short circuits SENSOR ARRAY User manual

INSTRUCTION MANUAL

SENSOR ARRAY

SENSOR ARRAY

Contents

The SENSOR ARRAY is just that, an array of sensors. The Motherboard and other Arduino

based microcontroller boards use various inputs and outputs to form functions for a device that

is of some use. The Sensor Array gives the Motherboard access to data about the surrounding

environment. This data can be saved for later, or used to trigger other actions like outputting to a

display, or triggering an alarm.

The sensors available on the Sensor Array are temperature and relative humidity via the DHT11,

sound via a microphone and amplier circuit, and light via a light dependent resistor. We have

also included a Micro SD card slot and a logic converter circuit to convert our microcontroller’s

5V logic to the 3.3V needed for the SD card’s logic.

Circuit

Assembly Instructions

Coding Basics

Projects

Component Index

4

12

20

24

26

Kit Contents

Tools Needed

1 x DHT11 Sensor

1 x Micro SD Card Slot

1 x Microphone

1 x Light Dependant Resistor

1 x LM386 Amp

1 x DIP8 Socket

3 x 100nF Ceramic Capacitors

1 x 47pF Ceramic Capacitor

5 x 10uF Electrolytic Capacitors

1 x 3.3V Regulator HT7533

3 x 2N7000 MOSFETs

9 x 10K Resistors

1 x 10 Ohm Resistor

1 x 10K Potentiometer

11 x Screw Terminals

4 x 5mm M3 Hex Screws

4 x Female/Male Standoffs

1 x Printed Circuit Board

Soldering Iron

Solder

Side Cutters

Screwdriver

Alan Key

0.3 - 0.5mm 2mm

2mm

104

3.3V

5V

U2

C4

Q3-5

R4-9

MK1 RV1

LM386

LDR

