Showcase 5008 User manual

5008

N SCALE 1:160

Nn3 CLASS A, 16 TON, T-BOILER SHAY LOCOMOTIVE SHELL KIT.

THIS IS A MODEL KIT SHELL DESIGNED TO BE POWERED BY

THE SEARAILS’ POWERMAX! POWERED TRUCK (NOT INCLUDED)

IT REQUIRES ASSEMBLY AND PAINTING

THE

MICHIGAN-CALIFORNIA

LUMBER COMPANY

SHAY #2

IN Nn3 SCALE

E P H R A I M S H A Y ’ S S I D E W I N D E R W A S ,

UNQUESTIONABLY, THE MOST POPULAR OF THE

THREE MAJOR GEARED LOCOMOTIVES AMONG

LOGGERS THROUGHOUT THE COUNTRY. ABOUT 2000 WERE BUILT BETWEEN 1884 AND 1945, WHEN

THE LAST SHAY LEFT THE LIMA PLANT. THEY RANGED IN SIZE FROM TINY 10 TON TEAKETTLES TO

4-TRUCK BEHEMOTHS, OF 150 TONS, AND COULD BE ORDERED TO SUIT A WIDE VARIETY OF TRACK

GAUGES. ONLY A RELATIVELY SMALL NUMBER OF THESE UNIQUE MACHINES ARE LEFT TODAY. A

FEW ARE STILL RUNNING WHILE OTHERS, FORTUNATELY, ARE PRESERVED IN PARKS AND

MUSEUMS.

ONE OF THESE IS THE LIMA NO. 122 BUILT IN 1884 FOR THE RUMSEY LUMBER CO. OF BIG RAPIDS,

MICHIGAN. AFTER A SUCCESSION OF OWNERS, IT WAS ACQUIRED BY THE MICHIGAN-

CALIFORNIA LUMBER COMPANY IN 1917 AND, AS THEIR #2, SERVED AS THE YARD SWITCHER IN

CAMINO, CA UNTIL 1951 WHEN IT WAS RETIRED AND PUT ON DISPLAY THERE.

THROUGHOUT ITS LONG CAREER, VARIOUS REPAIRS AND CHANGES TOOK PLACE SO THAT THE

ENGINE’S FINAL APPEARANCE, AS MICH-CAL #2, DOES NOT LOOK MUCH LIKE THE “TYPICAL” SHAY.

IN FACT, IT IS QUITE UNIQUE IN THIS RESPECT. BOTH THE CAB AND THE TANKS ARE HOMEMADE

ADDITIONS ALONG WITH NUMEROUS OTHER ALTERATIONS TO ITS ORIGINAL FORM. WHEN

BUILT, #122 WAS A WOOD BURNER AND HAD 26 INCH WHEELS. MICH-CAL CONVERTED IT TO BURN

OIL AND SUBSTITUTED 24 INCH WHEELS. ORIGINALLY CLASSED AS A 13 TON LOCOMOTIVE, THESE

CHANGES AND ADDITIONS BROUGHT ITS WEIGHT UP TO 18 TONS. A FINE EXAMPLE OF THE

INGENUITY OF LOGGING ROAD MASTER MECHANINCS.

....information courtesy the Precision Scale Co.

THIS MANUAL IS PRIMARILY CONCERNED WITH THE ASSEMBLY OF TWO SPECIFIC SHAY

LOCOMOTIVES BUT ENOUGH PARTS ARE INCLUDED TO ALLOW CONSTRUCTION OF OTHER SHAYS

OF SIMILAR SIZE AND VINTAGE. MANY OF THE PARTS ON PROTOTYPICAL SHAYS WERE PRETTY

MUCH STANDARD ON MOST ENGINES.

SHAY DESIGNS VARIED DEPENDING ON THE

YEAR IT WAS BUILT, THE TYPE OF FUEL USED,

TONNAGE AND THE DESIRES OF THE CUSTOMER

AS TO CERTAIN FEATURES AND DETAILS.

H O W E V E R , T H E S H A Y ’ S G E N E R A L

C H A R A C T E R I S T I C S R E M A I N E D F A I R L Y

CONSTANT, AT ANY GIVEN TIME, THROUGHOUT

THE DIFFERENT PERIODS OF ITS DEVELOPMENT.

