SHUN CHUAN MACHINERY RML-1640V User manual

-1-

Table of Contents

Introduction 2

Foreword 2

Contact Info 2

Functional Overview 2

Safety Instructions 3

Lathe Safety 4

Section 1 : Controls & Components 5

Identification 5

Control Panel 6

Headstock Controls 6

Carriage Controls 7

Tailstock Controls 7

Foot Brake 7

Section 2 : Setup 8

Physical Environment 8

Electrical Installation 8

Lighting 8

Weight Load 8

Space Allocation 8

Lifting & Moving 8

Leveling 9

Test Run 10

Spindle Break-in 11

Section 3 : Operation 13

CSS System 13

Chuck 13

Tailstock 15

Centers 16

Steady Rest 17

Follow Rest 17

Compound Slide 17

4-Way Tool Post 18

Apron Stop 18

Manual Feed 19

Spindle Speed 19

Power Feed 20

Positioning Gearbox Levers 21

Understanding Thread & Feed Rate Chart 21

End Gear Setup 22

Threading Controls 22

Cutting Fluid System 25

Section 4 : Maintenance 26

Schedule 26

Cleaning 26

Lubrication 26

Cutting Fluid System 31

Machine Storage 32

Section 5 : Service 33

Backlash Adjustment 33

Leadscrew End Play Adjustment 33

Gib Adjustment 34

Half Nut Adjustment 34

Feedrod Clutch Adjustment 35

V-Belts 35

Brake & Switch 36

Leadscrew Shear Pin Replacement 37

Gap Removal & Installation 38

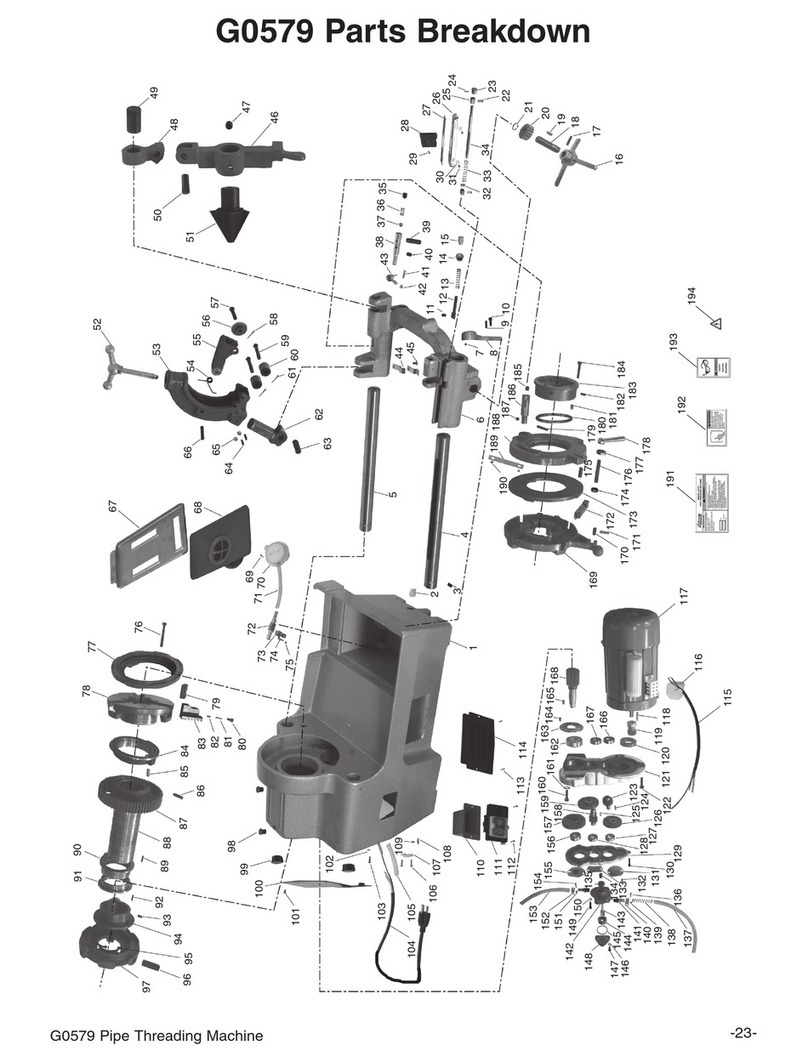

Section 6 : Parts 39

Headstock 39

Gearbox 45

Apron 49

Dail Indicator 51

4-Way Tool Post 54

Saddles 56

Bed & Shafts 59

End Gear - 14" 61

End Gear - 16" 64

Main Motor - The chip tray in the middle 67

Main Motor - Front moveable chip tray optional 69

Cabinet & Panel - The chip tray in the middle 71

Cabinet & Panel - Front moveable chip tray optional 73

Cabinet & Panel - Oil delivered 75

Conventional Tailstock 77

5C Collet Closer Attachment 79

Taper Attachment 81

Bed Stop 83

Bed Stop - MICROMETER 84

Steady Rest 85

Follow Rest 86

Chip Cover 87

-2-

Functional Overview

The Model RML-1640V High Precision Electrical

Variable Speed Lathe that has a pressurized headstock

oiling system. The electrical and mechanical controls

allow for complete spindle speed control from 20

to 2500 RPM. Merely shift one lever to high or low

range, and then just turn the spindle speed dial to

your needed RPM.

This lathe is also equipped with a CSS system that

gives consistent finishes between surfaces with

different diameters. During facing operations, as the

tool bit moves toward the center of the workpiece,

the spindle speed increases to maintain a constant

surface speed during cutting as diameter decreases.

The lathe gearbox has a selection of five levers that

control the speed and direction of the leadscrew

and feed rod. When threading or power feed turning

operations are selected, the carriage moves left or

right, or the cross slide will move in or out.

A feed direction quick change knob on the apron

allows for feed direction changes during power fed

operations without having to shut the lathe down

and shift the feed direction lever on the headstock.

A hand-operated oil pump allows for easy carriage

lubrication, and for speedy machine shutdown, a foot-

pedal brake system is used.

When cutting fluid is required, the built-in coolant

pump and delivery nozzle directs the coolant to the

point of cut. As cuts are made, the chips fall into the

chip catch drawer, which slides out for easy cleaning.

Foreword

We are proud to offer the Model RML-1640V High

Precision EVS Lathe. This machine is part of a

growing SUN MASTER family of fine metalworking

machinery. When used according to the guidelines

set forth in this manual, you can expect years of

trouble-free, enjoyable operation and proof of SUN

MASTER commitment to customer satisfaction.

The specifications, drawings, and photographs

illustrated in this manual represent the Model RML-

1640V when the manual was prepared. However,

owing to SUN MASTER’s policy of continuous

improvement, changes may be made at any time with

no obligation on the part of SUN MASTER.

Contact Info

We stand behind our machines. If you have any

service questions, parts requests or general

questions about the machine, please call or write our

local dealer whom you bought the lathe from or us.

SHUN CHUAN MACHINERY IND. CO., LTD.

No.5, Lin 1, Shan Kan Li, Yuan Li Town, Maoli County,

Taiwan.

TEL : +886-37-741591

FAX : +886-37-741593

http : //www.shunchuan.com

http : //www.sunmaster-cnc.com

Introduction

-3-

1. Owner’s Manual : All machinery and machining

equipment presents serious injury hazards to

untrained users. To reduce the risk of injury,

anyone who uses this item must read and

understand this entire manual before starting.

2. Safe Environment : Operating electrically

powered equipment in a wet environment may

result in electrocution; operating near highly

flammable materials may result in a fire or

explosion. Only operate this item in a dry location

that is free from flammable materials.

3. Trained / Supervised Operators Only :

Untrained users can seriously injure themselves.

Only allow trained and properly supervised

personnel to operate this item. Make sure safe

operation instructions are clearly understood. If

electrically powered, use padlocks and master

switches, and remove start switch keys to prevent

unauthorized use or accidental starting.

4. Work Area : Clutter and dark shadows increase

the risks of accidental injury. Only operate this

item in a clean, non-glaring, and well-lighted work

area.

5. Personal Protective Equipment : Operating or

servicing this item may expose the user to flying

debris, dust, smoke, dangerous chemicals, or

loud noises. These hazards can result in eye

injury, blindness, long-term respiratory damage,

poisoning, cancer, reproductive harm or hearing

loss. Reduce your risks from these hazards by

wearing approved eye protection, respirator,

gloves, or hearing protection.