DHT22

DHT11

U3

R1

R3

R2

C2 C8

C7

C3

C5

C6

U1

+

+

+

+

+

J2

C10

Sensor Array

LDR

LDR

LDR

MIC

MIC

MIC

CLK

Dout

Din

CS

DHT

DHT

DHT

DHT

DHT

DHT

DHT

DHT

C1

R10

GND

VCC

VCC

GND

J1

473

7533-1

2N

7000

50V 10uF

4

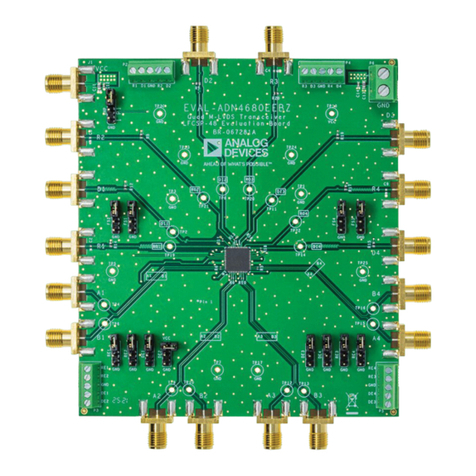

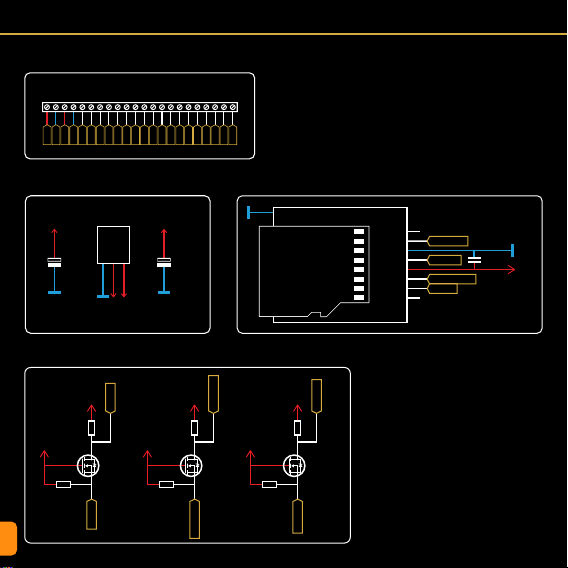

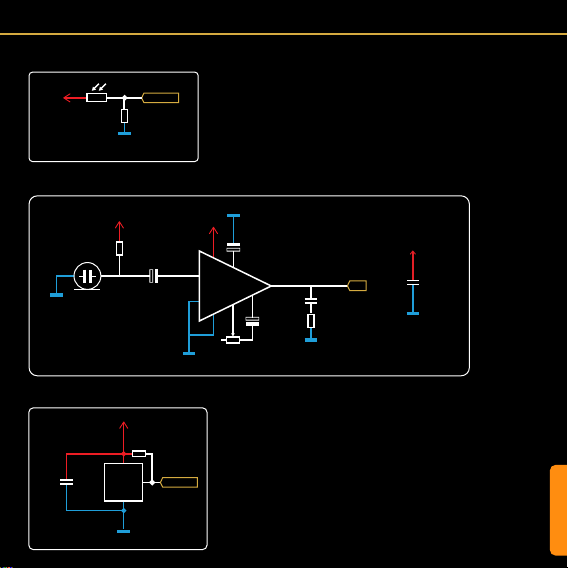

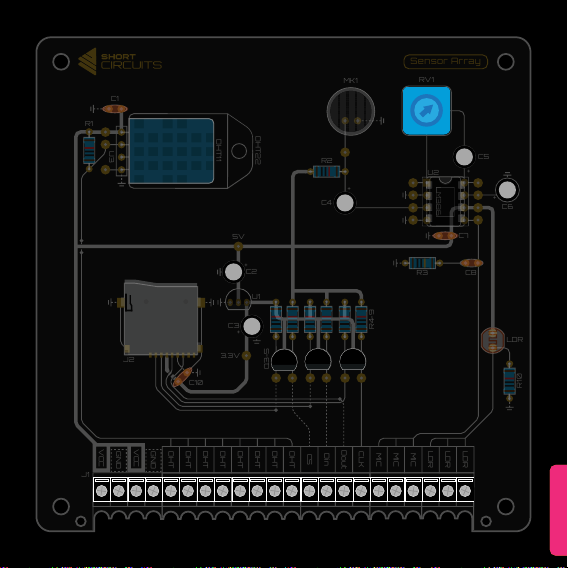

Circuit - Symbols and Designations

Copper power trace

Through hole solder pads

R

C

C

Q

RV

U

U

LDR

J

U

MK

Copper signal trace

Copper trace on back of board

Surface mount solder pads

Resistor

Ceramic capacitor

Electrolytic Capacitor

+

MOSFET

Potentiometer

LM386 Amplier

DHT11 Sensor

Light Dependant Resistor (LDR)

Micro SD Card Slot

Electret Microphone

Voltage Regulator

Mechanical hole

J

Screw terminal

Connected to GND plane

GND

Connected to VCC

+5V

PCB SCHEMATIC DESIGNATION

3

1

2

DHT22

DHT11

+

1

2

3

DAT0

VSS

CLK

VDD

CMD

DAT3/CD

DAT1

DAT2

SHIELD

1

2

3

+

CIRCUIT

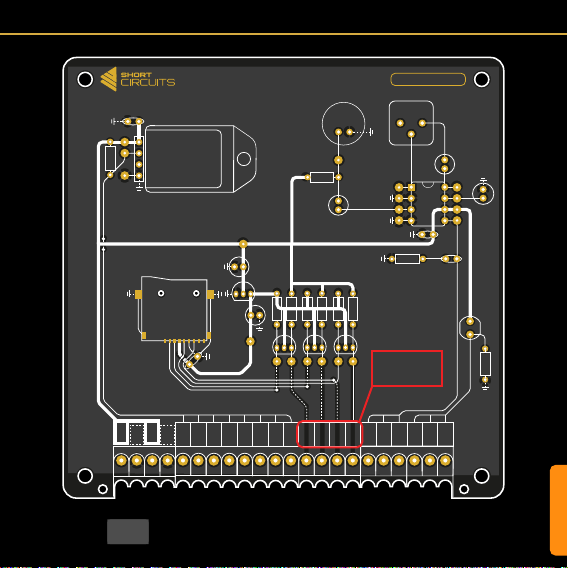

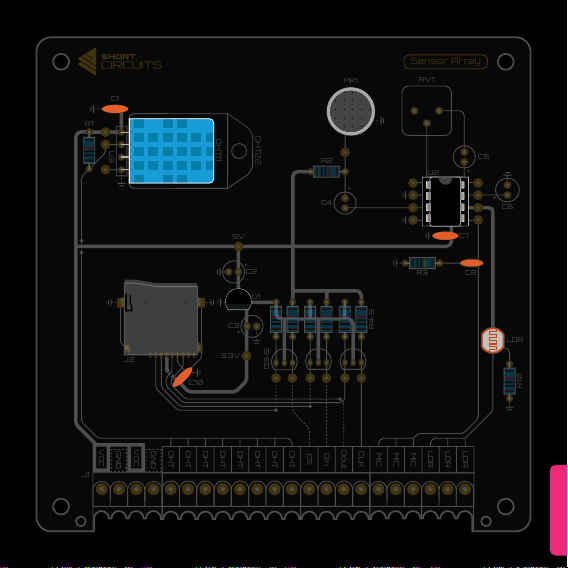

Circuit - PCB Design

Ground (GND) Copper Area On Bac

k of PCB

3.3V

5V

U2

C4

Q3-5

R4-9

MK1 RV1

LM386

LDR

DHT22

DHT11

U3

R1

R3

R2

C2 C8

C7

C3

C5

C6

U1

+

+

+

+

+

J2

C10

Sensor Array

LDR

LDR

LDR

MIC

MIC

MIC

CS

Din

Dout

CLK

DHT

DHT

DHT

DHT

DHT

DHT

DHT

DHT

C1

R10

GND

VCC

VCC

GND

J1

These labels are in the wrong

order on v1 of the PCB.

This image is correct.