THE LIMA SHAY #122

THIS ASSEMBLY MANUAL

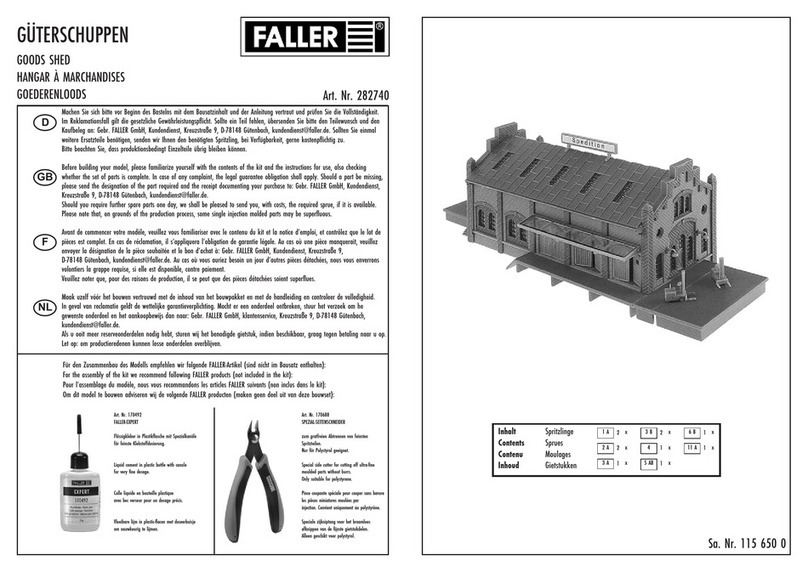

BUILT UP PHOTOS OF THE

MICH-CAL #2 ASSEMBLED KIT

MOST OF THE EARLY LOCOMOTIVES WERE SMALL - RANGING FROM 10 TO 17 TONS - AND NEARLY ALL

HAD “TEE” OR, MORE PROPERLY TERMED, BOOT BOILERS. IN LATER YEARS, THIS GAVE WAY TO THE

STRAIGHT BOILER AND THEWAGON TOP BOILER WITH RECTANGULAR FIREBOXES.

THE MOST COMMON FUEL WAS WOOD, ORIGINALLY,

BUT MANY ENGINES WERE CONVERTED TO COAL OR

OIL. MOST WOOD BURNING SHAYS CARRIED

DIAMOND STACKS WITH SOME TYPE OF SPARK

ARRESTOR, USUALLY A SCREEN AT THE TOP. COAL

AND OIL FIRED LOCOMOTIVES HAD TAPERED OR

“SHOTGUN” STACKS ALSO WITH WOME KIND OF

SPARK ARRESTING DEVICE AS A RULE.

AN INTERESTING FEATURE OF THE SHAY “CONCEPT’

IS THE FACT THAT ALMOST ANY SIZE, OR DESIGN OF

THE LOCOMOTIVE COULD BE ORDERED TO VARIETY

OF TRACK GAUGES WITHOUT ALTERING THE BASIC

DESIGN OF THE ENGINE. ONLY THE TRUCKS WERE

CHANGED, TO SUIT THE GAUGE, AND CYLINDERS

SLANTED AT WHATEVER ANGLE WAS REQUIRED TO

MATCH THE LOCATION OF THE CRANKSHAFT.

