Shopsmith MARK V PRO User manual

MARK

V

PRO

FENCE

ROUTER

TABLE

521962

-

-

-

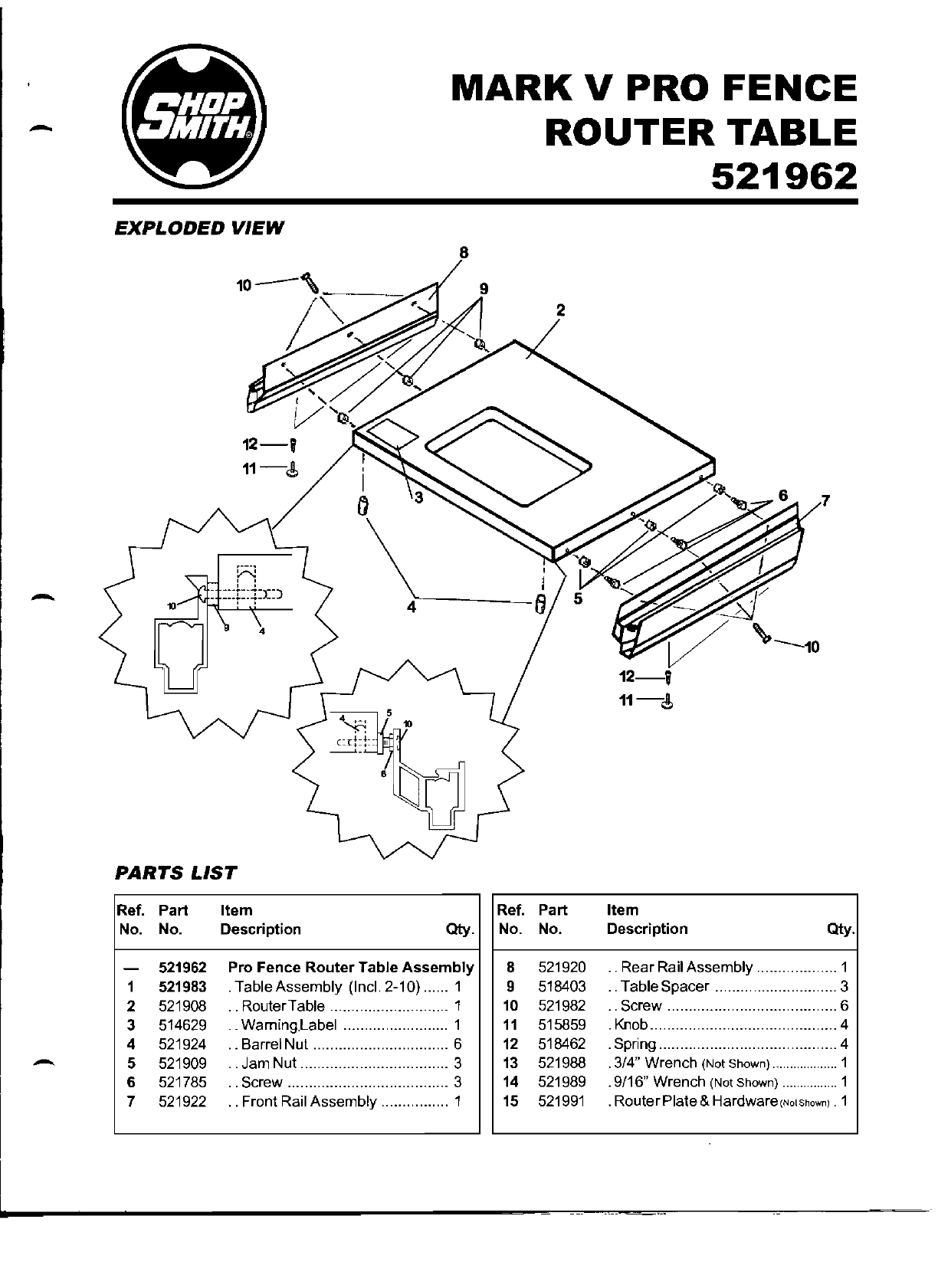

EXPLODED

VIEW

8

PARTS

LIST

Ref.

Part

Item

No. No.

Description

Qty.

-521962

Pro

Fence

Router

Table

Assembly

1 521983 ·TableAssembly (Inc!. 2-10) ...... 1

2 521908 · .RouterTable ............................ 1

3 514629 ·.

WamingLabel

......................... 1

4 521924 ·.BarreiNut ................................ 6

5 521909 · .Jam Nut ... ........................... .

..

3

6 521785 · .Screw ...................................... 3

7 521922 · .Front Rail Assembly ................ 1

Ref.

Part

No. No.

8 521920

9 518403

10

521982

11

515859

12

518462

13

521988

14 521989

15

521991

Item

Description

Qty.

..

Rear Rail Assembly

.....

......

....

1

TableSpacer

........ ..........

....

.... 3

.. Screw .................... ................... 6

.Knob.

........

.

.............

...

............. 4

.Spring ...................... ....... ........... 4

.3/4" Wrench (Not Shown)

...

...............

1

.9/16" Wrench (Not Shown) ................ 1

.

RouterPlate

& Hardware,N'lsh'W"' . 1

7

MARKVPROFENCEROUTERTABLE

521962

INTRODUCTION

The

Router

Table

can

be

used

with

the

shopsmith

MARKVPro Unit.

This instruction

manual

coverssafety, assem-

bly, alignment, operations

and

care of the

RouterTable.Read

through

the

entire

manual

before assembling

and

operating

the Router

Table.

SAFETY

The MARK V Pro Fence Router Table has

many

built-in safety-features,

but

the effec-

tivenessof

them

depends

on

you.

Power

Tool

safety requires

good

common

sense. Misuse

of this tool

can

cause

serious

injury.

Throughout

thismanual,

welist

WARNlNGs,

CAUTlONs,

and

NOTES. Weadvisethat

when

you

come to

one

of these

headings

that

you

read

them

until fully understood.

Their meanings are:

I-W-A--RN-I~NG--I

A

WARNINGisgivenwhenfailuretofollow

thedirections

Is

IikelytoresultlnInjury,loss

oflimb,

or

life.

A

CAUTION

is

given

when

failure

to

follow

the

directions

is

likely

to

result

in

damage

to

the

equip·

ment.

NOTE

A

NOTE

is

used

to

highlight

an

important

procedure,

practice,

or

condition.

I

WARNING

I

Toprotectyourselffrominjury:

• READ,

UNDERST

AND,

AND

FOLLOW

ALL

THE

INFORMATION

IN

THE IN-

STRUCTION

MANUAL.