6. Guards / Covers : Accidental contact with

moving parts during operation may cause severe

entanglement, impact, cutting, or crushing

injuries. Reduce this risk by keeping any included

guards/covers/doors installed, fully functional,

and positioned for maximum protection.

7. Entanglement : Loose clothing, gloves, neckties,

jewelry or long hair may get caught in moving

parts, causing entanglement, amputation,

crushing, or strangulation. Reduce this risk by

removing / securing these items so they cannot

contact moving parts.

8. Mental Alertness : Operating this item with

reduced mental alertness increases the risk of

accidental injury. Do not let a temporary influence

or distraction lead to a permanent disability!

Never operate when under the influence of drugs/

alcohol, when tired, or otherwise distracted.

9. Electrical Connection : With electrically

powered equipment, improper connections to the

power source may result in electrocution or fire.

Always adhere to all electrical requirements and

applicable codes when connecting to the power

source. Have all work inspected by a qualified

electrician to minimize risk.

10. Disconnect Power : Adjusting or servicing

electrically powered equipment while it is

connected to the power source greatly increases

the risk of injury from accidental startup.

Always disconnect power before any service or

adjustments, including changing blades or other

tooling.

11. Secure Workpiece / Tooling : Loose workpieces,

cutting tools, or rotating spindles can become

dangerous projectiles if not secured or if they

hit another object during operation. Reduce the

risk of this hazard by verifying that all fastening

devices are properly secured and items attached

to spindles have enough clearance to safely

rotate.

ATTENTION

It is essential to read this operation manual and understand the program instructions and maintenance

instructions before operating the machine.

This operation manual should be attached to the machine at all time where it is readily available to the

operator for reference.

Safety Instructions

-4-

1. Clearing Chips : Metal chips can easily cut

bare skin—even through a piece of cloth. Avoid

clearing chips by hand or with a rag. Use a brush

or vacuum to clear metal chips.

2. Chuck Key Safety : A chuck key left in the

chuck can become a deadly projectile when the

spindle is started. Always remove the chuck key

after using it. Develop a habit of not taking your

hand off of a chuck key unless it is away from the

machine.

3. Tool Selection : Cutting with an incorrect or

dull tool increases the risk of accidental injury

because extra force is required for the operation,

which increases risk of breaking or dislodging

components, which can cause small shards of

metal to become dangerous projectiles. Always

select the right cutter for the job and make sure

it is sharp. A correct, sharp tool decreases strain

and provides a better finish.

4. Securing Workpiece : An improperly secured

workpiece can fly off of the lathe spindle with

deadly force, which can result in a severe impact

injury. Make sure the workpiece is properly

secured in the chuck or faceplate before starting

the lathe.

5. Large Chucks : Large chucks are very heavy

and difficult to grasp, which can lead to crushed

fingers or hands if mishandled. Get assistance

when installing or removing large chucks to

reduce this risk. Protect your hands and the

precision-ground ways by using a chuck cradle

or piece of plywood over the ways of the lathe

when servicing chucks.

6. Safe Clearances : Workpieces that crash

into other components on the lathe may throw

dangerous projectiles in all directions, leading to

impact injury and damaged equipment. Before

starting the spindle, make sure the workpiece has

adequate clearance by hand-rotating it through

its entire range of motion. Also, check the tool

and tool post clearance, chuck clearance, and

saddle clearance.

7. Speed Rates : Operating the lathe at the wrong

speed can cause nearby parts to break or the

workpiece to come loose, which will result in

dangerous projectiles that could cause severe

impact injury. Large workpieces must be turned

at slow speeds. Always use the appropriate feed

and speed rates.

8. Stopping Spindle by Hand : Stopping the

spindle by putting your hand on the workpiece or

chuck creates an extreme risk of entanglement,

impact, crushing, friction, or cutting hazards.

Never attempt to slow or stop the lathe spindle

with your hand. Allow the spindle to come to a

stop on its own or use the brake (if equipped).

9. Crashes : Driving the cutting tool or other

lathe components into the chuck may cause an

explosion of metal fragments, which can result

in severe impact injuries and major damage to

the lathe. Reduce this risk by releasing automatic

feeds after use, not leaving lathe unattended,

and checking clearances before starting the

lathe. Make sure no part of the tool, tool holder,

compound slide, cross slide, or carriage will

contact the chuck during operation.

10. Long Stock Safety : Long stock can whip violently

if not properly supported, causing serious impact

injury and damage to the lathe. Reduce this risk

by supporting any stock that extends from the

chuck/headstock more than three times its own

diameter. Always turn long stock at slow speeds.

11. Coolant Safety : Contaminated cutting fluid

is a very poisonous biohazard that can cause

personal injury from skin contact alone. Incorrectly

positioned cutting fluid nozzles can splash on the

operator or the floor, resulting in an exposure or

slipping hazard. To decrease your risk, change

cutting fluid regularly and position the cutting fluid

nozzle where it will not splash or end up on the

floor.

Lathe Safety

-5-

11. Gearbox

12. Removable Chip Drawer

13. Apron

14. Brake Pedal

15. Thread Dial

16. Spindle Rotation ON / OFF Lever

17. Leadscrew

18. Feed shaft

19. Bed

20. Base

1. Headstock

2. Control Panel

3. D1-6 Camlock MT#6 Spindle

4. Steady Rest

5. 4-Position Tool Holder

6. Work Lamp

7. Follow Rest

8. Universal Cutting Fluid Tube and Nozzle

9. Cross Slide

10. Tailstock

Section 1 : Controls & Components

Identification

1

234

5

6

7

8

9

11

10

12

13 14 15 16

17

18

19

20

Figure 1. The RML-1460 EVS Lathe.

9. Spindle Range Lever : Shifts the headstock into

low or high range for spindle speeds between 20-

400 RPM or 400-2500 RPM.

10. Gearbox Range Lever : This lever puts the

gearbox in high or low range and has no effect

on spindle RPM.

11. Feed Direction Lever : This lever changes

the direction that the gearbox is turning at, and

as a result the leadscrew and feed rod change

direction.

12. Gearbox Levers : Moves the gearbox gears into

particular ratios, which then turn the leadscrew

and feed rod for threading and power feed

operations.