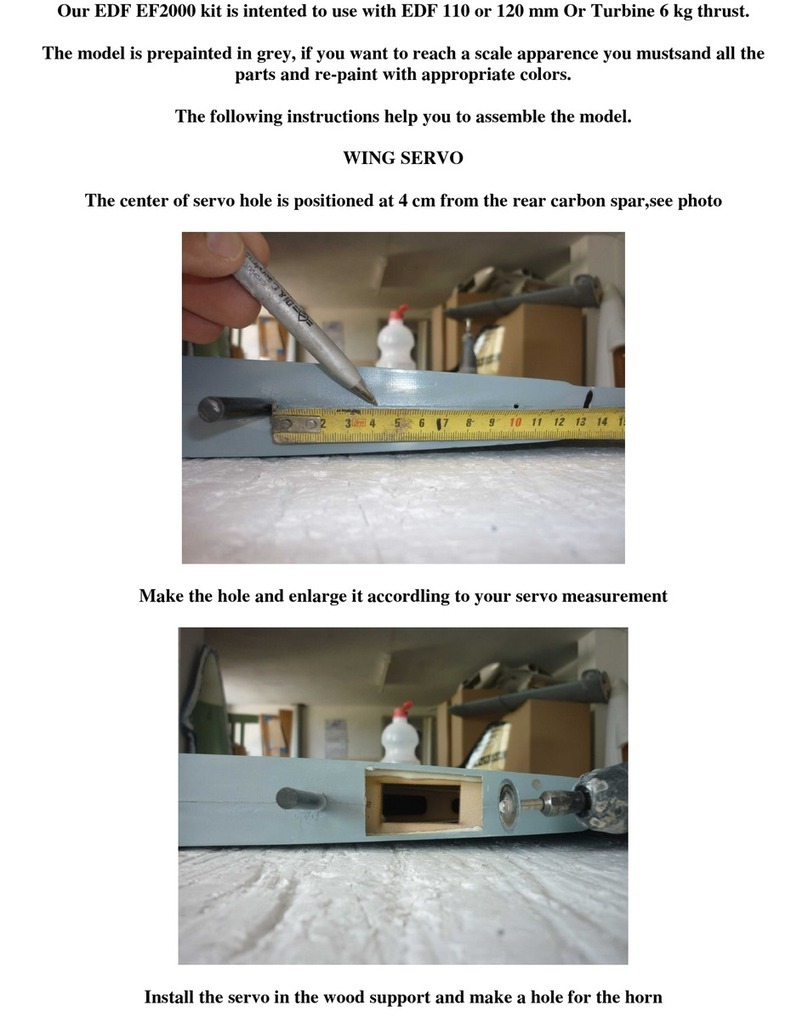

BUILT UP PHOTOS OF THE

CLASS A SHAY ASSEMBLED KIT

5008

N SCALE 1:160

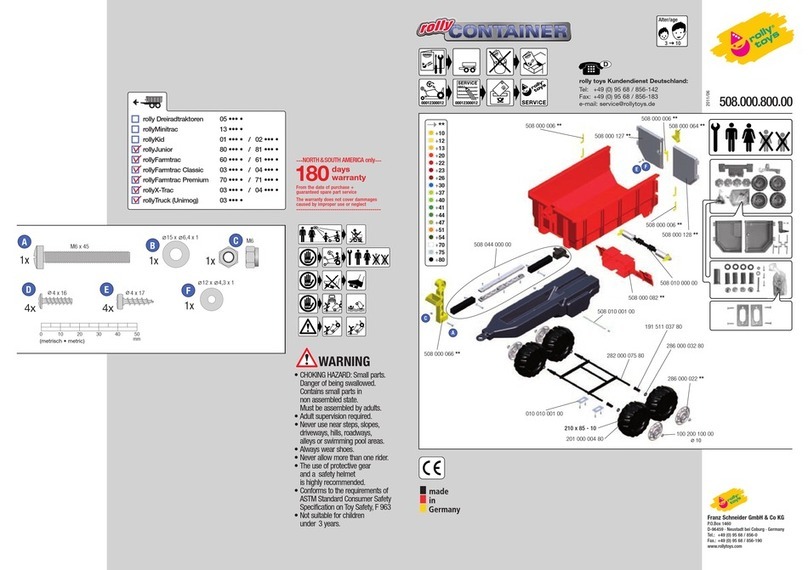

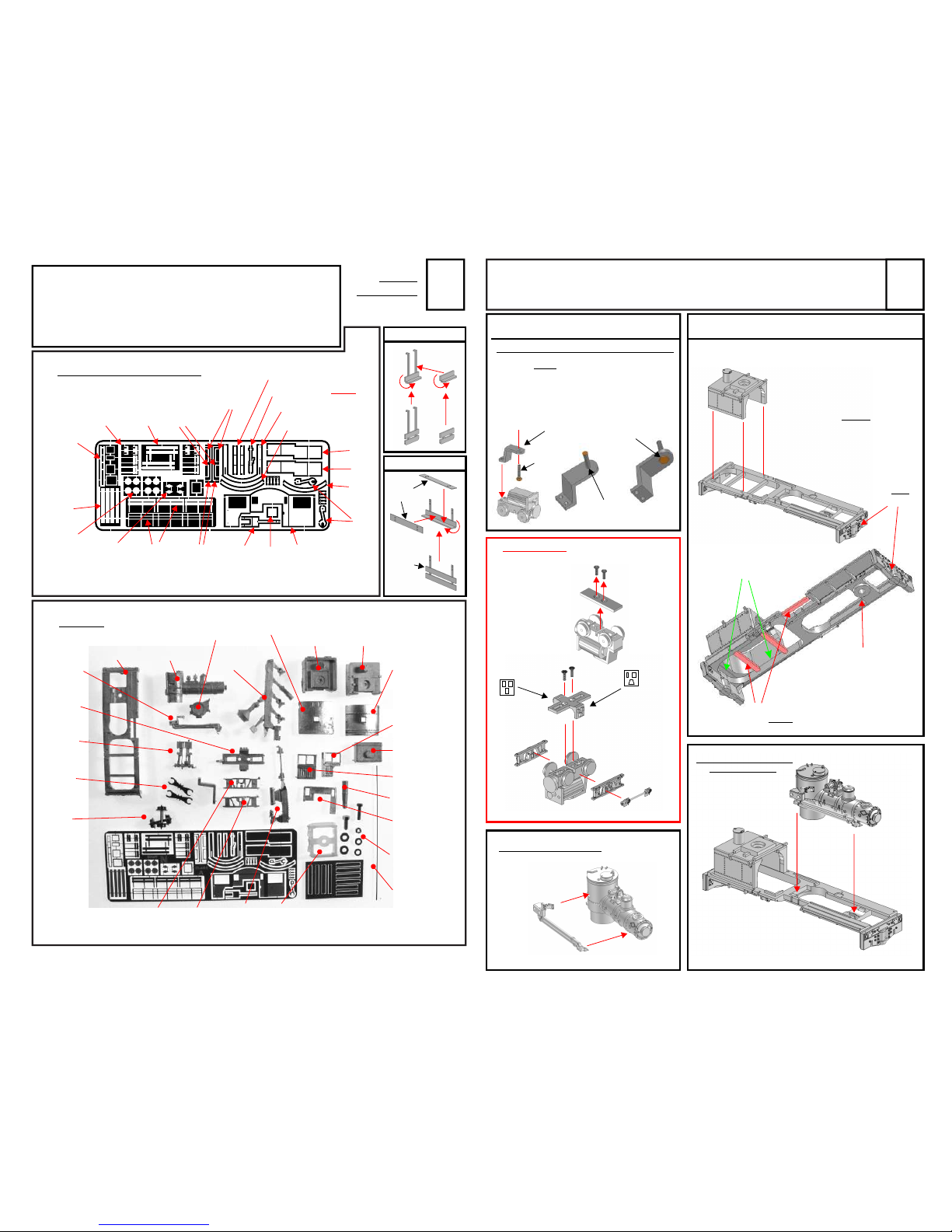

STEP ASSEMBLY

FOLD

PARTS

INCLUDED 1

PAGE

BOILER

FRAME

PIPING

ASSEMBLY

HARDWARE

MC2

BUNKER

BOILER

FOOT

MC2 CAB

ROOF

CA

CAB FRONT

CA

CAB RIGHT

CAB

ROOF

FRONT

TRUCK

DETAIL

SET 1

ENGINE

POWER

TRUCK

LEFT

CA

CAB LEFT

BRASS

ROD

DETAIL

SET 2

POWER

TRUCK

FRAME

POWER

TRUCK

RIGHT

PHOTO-

ETCH

FRET

WHEEL

SET

(2)

