SICK deTec4 Core User manual

OPERATING INSTRUCTIONS

deTec4 Ex

Safety light curtain

Described product

deTec4 Ex

Manufacturer

SICK AG

Erwin-Sick-Str. 1

79183 Waldkirch

Germany

Legal information

This work is protected by copyright. Any rights derived from the copyright shall be

reserved for SICK AG. Reproduction of this document or parts of this document is only

permissible within the limits of the legal determination of Copyright Law. Any modifica‐

tion, abridgment or translation of this document is prohibited without the express writ‐

ten permission of SICK AG.

The trademarks stated in this document are the property of their respective owner.

© SICK AG. All rights reserved.

Original document

This document is an original document of SICK AG.

2O P E R A T I N G I N S T R U C T I O N S | deTec4 Ex 8022883/2019-03-07 | SICK

Subject to change without notice

Contents

1 About this document........................................................................ 7

1.1 Scope......................................................................................................... 7

1.2 Target groups and structure of these operating instructions................ 7

1.3 Additional information.............................................................................. 8

1.4 Symbols and document conventions...................................................... 8

2 Safety information............................................................................ 10

2.1 General safety notes................................................................................ 10

2.2 Correct use................................................................................................ 11

2.3 Requirements for the qualification of personnel.................................... 13

3 Product description........................................................................... 15

3.1 Structure and function............................................................................. 15

3.2 Product characteristics............................................................................ 16

3.2.1 Device overview....................................................................... 16

3.2.2 Automatic calibration of the protective field width................ 16

3.2.3 Beam coding............................................................................ 16

3.2.4 Alignment aid........................................................................... 17

3.2.5 Restart interlock...................................................................... 17

3.2.6 External device monitoring (EDM).......................................... 17

3.2.7 Application diagnostic output................................................. 17

3.2.8 System plug.............................................................................. 17

3.2.9 Flexible control cabinet cabling and status indication on

both sides................................................................................. 18

3.2.10 Status indicators...................................................................... 18

3.3 Example applications............................................................................... 21

4 Project planning................................................................................ 23

4.1 Manufacturer of the machine.................................................................. 23

4.2 Operator of the machine.......................................................................... 23

4.3 Design........................................................................................................ 23

4.3.1 Scanning range and protective field width............................. 24

4.3.2 Minimum distance from the hazardous point....................... 25

4.3.3 Minimum distance to reflective surfaces............................... 27

4.3.4 Protection against interference from systems in close prox‐

imity to each other................................................................... 29

4.4 Integration in electrical control................................................................ 31

4.4.1 Restart interlock...................................................................... 34

4.4.2 External device monitoring (EDM).......................................... 35

4.4.3 Application diagnostic output................................................. 36

4.4.4 Connection of sender and receiver........................................ 36

4.4.5 Laser alignment aid................................................................. 37

4.4.6 Connection diagrams.............................................................. 38

4.5 Testing plan............................................................................................... 39

CONTENTS

8022883/2019-03-07 | SICK O P E R A T I N G I N S T R U C T I O N S | deTec4 Ex 3

Subject to change without notice

4.5.1 Test rod check.......................................................................... 39

4.5.2 Visual check of the machine and the protective device........ 42

5 Mounting............................................................................................. 43

5.1 Safety......................................................................................................... 43

5.2 Unpacking.................................................................................................. 44

5.3 Mounting the system plug........................................................................ 44

5.4 Mount the safety light curtain in the explosion-proof enclosure (only

if the safety light curtain is used in North America)............................... 45

5.5 Mount the optional cable gland............................................................... 47

5.6 Mount the handles to the cover of the explosion-proof enclosure........ 47

5.7 Installation................................................................................................ 48

5.7.1 Mounting the safety light curtain without alignment

bracket...................................................................................... 50