-6-

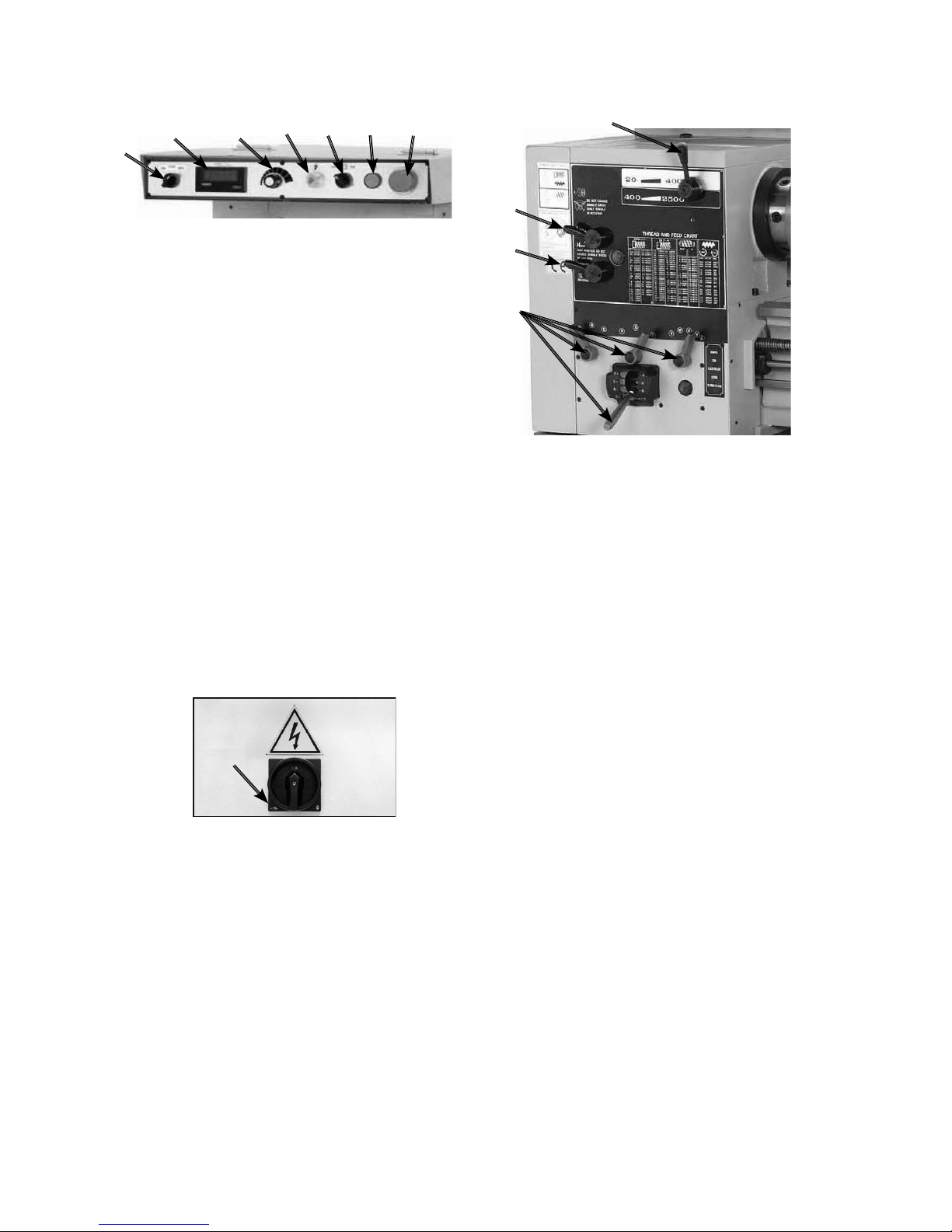

1. CSS ON / OFF Switch : Turns the constant

surface speed feature ON or OFF.

2. Tachometer Display : Indicates what RPM the

spindle is currently rotating at.

3. Spindle Speed Dial : Changes the spindle speed

to user-defined levels.

4. Power Light : Illuminates when lathe is receiving

power.

5. Cutting Fluid Pump Switch : Turns cutting fluid

delivery ON / OFF.

6. Jog Button : Turns the spindle motor ON while

being pressed and held.

7. Emergency Stop Button : Stops all machine

functions. Twist clockwise to reset.

8. Main Power Switch : Located at the rear of the

lathe on the electrical box cover, this switch turns

power ON / OFF to the lathe so lathe operations

can begin.

Headstock ControlsControl Panel

1234567

Figure 2. Control Panel.

8

Figure 3. Main Power Switch.

9

10

11

12

Figure 4. Headstock Controls.

1. Graduated scale : Indicates quill movement in

increments of 0.001" or 0.02mm.

2. Tailstock Lock Lever : Secures the tailstock in

place along the bedway.

3. Quill Lock : Locks the quill in position.

4. Quill : Moves toward and away from the spindle

and holds centers and tooling.

5. Quill Handwheel : Moves the quill toward or

away from the spindle.

6. Offset Scale : Indicates the distance of tailstock

offset from the spindle center line.

7. Tailstock Offset Screw : Adjusts and secures

the tailstock offset (1 of 2).

-7-

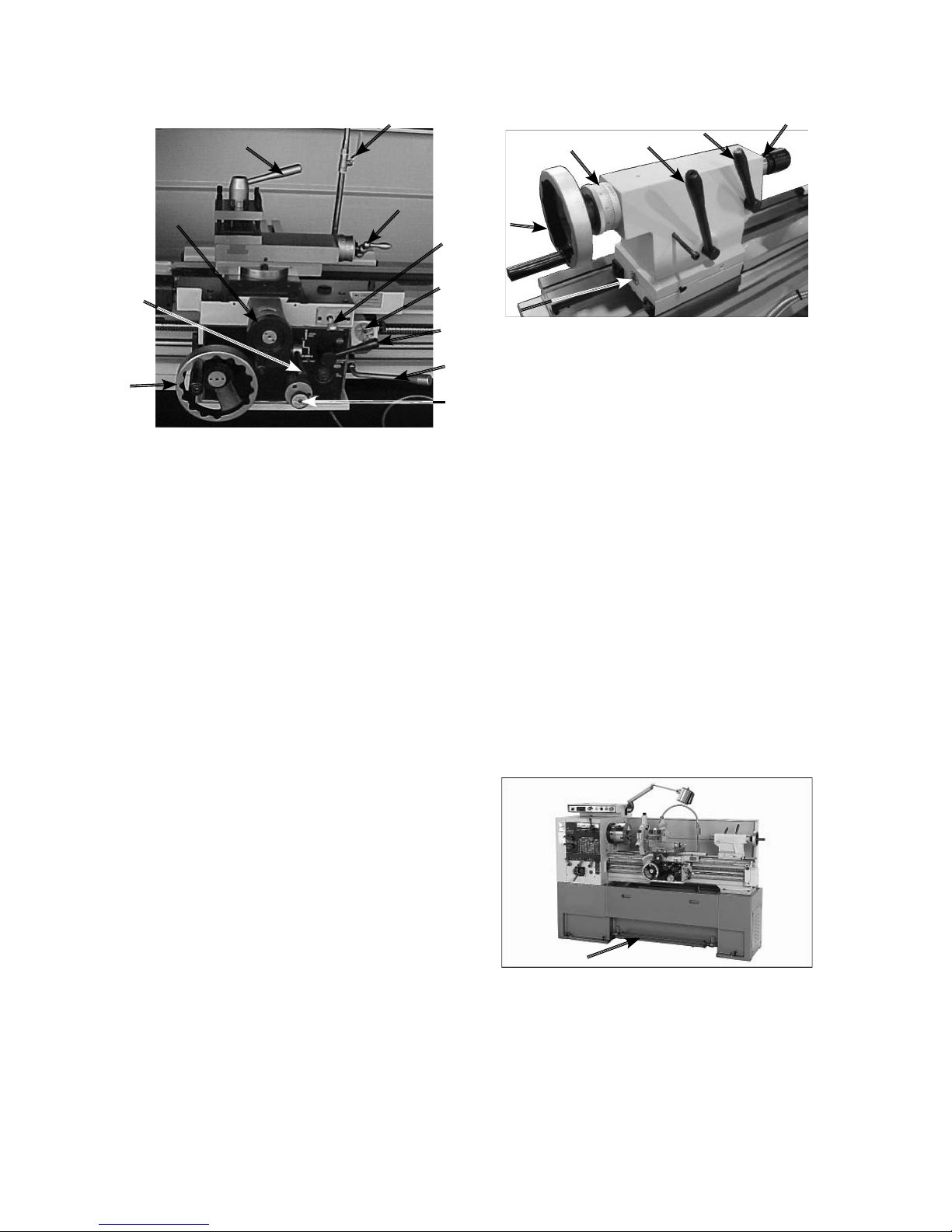

1. 4-Position Tool Post Lever : Used for locking

the rotary tool post in four possible detents.

2. Cutting Fluid Flow Control Lever : Used to vary

the flow of cutting fluid out of the nozzle.

3. Compound Hand Crank : Used to position the

compound along the compound slide.

4. Manual Carriage Oil Pump : Draws oil from the

apron case and lubricates the carriage and ways

through various oil ports.

5. Cross Slide Handwheel : Positions the cross

slide in or out.

6. Feed Control Lever : Engages and disengages

the cross feed and longitudinal feed gearing.

7. Longitudinal Carriage Handwheel : Allows for

manual movement of the carriage from left to

right along the bed.

8. Thread Dial : Indicates when to engage the half

nut during threading operations.

9. Halfnut Lever : Engages and disengages the

apron with the leadscrew for threading operations.

10. Spindle ON / OFF Lever : Used to start and stop

the lathe during normal operation.

11. Feed Direction Lever : This lever changes

the direction that the gearbox is turning at, and

as a result the leadscrew and feed rod change

direction.

Tailstock ControlsCarriage Controls

Figure 7. Foot Brake.

Figure 5. Carriage Controls.

1

3

4

5

6

7

8

9

10

11

2

Figure 6. Tailstock Controls.

1

5

6

234

Foot Brake

This lathe is equipped with a foot brake (Figure 6) to

quickly stop the spindle. Pushing the foot brake while

the spindle is ON cuts power to the motor and stops

the spindle. Once stopped, the spindle lever MUST

be returned to the neutral position before the spindle

can be restarted.

-8-

Physical Environment

The physical environment where your machine is

operated is important for safe operation and longevity

of parts. For best results, operate this machine in a

dry environment that is free from excessive moisture,

hazardous or flammable chemicals, airborne

abrasives, or extreme conditions. Extreme conditions

for this type of machinery are generally those where

the ambient temperature is outside the range of 9°

~ 72ºC(41° ~ 104ºF); the relative humidity is outside

the range of 20–95% (non-condensing); or the

environment is subject to vibration, shocks, or bumps.

