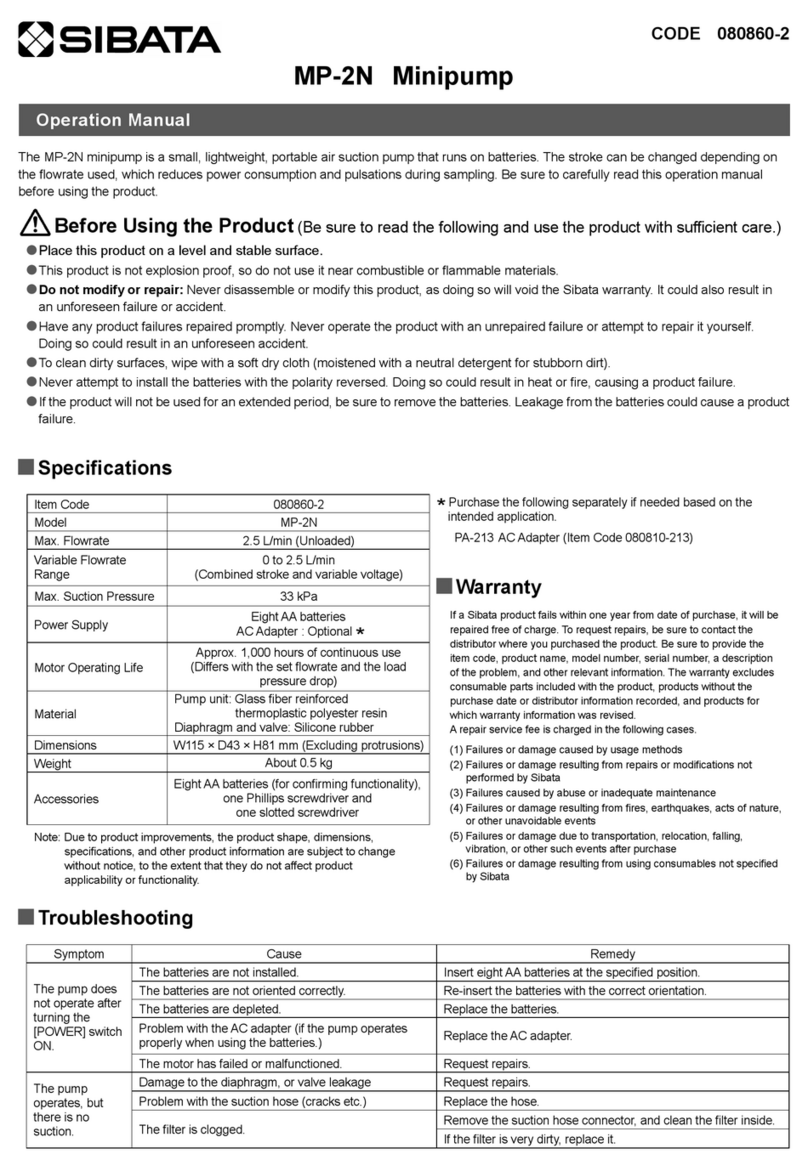

CODE 080800-32

Suction Pump SIP-32L

This is a diaphragm type suction pump, used for measurements of work environment and air. This pump runs quietly, and is lightweight

for easy transport. A buffer is built into the suction mechanism to minimize suction pulsations. It can also be used as a discharge pump.

Be sure to carefully read this operation manual before using the product.

Before Using the Product (Be sure to read this, and handle this product with due care.)

●Install this product horizontally at a stable location.

●Be sure to ground this product.

●This product is not explosion-proofed, so do not use it in the vicinity of combustible or flammable substances.

●[Modifications and Repairs Are Prohibited] Never disassemble or modify this product, as doing so will void the warranty with

Sibata. Doing so may also result in an unforeseen fault or accident.

●If a fault occurs, request repairs immediately. Never leave the fault as is or attempt your own repairs, as subsequent use may result

in an unforeseen accident.

●If this product starts to emit smoke, becomes abnormally hot, or is making strange noises, immediately stop using the product, turn

OFF the power, and remove the plug from the electrical outlet. Then request repair of the product.

●When removing the power plug from the outlet, hold the cord by the power plug to avoid pulling on the power cord. Be sure your

hands are dry before handling the power cord. Otherwise, there is a risk of electric shocks.

●Do not bend, stretch, or twist the cord. Do not connect it to a different cord.

●If you notice that the cord has become damaged or broken or that the plug does not connect properly, stop using it immediately and

request repairs.

●A breakdown will result if the pump sucks in dust or water. Prevent this by using filters or traps.

●Do not allow this product to be directly splashed with water.

If a Sibata product fails within one year from date of purchase, it

will be repaired free of charge. To request repairs, be sure to

contact the distributor where you purchased the product. Be sure

to provide the item code, product name, model number, serial

number, a description of the problem, and other relevant

information. The warranty excludes consumable parts included

with the product, products without the purchase date or distributor

information recorded, and products for which warranty information

was revised. A repair service fee is charged in the following cases.

(1) Failures or damage caused by usage methods

(2) Failures or damage resulting from repairs or modifications not

performed by Sibata

(3) Failures caused by abuse or inadequate maintenance

(4) Failures or damage resulting from fires, earthquakes, acts of

nature, or other unavoidable events

(5) Failures or damage due to transportation, relocation, falling,

vibration, or other such events after purchase

(6) Failures or damage resulting from using consumables not

specified by Sibata

Item code 080800-32

Model SIP-32L

φ

Power supply 100 VAC 50/60 Hz 1 A

Dimensions Approx. W150 ×D205 ×H177 mm

Weight Approx. 5 kg

Usage conditions

Use it indoors for 0.5 hours to 72 hours at a time,

for a total annual period of 3,000 hours max.

(Ensure that the pump unit is placed on a level surface.)

Note: Due to product improvements, the product shape, dimensions,

specifications, and other product information are subject to change

without notice, to the extent that they do not affect product

applicability or functionality.

■Troubleshooting

If you think there has been a breakdown, check the following points.

Problem Cause Remedy

There is no suction.

There is no running noise.

The power is not ON. Connect it to the power supply.

The coil temperature protection has

tripped.

The safety thermal cutoff has tripped due to an internal

temperature increase. This occurred because air was not delivered

due to damage to the diaphragm. Please buy a new pump.

The pump makes a running

noise, but there is no suction.

The diaphragm or valves are damaged.

Replace the chamber block set and L-tube as per Fig. 3.

The L-tube is damaged.