allow movement with firm pressure.

Figure 5

5. Use a 5/32" Allen Wrench to remove the

Table Insert, as demonstrated in Figure

6.

Figure 6

6. To install the Drill Chuck, mount the

Chuck on the Spindle and align the

Chuck's Set Screw with the Spindle

Knob's Set Screw, as shown in Figure 7.

This allows the Chuck's Set Screw to set

on the flat part of the Spindle. Use a

5/32" Allen Wrench to securely tighten

the Drill Chuck's Set Screw.

Figure 7

7. Install a 1/2" Straight Drill Bit in the

Drill Chuck and use the Chuck Key to

lock it place. See Figure 8.

SHOPSMITH MARK V 845180

Page 8

10. Both 90° Stops should contact the top of

the Table Support Tubes, as in Figure 11.

If they don't, use a 1/2" Wrench to adjust

the Stops.

Figure 11

11. Recheck the setting by loosening the Tilt

Lock, moving the Table, and then re-

peating Steps 9 and 10. (Rechecking the

setting is very important!)

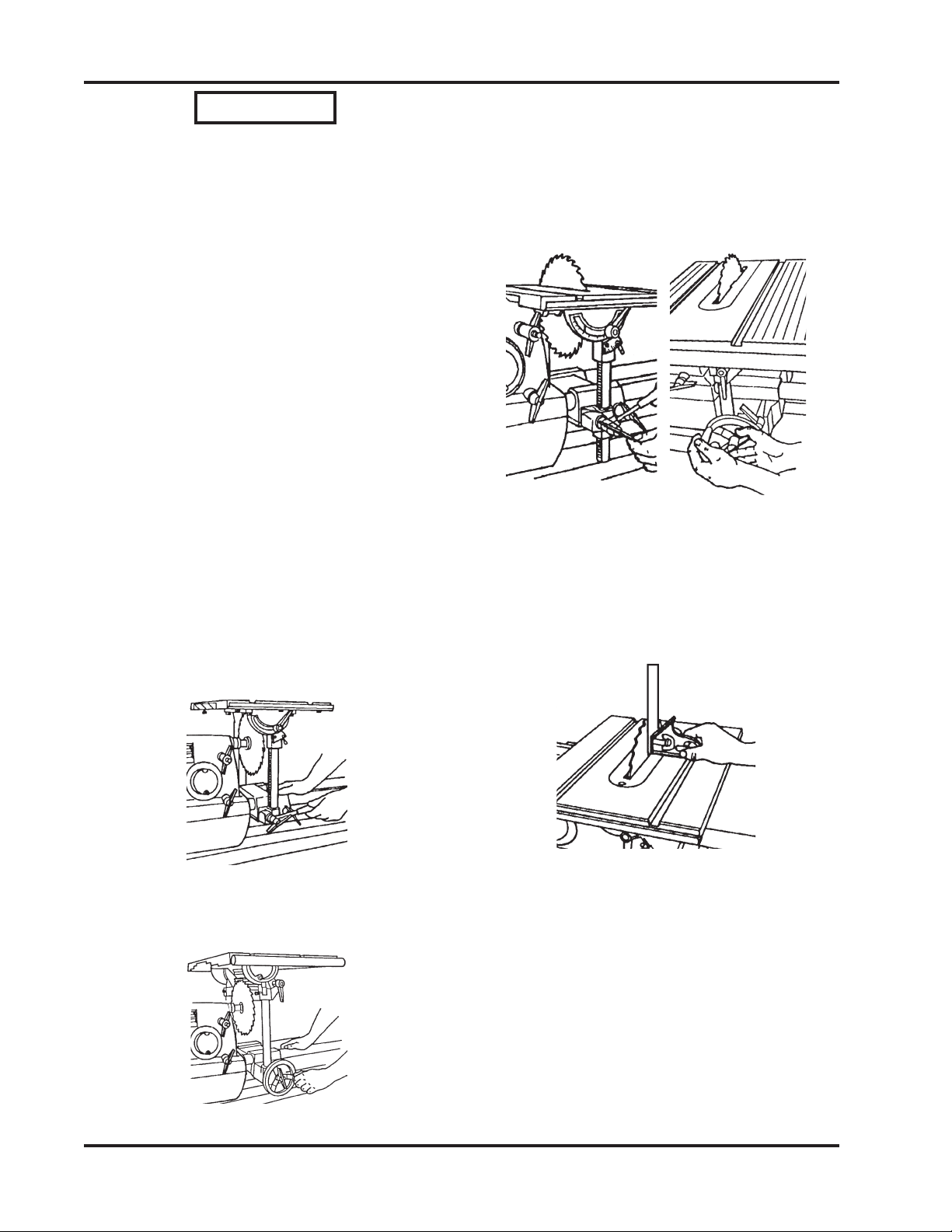

SET WORKTABLE'S 90° LEFT STOP

(MARK V MODELS 510 & 520)

1. Unlock the Carriage and Headstock.

Move the Headstock to the middle of the

Way Tubes. Then move the Carriage

between the Headstock and Base Mount

(right side).

2. Tighten the Headstock and Carriage

Locks. Place the MARK V in the vertical

position by loosening the Headrest

Handle, firmly grasping the Way Tubes

near the Headrest end, and lifting the

Tubes into the 90° position, as demon-

strated in Figure 12.

Figure 12

Figure 8

NOTE

Check the straightens of the Drill Bit by rolling it

on a flat surface or you can also hand-rotate the

Drill Chuck while holding the Combination Square

against the Drill Bit and the Table. If the Bit is not

straight DO NOT use it for these alignment instruc-

tions.

8. With the Drill Bit above the Table open-

ing, use the Quill Feed to extend the Drill

Bit 1/2" into the Table opening, as in

Figure 9.

Figure 9

9. Set the Combination Square against the

Drill Bit and Table, as shown in Figure

10. The Square should contact the Drill

Bit along its entire length. When the

Tableisexactly perpendicular to theDrill