DRAWBAR

(2)

CA

BUNKER

RUNNING

BOARDS/

BATTENS

MC2 OIL

BUNKER

MC2 STACK

PARTS

MC1

CA1

MC2

E1

MC2

MC3

CA

STEPS

MC0 MC4 MC5

WHISTLE

MC

STEPS

PILOT

STEPS

CAB

GRAB

IRONS

TENDER

GRAB

IRONS

PILOT

GRAB

IRONS

TENDER

BATTING

CA

LADDER

OPTIONAL

PILOT

BOARDS

NUMBER

PLATES BUILDER

PLATES

NOTE:

SOME PARTS

ON THE SPRUE

ARE NOT USED!

PHOTO-ETCH PART SPRUE

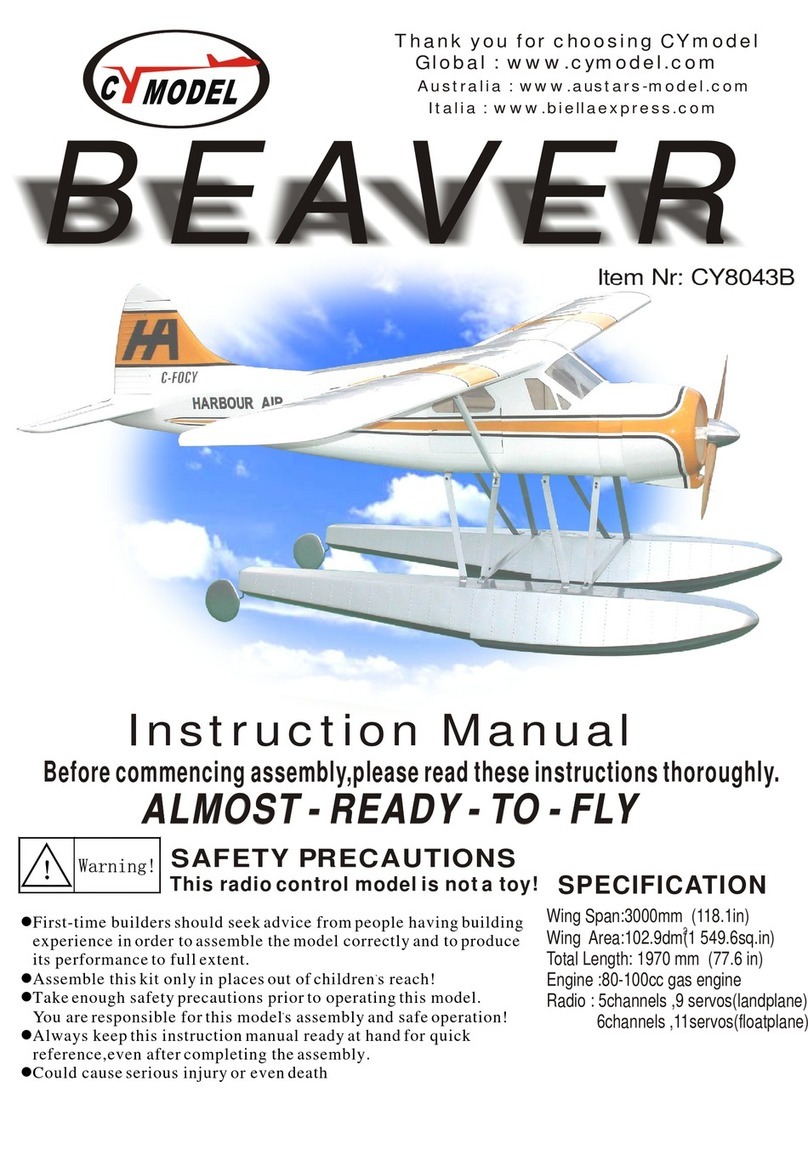

PILOT ASSEMBLY

FOLD

PILOT

PILOT

DECK

BOARDS

-REMOVE ANY FLASH FROM THE METAL PARTS AS REQUIRED.

-TEST FIT ALL PARTS BEFORE APPLYING GLUE. ESPECIALLY CHECK

THE FIT OF THE MICRO-TRAINS DRAWBAR (INCLUDED) AROUND

THE COUPLER PINS IN THE FRONT AND REAR BUMPERS.

-WE RECOMMEND BUILDING AND PAINTING THE SUB-ASSEMBLIES

AND THEN PAINTING BEFORE ATTACHING THE POWERMAX!

POWER AND THE FRONT TRUCK.

!

APPLY GLUE ON INSIDE

OF THE JOINT AREA

BETWEEN THE TENDER

AND THE FRAME TO

INCREASE THE STRENGTH

OF THE JOINT AREA

STEP 2

!