6

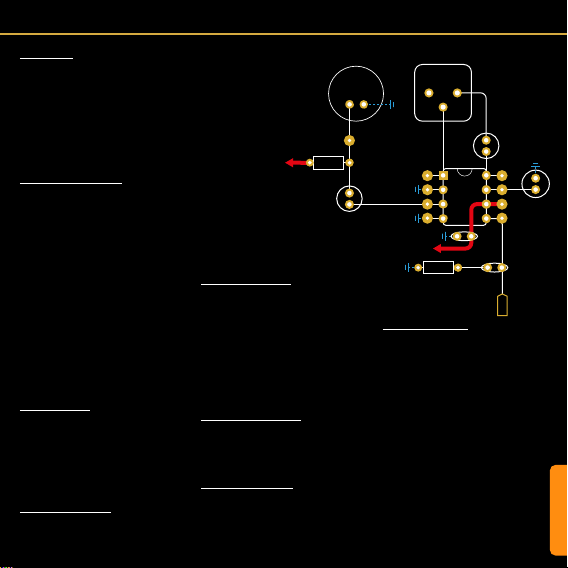

Circuit - Schematic

LDR

LDR

LDR

MIC

MIC

MIC

CS

Din

Dout

CLK

DHT

DHT

DHT

DHT

DHT

DHT

DHT

DHT

GND

VCC

GND

VCC

J1

IO

Terminal Block IO

+5V

+5V

+5V

GND

GND

C2

GND

Vin

Vout

1

2

3

1

2

3

1

2

3

1

2

3

U1

HT7533

10uF

+3.3V

+3.3V

+3.3V

GND

C3

J2

Q3

2N7000

R4

10K

R5

10K

10uF

3.3V Voltage Regulator

3.3V Logic Level Converters

Micro SD Card Slot

DAT0 DATA_OUT

CLK_3v3

DATA_IN_3v3

CS_3v3

VSS GND

CLK

VDD 3.3V

CMD

DAT3/CD

DAT1

DAT2

7

6

5

4

3

2

8

10

1

SHIELD

C10

100nF

CS_3v3

CS_5V

+5V

+3.3V

Q4

2N7000

R6

10K

R7

10K

DATA_3v3

DATA_5V

+5V

+3.3V

Q5

2N7000

R8

10K

R9

10K

CLK_3v3

CLK_5V

CIRCUIT

GND

GND

DHT11 Sensor

Light Dependant Resistor (LDR)

Microphone and Amplifier Circuit

MK1

R2

10K C6

10uF

C5

10uF

RV1

10K

U2

LM386

+

Vcc

3

2

2

4

1

1

85

7

6

BYPASSGAIN

GAIN

Vout

GND

-

R3

10Ω

C8

47pF

C4

10uF

++

+

+

+5V

+5V

+5V +5V

1

GND

IO

U3

DHT11

C1

100nF

R1

10K

VCC

2

4

DH_DATA

DH_DATA

GND

GND

GND

GND

MIC

+5V

GND

C7

100nF

8

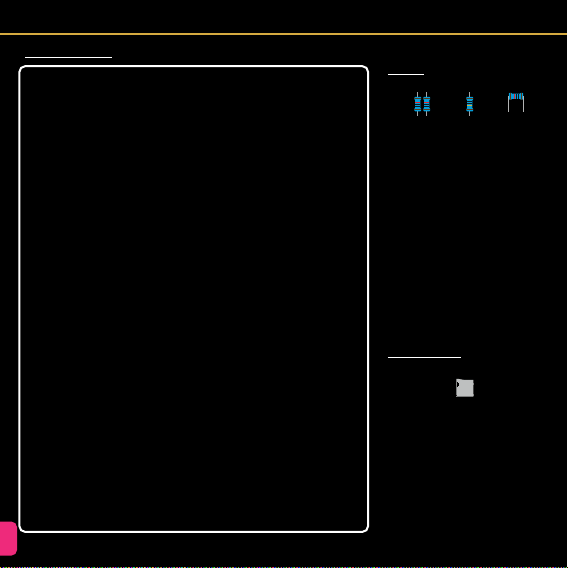

Designation

C1, C7, C10

C2 - C6

J1

J2

Q3-5

R1, R2, R4 - R10

R3

RV1

LDR

MK1

U2

U3

Value

100nF

10uF

11 x 2 pos

Micro SD

2N7000

10K

10Ω

10K

5K - 0.5M

-52dB

LM386

DHT11

Name

Ceramic Capacitor

Electrolytic Capacitor

Screw Terminal

Micro SD Card Slot

N Channel MOSFET

Resistor THT

Resistor THT

Resistor THT

Photoresistor THT

Electret Microphone

Amplifier IC

°C/RH Sensor

Footprint / Pitch

2.54mm

2.54mm

C9 47pF Ceramic Capacitor 2.54mm

3.5mm

TO-92

7mm

7mm

3mm

2.54mm

DIP8

U1 HT7533 3.3V Regulator TO-92

Datasheet

Bill of Materials (BOM)

CIRCUIT

Circuit - SD Card Slot & Circuit

Micro SD Card Slot (J2)

SD Cards can be used to store informa-

tion from sensors or interactions over long

periods of time. You could use it to log the

temperature of a room over the course of a

day, or even a year. The data could then be

imported into a spreadsheet and graphs can

be made! Marvelous. This is just one exam-

ple, but there are many more.

To interface an SD card with a microcontrol-

ler running Arduino code, we need to use SPI

mode. SD cards can interface using a more

complex protocol called SDIO. This is what

mobile phones and cameras use, but it is far

too complex for a microcontroller to manage.

The labels shown on the datasheet and

those on the SD slot’s diagram above are

SDIO pins. They are there for your reference

as datasheets often only mention these. SPI

uses 4 connections; a Chip Select, 2 data

lines, and a Clock Pulse. We have labeled

these from the SD slot’s point of view (the

“slave” in the master slave analogy. See the

Motherboard Manual p29 for more info).