Bit, lock the Table.

Figure 10

90° STOP

(Front)

Page 9

845180 SHOPSMITH MARK V

WARNING

AlwaysmakesuretheMARKVHead-

stockandCarriagearelockedandall

Castersareraisedoffthefloorbefore

lifting the MARK V into the vertical

Drill Press position.

3. Useyourfingers to tighten the Base Lock.

Figure 13

NOTE

The Base Lock is slightly off center to the counter-

sink found in the Base, as shown in Figure 13. This

offset allows the Base Lock to more firmly hold the

Base Arm in place.

4. Move the Worktable into the 90° posi-

tion by loosening the Table Tilt Lock, as

shown in Figure 14, then putting the

Worktable in the horizontal 90° position,

as shown in Figure 15. Retighten the

Table Tilt Lock only enough to allow

movement with firm pressure.

Figure 14

Figure 15

5. Use a 5/32" Allen Wrench to remove the

Table Insert, as demonstrated in Figure

16.

Figure 16

6. To install the Drill Chuck, mount the

Chuck on the Spindle and align the

Chuck's Set Screw with the Spindle

Knob's Set Screw, as shown in Figure 17.

This allows the Chuck's Set Screw to set

on the flat part of the Spindle. Use a 5/

32" Allen Wrench to securely tighten the

Drill Chuck's Set Screw.

Figure 17

7. Install a 1/2" Straight Drill Bit in the

Drill Chuck and use the Chuck Key to

lock it in place. See Figure 18.

SHOPSMITH MARK V 845180

Page 10

Figure 20

10. When the Table is exactly perpendicular

to the Drill Bit, lock the Table, as seen in

Figure 21.

Figure 21

11. Both 90° Stops (shown in Figures. 22 and

23) should contact the underside of the

Table. If they don't, use a 1/2" Wrench to

adjust the Stops.

Figure 22

90° Stop

(Front)

Figure 18

NOTE

Check the straitness of the Drill Bit by rolling it on

a flat surface or you can also hand-rotate the Drill

Chuck while holding the Combination Square

against the Drill Bit and the Table. If the bit is not

straight DO NOT use it for these alignment instruc-

tions.

8. With the Drill Bit above the Table Open-

ing, use the Quill Feed Handel to extend

the Bit 1/2" into the Table Opening, as

shown in Figure 19.

