3

EN

The operator

■must ensure that the additional carriage is only operated and maintained by

sufficiently trained staff, who have read and understood the instruction leaflet,

and, most importantly, the safety section;

■is responsible for ensuring that the additional carriage is kept in a

safe operating state;

■will stop using the additional carriage immediately when faults occur

which jeopardise safety.

A – Safety ➢Please read the instruction leaflet and safety information before starting up the

additional carriage.

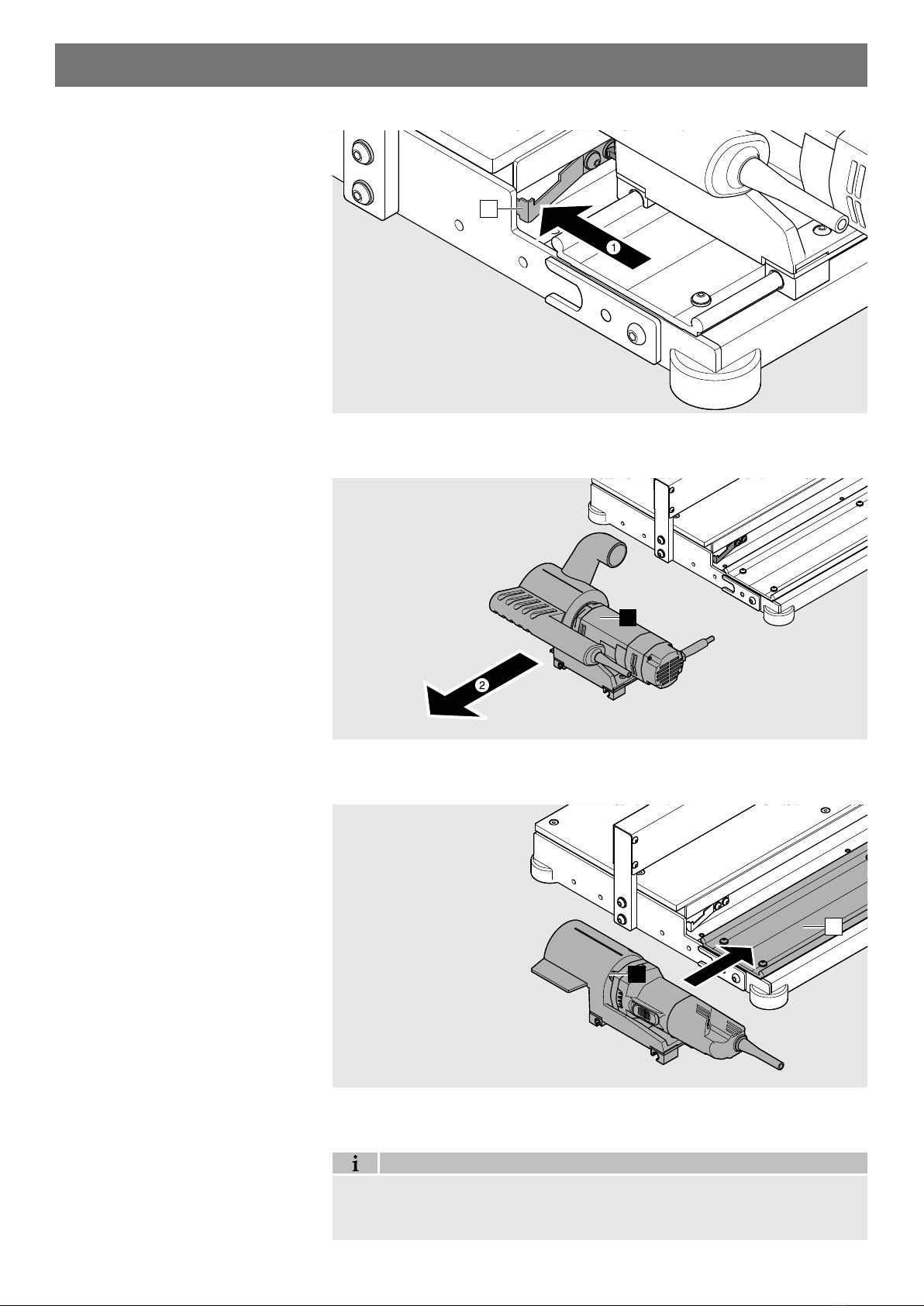

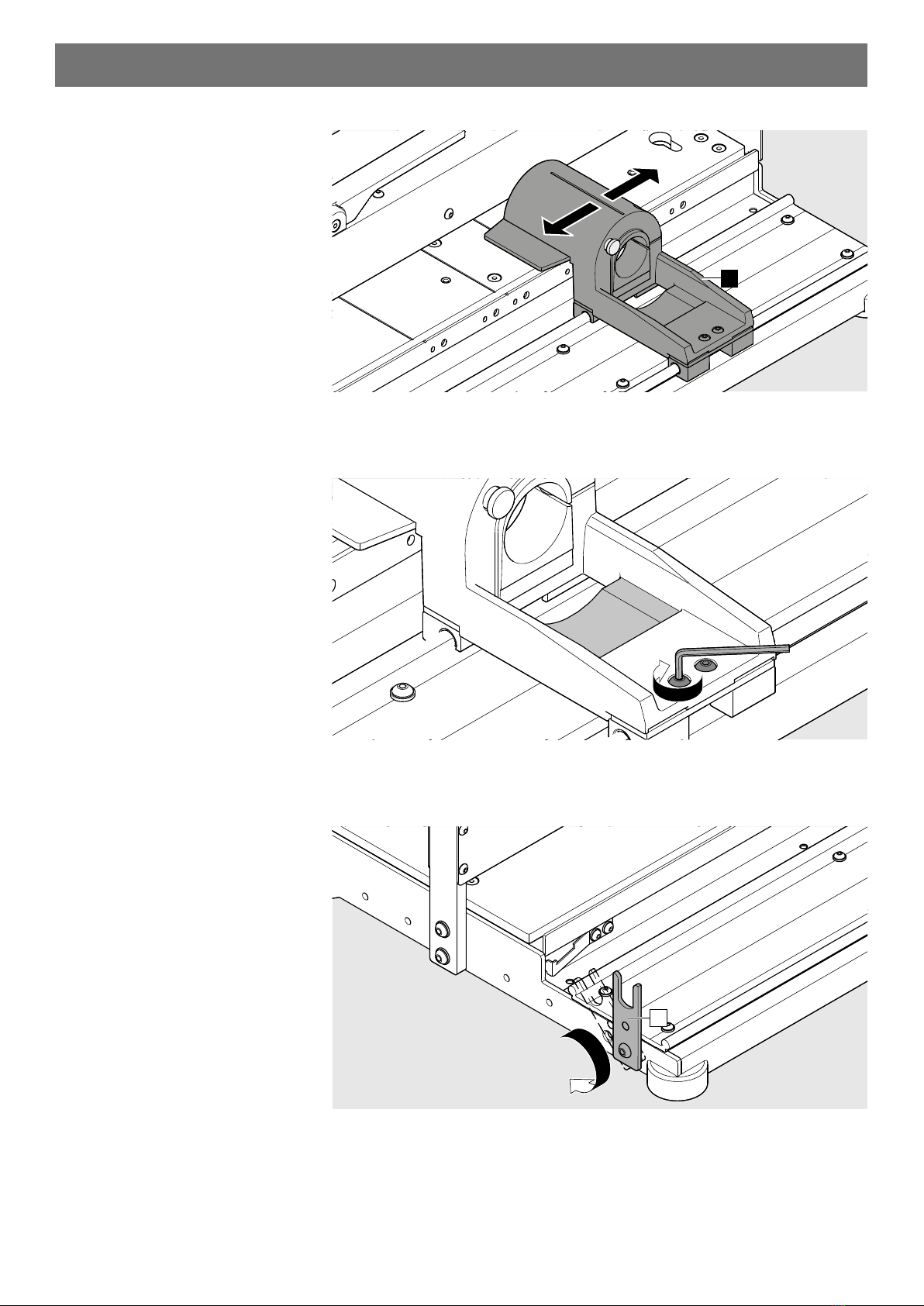

➢We recommend that you use the reference diagrams to make it easier to identify

the parts being described.

Safety principle

Handling

The additional carriage complies with current safety standards. Nevertheless, there

will still be certain residual risks if the information contained in this instruction leaflet

is not observed.

No solid wood or hard wood or plastic may be processed.

Residual risk according to

DIN ISO EN 12100

■The additional carriage is equipped with all the necessary protection features.

■However, there will still be some residual risks for the user, particularly when

removing the protective equipment or when control units fail.

■Other residual risks are identified by warning signs and safety information. It is

therefore necessary to observe the safety information.