3.3V Voltage Regulator (U1)

SD cards run off 3.3V and so does their log-

ic. Our system runs on 5V, so we use a 3.3V

Voltage Regulator to provide the 3.3V to the

card and to the logic level converter circuitry.

We have used a 7533 for this as it provides

SD Card Motherboard / Uno

CS (Chip Select) Any Pin

Data In (MOSI) D11

Data Out (MOSI) D12

CLK (SCK) D13

+3.3V

Q3-5

2N7000

R4-9

10K

C2

10uF

U1

HT7533

+

+

J2

SD Card Slot

C10

100nF

C3

10uF

Test Point

CS_5V

DATA_IN_5V

DATA_OUT_3v3

CLK_5V

+5V

+5V

GND

GND

GND

GND

GND

DAT0

VSS

CLK

VDD

CMD

DAT3/CD

DAT1

CD

DAT2

Dout

GND

CLK

VCC

Din

SDIOSPI

CS

the 3.3V we need at a max current rating that

exceeds our requirements.

Logic Level Shifting (Q3-5, R4-9)

Logic level shifting is needed when two com-

municating devices read a High (digital 1) at

different voltages.

The SD card regards 3.3V as high, and the

Microcontroller sees anything from 3-5V

as high.

This is ne when the SD card sends a 1 to

the microcontroller, as 3.3V is still considered

High and won’t destroy anything. This is why

DATA_OUT is not converted in our circuit.

The problem arises when the microcontroller

sends a 1 (5V) to the SD card. As the card is

only rated for 3.3V, this can cause damage.

There are a few ways to achieve logic level

shifting. One method is to use two resistors

to create a voltage divider (see Resistors in

the component index). However, this method

can be somewhat unstable and only works

in one direction.

Another method uses N-Channel MOSFETs

with some pull-up resistors. This method is

stable, fast and works in both directions. SD

cards in SPI mode are limited in speed so the

2N7000 works ne. For faster switching use

a dedicated logic level MOSFET.

Arduino, and therefore the Motherboard will

only read SD or SDHC Micro SD cards up

to 32GB. These must be formatted to FAT32.

This can be done by right clicking the SD

card in an explorer window on a Windows

PC, choosing format, selecting FAT32, then

formatting.

10

Circuit - Light Dependant Resistor (LDR)

Circuit - DHT11 Sensor

Light Dependant Resistor

A light dependent resistor is a simple device

that changes resistance depending on how

much light is hitting it. Increasing the light

intensity decreases the resistance.

Resistor (R10)

Because the LDR simply acts as a resis-

tor with varying resistance, connecting it

between 5V and the analog pin of the mi-

crocontroller won’t work. This would just

vary the current that can pass through the

resistor, but the voltage would stay pretty

much the same.

To achieve the effect we need for an accu-

rate reading on an analog pin, (a value be-

tween 0V and 5V), we need to use another

DHT11 Sensor (U3)

The DHT11 is an inexpensive sensor that

detects Temperature and Relative Humidi-

ty. It is a single data line device with some

complicated timing to deal with in the code.

Fortunately there are very useful libraries

available (“DHT Sensor Library” by Adafruit

for example) to handle all the complex stuff,

so you can concentrate on the data itself.

One of the limitations of the DHT sensors

is that they tend to interrupt anything else

that the microcontroller is controlling while

they are transferring data (a icker of the

display while the temperature is being read

for example).

The DHT11 has a more expensive cousin,

the DHT22. This sensor has a better tem-

perature and relative humidity range than the

DHT11, but this is only useful in certain situ-

ations. They are interchangeable though, so

if you nd yourself needing more range, then

swap the DHT11 out for a DHT22.

+5V

GND

GND

DHT22

DHT11

U3

DHT11/22

R1

10K

C1

100nF

DH_DATA

+5V

GND

LDR

R10

10K

LDR

Additional Components

As with any sensitive electronic device, a

bypass capacitor is always useful to smooth

out any noise. Also, the DHT11’s data line

needs to be held high according to its data-

sheet. So a 10K resistor is added between

it and Vcc.

resistor to form a voltage divider. The LDR

we are using has a resistance range some-

where between ~100 and ~0.5M (500K

ohms).

If the LDR has a lot of light shining on it, and

has a resistance value of around 100, the

analog pin would read closer to 5V (as this

is the path of least resistance) and show an

analogRead value of close to 1023.

If the LDR was in complete darkness and

had a resistance value of 500K, the path of

least resistance would be towards GND. This

would result in a value close to 0V and an

analogRead value close to 0.

If there was just enough light for the LDR to

have a resistance of 10K, we would read a

value of 2.5V and an analogRead of ~512.

These values can then be used to control

other functions. Maybe we would like to turn

on an LED when the light level gets too low,

or we could map the value to a range that we

can more easily understand, like 0-100, then

display it on a digital display as a percentage.

CIRCUIT

Circuit - Microphone & Amplifier

alternating current (AC) to pass. This removes

the DC supply voltage that powers the FET

from the AC audio signal produced by the

microphone.