Figure 19

9. Set the Combination Square against the

Drill Bit and Table, as shown in Figure

20. The Square should contact the Drill

Bit along its entire length.

Page 11

845180 SHOPSMITH MARK V

Figure 23

12. Recheck the setting by loosening the Tilt

Lock, moving the Table, and then re-

peating Steps 9 through 11. (Rechecking

the settings is very important!)

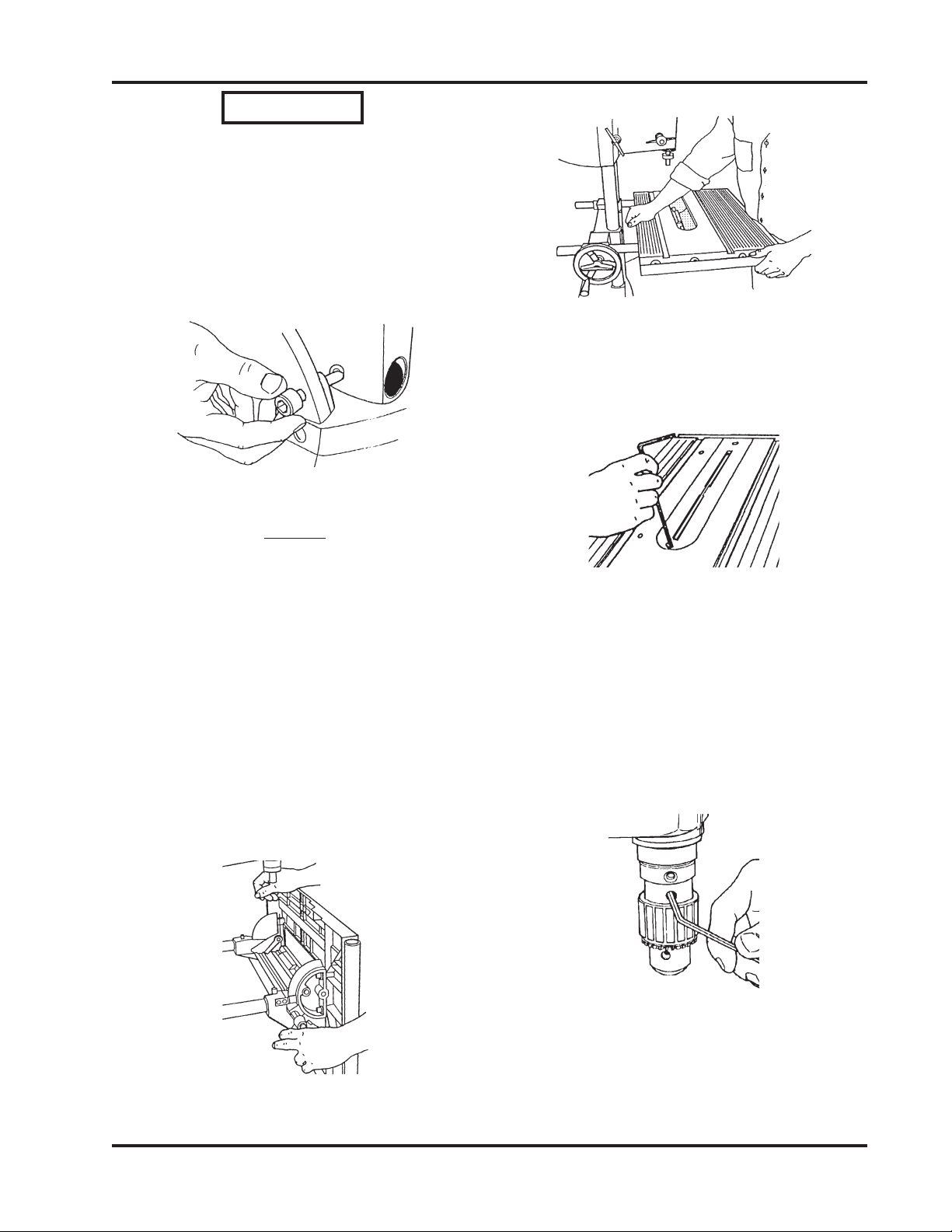

SET THE WORKTABLE'S 0° STOP

1. Remove the Drill Bit and Drill Chuck

from the Spindle.