Electrical Installation

Place this machine near an existing power source.

Make sure all power cords are protected from traffic,

material handling, moisture, chemicals, or other

hazards. Make sure to leave access to a means of

disconnecting the power source or engaging a lockout

/ tagout device.

Lighting

Lighting around the machine must be adequate

enough that operations can be performed safely.

Shadows, glare, or strobe effects that may distract or

impede the operator must be eliminated.

Weight Load

Make sure that the surface upon which the machine is

placed will bear the weight of the machine, additional

equipment that may be installed on the machine, and

the heaviest workpiece that will be used. Additionally,

consider the weight of the operator and any dynamic

loading that may occur when operating the machine.

Space Allocation

Consider the largest size of workpiece that will be

processed through this machine and provide enough

space around the machine for adequate operator

material handling or the installation of auxiliary

equipment. With permanent installations, leave

enough space around the machine to open or remove

doors/covers as required by the maintenance and

service described in this manual.

Model 1440 / 1640 1460 / 1660

A 2300mm ( 90.6” ) 2810mm ( 110.6” )

Lifting & Moving

This lathe is an extremely heavy machine. Serious

personal injury or death may occur if safe lifting and

moving methods are not followed. Get assistance

from a professional rigger if you are unsure about

your abilities or maximum load ratings of your lifting

equipment.

To lift and move your lathe :

1. Prepare the permanent location for the lathe.

2. Remove the shipping crate top and sides, then

remove the small components from the shipping

pallet.

3. To balance the lifting load, loosen the tailstock

lock lever ( Figure 9 ), move the tailstock to the

end of the bedway, then lock it in place.

Section 2 : Setup

Tailstock Lock Lever

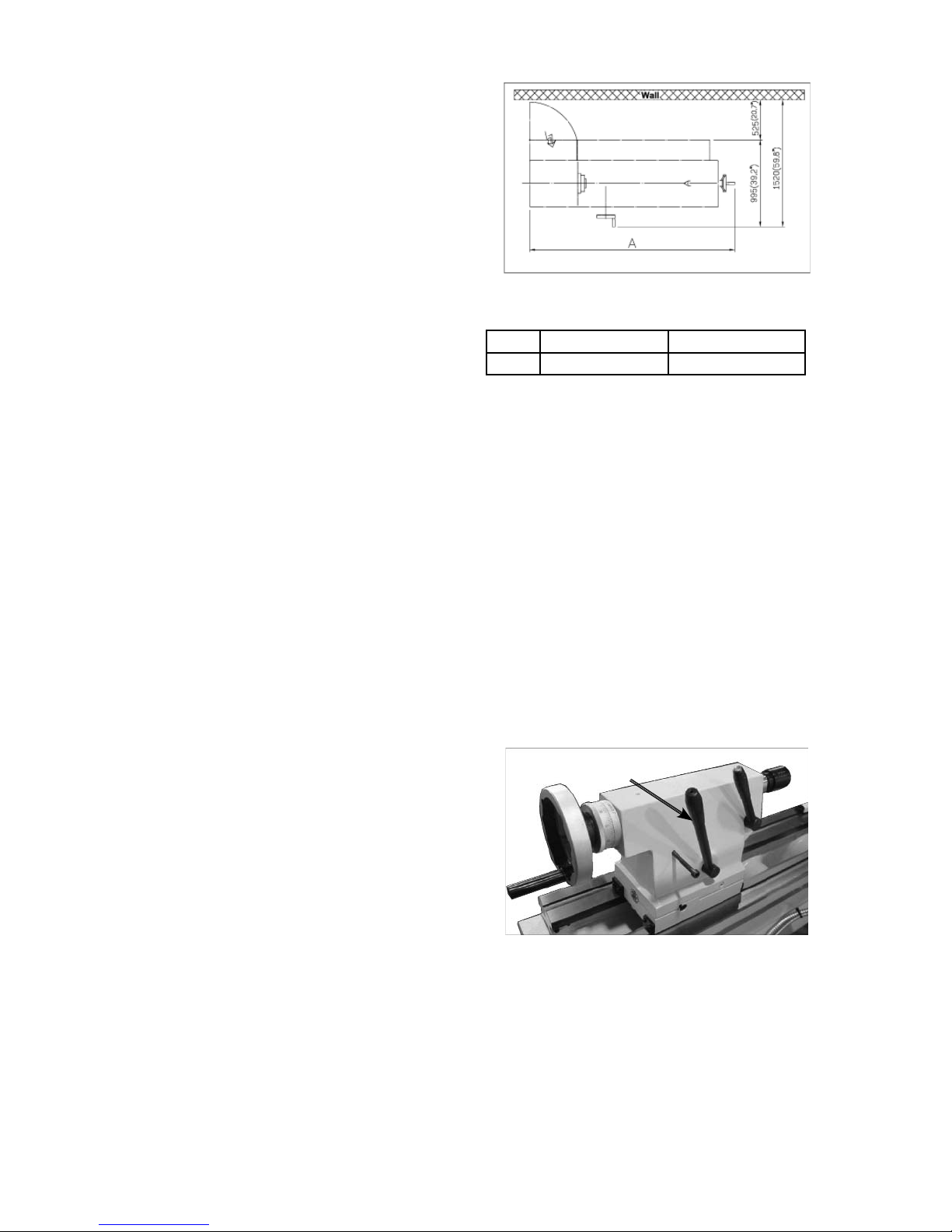

Figure 9. Tailstock lock lever.

Figure 8. Space required for full range of

movement.

4. To further balance the load, loosen the carriage

lock bolt, disengage the half nut lever, put the

feed control lever in neutral, then use the carriage

handwheel to move the carriage next to the

tailstock. ( Figure 10 )

-9-

7. Moving the machine with a forklift.

a. Make sure that the minimum forklift capacity

is more than 2 tons for security.

b. Forklift work should be cooperatively done

by two persons, that is an operator and

watchman, not to damage projecting on the

machine perimeter.

c. To put the fork, use the fork inserting the

plinth mid-lift.

d. Keep the machine’s balance of gravity at the

center of the forks.

5. Locking the carriage lock bolt and tailstock lock

lever.

6. Lifting the machine with crane.

a. Make sure that minimum crane capacity is

more than 2 tons for security.

b. Only an authorized crane operator should use

the lift machine.

c. Crane work should be cooperatively done

by two persons, that is, an operator and a

watchman, not to damage projecting on the

machine perimeter.

d. To put in the jig with wire set inserting to bed

way.

e. Make sure that two hexagon nuts is fixed.

f. Keep the machine’s center of gravity at the

center of the crane.

Figure 11. Lifting the machine with crane.

Figure 12. Moving the machine with a forklift.

Leveling

This lathe must be placed on the included leveling

studs and cast-iron feet. Complete support at each

of the six leveling stud locations is mandatory. The

bed cannot be twisted or bent, and the ways must

be perfectly level with the floor. If a misalignment

condition arises, adjust the leveling studs, or shim the

cast iron feet where they touch the floor until the bed

and ways are in alignment.

Figure 13. Leveling pads and screws.

Figure 10. Carriage controls set for moving

the carriage.

Carriage

Handwheel

Half Nut Lever

Feed Control

Lever

Lock Bolt

-10-

6. Move the headstock range lever ( Figure 16 ) to

the left so the headstock is in low range ( 20-400

RPM ).

Test Run

After all preparation steps have been completed, the

machine and its safety features must be tested to

ensure correct operation. If you discover a problem

with the operation of the machine or its safety

components, shut the machine down, disconnect it

from power, and do not operate it further until you

have resolved the problem.

To test run the lathe:

1. Disconnect the lathe from POWER !

2. Make sure that the headstock oil tank, gearbox,

apron, and lead screw reservoir oil levels are full.

3. Make sure that the chuck and jaws are secure.

4. Turn the pump switch to the OFF position, fill the

cutting fluid reservoir, and point the fluid nozzle

into the chip pan.

5. Turn the CSS ON / OFF switch to ON, turn the

spindle speed dial ( Figure 13 ) to its minimum

speed, and make sure the cross slide is backed

out to avoid possibility of a high-speed start.