5.7.2 Mounting the safety light curtain with alignment bracket.... 52

6 Electrical installation........................................................................ 56

6.1 Safety......................................................................................................... 56

6.2 System connection (flying leads, 8-wire)................................................. 58

7 Configuration..................................................................................... 60

7.1 Overview.................................................................................................... 60

7.2 Factory settings......................................................................................... 60

7.2.1 Reset to factory settings......................................................... 61

7.3 Configuration mode.................................................................................. 62

7.4 Configuring beam coding......................................................................... 62

7.5 Configuring the restart interlock.............................................................. 63

7.6 Configuring external device monitoring (EDM)....................................... 64

7.7 Configuring application diagnostic output.............................................. 64

7.8 Status indication on both sides............................................................... 65

8 Commissioning.................................................................................. 66

8.1 Safety......................................................................................................... 66

8.2 Overview.................................................................................................... 67

8.3 Switching on.............................................................................................. 67

8.4 Sender and receiver alignment................................................................ 68

8.4.1 Aligning the sender and receiver............................................ 68

8.4.2 Alignment with the alignment bracket................................... 70

8.4.3 Indication of the alignment quality......................................... 71

8.5 Check during commissioning and modifications.................................... 72

9 Operation............................................................................................ 73

9.1 Safety......................................................................................................... 73

9.2 Regular thorough check........................................................................... 73

9.3 LEDs........................................................................................................... 73

10 Maintenance...................................................................................... 76

CONTENTS

4O P E R A T I N G I N S T R U C T I O N S | deTec4 Ex 8022883/2019-03-07 | SICK

Subject to change without notice

10.1 safety......................................................................................................... 76

10.2 Regular cleaning....................................................................................... 76

10.3 Regular thorough check........................................................................... 78

11 Troubleshooting................................................................................. 79

11.1 Safety......................................................................................................... 79

11.2 Diagnostic LEDs........................................................................................ 79

11.2.1 Indications when switching on................................................ 79

11.2.2 Status indication...................................................................... 81

11.2.3 Fault indicators........................................................................ 83

12 Decommissioning............................................................................. 88

12.1 Protection of the environment................................................................. 88

12.2 Disposal..................................................................................................... 88

13 Technical data.................................................................................... 89

13.1 Data sheet................................................................................................. 89

13.2 Response time.......................................................................................... 92

13.3 Power consumption.................................................................................. 92

13.4 Table of weights........................................................................................ 92

13.5 Dimensional drawings.............................................................................. 93

14 Ordering information........................................................................ 98

14.1 Scope of delivery....................................................................................... 98

14.2 Ordering information deTec4 Ex.............................................................. 98

15 Accessories........................................................................................ 99

15.1 Brackets.................................................................................................... 99

15.2 Mounting accessories.............................................................................. 100

15.3 Connectors................................................................................................ 100

15.4 Alignment aid............................................................................................ 100

15.5 Deflector mirrors....................................................................................... 100

15.5.1 Function and use..................................................................... 100

15.5.2 Mounting.................................................................................. 101

15.5.3 Change in scanning range using deflector mirrors................ 101

15.5.4 Deflector mirror PNS75 - ordering information...................... 102

15.5.5 Deflector mirror PSN125 - ordering information................... 102

15.6 Mirror columns.......................................................................................... 102

15.7 Device columns......................................................................................... 102

15.8 Cleaning agent.......................................................................................... 103

15.9 Test rods.................................................................................................... 103

16 Annex.................................................................................................. 104

16.1 Compliance with EU directives................................................................. 104

16.2 Note on specified standards.................................................................... 105

16.3 Checklist for initial commissioning and commissioning........................ 106

CONTENTS

8022883/2019-03-07 | SICK O P E R A T I N G I N S T R U C T I O N S | deTec4 Ex 5

Subject to change without notice

17 List of figures..................................................................................... 107

18 List of tables....................................................................................... 109

CONTENTS

6O P E R A T I N G I N S T R U C T I O N S | deTec4 Ex 8022883/2019-03-07 | SICK

Subject to change without notice

1 About this document

These operating instructions contain information required during the life cycle of the

safety light curtain.

These operating instructions are available to all those who work with the safety light

curtain.

Please read these operating instructions carefully and make sure that you understand

the content fully before working with the safety light curtain.

1.1 Scope

These operating instructions only apply to the deTec4 Ex safety light curtain with one of

the following type label entries in the “Operating Instructions” field:

•8022831

This document is included with the following SICK part numbers (this document in all

available language versions):

8022831

1.2 Target groups and structure of these operating instructions

These operating instructions are intended for the following target groups: Project devel‐

opers (planners, developers, designers), installers, electricians, safety experts (e.g., CE

authorized representatives, compliance officers, persons who test and approve the

application), operators, and maintenance personnel.

The structure of these operating instructions is based on the life cycle phases of the

safety light curtain: Project planning, mounting, electrical installation, commissioning,

operation, and maintenance.