• ALSO, READ,

UNDERSTAND

AND

FOLLOW

ALL

the

information

that

came

--

with

your

Router

Motor

and

the

Router

Table

Plate

Package.

•

Read

the

Safety

section,

complete

the

Assembly

procedures

and

check

the

Alignment,

before

operating

the

MARK

V Pro

Router

Fence.

GENERAL

SAFETY..

RULES

•

Know

your

power

tool.

Read

the

instruc-

tion

manual.

Learn its

application

and

limitations

as

well

as specific

potential

hazards

peculiar

to

this

tool.

•

Ground

all tools

(unless

double

insu-

lated).

If

the

tool

is

equipped

with

an

approved

3-conductor

cord

and

a

3-prong

grounding

type

plug

to

fit

the

proper

grounding

type

receptacle,

the

green

con-

ductor

in

the

cord

is

the

journeying

wire.

...

Never

connect

the

green

wire

to

a

live

terminal.

•

Wear

proper

eye

and

ear

protection.

Also,

wear

a

dust

mask.

•

Keep

all

safety

guards

in

place.

Always

keep

the

guards

in

working

order,

in

proper

alignment,

and

in

proper

adjust-

ment.

Most

injuries

occur

on

unguarded

power

tools.

•

Remove

all

adjusting

keys

and

wrenches.

•

Wear

proper

apparel.

Do

not

wear

loose

clothing, ties, gloves, rings,

or

other

jew-

elry. Roll

long

sleeves

up

above

your

elbows,

wear

nonslip

footwear,

and

tuck

long

hair

under

a

hat.

•

Avoid

dangerous

environments.

Don't

use

power

tools

in

damp,

wet,

or

explo-

sive

atmospheres.

Page2

5'21962

MARKVPROFENCEROUTERTABLE

•

Keep

works

area

well

lit, clean,

and

free

from

clutter.

-•

Do

not

force

the

tool.

It

will

do

the

job

better

and

safer

atthe

rate

for

which

it

was

designed.

•

Use

the

right

tool.

Do

not

force a

tool

or

accessory

to

do

a

job

for

which

itwas

not

designed.

• For

directional

feed,

ALWAYS

feed

the

workpiece

into

the

cutter

against

the

rota-

tion

of

the

cutter.

NEVER

feed

the

workpiece

into

the

cutter

with

the

rota-

tion

of

the

cutter.

-

•

Check

for

damaged

parts.

A

damaged

guard

or

part

must

be

properly

repaired

or

replaced

before

further

use

of

the

tool.

If

a

strange

noise

or

vibration

develops,

immediately

turn

off

the

power,

unplug

the

machine

and

correct

the

problem.

Never

operate

a

power

tool

that

is

not

functioning

properly.

•

Secure

workpieces.

Use

clamps,

fixtures

and

other

devices

to

hold

workpieces

when

practical.

It's

safer

than

using

your

hands

and

frees

your

hands

to

operate

the

tool.

•

Do

not

overreach.

Keep

proper

footing

and

balance

at all

times.

•

Turn

off

the

tooland

waituntilitcomes

to

a

complete

stop

before

removing

workpieces

and

scraps.

•

Do

not

try

to

stop

the

tool

by

grabbing

the

workpiece

or

any

part

of

the

tools.

Turn

off

the

tool

and

let

it

come

to

a

complete

stop

by

itself.

•

Do

not

leave

the

tool

runningunattended.

-

Turn

off

the

power.

Don't

leave

the

tool

until

it

comes

to a

complete

stop.

•

Avoid

unintentional

starting.

Make

sure

the

switch

is

in

the

"off"

position

before

plugging

in

or

unplugging

the

tool.

•

Disconnect

tools.

Turn

off

and

unplug

tools

before

changing

accessories,

setups,

making

adjustments,

performing

main-

tenance,

or

repairs.

•

Do

not

stand

or

lean

on

the

tool. You

could

fall

into

the

tool

oritcould

tip

over

injuring

you

and/or

the

tool.

•

Maintain

tools.Keep

parts

and

toolssharp,

clean,

and

maintained

according

to

the

instruction

manual.

•

Make

your

workshop

child

proof.

Use

padlocks,

master

switches

and

remove

starter

keys.

•

Keep

children

away.

All

visitors

must

stay

a safe

distance

from

power

tools,

and

wear

ear

and

eye

protection.

•

Do

not

permit

anyone

who

is

inexperi-

enced

to

use

your

power

tools

without

proper

supervision.

MARK

V

PRO

FENCE

ROUTER TABLE SAFETY

RULES

• Be

sure

to

read

and

understand

this

en-

tire

instruction

manual

before

using

the

MARK

V Pro Fence

Router

Table.

Also,

do

not

use

the

MARK

V ProFence

Router

Table

unless

you

are

sure

it

is

assembled

properly,

all

safety

devices

are

installed,

and

you

understand

the

operations

you

are

attempting.

•

Keep

the

Guard

in

place

and

in

working

order.

Always

setthe

Guard

no

more

than

1/4"

above

the

workpiece.

I

Page3

I

I

~

~iiiiiiiiO==--====~-~~--

I

MARKVPROFENCEROUTERTABLE

521962

•

Keep

your

hands,

fingers,

and

other

parts

of

your

body

at

least

3"

away

from

the

rotating

bit.

•

Use

a

Push

Stick,

Push

Block,

Feather

Board(s),fixtures,

or

other

safety

devices

to

maneuver

a

workpiece

into

a

rotating

bit.

If

a

kickback

occurs,

these

devices

help

to

protect

your

hands

and

fingers.

•

Use

only

Shopsmith

Parts

and

Accesso-

ries

on

your

MARK

V

Pro

Fence

Router

Table.

NEVER

use

non-Shopsmith

Re-

placement

Parts

or

Accessories.

They

are

not

designed

like

Shopsmith

Parts. Us-

ing

non-Shopsmith

Parts

may

create

a

hazardous

condition

and

will

void

your

warranty.

Follow

your

Router

Motor

manufacturer's

recommendations

as

to

Replacement

Router

Motor

Parts.

•

Do

not

Rout

secondhand

lumber.

If

you

hit

a

nail,

screw,

or

other

foreign

object,

you

could

be

hit

by

pieces

of

metal

or

there

could

be

kickback.

•

Do

not

"freehand"

Rout

stock

less

than

12" x12"

or

equivalent.

•

Support

long

boards

and

sheet

materials

with

a

Roller

Stand(s)

placed

l'

to 4'

from

the

Worktable.

•

Always

use

a Fixture,Fence,

Miter

Gauge

with

Safety

Grip,

and/or

Starter

and

Guide

Pins

to

help

control

the

workpiece.

•

Always

feed

the

workpiece

against

the

rotation

of

the

bit,

not

with

it.

Otherwise,

the

bitwiJIgrab

and

throw

the

workpiece.

•

Keep

a

firm

grip

on

the

workpiece

at

all

times

and

never

hold

the

workpiece

with

your

hands

in

line

with

the

Router

Bit.

•

Always

use

a

Feather

Board

Assembly

or

other

devices

to

hold

or

guide

narrow

workpieces.

Also,

use

a

long

piece

of

scrap

stock

to

feed

narrow

workpiece

underneath

the

Guard

to

complete

a cut.

•

Cut

with

the

grain

of

the

wood

instead

of

against

it. You

will

get

a

smoother

cut

and

the

operation

will

be

safer.

•

Avoid

standing

in-line

with

the

workpiece

being

fed.

In

the

event

of

a

kickback

you

could

be

hit.

• Feed

the

workpiece

slowly.

Use

extracare

in

routing

workpieces

that

contain

fig-

ured

grain

of

knots,

as

these

may

cause

kickbacks.

•

When

you

are

routing

stock

up

to

10"

wide

across

the

grain,

use

your

Miter

Gauge

with

Safety

Grip

to

control

the

workpiece.

The

workpiece

must

extend

5-1/2"

away

from

the

router

bit.

•

When

stop

routing,

always

you

a

Stop

Block(s) to

control

the

length

of

cut. Fail-

ure

to

use

Stop

Blocks

could

cause

the

bit

to

grab

and

throw

the

workpiece.

•

When

routing

oversized

stock,

always

use

a

least

one

Push

Block

to

help

control

the

workpiece

firmly

against

the

fence.

•

Do

not

work

with

stock

thatis

too

small

or

too

large

to

handle

safely;

that

is

warped,

bowed,

or

cupped;

or

that

has

loose

knots

or

other

defects.

•

Plan

the

operation

before

you

begin.

If

you

are

in

doubt

about

how

to

complete

an

operation

safely,

do

not

attempt

it,

contact

a

Shopsmith

Service

Representa-

tive

for advice.

• Free

freehand

routing

use

a

Guide

Pin,

do

not

rout

a

workpiece

which

has

less

-

than

a

4"

radius.

Page4

r

521962

MARKVPROFENCEROUTERTABLE

•

The

minimum

length

of

stock

should

be

no

less

than

8".

You

should

also

use

a

-

Push

Stick

and/or

Push

Block

on

any

stock

between

8"

to

18"

long.

EYE

PROTECTION

Always

wear

eye

protection

when

you

use

power

tools.

Use

Goggles,

Safety

Glasses

or

a Face

Shield,

to

protect

your

eyes.

•

Goggles

completely

surround

and

pro-

tectyour

eyes.

Many

Goggles

will

also

fit

over

Regular

Glasses.

Be

sure

your

Goggles

fit

closely,

but

comfortable.

•

Safety

Glasses

don't

fog

as

easily

as

Goggles

and

can

be

worn

at

all

times.

Regular

Glasses

normally

have

only

im-

pact

resistant

lenses.

They

are

not

Safety

Glasses.

• A Face

Shield

protects

your

entire

face,

-

not

just

your

eyes.

HEARING

PROTECTION

Prolonged

exposure

to

high

intensity

noise

from

high-speed

power

tools

can

damage

your

hearing.

•

Hearing

Protectors

screen

out

noise

lev-

els

that

can

damage

your

ears,

and

are

recommended

for

ALL

uses

with

Routers

mounted

in

Router

Tables.

GUARDING

FOR

RQUTING

Most

shop

accidents

happen

to

woodwork-

ers

who

fail

to

follow

instructions,

or

fail

to

use

Guards

and

Safety

Devices.

Although

proper

use

of

Guards

and

Safety

Devices

often

requires

additional

setup,

the

protec-

tion

for

you

and

your

family

is

well

worth

the

-effort.

DRESS

Loose

hair

and

clothing,

which

could

be

entangled

in

rotating

bits,

are

very

hazard-

ous.

•

Tuck

long

hair

under

a

hat

or

tie

it

up

above

the

shoulders.

Do

not

wear

ties,

gloves,

loose

clothing,

rings

or

other

jew-

elry.

Roll

sleeves

up

above

your

elbows.

ELECTRICAL

REQUIREMENTS

Follow

the

electrical

requirements

that

ap-

pear

in

the

instruction

manual

that

cam

with

your

Router

Motor.

Do

not

overload

your

electrical

circuits

UNDER-TABLE

MOUNTED

ROUTER

The

Router

is

not

included

with

the

MARK

V

Pro

Fence

Router

Table.

You

will

have

to

purchase

a

Router

or

use

one

that

you

al-

ready

own.

Any

UL

approved

router

can

be

used.

The

specifications

for

the

router

that

you

can

use

are:

•

Use

only

UL

approved

Routers

•

The

Router

must

not

exceed

3

hp.

•

The

Router

switch

is

best

located

so

that

it

can

face

toward

the

front

of

the

Mark

V

Router

Table.

It

can

then

be

easily

and

safely

reached

during

operations.

•

The

Router

switch

must

be

able

to

stay

in

the"

on"

position

without

being

held

by

hand.

It

also

must

easily

switch

off

as

needed.

Page5

•

MARKVPROFENCEROUTERTABLE

521962

•

The

Shop

smith

Accessory Switch is rec-

ommended

if

the

router

motorswitch

does

not

meet

the above criteria.

SAWDUST

AND

CHIPS

Sawdust

and

chips

can

be a fire

hazard

and

breathing

sawdust

can

be

a health hazard.

The

sawdust

from

some

woods

is toxic. To

help

protect

yourself

from

sawdust:

• Attach

the

MARK

V Pro

Router

Table

to

a

dust

collection

system.

•

Or

wear

a close-fitting

dust

mask.

Clean

or

replace

the

filters

in

the

mask

regu-

larly. Also,

open

a

window

or

use

a

fan

to

ventilate

your

shop.

MOUNTING

ROUTER

BITS

•

Turn

off

and

unplug

the

Router

before

mounting

router

bits.

•

Follow

the

recommendations

of

the

Router

manufacturer

as to

the

sizes

and

types

of

router

bits

to use.