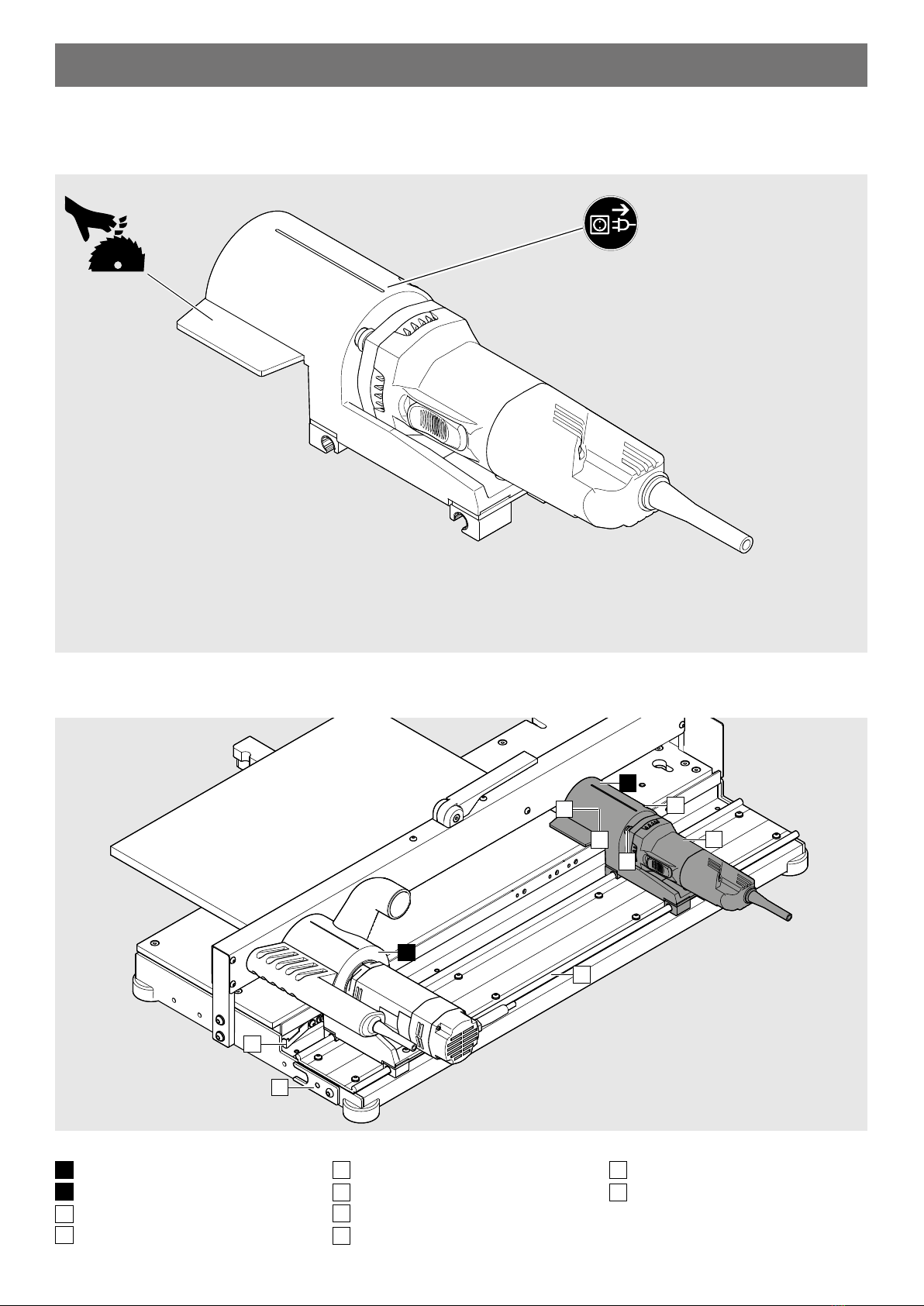

Intended use

Foreseeable misuse

The additional carriage is only intended to be used to process drawer bases for Blum

LEGRABOX and TANDEMBOX. The additional carriage may only be used under the

following conditions:

■The additional carriage may only be operated by fully trained specialist staff.

■The additional carriage may only be used in combination with the base router.

■The additional carriage has been designed for professional traders.

■Only particle board and medium-density fibreboard (MDF) may

be used as materials.

■The device should only be installed in dry, enclosed rooms.

■Only for drawer bases with a thickness of 15 –19 mm

(depending on the device type)

■Only original Blum tools may be used.

■No liability can be accepted for any other use.

Responsibilities