WE RECOMMEND

THAT YOU

ASSEMBLE THE

SUB-FRAME AND

PAINT IT BEFORE

ATTACHINGTO THE

POWERMAX! UNIT.

DRILL AND TAP THIS

HOLE FOR A 1-72 BOLT BY

DRIVING THE INCLUDED

1-72 HEX BOLT INTO THE

BOLSTER HOLE TO

TAP IT.

IT SHOULD THREAD

ITSELF INTO THE HOLE

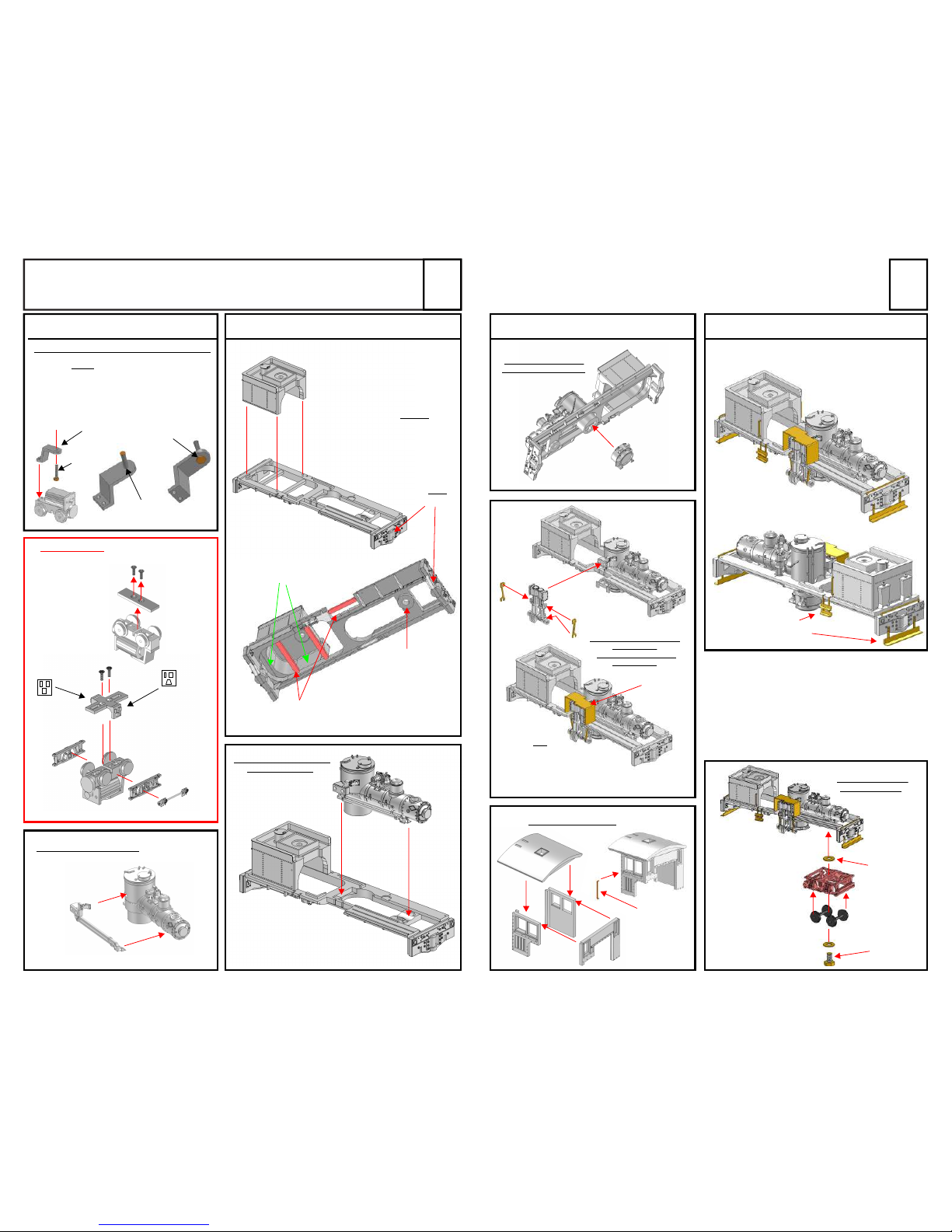

STEP 1

Drill and Tap for

0-80

Machine

Screw

File Down Machine

Screw Head

for clearance over

motor.

Add Tiny Drop

of CA (Super Glue)

for Thread Lock.

0-80 x .25”

Brass Machine

Screw

PLEASE NOTE!!

MODIFYING YOUR

POWERMAX! IN

THIS WAY WILL

VOID YOUR

WARRANTY. THIS

STEP IS FOR

VISUAL AESTHETIC

ONLY. THE SHAY

WILL OPERATE

WITHOUT

PERFORMING THIS

MODIFICATION.

PREPARE THE POWERMAX POWER TRUCK

(THE POWERMAX! POWER TRUCK

IS NOT INCLUDED IN THE KIT)

THE CENTER PIVOT MOUNTING BRACKET IS

INCLUDED IN THE KIT WITH PERMISSION FROM

SEARAILS. IT WILL NEED TO BE PREPARED IN

THE STEPS SHOWN BELOW.

REMOVE THE

BOTTOM PLATE

FROM THE

POWERMAX!

MECHANISM

TAB PATTERN

FOR LEFT

SIDE OF TRUCK

TAB PATTERN

FOR DRIVER

SIDE OF TRUCK

ATTACH THE BUNKER

TO THE FRAME.

USE THE LOCATING PINS

ON THE FRAME AND THE

CORRESPONDING HOLES IN

THE TENDER.

ALLOW THE GLUE TO DRY

COMPLETELY BEFORE

REMOVING THE BRACING.

BRACING TO BE

REMOVED AFTER

GLUEING THE TENDER

ATTACH THE BOILER

TO THE FRAME

ASSEMBLE THE BOILER

BOILER

ASSEMBLY

FRAME

ASSEMBLY

BOILER

PIPING

BUNKER

FRAME

REMOVE

ANY FLASH

FROM THE

COUPLING

PIN AREAS

AND TEST-FIT

THE MTL

DRAWBAR

FOLOWING ARE SPECIFIC ASSEMBLY INSTRUCTIONS FOR THE

Nn3 MICHIGAN-CALIFORNIA LUMBER COMPANY SHAY #2

FOR ALTERNATE ASSEMBLY INSTRUCTIONS FOR THE CLASS A SHAY

PLEASE TURN TO PAGE 5 2

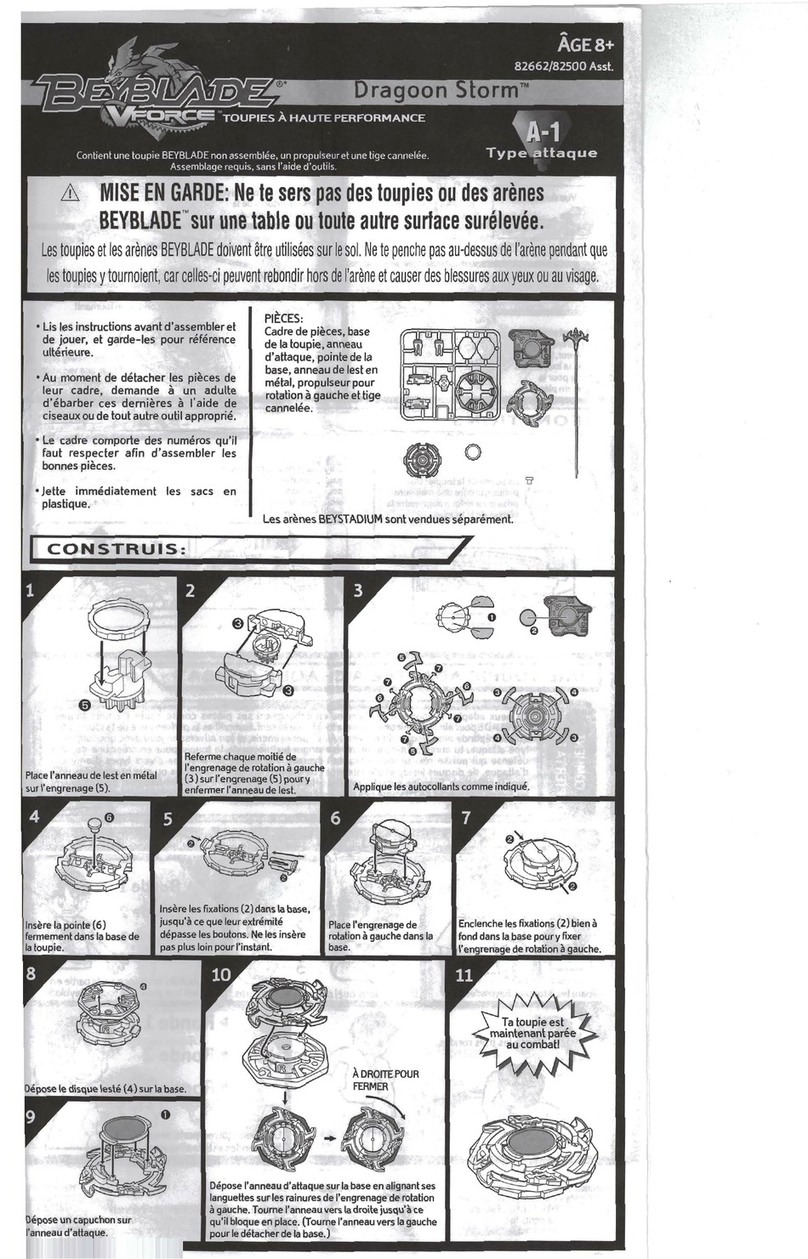

PAGE

STEP 3

ATTACH THE BOILER

FOOT TO THE BOLIER

BOILER

FOOT

ASSEMBLE

THE ENGINE

(OPTIONAL)

AND

ATTACH IT TO

THE PIPING

FORM THE

ENGINE FENDER

PART MC1

AND SET IN PLACE

!

DO NOT GLUE IN PLACE UNTIL

THE CAB IS ASSEMBLED AND

TEST FIT

ASSEMBLE THE CAB

USE CA TYPE SUPER GLUE

TO ATTACH THE PHOTO-ETCH

PARTS TO THE CAST

METAL ROOF.