LM386 Amplier IC (U2)

The LM386 is a low cost and commonly avail-

able audio power amplier. The datasheet tells

us that the amplier needs minimal external

components, has an operating current drain of

4mA, and offers voltage gains from 20 to 200.

The datasheet also provides a range of exam-

ple circuits that can help get you started. We

have used the minimum component example

with a few changes.

Bypass Capacitor (C6, C7)

Both of these capacitors help lter out any

noise from the power supply that would oth-

erwise enter the amplier.

Output Filtering (C8, R3)

C8 and R3 are used as a lter. This type of

lter is called a Boucherot Cell and is used to

dampen high frequency oscillations. It pro-

vides an escape path for high frequency oscil-

lations to prevent them building up.

Sound Sensor

This microphone and accompanying ampli-

er circuit are used as a sound sensor rather

than an audio recording device. We can use

it to listen for a clap which can trigger another

action. We can also use it to measure relative

ambient/background noise levels. With a bit of

calibration and testing this could be used to

warn you if you’re being too loud!

Electret Microphone (MK1)

An electret microphone (a type of condenser

mic) acts as a capacitor. It has two conduc-

tors separated by an insulating layer (air in this

case). When sound waves hit the rst conduc-

tor (the membrane) it vibrates. This changes

the distance between the membrane and the

other conductor. This acts as a variable ca-

pacitor that changes depending on the sound

waves hitting it.

The word “electret” is formed from the words

“electrical” and “magnet”. This is because

the membrane is permanently electrically

charged, which makes it act like a magnet.

This helps convert the capacitance to voltage,

which is then amplied inside the microphone

by a transistor.

Load Resistor (R2)

The built in Field Effect Transistor (FET) needs

to be powered for it to amplify the voltage

generated by the microphone. This is where

the load resistor comes in. This resistor, tied to

Vcc, will provide a small amount of bias for the

transistor to operate.

Coupling Capacitor (C4)

An electrolytic capacitor is used in series with

the output of the microphone. A capacitor in

series will block direct current (DC) and allow

Gain Control (RV1, C5)

Normally you would control the volume using

a pot attached to the input of the amp. This

would allow you to lower the volume from its

max (It doesn’t add volume). To enable us to

pick up background sounds and get an idea of

general ambient noise we added the pot to the

gain control rather than the input. This enables

us to change the amount of gain (increase in

volume from input to output).

The datasheet shows us an example of a static

resistor in series with a capacitor between pins

1 and 8. Different values of resistor will give

us a different gain. Without a resistor (0), the

gain is set to 200 (so when the pot is turned

fully to the right). When the pot sits at around

2K the gain is set to 20 (yes we should have

used a 2K pot...). You can experiment with the

code and the pot to get the desired effect.

+5V

+5V

GND

GND

GND

GND

GND

GND

U2

LM386

C4

10uF

MK1

RV1

10K

LM386

R3

10Ω

R2

10K

C8

47pF

C7

100nF

C5

10uF

C6

10uF

+

+

+

MIC

12

Assembly Instructions

General Soldering tips

1. ALWAYS KEEP YOUR TIP CLEAN

To ensure the soldering iron can transfer

enough heat from it to your solder/compo-

nent leg you must keep the tip clean and

shiny. A dull tip means the outside layer

of metal has oxidise. This oxidised layer

is a poor transferrer of heat. Because of

this, you will have to hold the tip against

the component for a longer period of time,

which can result in the component failing.

It’s also very frustrating.

To keep your soldering iron tip clean, wipe

it on a wet sponge or wire ball, then apply

some solder to coat it, then wipe it again.

Ideally, you should do this after every com-

ponent. At the very least, do it after every

4 components.

2. CONTACT

When soldering, make sure the tip of your

iron is making contact with both the leg of

the component and the pad on the PCB.

Apply heat to the area, then, within a sec-

ond or two, apply the solder to the point

of contact.

3. HEAT

It is better to be too hot than too cold. As

mentioned earlier, when the iron tip isn’t hot

enough, you have to hold it on longer. This

allows heat to transfer into the component

and could cause a failure. It is better to set

your soldering iron a little hot so the solder

melts instantly and ows around the leg of

the component with ease. You can start at

around 350C and adjust from there.

4. SOLDER

Leaded solder is much easier to work with,

which makes it easier to learn with. It can

be hard to nd in some countries, but can

often be ordered from China. There are po-

tential health risks, but these are very low.

Make sure you have a fan pointing away

from your work area to blow the fumes

away. Work in a well ventilated area.

Thinner is better. Working with a thick wire

of solder can get messy. Use 0.4-0.5mm

solder for more control. You will have to

feed more into the solder joint, but you

have more control when there are other

pins close by that you want to avoid. This

is essential when soldering surface mount

components and Integrated Circuits.

5. SAFETY

350C is obviously very hot. Stuff catches

re at this temperature. Skin fries. Please

be careful. Remember to turn it off when

you are nished. This will prevent a poten-

tial house re and also save your iron tip

from continued oxidation.

6. ANGLE OF ATTACK

When soldering, make sure you position

the board so that it is easy to access the

area you are working on. It is easy to make

a mistake when you are trying to maneuver

your iron into position around some obsta-

cle. You may have to spin the board 180

degrees, or make sure you have snipped

the legs off the previous component. It’s

easy to be impatient so try to plan ahead.