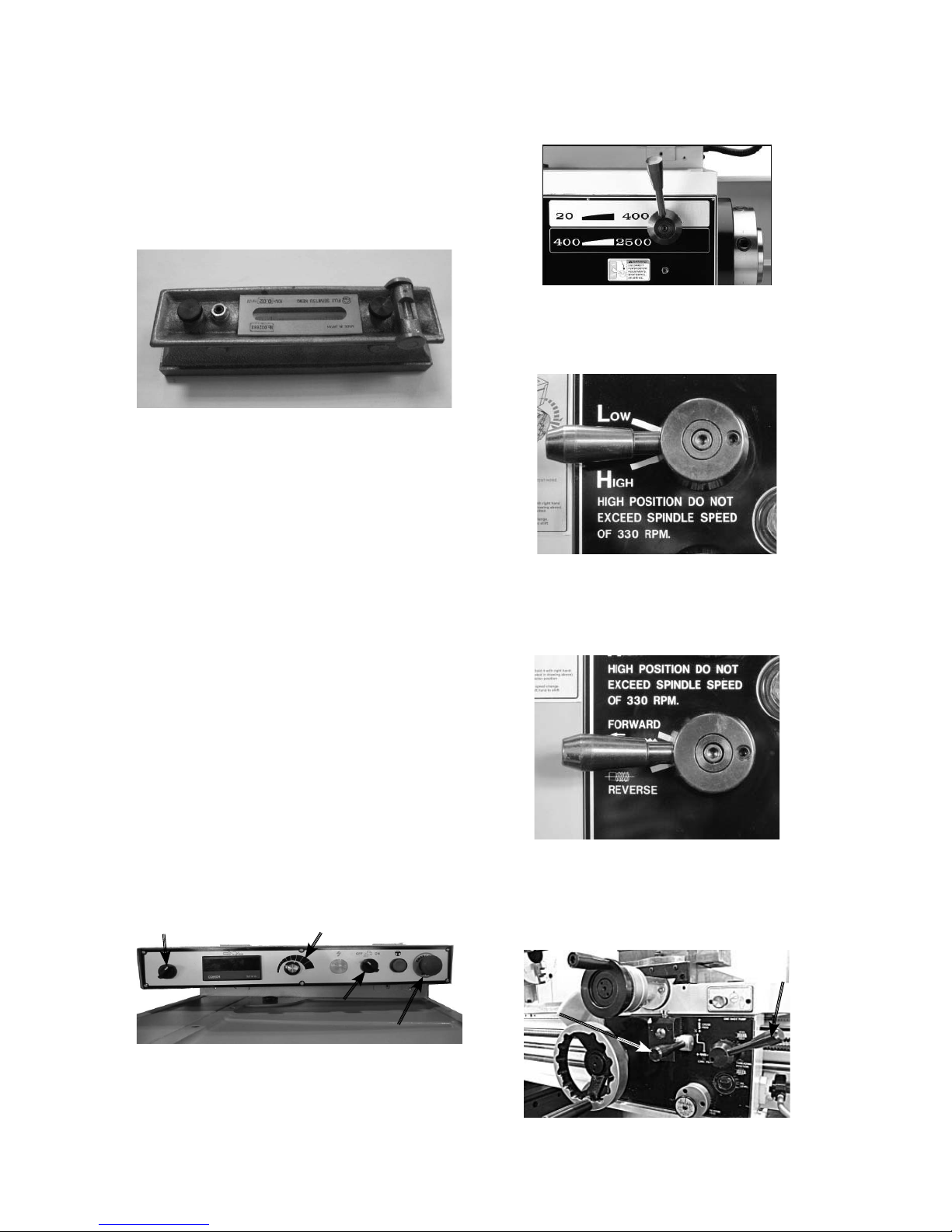

Figure 15. Control panel.

CSS ON / OFF Switch Spindle Speed Dial

Pump Switch

Emergency Stop Switch

Figure 16. Headstock range lever.

Figure 17. Gearbox range lever.

Figure 18. Feed forward / reverse lever.

To level the machine, use a precision level to make

sure the bedways are level from side-to-side and

from front-to-back.

Leveling machinery helps precision components,

such as bedways, remain straight and flat during the

lifespan of the machine. Components on an unleveled

machine may slowly twist due to the dynamic loads

placed on the machine during operation.

Figure 14. Example of a precision level.

Figure 19. Apron disengaged.

Neutral

Half nut Lever

Disengaged

7. Move the Gearbox range lever to neutral as

shown in Figure 17.

8. Move the feed direction forward / reverse lever to

neutral as shown in Figure 18.

9. Disengage the half nut lever, put the feed control

lever in neutral, and make sure the carriage lock

bolt is loose as shown in Figure 19.

-11-

10. Using a 10mm hex wrench, loosen the carriage

lock ( Figure 20 ) so the carriage is free to slide.

Figure 20. Carriage lock.

Figure 21. Spindle ON / OFF lever.

Figure 22. Main Power Switch in ON position.

Figure 23. Oil pump sight glass.

14. Make sure that all bystanders are out of the way,

tools are cleared away, and the chuck key is

removed from the chuck.

15. Move the spindle ON/OFF lever down and the

chuck will rotate.

16. Observe and listen for any abnormal noises or

vibration. The lathe should run smoothly with little

or no vibration or rubbing noises.

17. Push the foot brake, and the lathe should come

to a quick stop.

18. Open the lathe headstock side cover

approximately 25mm so the door safety limit

switch opens and disables the lathe from starting

19. Attempt to start the lathe. Should the lathe

start, the safety limit switch is faulty and needs

replacement.

20. Close the door and start the lathe again, and

push the EMERGENCY STOP switch and the

lathe should stop.

21. Turn the cutting fluid pump on, and fluid should

flow from the nozzle.

22. The test run is now finished. Shut the lathe down

and begin the Spindle Break-In procedure.

11. Move the spindle ON / OFF lever to the OFF

position as shown in Figure 21.

12. Connect the lathe to power, and at the rear of the

headstock, turn the master power switch to the

ON position ( Figure 22 ).

13. Rotate the red EMERGENCY stop switch knob

clockwise until it pops out and the pump will turn

on. Observe the oil pump tube sight glass ( Figure

23 ). When oil flows out of the tube and against

the sight glass, you can start the lathe.

Spindle Break-in

It is essential to closely follow the proper break-

in procedures to ensure trouble-free performance.

Complete this process once you have familiarized

yourself with all instructions in this manual and

completed the test run.

To break-in the spindle :

1. Complete the Test Run procedure.

2. Turn the CSS ON / OFF dial to OFF and the

spindle speed dial to the minimum speed.