2. Loosen the Base Lock. Firmly grasp the

Way Tubes and lower the Headstock

into the horizontal position, then engage

the Headrest.

3. Loosen the Table Tilt Lock and place the

Table in the horizontal 0° position. Re-

tighten the Table Tilt Lock only enough

to allow movement with firm pressure.

4. Mount the Saw Blade on the Arbor:

b. HoldtheBladewiththeteethpoint-

ing toward you, as shown in Figure

25, then insert the Arbor through

the hole. Replace the Nut and fin-

ger tighten it.

90° Stop

(Rear)

a. Remove the Arbor Nut by turning

it clockwise, as seen in Figure 24.

Hold the Arbor with the threaded

part pointing to the left.

c. Place the Blade and Arbor on your

Workbench with the Nut pointing

up.

d. Hold the Arbor with an Adjustable

Wrench and tighten the Arbor Nut

with the Arbor Wrench, as demon-

strated in Figure 26. Another way

to tighten the Arbor Nut is to clamp

the Arbor in a Bench Vise, as illus-

trated in Figure 27, and tighten the

Nut with the Arbor Wrench.

Figure 24

Figure 25

Figure 26

Figure 27

SHOPSMITH MARK V 845180

Page 12

10. Place the Combination Square against

both the Saw Blade and Worktable, as

seen in Figure 32. Make sure the square's

blade does not touch a saw tooth and

does rest in a gullet between teeth.

Figure 32

11. If the Worktable is not exactly perpen-

dicular to the Saw Blade, adjust the

Worktable so it is perpendicular to the

Saw Blade, then tighten the Tilt Lock.

(MARK V MODEL 500)

12. Use a Small Screwdriver to back out the

0° stop 2-3 turns. Depress the Plunger

WARNING

The only time the Saw Blade is used

without the Upper or Lower Saw

GuardsisduringalignmentandONLY

after the MARK V is turned off and

unplugged.