WE RECOMMEND THAT YOU ADD

THE PHOTO-ETCH DETAILS PRIOR

TO PAINTING TO ENSURE A

GOOD BOND BETWEEN

THE BRASS DETAILPARTS

AND THE PEWTER

CASTINGS

USE THESE ILLUSTRATIONS

AND THE INCLUDED PHOTOS

FOR REFERENCE

SEE DETAILS

ON PILOT ASSEMBLIES

FOLD THE PHOTO-ETCH

CAB ALONG THESE

LINES.

FOLD HERE

ROOF

BRACES

GRAB

IRONS

ASSEMBLE THE CAB - CONTINUED

PHOTO-ETCH

CAB

3

PAGE

E1

E1

MC1

AS ORIGINALLY BUILT, THE MICHIGAN-CALIFORNIA #2 WAS USED AS A ROAD

LOCOMOTIVE, HAULING LOGS OUT OF THE WOODS TO THE MILL. LATER IT WOULD BE

RELEGATED TO YARD DUTY. THESE LITTLE “COFFEE GRINDERS” GOT THE LOGS OUT OF

THE WOODS OVER UNBELIEVABLE TRACK AND UNDER CONDITIONS IMPOSSIBLE FOR

OTHER MEANS OF TRANSPORT.

ATTACH THE CAB REAR

FIRST TO USE FOR THE

ALIGNMENT OF THE CAB

FRONT AND SIDES.

ASSEMBLE THE

FRONT TRUCK

THE FRONT TRUCK

IS A 3D PRINTED

PART THAT HAS

BEEN PRE-CLEANED.

PRIME AND PAINT

AND THEN INSERT

THE METAL WHEELS.

THE MATERIAL IS

RESILIENT ENOUGH

TO ALLOW CAREFUL

INSERTION OF THE

WHEELS.

1-72

HEX BOLT

1-72

WASHER

0-80 BRASS NUT

LEAVE A “LOOSE” FIT TO

ALLOW THE POWERMAX

MECHANISM TO ROTATE.

ADD A TINY DROP OF

WHITE GLUE TO THE

0-80 SCREW TO ACT AS A

THREAD LOCK. THIS WILL

ALLOW THE TRUCK

MECHANISM TO BE

REMOVED IF NECESSARY

AND ALSO PREVENT

THE NUT BECOMING

LOOSE.

ATTACH THE

POWERMAX

POWER TRUCK

0-80 BRASS

WASHER

APPLY GREASE

LUBRICANT

0-80 BRASS

WASHER

APPLY GREASE

LUBRICANT

ADD THE DETAILS

OIL

TANK

MC2

SMOKE

STACK

HEADLIGHT

ASSEMBLY

FOLD ALONG

THESE LINES

WATER

PUMP

WHISTLE

NUMBER AND

BUILDER PLATES

ATTACH CAB

(GLUE IS

OPTIONAL)

DETAILS CAN BE ADDED USING THE

SUPPLIED BRASS ROD.

4

PAGE

NO. 2 WAS THE SWITCH ENGINE IN THE YARDS AT CAMINO, WITH TOM JINKERSON AS

ENGINEER FROM ABOUT 1906 UNTIL THE NARROW GAUGE WAS ABANDONED IN 1951.

SINCE THEN, IT HAS RESTED ON A SHORT DISPLAY TRACK IN CAMINO. IT IS POSSIBLY

THE OLDEST SHAY IN EXISTENCE. ...from “Pino Grande” by R.S. Polkinghorn

THIS TWO TRUCK SHAY SHELL KIT IS

DESIGNED TO BE POWERED BY THE SEARAILS’

POWERMAX! POWER TRUCK. IT IS A N SCALE

MODEL DESIGNED TO RUNON Z SCALE TRACK.

P L E A S E F O L L O W T H E O P E R A T I N G

INSTRUCTIONS FOR THE POWERMAX! FOR

OPTIMUM PERFORMANCE.

!

APPLY GLUE ON INSIDE

OF THE JOINT AREA

BETWEEN THE TENDER

AND THE FRAME TO

INCREASE THE STRENGTH

OF THE JOINT AREA

STEP 2

!

WE RECOMMEND

THAT YOU

ASSEMBLE THE

SUB-FRAME AND

PAINT IT BEFORE

ATTACHINGTO THE

POWERMAX! UNIT.

DRILL AND TAP THIS

HOLE FOR A 1-72 BOLT.

DRIVE THE INCLUDED

1-72 HEX BOLT INTO THE

BOLSTER HOLE TO

TAP IT.

IT SHOULD THREAD

ITSELF INTO THE HOLE

STEP 1

Drill and Tap for

0-80

Machine

Screw

File Down Machine

Screw Head

for clearance over

motor.

Add Tiny Drop

of CA (Super Glue)

for Thread Lock.

0-80 x .25”

Brass Machine

Screw

PLEASE NOTE!!

MODIFYING YOUR

POWERMAX! IN

THIS WAY WILL

VOID YOUR

WARRANTY. THIS

STEP IS FOR

VISUAL AESTHETIC

ONLY. THE SHAY

WILL OPERATE

WITHOUT

PERFORMING THIS

MODIFICATION.

