www.hl-yeah.com

5 / 20

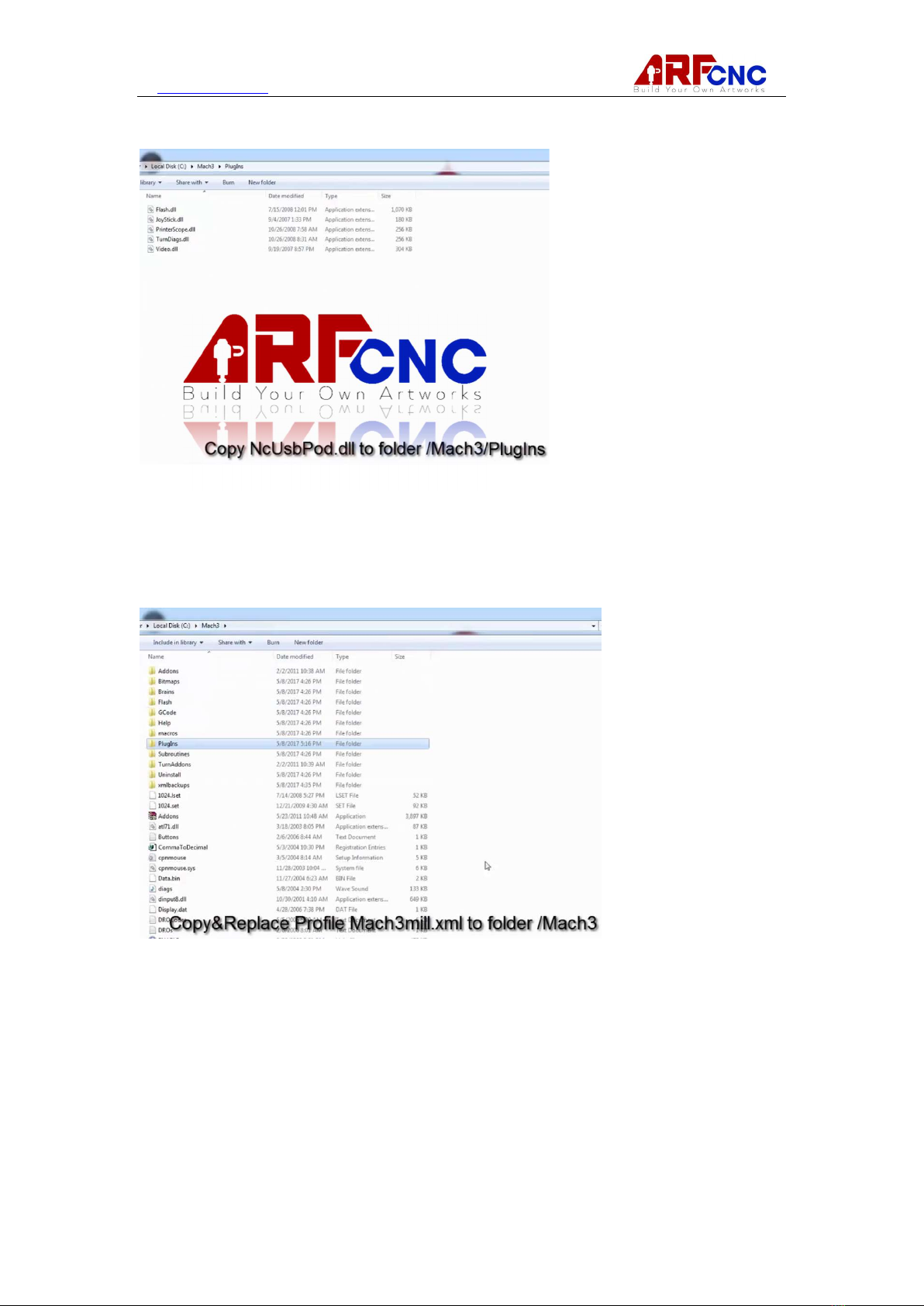

Chapter 3 Installing Mach3 Software

And XHC USB Motion Controller

Mach3 is distributed by ArtSoft USA over the Internet. You download the package as

one self installing file. When installed, it will run for an unlimited period as a

demonstration version. As demonstration software, it places a few limitations on the

speed, the size of job that can be undertaken, and the specialist features supported.

When you purchase a licence, you can “unlock” the demonstration version you have

already installed and configured to give full software functionality. Details of pricing

and options are available at www.machsupport.com.

3.1.1 Downloading Download the installation package from www.machsupport.com.

Use the right mouse button and Save Target as… to put the self-installing file on the

Desktop or in a convenient folder. You should be logged in to Windows as an

Administrator. When the file has downloaded, it can be run immediately by using the

Open button on the download dialog window, or the download dialog window can be

closed and the installation done later. When you want to do the installation, run the

file you downloaded and saved. For example, if you saved the installation file on the

Desktop, just double-click it. If you saved the file in a folder, run Windows Explorer

(right click Start button), and double-click on the name of the downloaded file in the

folder.

3.1.2 Installing This section will guide you through the installation of the Mach3

software. If you already have a version of Mach3 installed on the computer, you can

install the new version on top of it. You do not need to remove the old version first.

3.1.2.1 If a machine tool is connected, disconnect it now. You do not need a

machine tool connected to install the software. In fact, if you are just starting it is

probably better not to have one connected. If a machine tool is connected to your

computer, note where the cable or cables from the machine tool are plugged into

your PC. Turn off the PC, the machine tool, and its drives, and unplug the cable

connector(s) from the back of the PC. Now switch the PC back on.

3.1.2.2 Run the Mach3 software installation package. When you run the downloaded

file, you will be guided through the usual installation steps for a Windows program

such as accepting the license conditions and selecting the folder for Mach3. ArtSoft

USA recommends that you allow Mach3 to use its default installation folder C:\Mach3.

The background image during installation is the standard Mach3Mill screen – do not

worry if you are planning to control a lathe, as Mach3Turn is also being installed. You

will be asked if you want to install various program components, as shown in Figure

3-1: