5

17. Use outdoor rated extension cords.

When a tool is used outdoors, use only

extension cords that are intended for outdoor

use and are so marked.

18. Stay alert. Watch what you are doing.

Use common sense. Do not operate a power

tool when you are tired.

19. Check for damaged parts. Before using a

tool check that there are no damaged parts. If a

part is slightly damaged, carefulty determine if

it will operate property and perform its intended

function. Check for alignment of moving parts,

binding of moving parts, breakage of parts,

proper mounting and any other conditions

that may affect the operation of the tool. A part

that is damaged should be properly repaired

or replaced by an authorised service facility,

unless otherwise indicated in this Instruction

Manual. Defective switches must be replaced

by an authorised service facility. Do not use a

tool if the switch does not turn the tool on and

off correctly.

20. Guard against electric shock. Prevent

body contact with grounded objects such as

water pipes, radiators, cookers and refrigerator

enclosures.

21. Use only approved parts. When servicing,

use only identical replacement parts. Use an

authorised service facility to t replacement

parts.

WARNING. The use of an accessory or

attachment, other than those recommended in

this Instruction Manual may present a risk of

personal injury.

Additional safety rules for electric routers

- Remove the plug from the socket before

carrying out any adjustment, servicing or

maintenance.

- Fully unwind cable drum extensions to avoid

potential overheating.

- When an extension cable is required, you

must ensure it has the right ampere rating

for your power tool and is in a safe electrical

condition.

- Ensure your mains supply voltage is the same

as your tool rating plate voltage.

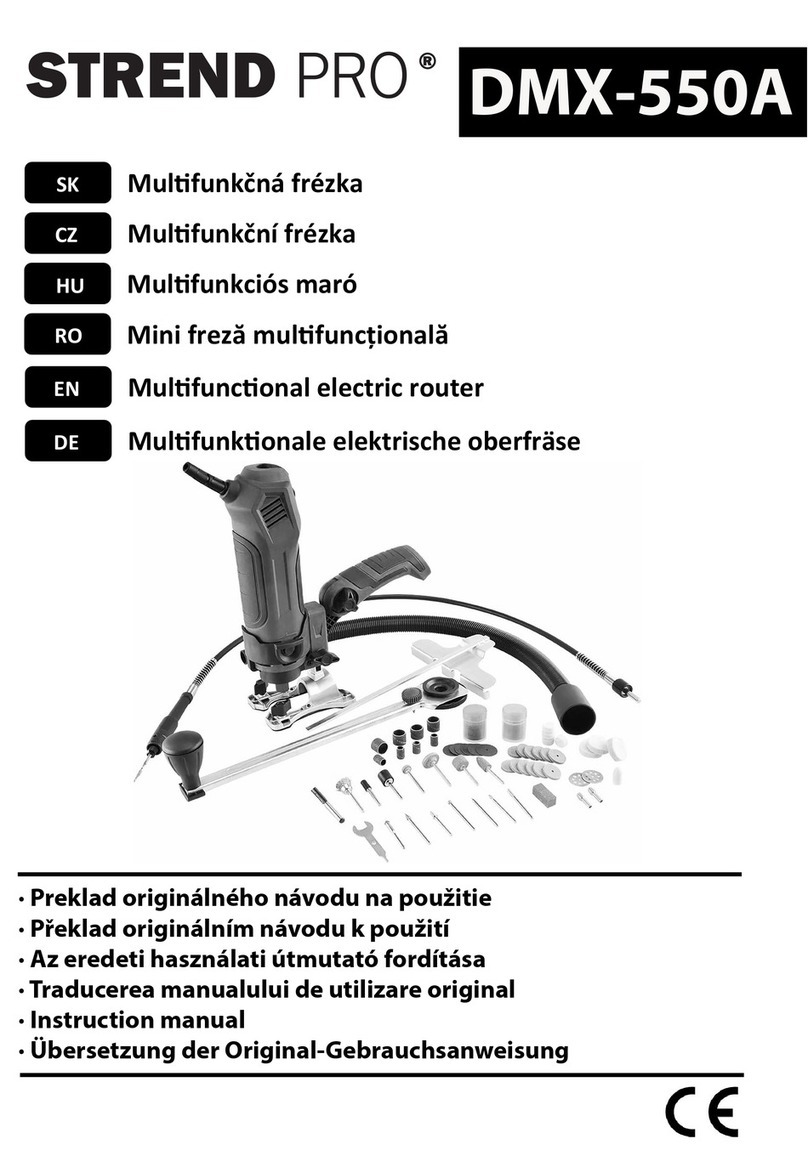

- Your tool is double insulated far additional

protection against a possible electrical

insulation failure within the tool.