•

Make

sure

the

router

bit

is

secured

prop-

erly

in

the

collet. Loose

bits

could

work

free

and

cause

serious

injury.

Insetthe

bit

all

the

way

into

the collet

and

retract

it

a

bout

1/8"

to

avoid

transferring

vibra-

tions

to

the

motor

armature

and

bending

the

shank

of

the

bit.

• Be

sure

the

bit

is

positioned

with

the

cutting

edge

facing

to

the

right.

•

Listen

for

chatter

or

signs

of

looseness

at

start-up.

If

you

hear,

see

or

suspect

prob-

lems,

stop

the

tool

immediately,

unplug

it,

and

check

the

tool

thoroughly.

Correct

any

problem

before

proceeding.

If

you

are

unable

to locate

the

problem,

you

can

contact

your

Shopsmith

Service Repre-

sentative

or

store

personnel

for advice.

Never

operate

the

Mark

V

Router

Table

if

it

is

not

functioning

properly.

•

Keep

bits

clean,

maintained

and

sharp.

•

Don'ttryto

make

your

own

collet

adapter

to

hold

different

sized

bits. Balance

is

important

at

high

speeds,

so

always

buy

appropriately

sized

collets.

TYPES

OF

ROU"rER

BITS

Router bits come in a

wide

variety

of

shapes

and

sizes designed to

be

used

at

very

high

speeds. The

part

of

the

bit

mounted

in

the

router

chuck

is called

the

shank

and

the

rounded

extension

beyond

the

cutter

on

some

bits is called the pilot. The cutting

edge

of

the

bitis called a flu

teo

Router bits have one,

two

or

threeflutes

and

the

more

flutes

there

are

on

the

bit, the

more

cuts

that

can

be

made

per

minute. A

higher

number

of

flutes reduces

theloadon the

motor

and

producesasmoother

cut.

Quality bits

are

made

of high-speed steel,

solid

carbide

or

carbide-tipped steel. High-

speed

steel bits are

heat

treated for extra

hardness

and

to

hold

keen

cutting

edges.

Carbide bits (solid

or

tipped) are the finest

bits available today.

Although

more

expen-

sive,

they

will

out

last

high

speed

steel bits

at

a 15 to 1 ratio

on

softwoods

and

are

high

recommended

for use

on

hardwoods,

plastic

laminates,

plywood

and

particle board.

Router bits are generally classified into four

different categories: grooving bits, edge-cut-

ting bits, panel bits

and

laminate

and

veneer

trimming bits.

CARE

AND

MAINTENANCE

OF

ROUTER

BITS

You will enjoy longer use

of

your

router

bits

if

you

make

it

a

point

to handle, use

and

-.

sharpen

them

properly.

Page6

MARKVPRO

FENCE

ROUTER

TABLE

521962

-• Use

your

router

bits only for the job

they

ASSEMBLY

are

intended

to do. I

WARNING

I

•

Make

sure

thebit

is

mounted

rigidly inthe

collet.

Make

sure

the

Speed

Dial

is

set

to "Slow",

then

turn

off

and

unplug

the

MARK

V

be-

• Learn to

cut

your

workpiece

at

the

proper

fore

performing

any

ASSEMBLY

proced

ure.

speed

to

prevent

heat

buildup

that

can

cause

the loss of bit temper. 1.

With

your

MARK V Pro Fence

System

setup

in

the

Horizontal

Position,

remove

all Accessories, leaving

only

the

Main

• Between operations, set

your

bits in a safe

Saw

Table

Assembly

in

the

Carriage

place

where

they

will

not

fall

or

get hit. Assembly.

Adjust

the

Saw

Table to a

comfortable height.

2.

Loosen

both

the Headstock

and

Car-

Never

use

solvent

on

a

bearing-piloted

bit

without riage Locks. Slide the Headstock to the

first

removing

the

bearing.

left

and

theCarriagetotheright, as far as

they will go. Lock into position.

•

Mter

use,

clean

bits

thoroughly.

3.

Place the Router Table facedown

on

a

•

Sharpen

your

bits

with

a

small

slip

stone

clean,flat

shop

table

or

bench. Locate

the

or

oil

stone

with

oil.

Hone

the

fact

of

each

package

containing

the RouterPlate

and

cutter

with

light

strokes

in

one

direction.

assemble

the

Brackets ONLY, according

Never

hone

the

outside

edge

because

it

to the

included

instructions.

reduces

the

diameter

of

the

cutter.