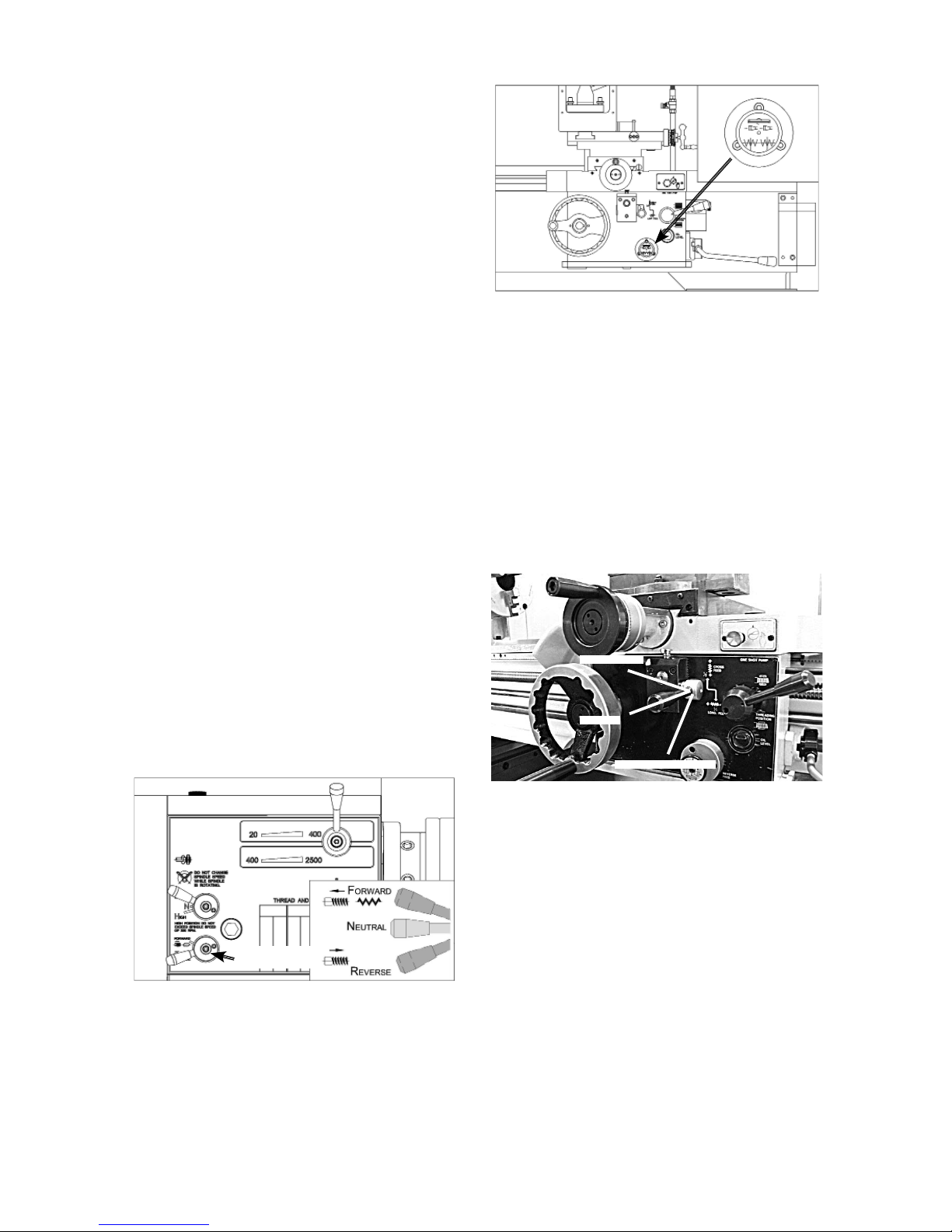

3. Move the gearbox range lever ( Figure 24 ) to low

range.

Figure 24. Gearbox range laver.

-12-

4. Move the headstock range lever to low range.

5. Move the feed direction forward / reverse lever (

Figure 25 ) to FORWARD.

7. Turn the lathe ON, and let it run for ten minutes in

each speed of 20, 200, and 400 RPM, using the

dial to adjust the speed.

8. After completing Step 7, stop the lathe and move

the gearbox range lever to neutral, and move the

headstock range lever to high.

9. Turn the lathe ON and let it run at for ten minutes

in each speed of 400, 1000, and 2500 RPM.

10. After completing Step 9, reduce the spindle

speed to 400 RPM and let the lathe run for a

final 15 minutes to allow the machine to cool and

circulate the oil.

11. Shut the lathe down, replace the headstock and

gearbox oil, and re-tension the V-belts.

Figure 26. Power feed and half nut levers

disengaged.

Half nut Lever Disengaged

Nuetral

Figure 25. Feed forward / reverse laver.

6. Disengage the half nut and the power feed levers

shown in Figure 26.

-13-

CSS System

This lathe is equipped with a CSS (Constant Surface

Speed) system (Figure 27) that gives consistent

finishes between surfaces with different diameters.

To install a chuck :

1. Disconnect lathe from POWER !

2. Place a piece of plywood across the lathe ways

and position it just under the chuck.

3. Place the chuck on the cradle.

4. Make sure the chuck taper and spindle taper

mating surfaces are perfectly clean.

5. Inspect and make sure that all camlock studs are

undamaged, are clean and lightly oiled, and that

the camlock stud cap screws are in place and

snug.

6. If equipped, align the chuck-to-spindle timing

marks ( Figure 29 ), and slide the chuck onto the

spindle.

Section 3 : Operation

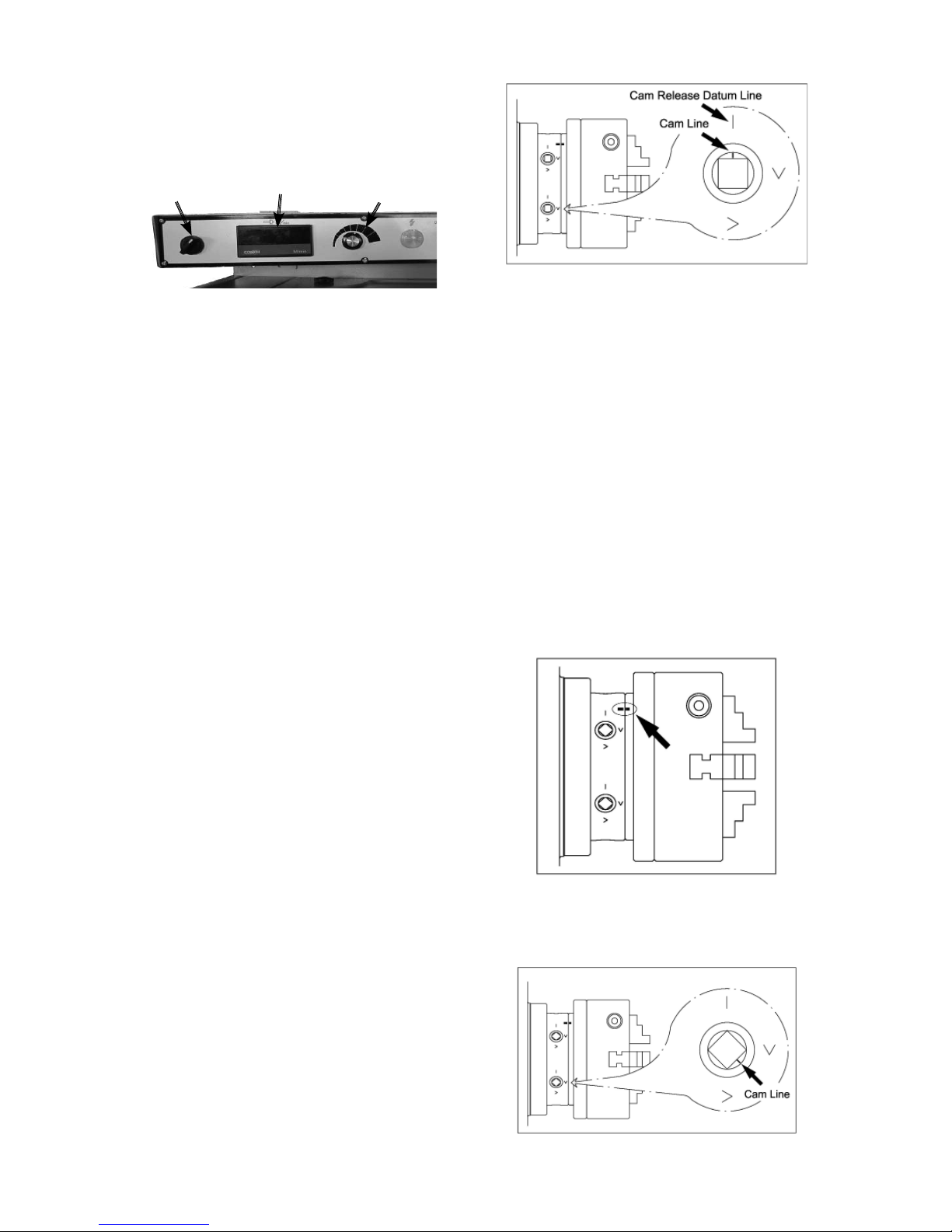

Figure 27. CSS System.

Spindle RPM Readout

CSS Switch Spindle Speed dial

Figure 28. Camlock loosened with the

cam line aligned with the datum line.

Figure 29. Chuck timing marks aligned.

Figure 30. Cam and lines.

If the CSSSS switch is in the ON position, the spindle

speed automatically changes with the position of the

cross slide. For example, during facing operations, as

the tool bit moves toward the center of the workpiece,

the spindle speed increases to maintain a constant

surface speed during cutting as diameter decreases.

As a result of this automatic spindle speed control,

surface finishes are consistent, tooling lasts longer,

and fewer workpieces will be lost from mistakes.

Another benefit derived from the CSSSS feature

is that from reduced machine shutdown and less

lever shifting cycles, shorter machining time will be

achieved which can mean increased productivity.

Note: When the CSSSS switch is in the ON position,

the spindle RPRPM can be adjusted with the spindle

speed dial.

When the CSSSS switch is in the OFF position, the

cross slide position has no effect on spindle speed.

The spindle speed is only adjusted with the spindle

speed dial.

Chuck

This lathe is shipped with the 3-jaw chuck installed.

This is a scroll-type chuck, meaning that all three

jaws move in unison when adjusted.

The included 4-jaw chuck features independent jaws,

which are used for square or unevenly-shaped stock.