- Always check walls, oors and ceilings to

avoid hidden power cables and pipes.

- After long working periods external metal

parts and accessories could be hot.

- Always wear eye and ear protection and use

a dust mask.

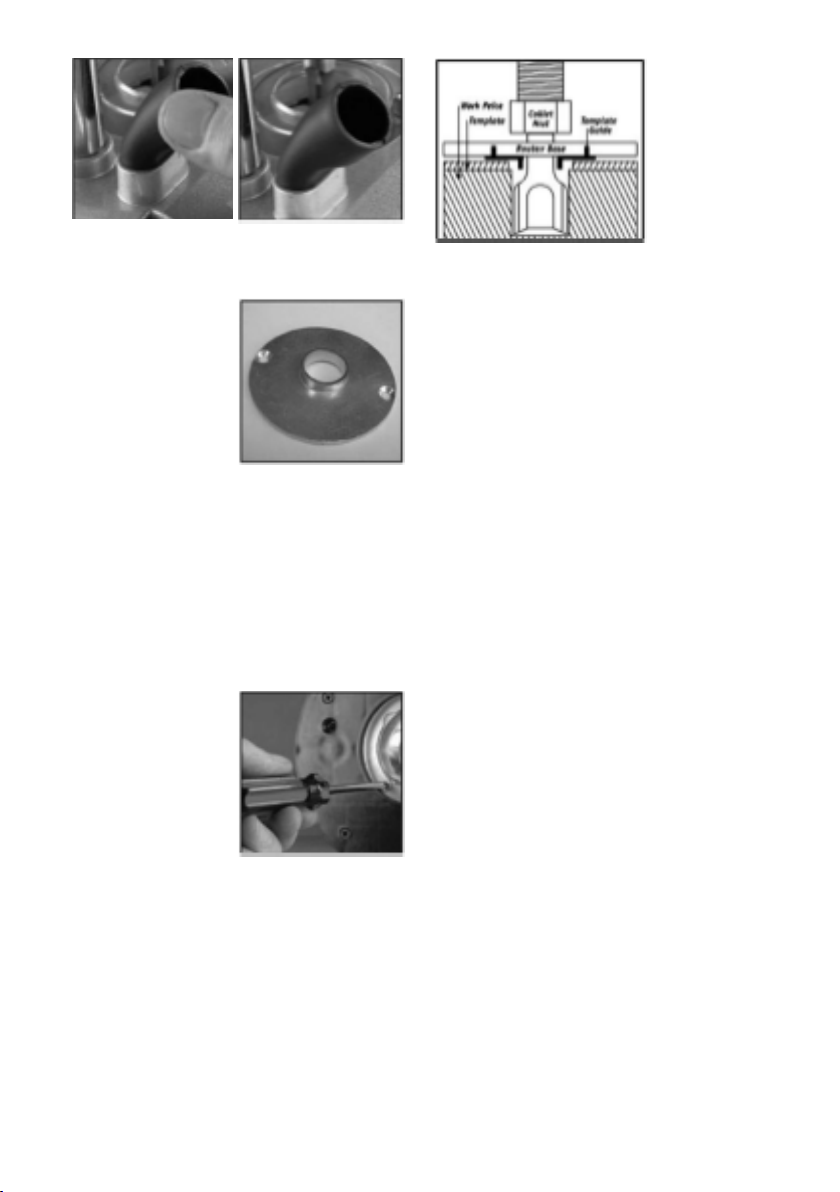

- Handle router bits with care, they can be

extremely sharp.

- Check the bit carefully for signs of damage or

cracks before use. Replace cracked or

damaged bits immediately.

- Remove all nails, screws and other objects

from the workpiece. You can damage the bit

and the tool by cutting into a nail or other metal.

It can also present a safety hazard.

- Always use both handles and make sure

that you have a good grip on the router before

procceding with any work.

- Keep your hands away from the rotating bit

- Make sure that the bit is not in contact with

the workpiece when you switch the machine on.

- Before using the tool to make a cut, switch

on and let it run far a while. Watch for vibration

or wobbling that could indicate an improperty

installed bit.

-Take notice of the direction of rotation of the bit

and the direction of feed.

- Do not leave the machine running unattended.

Operate the tool only when controlled by both

hands.

-Always switch off and wait until the bit has

come to a complete standstill before removing

the machine from the workpiece.

- Do not touch the bit immediately after

operation. It may be extremely hot and could

burn your skin.

- Rags, cloths, cord, string and the like should

never be left around the work area.

- Use safety equipment including safety

goggles or shield, ear protection, dust mask

and protective clothing including safety gloves.