Resistors

Bend each leg of the resistor by 90 de-

grees, as close to the resistor as possible

(g.1). Then insert the legs into the correct

holes by nding the correct reference (R1,

R2 etc) on the board, or by using the pic-

ture on the next page as a guide. Polarity

is not important with resistors, so either

way is ne.

Hold the resistor in place with sticky tack

or tape, then ip the board over, ready for

soldering. Solder each leg by holding the

soldering iron tip to the leg and the pad,

then apply the solder to the joint. Let it ow

around the leg and create a shiny cone. Use

ush cutters to cut the legs off, then briey

hold the soldering iron to the joint to re-ow

the solder.

Micro SD Card Slot

This is by far the most difcult component

to solder in this kit. It is similar to the USB

socket in the Motherboard kit, but slightly

easier. If you would like to leave this to the

end, make sure you leave C10 to the end.

Start off by placing the SD card slot in the

correct position according to the footprint

J2. While making sure the row of pins are

lined up with the pads on the board, use

R1, R2, R4-10 R3

10K 10 g.1

J2

Micro SD Card Slot

3.3V

5V

U2

C4

Q3-5

R4-9

MK1 RV1

LM386

LDR

DHT22

DHT11

U3

R1

R3

R2

C2 C8

C7

C3

C5

C6

U1

+

+

+

+

+

J2

C10

Sensor Array

LDR

LDR

LDR

MIC

MIC

MIC

CLK

Dout

Din

CS

DHT

DHT

DHT

DHT

DHT

DHT

DHT

DHT

C1

R10

GND

VCC

VCC

GND

J1

ASSEMBLY

14

sticky tack to hold the component in place

and solder the four pads around the sides.

Apply some ux to the pins to help prevent

bridges. Now clean your tip and apply

a little solder to it. Press the tip down on

the rst pin in the row and drag away from

the pin. This should leave enough solder to

bond the pin to the pad. Try to avoid getting

any solder on the second pin. A thin tip is

good for this. Now repeat the process for

each pin.

If you accidentally bridged two or more

pins, apply more ux to the area, clean your

tip, then drag the tip between the two pins

then wipe it clean. Repeat this until you

have removed the bridge. If it isn’t working,

add more ux. If the solder isn’t liquefying

enough increase the temperature of the

iron a little. If this doesn’t help, make sure

your tip is shiny. If it isn’t, you may need to

clean it more thoroughly and add solder to

make it shiny. If the tip dulls quickly, or the

solder refuses to stick to it, your iron may

be too hot.

A video guide will be made shortly after the

manual is published.

Light Dependant Resistor (LDR)

Solder this like any other two legged

through hole component. Add some tack,

ip the board and solder the joints. This

component isn’t polarity sensitive.

LDR

Light Dependant Resistor

Ceramic Capacitors

Install the ceramic capacitors into the cor-

responding holes (C1, C7, C8, C10). They

will easily fall out, so add some sticky tack

or tape to secure them. Polarity does not

matter. Flip the board and solder the pins

to the pads, then trim and re-ow.

IC Socket (DIP-8)

We are going to solder a socket to the PCB

rather than the chip itself. We do this to

avoid heating up the IC and to enable us to

swap it out if it stops working.

Insert the socket into the area marked U2.

Pay attention to the semi-circle indicator

and match the one on the socket with the

one on the board.

Now, stick it in place and solder 1 corner

pin, then the diagonally opposite corner.

Now check alignment and whether its ush

with the board. If one corner is too high,

add pressure to it while heating the pin

underneath.

Now you can solder all the other pins know-

ing that the socket will stay exactly where it

needs to be. If you accidentally bridge two

of the pins, wipe your clean iron tip through

the center of them until they are separated.

104

104 104

C1, C7, C10 C8

100nF (0.1uF) 47pF (0.047nF)

473

U2

DIP8 Socket

U2

LM386

DHT11

The DHT11 is a simple component to sol-

der. The leads are generously spaced. Insert

the leads into the corresponding footprint

(U3). Orient the module so the holes in the

case face upwards when the module is lay-

ing at. Lay the module at and x it in place

with some tack or a bit of glue. Now solder

the pins to the pads. Snip and reow. You

can swap this out for a DHT22, available on

the usual online retail websites.

Microphone

The microphone is polarity sensitive, so

make sure the mic lines up with the foot-

print when inserted. Solder it like any other

through hole component.

3.3V Voltage Regulator (HT7533)

The HT7533 is the rst of two components

that use the TO92 form factor. TO92s can

be tricky to solder because the legs are

often close together. We have spaced the

pads out a little to make it easier. Notice

the semi-circular shape of the TO92 looking

from the top. Match this with the footprint

on the PCB.

The outer legs will spread out a little as you

U3

DHT11/DHT22

MK1

Electret Microphone

Assembly Instructions

U1

3.3V Voltage Regulator (HT7533)

7533-1

ASSEMBLY

3.3V

5V

U2

C4

Q3-5

R4-9

MK1 RV1

LM386

LDR

DHT22

DHT11

U3

R1

R3

R2

C2 C8

C7

C3

C5

C6

U1

+

+

+

+

+

J2

C10

Sensor Array

LDR

LDR

LDR

MIC

MIC

MIC

CLK

Dout

Din

CS

DHT

DHT

DHT

DHT

DHT

DHT

DHT

DHT

C1

R10

GND

VCC

VCC

GND

J1

16

Assembly Instructions

insert it into the holes. Don’t push it too

far as the legs will spread too much and

crack the black casing. Stop when there’s

a 2-3mm gap. Add sticky tack to hold in

place, ip, solder, snip and re-ow.