If neither chuck can hold your workpiece, the cast-iron

faceplate has slots for T-bolts that hold standard or

custom clamping hardware. With the correct clamping

hardware, this faceplate will hold non-cylindrical parts

such as castings.

The chucks and faceplate have a D-6 camlock mount.

A chuck key is used to turn the locking cams ( Figure

28 ) to secure / release the chuck / faceplate.

7. Turn a camlock with the chuck key until the cam

line falls between the "V" marks shown in Figure

30.

-14-

8. Lock the other cams in a crisscross or star

pattern so the chuck is drawn up evenly on all

sides without any chance of misalignment.

9. Remove the chuck key.

To remove a chuck :

1. Disconnect lathe from POWER !

2. Place a piece of plywood across the lathe ways

to protect the ways, or use a support cradle and

position it just under the chuck.

3. Turn a cam with the chuck key until the cam line

aligns with the cam release datum line.

4. Unlock the other cams in the same manner. Make

sure to support the chuck as you align the last

cam.

5. Remove the chuck key.

Installing and Adjusting Camlock

Stud

When fitting a chuck or faceplate with camlock studs,

or when mounting a new chuck or faceplate, it may

be necessary to install or adjust the camlock studs.

In order to properly install or adjust one or more

camlock studs, you must remove a stud locking cap

screw, then thread the camlock stud in or out until the

line on the side of the stud is flush with the top of the

chuck casting.

3-Jaw Chuck

The 3-jaw scroll-type chuck included with this

lathe features hardened steel jaws that center the

workpiece. When the operator opens or closes the

jaws with the chuck key, the jaws move in unison.

There are two sets of jaws included with the 3-jaw

chuck ─inside and outside jaws. Use the correct jaws

for the size and configuration of the workpiece to hold

it firmly and securely on the chuck.

Numbered from 1-3, the jaws must be used in the

matching numbered jaw guides, as shown in Figure

31.

To change the jaw :

1. Disconnect Lathe from POWER !

2. Place a piece of wood over the ways to protect

them from potential damage.

3. Insert the chuck key and turn it counterclockwise

to back the jaws out and remove them.

4. Clean the jaw mating surfaces and apply a thin

film of white lithium grease to the mating surfaces.

5. Set the previously mounted jaws aside in a safe

place free of moisture and abrasives.

6. Rotate the chuck key clockwise until you see

the tip of the scroll gear lead thread just begin to

Insert jaw #1 into jaw guide #1 and hold the jaw

against the scroll gear lead thread.

7. Rotate the chuck key clockwise one turn to

engage the tip of the scroll gear lead thread into

the jaw.

Lead Thread

Figure 32. Inserting jaw.

Jaw Guide #1

Jaw Numbers

Figure 31. Jaw guides and jaw numbers.

8. Pull on the jaw—now it should be locked into the

jaw guide.

9. Repeat the Steps 6–8 on the remaining jaws.

To mount a workpiece in the 3-jaw chuck :

1. Disconnect Lathe from POWER !

2. Place a chuck cradle or plywood on the bedway

below the chuck to protect it.

3. Use the chuck key to move the jaws and mount

the workpiece to the chuck, similar to one of the

methods shown in Figure 33. Make sure the

workpiece is mounted firmly on the chuck.

-15-

Figure 33. Examples of workpiece

mounted in the 3-jaw chuck.

4. Rotate the chuck by hand to make sure the

workpiece makes even contact with all three jaws

and is centered.

4-Jaw Chuck

The 4-jaw chuck features independently adjustable

hardened steel jaws to hold non-cylindrical or off-

center workpieces. Each jaw can be removed from

the chuck body and reversed for a wide range of work

holding versatility.

To mount a workpiece on the 4-jaw chuck :

1. Disconnect Lathe from POWER !

2. Place a chuck cradle or plywood on the bedway

below the chuck to protect it.

3. Use the chuck key to open each jaw so the

workpiece will lay flat against the chuck face or

jaw steps.

4. With help from another person or a supporting

device, mount the workpiece centered on the

chuck, then turn each jaw until it makes contact

with the workpiece.

5. Tighten each jaw in small increments. After you

have adjusted the first jaw, continue tightening in

an opposing sequence.

6. After the workpiece is held in place by the jaws,

turn the chuck by hand and pay attention to the

workpiece alignment.

Tailstock

The tailstock on your lathe can be used to support

workpieces with the use of a live or dead center.

Figure 34. Tailstock and quill lock handles in

locked position.

Quill Handwheel

Tailstock Lock Lever

Tailstock Lock Lever

To move the tailstock :

1. Pull back on the lock lever.

2. Slide the tailstock to the desired position.

3. Push the tailstock lock lever forward to lock the

tailstock to the lathe bed.

To use the tailstock quill :

1. With the tailstock locked to the bed, release the

quill lock lever.

2. Turn the quill feed handwheel clockwise to

feed/move the quill towards the spindle, or turn

counterclockwise to move the quill away from the

spindle.

3. Push the quill lock lever forward to lock the quill

in place.

To install tooling in the tailstock :

1. With the tailstock locked, unlock the quill lock

lever.

2. Turn the quill handwheel CW to extend quill about

25mm out of the casting.

3. Insert a tapered drill arbor or a tapered drill bit

into the quill until the taper is firmly seated and

the tang is locked to the quill slot.

4. Turn the quill handwheel CW to feed the drill bit

into the rotating workpiece.

5. To remove the tooling from the tailstock, turn the

quill handwheel CCW until the tooling is pushed

out of the taper.

To offset the tailstock :

1. Lock the tailstock in position, and adjust the left

and right jack screws until the scale ( Figure 35 )

indicates the offset you want. See Figure 36 for

adjustment direction.

It can also be used to drill or bore holes in the center

of a part or cut shallow tapers by using the offset

adjustment.

-16-

Figure 35. Tailstock offset adjustments.

Scale

Left Side

Jack Screw

Centers

Dead Centers

The dead center achieves more accurate results than

a live center, but it requires low spindle speeds and

a small amount of oil to reduce friction heat that may

damage the workpiece.

Use the HSS dead center in the spindle, where the

workpiece does not rotate on the tip and does not

generate friction.

Use the carbide-tipped dead center in the tailstock

where the workpiece will rotate against it and

generate friction. The carbide-tipped dead center can

better withstand the effects of friction; however, the tip

of the center must be lubricated to avoid premature

wear and maximize smooth operation. Also, using

low spindle speeds will also reduce the heat and wear

from friction.

Live Centers

A live center has bearings that allow the center tip and

the workpiece to rotate together, and can be installed

in the spindle and the tailstock quill for higher speeds,

but with a slight bit of accuracy loss.

Mounting Dead Center in Spindle

1. Disconnect Lathe from POWER !

2. Thoroughly clean and dry the tapered mating

surfaces of the spindle bore, tapered sleeve, and

the center.

3. Insert the center into the sleeve, then insert the

sleeve into the spindle bore through the chuck or

faceplate.

Removing Center from Spindle

To remove the sleeve and center from the spindle,

insert a piece of round bar stock or similar tool through

the outboard end (on the left side of the headstock),

then tap the sleeve loose.

Mounting Center in Tailstock

Either a dead center or live center can be mounted

in the tailstock. Mounting instructions are the same

for both.

Figure 36. Jack screw adjustment verses

tailstock movement.

Figure 37. Example of using a dead

center installed in the tailstock.

2. When the offset is achieved, snug the jack screws

so the tailstock position is locked.

To mount a center in the tailstock :

1. Disconnect Lathe from POWER !

2. Thoroughly clean and dry the tapered mating

surfaces of the tailstock quill bore and the carbide-

tipped dead center.

3. Use the tailstock quill handwheel to feed the quill

out from the casting about 25mm.

4. Insert the center into the tailstock quill.

5. Seat the center firmly into the quill during

workpiece installation by rotating the quill

handwheel clockwise to apply pressure.

Removing Center from Tailstock

To remove the center from the quill, hold onto it with a

rag in one hand, then rotate the tailstock handwheel

counterclockwise to draw the quill back into the

casting until the center released.

-17-

Steady Rest

The steady rest supports long shafts and can be

mounted anywhere along the length of the bed.

To install and use the steady rest :

1. Disconnect Lathe from POWER !

2. Thoroughly clean the machined base of the

steady rest, then place it on the lathe bedways so

the triangular notch fits over the bedway prism.