Hone

each

cutter

edge

with

the

same

number

of

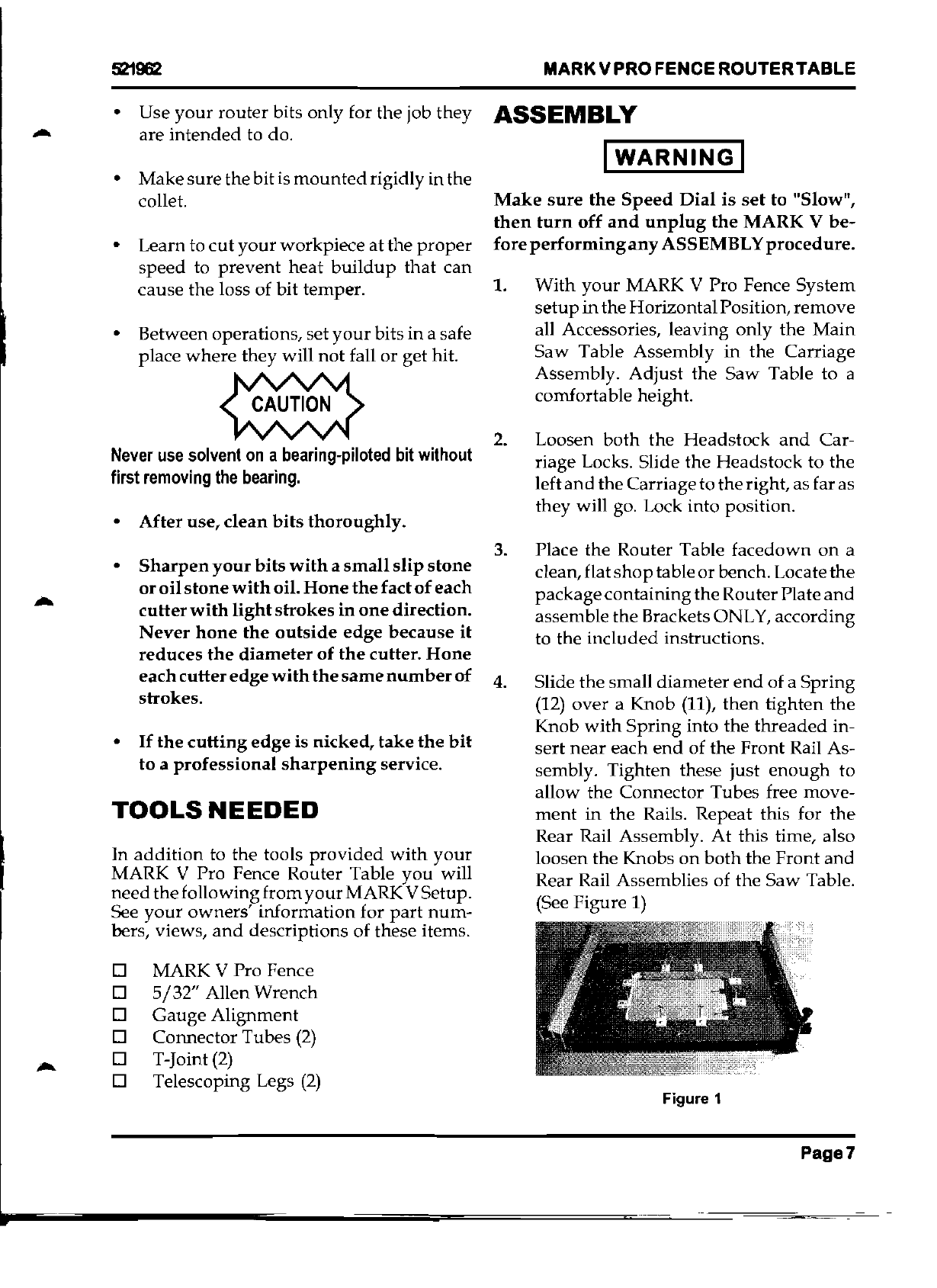

4.

Slide the small

diameter

end

of a

Spring

strokes.

(12)

over

a Knob (11),

then

tighten

the

Knob

with

Spring

into the

threaded

in-

•

If

the

cutting

edge

is

nicked,

take

the

bit

sert

near

each

end

of the

Front

Rail As-

to

a

professional

sharpening

service. sembly.

Tighten

these just

enough

to

allow the Connector Tubes free

move-

TOOLS

NEEDED

ment

in

the Rails.

Repeat

this for

the

Rear Rail Assembly.

At

this time, also

In

addition

to the tools

provided

with

your

loosen the Knobs

on

both

the Front

and

MARK V Pro Fence Router Table

you

will Rear Rail Assemblies of the

Saw

Table.

need

the

following from

your

MARKVSetup. (See Figure 1)

See

your

owners'

information

for

part

num-

bers, views,

and

descriptions of these items.

o MARK V Pro Fence

o

5/32"

Allen

Wrench

o

Gauge

Alignment

o

Connector

Tubes

(2)

o T-Joint

(2)

o Telescoping Legs

(2)

-Figure 1

Page7

MARKVPROFENCEROUTERTABLE

5'21962

5.

Insert

one

Connector Tube into

both

the

Front Rail

(7)

and

Rear Rail

(8)

of the

Router Table.

6.

Position

both

Connector

Tubes

evenly,

so

that

an

equal

amount

is

protruding

out

from both

ends

ofthe Rails

(7

and

8).

(See Figure

2)

Figure 2

7.

Tighten all the Knobs

(11)

of the Router

Table,

in

place.

8.

Make

sure

that

the

Front

Rail (7)is posi-

tioned

next to

the

Front

Rail of

the

Saw

Table, slide the

Connector

Tubes into

the Saw Table Rails. (See Figure

3)

Figure 3

9.

Tighten the Knobs

(11)

of

the

Saw

Table,

to

hold

the

Connector

Tubes

in

place.

10. Attach a T-Joint,

with

Telescoping Leg,

to

the

Connector

Tube

extending

from

each

of the Router Table Rails

(7

and

8).

Tighten the T-Joint Set Screw

with

a

5/

32" Allen Wrench.

11.

Adjust

each Telescoping Leg to

support

the

end

of the Router Table. (See Figure

4)

Figure 4

12. Locate the Router Table Plate Package

and

follow the

included

instructions to

assemble

and

install the

remaining

parts

of the Router Table Plate. These instruc-

tions

also

give

you

the

information

needed

for

mounting

your

Router

and

aligning

the

Plate to the Table.

ALIGNMENT

Your MARK V Pro Fence Router Table At-

tachment

has

been pre-aligned

at

our

Dayton

Factory,

However,

do

to

Environmental

changes,

it

may

be necessary to

make

adjust-

ments

as required.

Should

you

experience trouble sliding the

Connector

Tubes

through

the Rails

on

either

the Router Table

or

Saw

Table, follow these

instructions to correct

the

problem.

1.

Loosen the 3 Screws

(10)

located in

the

Front Rail

(7)

2.

Review the assembly instructions for

in

this

manual

to

insure

steps 1 to 9

are

completed

correctly.

3.

If

after rechecking

your

assemblyproce-

dures,

you

are

still experiencing trouble

Page8

521962

MARKVPROFENCEROUTERTABLE

sliding

your

Connector Tubes, follow

these

steps

to

adjust

the Front Rail As-

sembly of the Router Table.

a. Place

an

accurate straightedge

across

the

front surfaces of

both

FrontRailAssembliesfor

the

Saw

Table

and

the

Router

Table.

Make

note

as to

where

the

"gap" is

on

the

Router

Table Rail so

that

you

can

adjust

it parallel to the

Saw

Table Rail.

b.

To

move

the

Front

Rail As-

sembly

away

from

the Router

Table,

turn

the

Screw

(6)

counter

clockwise. To

move

the

Front

Rail Assembly to-

ward

Router Table,

turn

the

Screw

(6)

clockwise.

-

l

Do

not

adjust

the

middle

screw.