If you accidentally bridge two pads togeth-

er, clean your iron, re-tin the tip, then drag

the tip through the gap between the pads.

This should separate them. If it doesn’t, re-

peat the process. If your tip isn’t clean, the

solder won’t stick to the tip when you drag

it through, so make sure that tip is clean

and re-tinned.

MOSFETs (2N7000)

The 2N7000 MOSFETs are also in TO92

packages, so follow the same instructions

as the HT7533.

Potentiometer

Insert the legs of the Potentiometer into RV1

on the board. Hold the potentiometer with

some sticky tack and align the blue case

with the footprint. Flip the board and solder

the three pins. Snip and re-ow.

Electrolytic Capacitors

Electrolytic Caps can be soldered upright or

laying against the PCB. This kit is designed

to have them standing up. Other than being

2N

7000

2N

7000

2N

7000

Q3-5

N-Channel MOSFETs

RV1

Potentiometer

50V 10uF

50V 10uF

50V 10uF

50V 10uF

50V 10uF

C2 - C6

10uF Electrolytic Capacitors

tricky to hold in place, the caps are easy to

solder. Build up some sticky tack around

the cap to hold it in place or use some tape.

Then solder the pins as usual.

Terminal Blocks

The terminal blocks are interlocking, so

slide each of them together to make a chain

of 11. To make this line of terminal blocks t

in their holes, you may need to squeeze the

blocks together a bit.

If you are using the Rack case to display

your boards, I would suggest clipping the

legs off. These can interfere with the wires

and cause a short when they are sand-

wiched between the case and the board.

J1

CIRCUIT

3.3V

5V

U2

C4

Q3-5

R4-9

MK1 RV1

LM386

LDR

DHT22

DHT11

U3

R1

R3

R2

C2 C8

C7

C3

C5

C6

U1

+

+

+

+

+

J2

C10

Sensor Array

LDR

LDR

LDR

MIC

MIC

MIC

CLK

Dout

Din

CS

DHT

DHT

DHT

DHT

DHT

DHT

DHT

DHT

C1

R10

GND

VCC

VCC

GND

J1

ASSEMBLY

18

al, listen for a sound from your multimeter.

If there is none, excellent, you don’t have a

short between Vcc and GND. You can jump

over to the Power Test.

If you here a constant sound from your meter

when the probes are in contact with Vcc and

GND then you have a short. Check the back

of the board again for solder bridges. Focus

on the areas marked with boxes on the dia-

gram on the next page. This is where Vcc

and GND are closest.

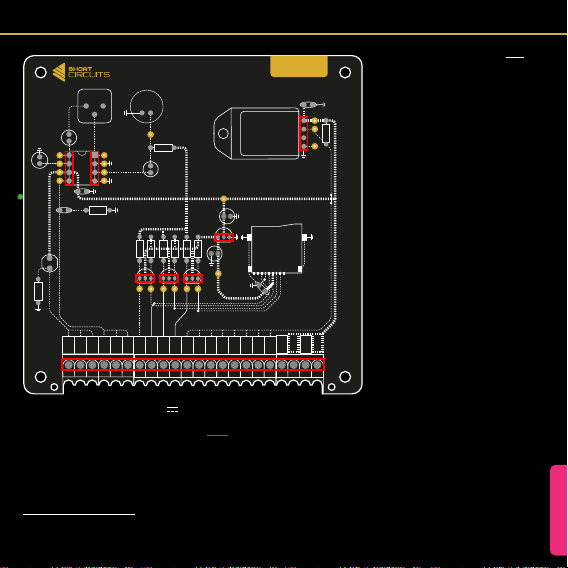

Testing for faults

Before you power on the board, there are a

few things we need to do.

Visual Check

Firstly we need to do a visual check of the

back of the board. We are looking for solder

bridges that connect two pads that aren’t

meant to be connected. A magnifying glass

is a good tool to have when doing this. The

most likely areas for this are highlighted with

red boxes on the diagram of the back of the

PCB and the SD card slot contacts on the

front of the board.

If you see any solder bridges, bring your iron

up to temperature and drag it between the

two pads. You may have to repeat this a

few times. Make sure your iron is clean or

the solder won’t cling to it. Add ux to aid

the process.

Short Circuits

Now we need to check for short circuits (the

bad kind). If we have a short circuit some-

where on the board and we connect it to

power, or a Motherboard kit, we could dam-

age something. To check for shorts, get your

multimeter and put it in continuity mode ( )

Make sure the black cable is plugged into

the common socket and the red cable into

the red socket that also has the symbol

on it. Touch the probes together and make

sure it makes a sound. Now press the black

probe on one of the green circles indicated

in the diagram. These are all connected to

the large ground plane on the underside of

the board. Keep it held there while you press

the red probe onto one of the red circles

indicated in the diagram. The screw of the

Vcc terminal and the metal case of the SD

card slot are the most convenient. Making

sure they are both making contact with met-

Polarity

Check all the components that are polarity

dependent. In this circuit, that would be the

DHT11, Electrolytic Caps, Microphone, Volt-

age Regulator, MOSFETs and the LM386.