PREPARE THE POWERMAX POWER TRUCK

(THE POWERMAX! POWER TRUCK

IS NOT INCLUDED IN THE KIT)

THE CENTER PIVOT MOUNTING BRACKET IS

INCLUDED IN THE KIT WITH PERMISSION FROM

SEARAILS. IT WILL NEED TO BE PREPARED IN

THE STEPS SHOWN BELOW.

REMOVE THE

BOTTOM PLATE

FROM THE

POWERMAX!

MECHANISM

TAB PATTERN

FOR LEFT

SIDE OF TRUCK

TAB PATTERN

FOR DRIVER

SIDE OF TRUCK

ATTACH THE BUNKER

TO THE FRAME.

USE THE LOCATING PINS

ON THE FRAME AND THE

CORRESPONDING HOLES IN

THE TENDER.

ALLOW THE GLUE TO DRY

COMPLETELY BEFORE

REMOVING THE BRACING.

BRACING TO BE

REMOVED AFTER

GLUEING THE TENDER

ATTACH THE BOILER

TO THE FRAME

ASSEMBLE THE BOILER

BOILER

ASSEMBLY

FRAME

ASSEMBLY

BOILER

PIPING

BUNKER

FRAME

REMOVE

ANY FLASH

FROM THE

COUPLING

PIN AREAS

AND TEST-FIT

THE MTL

DRAWBAR

FOLOWING ARE ASSEMBLY INSTRUCTIONS FOR A

Nn3 CLASS A, 16 TON SHAY LOCOMOTIVE 5

PAGE

STEP 3

WE PAINTED THE COMPLETED MAIN

ASSEMBLY AND THE COMPLETED

CAB ASSEMBLY AT THIS POINT.

WE USED A SPRAY ON PRIMER FOR

METAL FROM TAMIYA AND THEN

PAINTED THE MODEL WITH

TESTORS FLAT BLACK SPRAY.

STEP 4

ATTACH THE BOILER

FOOT TO THE BOLIER

BOILER

FOOT

ASSEMBLE THE ENGINE

(OPTIONAL)

AND ATTACH IT TO

THE PIPING

FORM THE

ENGINE FENDER

PART CA1

AND SET IN PLACE

!

DO NOT GLUE IN PLACE UNTIL

THE CAB IS ASSEMBLED AND

TEST FIT

ASSEMBLE THE CAB

PHOTO-ETCH

GRAB IRON

(SEE PE SHEET

FOR PART)

WE RECOMMEND THAT YOU ADD

THE PHOTO-ETCH DETAILS PRIOR

TO PAINTING TO ENSURE A

GOOD BOND BETWEEN

THE BRASS DETAILPARTS

AND THE PEWTER

CASTINGS

USE THESE ILLUSTRATIONS

AND THE INCLUDED PHOTOS

FOR REFERENCE

ASSEMBLE THE

FRONT TRUCK

THE FRONT TRUCK

IS A 3D PRINTED

PART THAT HAS

BEEN PRE-CLEANED.

PRIME AND PAINT

AND THEN INSERT

THE METAL WHEELS.

THE MATERIAL IS

RESILIENT ENOUGH

TO ALLOW CAREFUL

INSERTION OF THE

WHEELS. 1-72

HEX BOLT

1-72

WASHER

SEE DETAILS

ON STEP ASSEMBLIES

6

PAGE

E1

E1

CA1

WE RECOMMEND THAT YOU ADD THE PHOTO-ETCH DETAILS PRIOR TO PAINTING

TO ENSURE A GOOD BOND BETWEEN THE BRASS DETAILPARTS AND THE PEWTER

CASTINGS

WE PAINTED THE COMPLETED MAIN

ASSEMBLY AND THE COMPLETED

CAB ASSEMBLY AT THIS POINT.

WE USED A SPRAY ON PRIMER FOR

METAL FROM TAMIYA AND THEN

PAINTED THE MODEL WITH

TESTORS FLAT BLACK SPRAY.

ASSEMBLE THE

FRONT TRUCK

THE FRONT TRUCK

IS A 3D PRINTED

PART THAT HAS

BEEN PRE-CLEANED.

PRIME AND PAINT

AND THEN INSERT

THE METAL WHEELS.

THE MATERIAL IS

RESILIENT ENOUGH

TO ALLOW CAREFUL

INSERTION OF THE

WHEELS.

1-72

HEX BOLT

1-72

WASHER

0-80 BRASS NUT

LEAVE A “LOOSE” FIT TO

ALLOW THE POWERMAX

MECHANISM TO ROTATE.

ADD A TINY DROP OF

WHITE GLUE TO THE

0-80 SCREW TO ACT AS A

THREAD LOCK. THIS WILL

ALLOW THE TRUCK

MECHANISM TO BE

REMOVED IF NECESSARY

AND ALSO PREVENT

THE NUT BECOMING

LOOSE.

ATTACH THE

POWERMAX

POWER TRUCK

0-80 BRASS

WASHER

APPLY GREASE

LUBRICANT

0-80 BRASS

WASHER

APPLY GREASE

LUBRICANT

ADD THE DETAILS

SMOKE

STACK

OPTION

ATTACH CAB

(GLUE IS

OPTIONAL)

WATER

PUMP

NUMBER AND

BUILDER PLATES

DETAILS CAN BE ADDED USING THE

SUPPLIED BRASS ROD.

7

PAGE