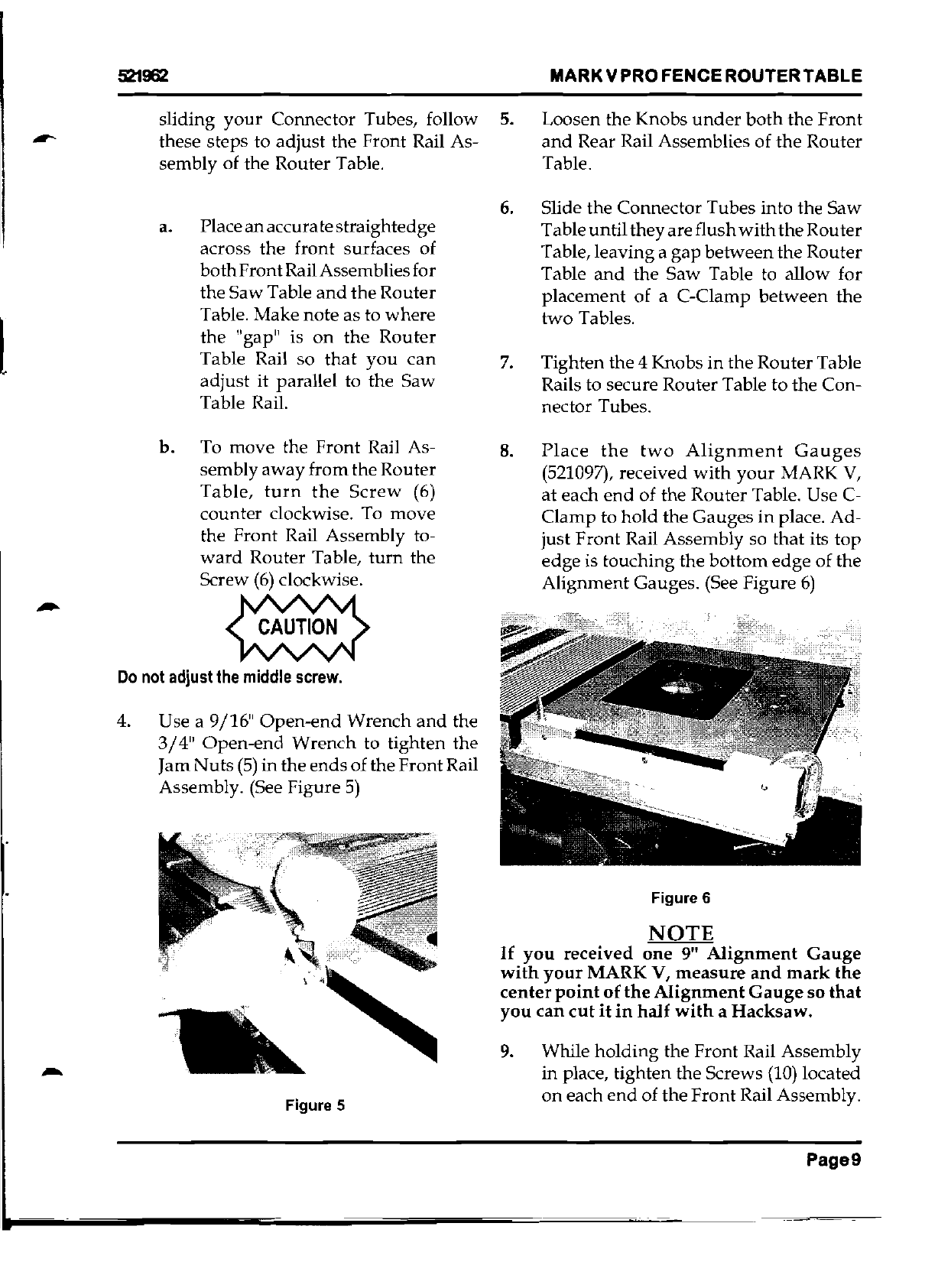

4. Use a 9/16"

Open-end

Wrench

and

the

3/4"

Open-end

Wrench

to tighten the

Jam

Nuts

(5)

in

the

ends

of

the

Front

Rail

Assembly. (See Figure

5)

Figure 5

-

5.

Loosen the Knobs

under

both

the

Front

and

Rear Rail Assemblies

of

the

Router

Table.

6.

Slide

the

Connector Tubes into the

Saw

Table

until

they

are

flush

with

the

Router

Table,

leaving

a

gap

between

the

Router

Table

and

the

Saw

Table to allow for

placement

of

a C-Clamp

between

the

two

Tables.

7.

Tighten

the

4 Knobs in the RouterTable

Rails to secure Router Table

to

the Con-

nector Tubes.