Powering the Board

We can now connect the Sensor Array to

the Motherboard. Connect VCC, and GND

to the Motherboards Power Out terminals.

Check that the board is receiving 4.5-5V by

3.3V

5V

U2

C4

Q3-5

R4-9

MK1 RV1

LM386

LDR

DHT22

DHT11

U3

R1

R3

R2

C2 C8

C7

C3

C5

C6

U1

+

+

+

+

+

J2

C10

Sensor Array

LDR

LDR

LDR

MIC

MIC

MIC

CLK

Dout

Din

CS

DHT

DHT

DHT

DHT

DHT

DHT

DHT

DHT

C1

R10

GND

VCC

VCC

GND

J1

ASSEMBLY

switching the multimeter to DC Voltage ( )

and putting the probes on the same points

as last time.

Check the 3.3V regulator is working by plac-

ing the black probe on a GND point and the

red probe on the test point labelled 3.3V,

below the regulator (U1)

Testing the Various Functions

Now you connect each sensor to the Moth-

erboard to test they work. Follow the “Data

Logger” connection diagram in the Project

Ideas section, then upload the test code

(HERE). Open the Serial Monitor in the Ar-

duino IDE and check the output. The text

will tell you if your SD card is inserted and

working, as well as 4 numerical outputs for

temperature, relative humidity, sound and

light. The temperature and humidity reading

should be what you expect. The microphone

reading will be all over the place. This is be-

cause the reading is a brief point on a rapid-

ly oscillating AC audio signal. To better view

this, try the test script which has been modi-

ed for use with the Serial Plotter (LINK). Up-

load this s ketch, then open the Serial Plotter

which is found in Tools on the task bar (or

press Ctrl+Shift+L). This will show you a

graph of the data over time. Play around with

the LDR by covering it or shining a light on

it. Clap to see if the microphone reading re-

sponds. If something doesn’t work, go back

and look at that part of the circuit. Check for

soldering and orientation mistakes.

Still having problems? Head over to the

forums on our website for help and sup-

port. www.shortcircuits.cc

LDR

LDR

LDR

MIC

MIC

MIC

CLK

Dout

Din

CS

DHT

DHT

DHT

DHT

DHT

DHT

DHT

DHT

C1

R10

3.3V

5V

Q3-5

R4-9

LM386

LDR

DHT22

DHT11

U3

R1

R3 C2

C8

C3

C6

J2

C10

U2

U1

+

+

+

C4

MK1

RV1

R2

C5

+

+

C7

BACK

GND

VCC

VCC

GND

J1

20

Coding Basics - DHT11

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

//Adding Libraries

#include <Adafruit_Sensor.h> // includes Adafruit sensor library

#include <DHT.h> // includes DHT library

#include <DHT_U.h> // includes DHT_U library

//Input Pin Variables

#dene DHTPIN 9 // Digital pin connected to the DHT sensor

#dene DHTTYPE DHT11 // Indicate the sensor type: DHT11 or DHT22

DHT_Unied dht(DHTPIN, DHTTYPE); // sets the pin and type

//Other Variables

int temp = 0; // variable to hold temperature data

int humid = 0; // variable to hold humidity data

//Void Setup - runs once at start

void setup()

{

Serial.begin(9600); // Initialise Serial Monitor

dht.begin(); // Initialise DHT Sensor

}

//Void Loop - repeats forever

void loop()

{

sensors_event_t event; // Prepares for the following events

dht.temperature().getEvent(&event); // Gets the temperature data from the DHT

temp = event.temperature; // Saves the temperature to a variable

dht.humidity().getEvent(&event); // Gets the relative humidity data from the DHT

humid = event.relative_humidity; // Saves the relative humidity to a variable

Serial.print(“Temp: “); // print text to Serial Monitor

Serial.println(temp); // print variable’s value and start a new line

Serial.print(“R.Humidity: “); // print text

Serial.println(humid); // print variable’s value and start a new line

delay(5000); // delay for 5 seconds

}

These code examples and explanations

will test all of the Sensor Array’s functions

and teach you the basics. We will cover the

following:

• Read the temperature and relative

humidity from the DHT11 sensor

• Read an analog value from the LDR

• Read and interpret values from the

microphone

• Write data to a micro SD card

As always, you will need to open the Arduino

IDE and either open a new sketch or down-

load the sketches from the links provided.

The rst sketch will handle the DHT11 sen-

sor. The DHT11 is a complex device to inter-

face with. Writing code from scratch would

be very complex. Fortunately, lots of lovely

people have written libraries to help people

write code for Arduinos and compatible

microcontroller devices like ours. Thanks

goes out to them! They make hobbyists lives

a lot easier.

Libraries can be downloaded using “the

Manage Libraries...” option under Tools in

the taskbar. You will need to add two librar-

ies to help us use the DHT11. Search for and

install the following:

• Adafruit Unied Sensor

• DHT sensor library

You can download the full sketch HERE.

Reading the comments for each line will

give you a good understanding of what is

happening. The DHT sensor code refers to

separate les downloaded with the librar-

ies. You don’t need to understand these to

write your own code, just copy the code and

adapt it as needed.