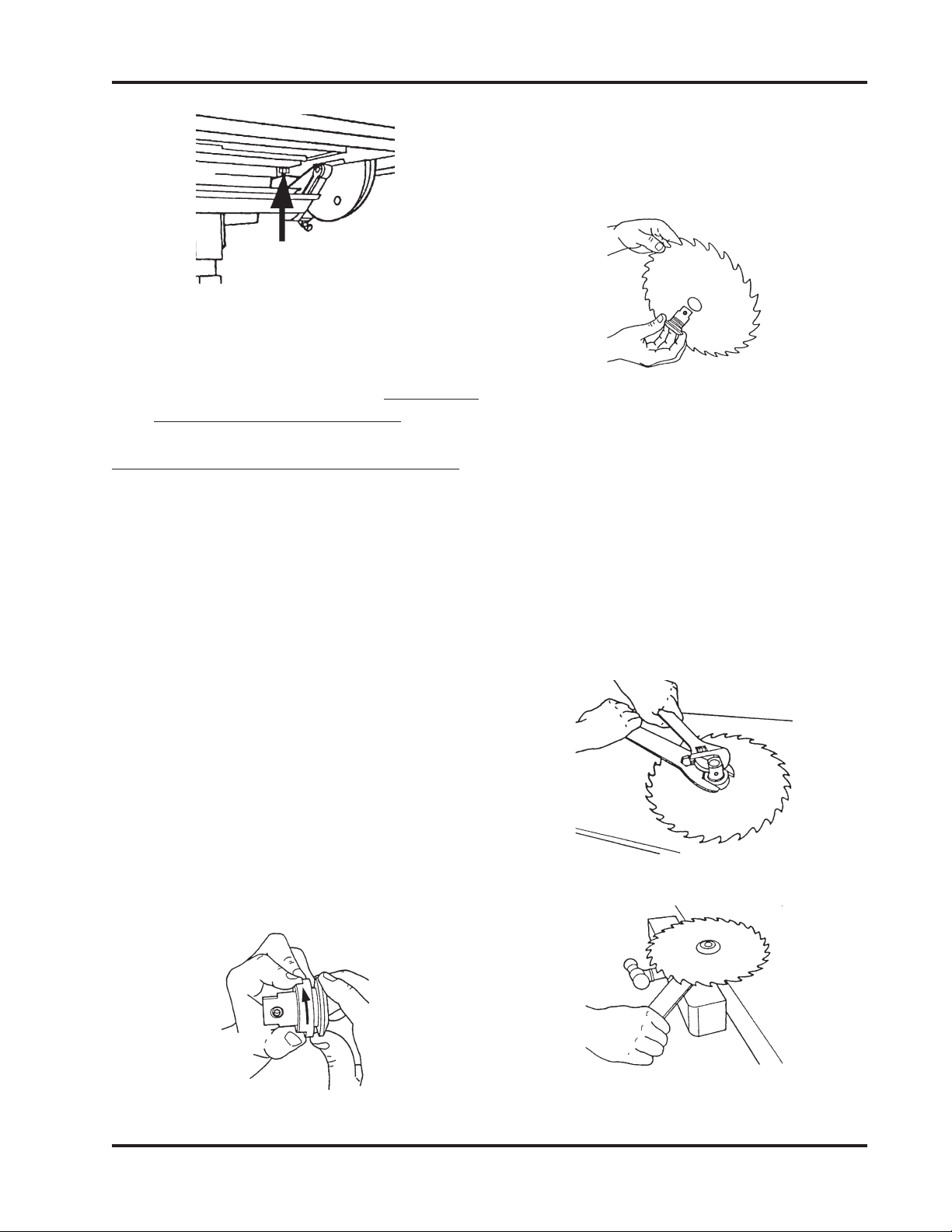

5. Mount the Saw Blade on the Spindle and

align the Arbor Set Screw with the

Spindle Knob's Set Screw, then use a 5/

32" Allen Wrench to tighten the Arbor

Set Screw.

6. Reinstall the Table Insert in the Work-

table.

7. Raise the Worktable so that it clears the

top of the Saw Blade.

8. Loosen the Carriage Lock and slide the

Carriage so the Saw Blade is directly

beneath the slot in the Table Insert. See

Figure 28 or 29. Tighten the Carriage

Lock.

MARK V Model 500

Figure 28

MARK V Models 510 & 520

Figure 29

9. Lower the Worktable (nearly all the way

down) so the Saw Blade comes through

the slot. Lock the Table Height, as seen in

Figure 30 or 31.

Figure 31

MARK V

Models 510 & 520

Figure 30

MARK V

Model 500

Page 13

845180 SHOPSMITH MARK V

ADJUSTTHEWORKTABLE'S 45°STOP

(MARK V Model 500)

1. Loosen the Table Height Lock and raise

the Table until it clears the Saw Blade.

Tighten the Height Lock.

2. Loosen the Tilt Lock and tilt the Work-

table to the right.

3. Tighten the Tilt Lock only enough to

allow movement with firm pressure.

4. Loosen the Quill Feed (shown in Figure

37) and extend the Quill so the Saw

under the Table Tilt Indicator up toward

the Front Trunnion, and hole it there

with your finger. Slowly turn the 0° stop

in until you feel it just touch the Plunger.

See Figure 33.

Figure 33

13. Recheck the setting by repeating Steps

10 through 12. (It is very important to

recheck this setting!)

(MARK V MODELS 510 & 520)

12. To adjust the 0° Stop, simultaneously

depress the Table Stop Pin and use a 1/

2" Wrench to adjust the Stop Bolt. The

Stop Bolt should just contact the side of

the Stop Pin. Once the Stop Bolt is ad-

justed, the Stop Pin will "snap" back

when the Tilt Lock is tightened. See Fig-

ure 34.

Figure 34

13. Loosen the Tilt Lock, tilt the Worktable,

then depress the 0° Stop Pin until the

Stop Bolt contacts it. Tighten the Tilt

Lock, and recheck the setting by repeat-

ing Steps 10 through 12. (It is very impor-

tant to recheck this setting!)

ADJUSTTHETABLE TILT INDICATOR

1. Tighten the Table Tilt Lock and check

that the 0° mark on the Indicator aligns

with the 0° mark on the Trunnion.

2. Toadjust the scale,usea MediumPhillips

Screwdriver to loosen the two Screws

which hold the Indicator to the Tie Bar.