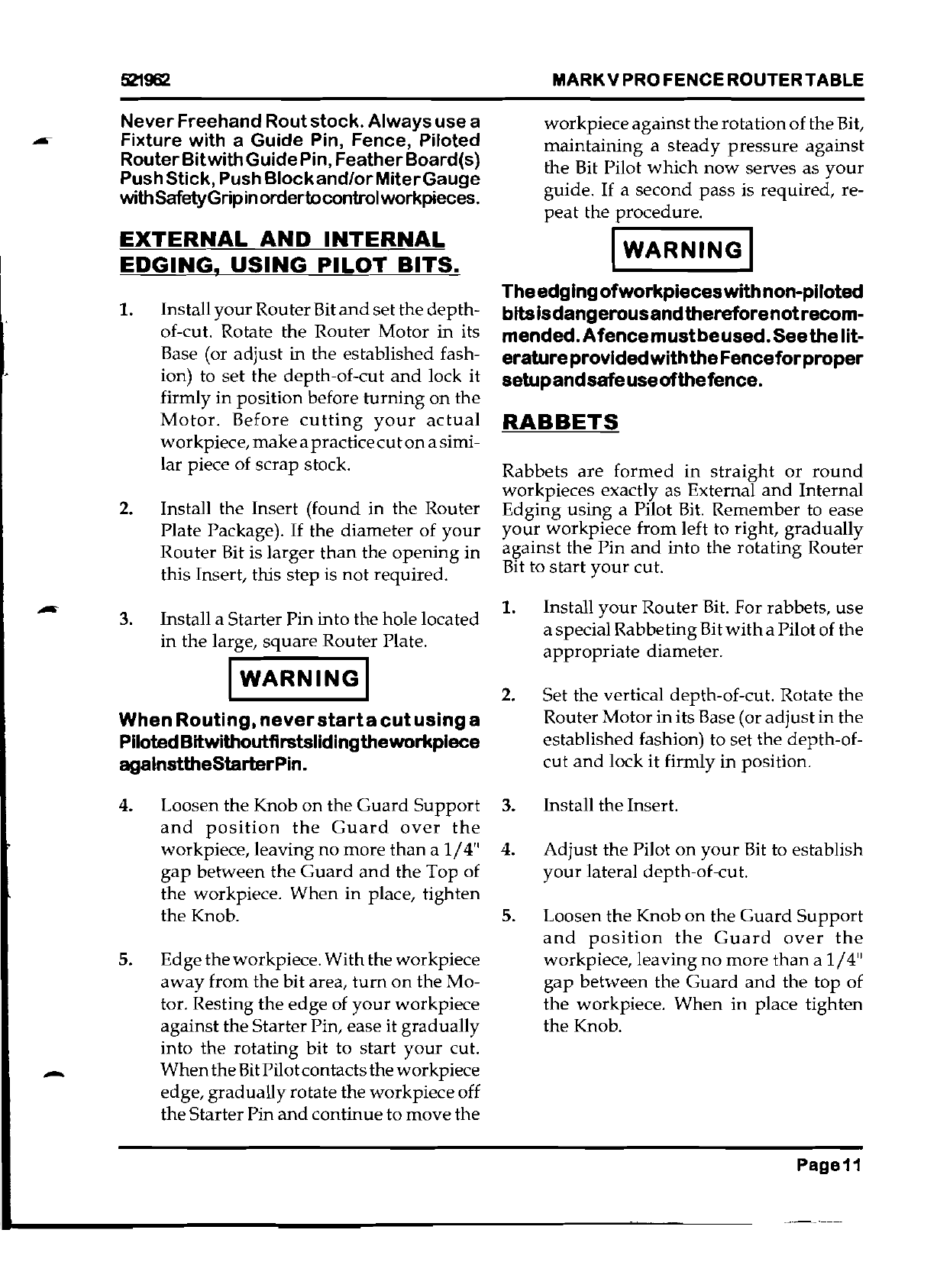

8.

Place

the

two

Alignment

Gauges

(521097), received

with

your

MARK

V,

at

each

end

of the

Router

Table. Use C-

Clamp

to

hold

the Gauges

in

place. Ad-

just

Front

Rail Assembly so

that

its

top

edge

is touching the

bottom

edge

of

the

Alignment

Gauges. (See Figure

6)

Figure 6

NOTE

If

you

received

one

9"

Alignment

Gauge

with

your

MARK

V,

measure

and

mark

the

center

point

of

the

Alignment

Gauge

so

that

you

can

cut

it

in

half

with

a

Hacksaw.

9.

While

holding

the Front Rail Assembly

in

place, tighten the Screws

(10)

located

on

each

end

of

the

Front

Rail Assembly.

Page9

MARKVPROFENCEROUTERTABLE

521962

10.

Turn

the

middle

screw (10)

either

clock-

wise

or

counterclockwise

then

tighten

the

Jam

Nut

using

the

two

open-end

wrenched.

Tighten

the

Screw.

11. Remove

the

C-Clamps

and

Alignment

gauges

and

complete

your

assembly

in-

structions

beginning

at

Step 10.

OPERATIONS

I

WARNING

I

Be

sure

toturn

off

and

unplug

the

Router

beforemakinganyadjustmentsorchanglng

RouterBlts.

1. Install

the

Router

Bit. Insert

the

Router

Bit all the

way

into

the

Collet

and

retract

about

1/8"

to

avoid

any

transi-

tion

radius

where

its

shank

becomes

larger

for

the

profile.

NOTE

The

rotary

depth-of-eut

stop

found

on

some

Plunge

Routers

may

not

allow

some

1/4"

Shank

Router

Bits to

achieve

a

full

depth-of-

cut, to

temporarily

solve

this

problem,

re-

move

the

rotary

depth-of-eut

stop.

I WARNINGl

MakesuretheRouterBitissecuredproperly

intheCollet.Loose

Bitscouldworkfreeand

causeseriousinjury.

2.

Mount

accessories.

Depending

on

the

type

of

Routing

you

are

doing,

mount

the

appropriate

Fixture, Fence(s),

andl

or

Safety Devices

such

as

Feather

Board(s) to

help

control workpiece.

3.

Set

the

depth-of-cut. Rotate the

Router

Motor

in

its Base to set

the

depth-of-

cut

and

lock it firmly in position be-

fore

turrung

it on. Before

cutting

your

actual workpiece,

make

a practice

cut

-

on

a piece of

scrap

stock.

When

some

Routers'

depth-of-cut

lock

is

loosened,

they

may

tend

to

drop

down

from

the

Router

Table.

4. Install

and

adjust

the

Guard.

I

WARNINGI

TheGuard(515704)forfreehandcutsisan

accessory

.Itnotonly

Improvessafeopera-

tionsbutalsoactsasaDustCollectionChute.

We

strongly

recommend

its

purchase

and

use.Followoperationinstructionsthrough-

outthismanualforproperuseoftheGuard.

Avoidtakingdeepcuts.Withtheexception

ofsingle-passdovetail

cuts,limitdepth-of-

cutto114"foreach

passwhenusingBits

up

to

112"diameterlnhardwood.Limitdepth- -

of-cutto3IBR -112"foreachpasswhenuslng

Bits

upto

112"dlameterinsoftwood.When

usingBitsover112"dlameter,limitdepth-of-

cutto

halftherecommendeddepthsfor112"

diameterBits.

5.

Make

the cut. After following all

setup

procedures

and

checking

to be

sure

that

everything

is

tightened

properly,

you're

ready

to

turn

on

the

Router

Motor

and

make

your

desired

cuts.

NOTE

To

prevent

dwell

marks

or

burns

on

your

workpiece,

always

work

in

a

continuous

mo-

tion

without

stopping.

Always

remember

to

raise

or

slide

your

workpiece

carefully

away

from

the

rotating

bitbefore

turning

the

motor

off.

IWARNING

I -

NeverRoutwithouttheGuardin place.

Page10

MARKVPRO

FENCE

ROUTER

TABLE

521962

Never

Freehand Routstock. Always usea workpiece

against

the

rotation

of

theBit,

Fixture with a Guide Pin, Fence, Piloted

maintaining

a

steady

pressure

against

RouterBitwithGuidePin, FeatherBoard(s) the Bit Pilot

which

now

serves as

your

PushStick, Push

Blockand/orMiterGauge

guide.

If

a

second

pass

is required, re-

with

SafetyGrip

inordertocontrolworkpieces.

peat

the procedure.

EXTERNAL

AND

INTERNAL

I

WARNING

I

EDGING,

USING

PILOT

BITS.

Theedging

of

work

pieceswithnon-piloted

1. Install

your

RouterBit

and

setthe

depth-

bitsIsdangerousandthereforenotrecom-

of-cut. Rotate the Router

Motor

in its mended.A

fence

mustbe

used.Seethelit-

Base (or

adjust

in the established fash- eratureprovided

with

theFenceforproper

ion) to

set

the depth-of-cut

and

lock it setupandsafeuseofthefence.

firmly

in

position before

turning

on

the

Motor.