3. Position the steady rest where required to

properly support the workpiece, then tighten the

hex nut shown in Figure 38 to secure it in place.

Figure 38. Steady rest components.

Finger Adjustment Knob

Wing Bolt

Finger Roller

Hex. Nut

Lock Knob

Figure 39. Workpiece mounted in

the steady rest.

Figure 40. Follow rest attachment.

CAP Screws

4. Loosen the lock knob and open the steady rest so

the workpiece can rest on the bottom two finger

rollers, as shown in Figure 39.

Follow Rest

The follow rest mounts to the saddle with two cap

screws (Figure 40). It is used on long, slender parts

to prevent workpiece flexing from the pressure of the

cutting tool during operation.

Adjust the sliding finger rollers on the follow rest in the

same manner as those on the steady rest.

Compound Slide

The compound slide handwheel has an indirect-read

graduated scale. This means that the distance shown

on the scale represents the actual distance the tool

moves, which of course, will remove twice as much

material from the diameter of the workpiece. The

base of the compound slide has another graduated

scale used for setting the tool to a specific angle.

To set the compound slide at a certain angle :

1. Loosen the two hex nuts at the base of the

compound slide (1 of 2 shown in Figure 41).

Figure 41. Compound slide set at an angle.

Lock Knob

Compound slide

5. Close the steady rest so that the workpiece is

inside the finger rollers, then tighten the lock

knob.

6. Loosen the three wing bolts so the finger roller

positions can be adjusted.

7. Use the finger adjustment knobs to just touch

the finger rollers against the workpiece without

causing workpiece deflection.

8. Tighten the three wing bolts.

2. Rotate the compound to the desired angle, as

indicated by the scale at the base, then retighten

the two hex nuts.

-18-

Figure 42. 4-way tool post.

Tool Post Bolts

Cutting Tool

Figure 43. Cutting tool aligned with

workpiece center.

4-Way Tool Post

The four-way tool post is mounted on top of the

compound slide, and allows a maximum of four tools

to be loaded simultaneously.

The four-way tool post allows for quick indexing to

different tools. This is accomplished by loosening

the top handle, rotating the tool post to the desired

position, then re-tightening the handle to lock the tool

into position.

To load the tool post :

1. Choose the desired cutting tool.

2. Loosen the tool post bolts so that the cutting tool

can fit underneath them.

3. Firmly secure the cutting tool with at least two tool

post bolts, as shown in Figure 42.

Aligning Cutting Tool with Tailstock

Center

For most operations, the cutting tool tip should be

aligned with the spindle center line, as illustrated in

Figure 43.

There are a number of ways to check and align the

cutting tool to the spindle center line. Below are two

common methods :

• Align the tip of the cutting tool with a center

installed in the tailstock. For this to work, the

tailstock must be aligned to the spindle center

line.

• Make a facing cut on a piece of round bar stock.

If the tool is above/below the spindle center line,

a nub will be left in the center of the workpiece.

Adjust the height of the workpiece, then repeat

the facing cut to check the adjustment. Repeat

as necessary until the center of the workpiece is

smoothly faced.

To align the cutting tool with the tailstock center :

1. Mount the cutting tool in the tool post, then turn

the tool post so the tooling faces the tailstock.

2. Install a center in the tailstock, and position the

center tip near the tip of the cutting tool.

3. Lock the tailstock and quill in place.

4. Adjust the height of the cutting tool with a steel

shim, so the tip just touches the end of the

tailstock center.

Apron Stop

Use the adjustable apron stop collar to set the location

where the carriage will be disengaged by the feedrod

friction clutch.

When the adjustable apron stop contacts the stop

collar during a longitudinal feeding operation, the

clutch disengages the feedrod from the apron and the

carriage movement stops.

Figure 44. Apron stop and collar.

Stop Collar

Apron

Apron Stop

-19-

Longitudinal Handwheel

The longitudinal handwheel moves the carriage left or

right along the bed. Use this control when setting up

the machine for facing or turning.

Cross Slide Handwheel

The cross slide handwheel moves the top slide toward

and away from the work. Turning the dial clockwise

moves the slide toward the workpiece. Adjust the

graduated scale by holding the handwheel with one

hand and turning the dial with the other.

Compound Slide Handwheel

The compound slide handwheel controls the position

of the cutting tool relative to the workpiece. The

compound is adjustable for any angle within its range.

The combo inch/metric graduated scale is engraved

into a rotatable barrel. Angle adjustment is secured

by cap screws on the base of the compound.

Spindle Speed

Using the correct spindle speed is important for safe

and satisfactory results, as well as maximizing tool

life.

To set the spindle speed for your operation, you

will need to :

1. Determine the best spindle speed for the cutting

task.

2. Configure the lathe controls to produce the

required spindle speed.

Figure 45. Carriage Controls.

Longitudinal

Handwheel

Cross Slide

Handwheel

Compound Slide

Handwheel

Determining Spindle Speed

Many variables affect the optimum spindle speed

to use for any given operations, but the two most

important are the recommended cutting speed for the

workpiece material and the diameter of the workpiece,

as noted in the formula :

RPM = D

CSx4

RPM = Spindle speed, revolution per minute.

CS = Cutting speed in surface feet per minute ( SFM )

D = Diameter of workpiece

EXAMPLE :

If the cutting speed is 40 for a certain alloy steel and

the workpiece is 2 inches in diameter, find the rpm as

follows :

RPM = = 80

After calculating the RPM, use the nearest or next

lower speed on the lathe and set the spindle speed.

Cutting speed, typically defined in feet per minute

(FPM), is the speed at which the edge of a tool moves

across the material surface.

A recommended cutting speed is an ideal speed

for cutting a type of material in order to produce the

desired finish and optimize tool life.

The books Machinery’s Handbook or Machine Shop

Practice, and some internet sites, provide excellent

recommendations for which cutting speeds to use

when calculating the spindle speed.

These sources also provide a wealth of additional

information about the variables that affect cutting

speed and they are a good educational resource.

Also, there are a large number of easy-to-use spindle

speed calculators that can be found on the internet.

All of these sources will help you take into account all

the applicable variables in order to determine the best

spindle speed for the operation.

Setting Spindle Speed

1. Make sure the spindle is turned OFF and it has

come to a complete stop.

2. Use the chart in Figure 46 to determine the

available spindle speed range closest to your

calculated spindle speed.

SPEEDS

LEVER RPM

LOW 20 – 40

HIGH 400 - 2500

Figure 46. Spindle speed range chart.

Manual Feed

You can manually move the cutting tool around

the lathe for facing or turning operations using the

handwheels shown in Figure 45 and described below.

-20-

3. Adjust the spindle speed range lever to the range

that covers your calculated spindle speed.

4. Turn the spindle ON and slowly turn the variable

speed dial to carefully adjust the spindle speed to

your calculated spindle speed.

Power Feed

On this machine, both the carriage and cross slide

have power feed capability. The rate that these

components move (feed rate) is controlled by how the

levers are configured on the gearbox.

Feed rate and spindle speed must be considered

together. The sources you use to determine the

optimum spindle speed for an operation will also

provide the optimal feed rate to use with that spindle

speed.

Often, the experienced machinist will use the feeds

and speeds given in their reference charts or web

calculators as a starting point, then make minor

adjustments to the feed rate (and sometimes spindle

speed) to achieve the best results.

The carriage can alternately be driven by the

leadscrew for threading operations. However, this

section covers using the power feed option for

the carriage and cross slide components for non-

threading operations.

Power Feed Controls

The feed direction lever controls direction of the

carriage. The quick change feed direction knob

reverses the feed direction of the carriage while the

lathe is running.

Figure 49. Feed control lever positions.

Cross Feed

Neutral

Longitudinal Feed

To engage the power feed :

1. Make sure the spindle is OFF and has come to a

complete stop.

2. Use the feed direction lever to select the direction

that the feed rod will rotate.

3. Use the feed control lever on the front of the apron

to engage power feed for either the carriage or

the cross slide (see Figure 49). To engage the

carriage, push the lever to the left and down. To

engage the cross slide, push the lever to the right

and up.

Feed Direction

Lever

Figure 47. Feed Direction Lever.

Figure 48. Quick change feed direction knob.

To use the quick change feed direction knob :

1. While the lathe is running, place the feed control

lever in neutral.

2. Push or pull the quick change feed direction knob

to change the direction of the feed rod.

3. Re-engage the feed direction lever. The feed

rod rotation will now be reversed, causing the

engaged carriage or cross slide to move in the

opposite direction.

Table of contents