See Figure 35 or 36. Then while holding

the Indicator in position so the 0's are

aligned, retighten the Screws.

MARK V

Model 500

Figure 35

MARK V

Models 510 & 520

Figure 36

SHOPSMITH MARK V 845180

Page 14

7. Loosen the Tilt Lock and tilt the Table

past the 45° setting. Then depress the

Plunger and tilt the Table back toward

that angle until the Stop hits the Plunger.

Tighten the Tilt Lock, then check the

angle. If the angle is not 45°, the Stop

needs adjusting.

8. To adjust the 45° Right Stop, see Figure

40. Set the Table to 45° Right. Then use

the Combination Square to set the tilt of

the Table to precisely 45° Right. Use a

Small Screwdriver to back out the 0° stop

2-3 turns. Depress the Plunger under the

Table Tilt Indicator up toward the Front

Trunnion, and hold it there with your

finger. Slowly turn the 45° Stop in until

you fell it touch the Plunger.

Figure 40

9. Loosen the Tilt Lock and move the Table.

To recheck the 45° Stop, repeat Steps 4

through 9. (It is very important to re-

check the setting!)

ADJUSTTHEWORKTABLE'S 45°STOP

(MARK V MODELS 510 & 520)

1. Loosen the Table Height Lock and raise

the Table until it clears the Saw Blade.

Tighten the Height Lock.

2. Loosen the Tilt Lock and tilt the Work-

table to the right until it makes contact

with the two 45° Stop Bolts.

3. Tighten the Tilt Lock only enough to

allow movement with firm pressure.

Blade is centered beneath the slot in the

Table Insert. When it is centered, lock the

Quill Feed.

Figure 37

5. Lower the Worktable so the Saw Blade

extends through the Table Insert slot.

See Figure 38. Lock the Table Height.

Figure 38

6. Remove the Blade from the Combina-

tion Square and place the Square against

the Saw Blade and the Worktable, as

shown in Figure 39. Make sure the Com-

bination Square doesn't rest on the Table

Insert.

Figure 39

Page 15

845180 SHOPSMITH MARK V

4. Loosen the Quill Feed (shown in Figure

41) and extend the Quill so the Saw

Blade is centered beneath the slot in the

Table Insert. When it is centered, lock the

Quill Feed.

Figure 41

5. Lower the Worktable so the Saw Blade

extends through the slot. See Figure 42

Lock the Table Height.

Figure 42

6. Remove the bar from the Combination

Square and place the square against the

Saw Blade and the Worktable, as shown

in Figure 43. Make sure the Combination

Square doesn't rest on the Table Insert.

Figure 43

7. If the Worktable is not exactly 45° to the

Saw Blade, adjust the Worktable so it is.

8. Tighten the Tilt Lock, then use a 1/2"

Wrench to adjust the 45° Stop on the

front side of the Worktable (shown in

Figure 44).

Figure 44

9. Also, the back side of the Worktable

(shown in Figure 45). The stops should

just contact the underside of the Table.

Figure 45

10. Loosen the Tilt Lock and move the Table.

To recheck the 45° stops, repeat Steps 4

through 8. (It is very important to re-

check the setting!)

ALIGN THE MITER GAUGE SLOTS

1. Return the Worktable to the horizontal

0° stop and tighten the Tilt Lock. The

Carriage Lock and Headstock Lock

should also be tightened.

2. Place the Miter Gauge in the Right Miter

GaugeSlot, anduse a5/32"Allen Wrench

to remove the Quick Clamp from the

Safety Grip, as shown in Figure 46.

SHOPSMITH MARK V 845180

Page 16

Figure 48

Figure 49

5. If the Miter Slots need to be aligned, do

the following:

(MARK V MODEL 500)

Figure 50

a. Use a 9/16" Wrench to loosen the

Bolts which hold the Worktable to

the Trunnions, (Front Trunnion

Bolts shown in Figure 50) and the

Table Base. Loosen these four Bolts

only enough to allow movement

with firm pressure.