Before

cutting

your

actual

RABBETS

workpiece,

make

apractice

cut

on

asimi-

lar piece of scrap stock.

Rabbets

are

formed

in

straight

or

round

workpieces exactly as External

and

Internal

2.

Install the Insert (found in the Router

Edging

using

a Pilot Bit. Remember to ease

Plate Package).

If

the

diameter

of

your

your

workpiece

from

left to right,

gradually

against the

Pin

and

into the rotating Router

Router

Bit is larger

than

the

opening

in Bit to

start

your

cut.

this Insert, this step is

not

required.

1. Install

your

Router

Bit. For rabbets,

use

3.

Install a Starter Pin into the hole located a special Rabbeting

Bitwitha

Pilot of the

in the large,

square

Router Plate.

appropriate

diameter.

I

WARNING

I

2.

Set the vertical depth-of-cut. Rotate the

When

Routing,

never

starta

cut

using

a Router

Motor

in

its Base (or

adjust

in the

PilotedBitwithoutflrstslidingtheworkpiece established fashion) to set the depth-of-

agalnsttheStarterPin. cut

and

lock

it

firmly in position.

4. Loosen the Knob

on

the

Guard

Support

3. Install the Insert.

and

position

the

Guard

over

the

workpiece, leaving

no

more

than

a

1/4"

4. Adjust the Pilot

on

your

Bit to establish

gap

between

the

Guard

and

the Top of

your

lateral depth-of-eut.

the workpiece.

When

in

place, tighten

the Knob. 5. Loosen

the

Knob

on

the

Guard

Support

and

position

the

Guard

over

the

5. Edgetheworkpiece.With the workpiece workpiece,

leaving

no

more

than

a

1/4"

away

from

the

bit area,

tum

on

the Mo-

gap

between

the

Guard

and

the

top

of

tor. Resting

the

edge

of

your

workpiece

the

workpiece.

When

in

place tighten

against the Starter Pin, ease it

gradually

the Knob.

into the

rotating

bit to

start

your

cut.

When

the

Bit

Pilotcontactstheworkpiece

-edge,

gradually

rotate the

workpiece

off

the

Starter

Pin

and

continue

to

move

the

Page11

MARKVPROFENCEROUTERTABLE

5'21962

MAINTAINING

YOUR

PRO

FENCE

ROUTER

TABLE

I

WARNING

I

BeforedolnganyMaintenanceprocedures

toyourRouterTable,besuretoturnoffand

unplug

the

Router.

ALSOremovetheRouterBitandanyother

Accessories,Fences,

or

Fixtures

that

are

mountedon

the

RouterTable.

The

maintenance

intervals

listed

here

are

based

on

normal

operation

and

assume

that

you

will

be

careful

not

to

abuse

your

Router

Table.

If

you

work

the

unit

unusually

hard,

you'll

need

to

maintain

it

more

often.

If

an

unusual

noise

or

vibration

develops,

turn

off

the

Motor

IMMEDIATELY

and

check

to

see

what

could

be

causing

the

problem.

DO

NOT

operate

the

Router

Table

again

until

you

have

corrected

the

cause

of

the

unusual

noise

or

vibration.

MAINTENANCE

SCHEDULE

As

needed

...

•

Have

Router

Bits

sharpened.

Every

5

hours

of

running

time

...

•

Clean

the

Router Table

thoroughly.

•

Check

alignments

and

adjustments.

•

Check

tightness

of all critical

hard-

ware.

Every

6

months

or

as

needed

..•

• Clean

and

wax

the

Router Table.

To

estimate

running

time,

use

this rule: The

average

woodworker

will

use

power

tools

onl\'

10% of

the

total

time

spent

in

the

shop

-

at

the most. You

may

not

use

your

Router

Table

as

much

as

other

power

tools.

If

you

work

in

your

shop

for

25

hours,

you

have

probably

logged

less

than

an

hour

of

running

-

time

on

your

Router Table.

CLEANING

As

you

work,

sawdust

will

accumulate

on

the

Router Table

and

this

residue

can

affect per-

formance.

Clean

the

Router

Table

and

Motor

with

your

Dust

Collector

or

Shop

Vacuum.

Use

the

Brush

and

CreviceTool Attachments.

After

vacuuming,

clean

all major metal

parts

of

the

Router

Table (except

the

Router

Motor)

with

mineral

spirits to

remove

all dirt,

grease

and

any

built-up

wood

pitch. Use a clean

slightly

damp

cloth to

wipe

all

residue

from

the

Guard

and

Worktable. Clean

the

Router

Motor

as

instructed

in

the

manual

that

carne

with

your

Router Motor.

WAXING

After a

thorough

cleaning,

wax

and

buff

the

TableSurface.

Apply

the

wax

sparingly,

then

-

buff

it

thoroughly.

If

you

apply

too

much

wax

or

don't

buff

it,

the

wax

will mix

with

the

sawdust,

impede

the

movement

of

parts,

and

leave

residue

on

the

stock.

Except

for

the

Laminated

Router

Table

surface,

DO

NOT

wax

or

use

solvents

on

any

other

plastic

parts.

NOTE

If

you

have

any

questions,

please

call

our

Customer

Service

Department

TollFree800-

762-7555

or

send

an

E-mail

to

visit

our

Website

atwww.shopsmith.com

e

,·

Shopsmith

n:.

~

6530 Poe Avenue

Dayton,

Ohio

45414

845512

Rev A

09/01

©

2001

Shopsmith,

Inc.

All

Rights

Reserved

Printed

In

U.S.A.

L

This manual suits for next models

1

Table of contents

Other Shopsmith Wood Router manuals

Popular Wood Router manuals by other brands

Ryobi

Ryobi RE180PL Operator's manual

SainSmart

SainSmart Genmitsu CNC Assembly instruction

XYZ Machine Tools

XYZ Machine Tools TRAK 2OP M11 Mill Safety, Installation, Maintenance, Service and Parts List

Lumberjack

Lumberjack RTS650 Safety and operating manual

DeWalt

DeWalt D26200 Original instructions

DeWalt

DeWalt DW616 instruction manual

HOLZMANN MASCHINEN

HOLZMANN MASCHINEN TFM610V operating manual

Porter-Cable

Porter-Cable 893PK instruction manual

Ergo tools

Ergo tools Pattfield E-OF 1200 operating instructions

Clarke

Clarke CR4 Operation & maintenance instructions

DeWalt

DeWalt DCW600B-CA instruction manual

Craftsman

Craftsman 320.27666 Operator's manual