Figure 46

3. Insert the Long 5/32" Allen Wrench

through the Miter Gauge. Borrow a Set

Screw from the Lathe Tool Rest and use

the Short 5/32" Allen Wrench to install it

in either top Miter Gauge hole, as seen in

Figure 47. Place the tip of the Long

Wrench against the front side of the Saw

Blade and tighten the Set Screw.

Figure 47

4. MovetheMiter Gauge from front to back

along the Saw Blade, as shown in Figs. 48

and 49. If it hangs up on the Blade or a

gapdevelops, the MiterGaugeSlots need

to be aligned. Make sure the Allen

Wrench does not contact a Saw Blade

tooth, because the tooth "set" will cause

misalignment.

Trunnion Bolts

(Front)

Page 17

845180 SHOPSMITH MARK V

Figure 51

b. Adjust the Worktable, then again

move the Miter Gauge and Wrench

along the face of the Saw Blade

until the Wrench tip consistently

contacts the entire Saw Blade sur-

face.

c. When the Miter Gauge Slot is

aligned, tighten the two Trunnion

Bolts which are closer to the Head-

stock. Then tighten the other two

Trunnion Bolts.

d. LoosentheTableTiltLockandmove

the Table, then return it to the hori-

zontal 0° position. Recheck the Slot

alignment. If it is off, repeat steps 5a

through 5c. (It is very important to

recheck this setting!)

(MARK V MODELS 510 & 520)

a. Tilt the Table to 45° and tighten the

Tilt Lock.

b. Use a 5/16" Allen Wrench to loosen

all four Bolts which hold the Work-

table to the Trunnions, as pointed

out in Figure 51. Loosen the Bolts

only enough to allow movement

with firm pressure.

c. Position the Worktable back to the

horizontal 0° and tighten the Tilt

Lock.

d. Adjust the Worktable, then again

move the Miter Gauge and Wrench

along the face of the Saw Blade

until the Wrench tip consistently

contacts the entire Saw Blade sur-

face.

e. When the Miter Gauge Slot is

aligned, use the 5/16" Allen

Wrench to retighten the two Trun-

nion Bolts which are closer to the

Headstock. Then loosen the Table

Tilt Lock, tilt the Worktable to 45°,

and tighten the Table Tilt Lock. Use

the 5/16" Allen Wrench to tighten

the other two Trunnion Bolts.

NOTE

If you find it difficult to loosen the Bolts, consider

using a T-Handle Allen Wrench, or use a Box End

Wrench for extra torque. Another alternative is to

use the hanging hole in an Adjustable Wrench, as

demonstrated in Figure 52 and 53.

Figure 52

Figure 53

Trunnion Bolts

SHOPSMITH MARK V 845180

Page 18

slide it back and forth in the Slot to check

if the Miter Gauge scrapes against the

Table.Ifthe Miter Gauge rocks or scrapes

the Table, adjust the Glides.

Figure 56

3. If the Glides need to be adjusted, do the

following:

Miter Gauge shown

before adjusting the glides.

a. Remove the Miter Gauge from the

Slot and turn it over.

b. Use a Medium Screwdriver to ad-

just the Glides in or out, as illus-

tratedin Figure 71,so that theGlides

hold the Miter Gauge 1/64" to 1/

32" off the Worktable and the Miter

Gauge does not rock in the Slots.

Figure 57

4. Return the Miter Gauge to the Slot and

recheck and readjust it, if needed.

ADJUST THE MITER GAUGE FACE

1. Remove the Safety Grip from the Miter

Gauge.

2. Put the Miter Gauge in the Right Slot and

place the Combination Square against

the Saw Blade and Miter Gauge Face, as

seen in Figure 58.

NOTE

Tighten the Bolts only after the Table Tilt Lock is

secured. Otherwise the Worktable will bow or bind

the next time the Table Tilt Lock is tightened.

INSTALL THE TABLE INSERT

1. Place the Table Insert in the Worktable

recess. Use a 5/32" Allen Wrench to start

both screws. See Figure 54.

Figure 54

2. First tighten the rear screw. Then the

front of the insert will be sprung slightly

above the Table. Level the insert by plac-

ing your hand on the front of the insert,

and slowly turning the front screw until

it draws the front of the insert flush with

the Worktable surface. Shown in Figure

55.

Figure 55

ADJUST THE MITER GAUGE GLIDES

1. Place the Miter Gauge in the Worktable's

Miter Gauge Slot.

2. Check to see if the Miter Gauge wobbles

side-to-side, typified by Figure 56. Also,

Page 19

845180 SHOPSMITH MARK V

ADJUST THE 90° POSITIVE STOP

1. Use a Small Screwdriver to back out the

90° Stop Screw 2 to 3 turns, as shown in

Figure 61.

Figure 61

2. Depress the Plunger, then turn the Stop

Screw until you feel it touch the Plunger.

ADJUST BOTH 45° STOPS

1. Loosen the Lock Knob and pull out the

Plunger. Then, at the same time, rotate

the Miter Gauge and push in the Plunger

until it hits the 45° Stop (there is one on

each side of the 90° Stop).

2. Use a Combination Square to set the

MiterGaugeFaceat45° to the Saw Blade.

If the 45° Stop needs adjustment, use a

Medium Screwdriver to back out the 45°

Screw 2 to 3 turns.

3. Depress the Plunger, then turn the Stop

Screw until you feel it touch the Plunger.

4. To adjust the other 45° Stop, repeat Steps

1 to 3.

REMOVE THE SAW BLADE

1. Loosen the Table Height Lock and raise

the Table so that it clears the Saw Blade,

a. Use a Long Allen Wrench to loosen

the Lock Knob and adjust the Miter

Gauge so it is perpendicular to the

Saw Blade, then tighten the Lock

Knob. See Figure 59.

Figure 59

b. Use a Medium Screwdriver, loosen

the Screw which holds the Indica-

tor Plate, and set its 0° to the Miter

Gauge's 90°. Tighten the Screw. See

Figure 60.

Figure 58

3. If the Miter Gauge Face is not perpen-

dicular to the Saw Blade, do the follow-

ing:

Figure 60

90° Stop

45° Stop

45° Stop

SHOPSMITH MARK V 845180

Page 20

then tighten the lock. Unlock the Car-

riage Lock and move the Worktable to

the right.

2. Use the 5/32" Allen Wrench to loosen

the Arbor Set Screw. Remove the Saw

Blade. See Figure 62.

Figure 62

3. Unlock the Table Height Lock and lower

the Table to a comfortable working

height. Tighten the Lock.

ALIGN THE RIP FENCE

(MARK V MODEL 500 STYLE 1)

1. Place the Rip Fence on the Worktable by

first putting the Fence Base on the Front

Rail, then lowering the rest of the Rip

Fence.

2. Use a 5/32" Allen Wrench to back out the

two Adjusting Set Screws from the Fence

Base so they don't contact the infeed

edge of the Table Rail.

NOTE

The Outfeedlock should press against the bottom

edge of the Table, not hook under it. As you tighten

the Locking Handle, a clamp just behind the Fence

Base pulls the Rip Fence so the Fence Base rests

flush against the Table mounting bar, and is now

automatically aligned to the Blade. The Outfeed

Lock now secures the Fence at the same time.

3. Place the Miter Gauge in the Left Slot of

the Worktable on the infeed side, as

shown in Figure 63.

Figure 63

4. Insert the Long 5/32" Allen Wrench

through the Miter Gauge and secure it

using a Short 5/32" Allen Wrench and a

Set Screw borrowed from the Lathe Tool

Rest, as seen in Figure 64.

Figure 64

CAUTION

Be sure the end of the Allen Wrench is smooth.

Watchthatyoudon'tscratchtheRipFencesurface.

5. Move the Rip Fence toward the Allen

Wrench until it just touches it. When is

doestouchthe Fence, lock the Base Knob,

as in Figure 65.

Figure 65

Other manuals for MARK V

1

Table of contents

Other Shopsmith Wood Router manuals

Popular Wood Router manuals by other brands

BLUM

BLUM M35.ZS00 Safety, operating and maintenance instructions

ARF CNC

ARF CNC 6040 user manual

Mafell

Mafell LO 55 Translation of the original operating instructions

Craftsman

Craftsman 720.25251 owner's manual

MasterForce

MasterForce 241-0836 operating manual

Professional Woodworker

Professional Woodworker 46662 manual