In many applications, the target groups are assigned as follows to the manufacturer

and the organization operating the machine in which the safety light curtain is inte‐

grated:

Area of responsibility Target group Special chapters of these operating instruc‐

tions 1)

Manufacturer Project developers

(planners, developers,

designers)

"Project planning", page 23

"Configuration", page 60

"Technical data", page 89

"Accessories", page 99

Installers "Mounting", page 43

Electricians "Electrical installation", page 56

Safety specialists "Project planning", page 23

"Configuration", page 60

"Commissioning", page 66

"Technical data", page 89

"Checklist for initial commissioning and com‐

missioning", page 106

Operating company Operator "Operation", page 73

"Troubleshooting", page 79

Maintenance person‐

nel

"Maintenance", page 76

"Troubleshooting", page 79

"Ordering information", page 98

1) Chapters not listed here are intended for all target groups. All target groups must take into account the

safety and warning instructions of the complete operating instructions!

ABOUT THIS DOCUMENT 1

8022883/2019-03-07 | SICK O P E R A T I N G I N S T R U C T I O N S | deTec4 Ex 7

Subject to change without notice

In other applications, the operating organization is also the manufacturer of the equip‐

ment with the corresponding allocation of the target groups.

1.3 Additional information

www.sick.com

The following information is available on the Internet:

•This document in other languages

•Data sheets and application examples

•CAD data and dimensional drawings

•Certificates (e.g. EU declaration of conformity)

•Guide for Safe Machinery Six steps to a safe machine

1.4 Symbols and document conventions

The following symbols and conventions are used in this document:

Safety notes and other notes

DANGER

Indicates a situation presenting imminent danger, which will lead to death or serious

injuries if not prevented.

WARNING

Indicates a situation presenting possible danger, which may lead to death or serious

injuries if not prevented.

CAUTION

Indicates a situation presenting possible danger, which may lead to moderate or minor

injuries if not prevented.

NOTICE

Indicates a situation presenting possible danger, which may lead to property damage if

not prevented.

NOTE

Indicates useful tips and recommendations.

Instructions to action

bThe arrow denotes instructions to action.

1. The sequence of instructions for action is numbered.

2. Follow the order in which the numbered instructions are given.

✓The check mark denotes the result of an instruction.

LED symbols

These symbols indicate the status of an LED:

oThe LED is off.

ÖThe LED is flashing.

OThe LED is illuminated continuously.

1 ABOUT THIS DOCUMENT

8O P E R A T I N G I N S T R U C T I O N S | deTec4 Ex 8022883/2019-03-07 | SICK

Subject to change without notice

Sender and receiver

These symbols indicate the sender and receiver of the device:

sThe symbol indicates the sender.

rThe symbol indicates the receiver.

ABOUT THIS DOCUMENT 1

8022883/2019-03-07 | SICK O P E R A T I N G I N S T R U C T I O N S | deTec4 Ex 9

Subject to change without notice

2 Safety information

This chapter contains information on general safety for the safety light curtain.

More safety information about specific usage situations of the safety light curtain is

available in the respective chapters.

2.1 General safety notes

DANGER

Hazard due to lack of effectiveness of the protective device

In the case of non-compliance, it is possible that the dangerous state of the machine

may not be stopped or not stopped in a timely manner.

bPlease read this document carefully and make sure that you understand the con‐

tent fully before working with the device.

bFollow all safety notes in this document.

CAUTION

Laser class 1

LASER

1

Figure 1: Laser class 1

This device has been classified in accordance with the following standards:

•IEC 60825-1:2007/EN 60825-1:2007

•IEC 60825-1:2014/EN 60825-1:2014

•21 CFR 1040.10 and 1040.11, except for deviations pursuant to Laser Notice

No. 50 dated 2007-06-24

The laser is eye-safe. Looking directly into the laser may cause temporary impairments.

The outlet opening of the laser radiation is located in the sender, see figure 4,

page 18. The laser is only active when the laser alignment aid is switched on.

Laser identification is located on the rear of the sender.

bComply with the latest version of the applicable provisions on laser protection.

CAUTION

If any operating or adjusting devices other than those specified in this document are

used or other methods are employed, this can lead to dangerous exposure to radiation.

bOnly use the operating or adjusting devices specified in this document.

bOnly follow the methods specified in this document.

bDo not open the housing, except for the purposes of the installation and mainte‐

nance work specified in these operating instructions.

2 SAFETY INFORMATION

10 O P E R A T I N G I N S T R U C T I O N S | deTec4 Ex 8022883/2019-03-07 | SICK

Subject to change without notice

WARNING

Risk of ineffectiveness of the protective device

Please observe the following information to ensure that you are using the deTec4 Ex

safety light curtain safely and correctly.

bNational and international regulations and guidelines must be observed when

mounting, using, and commissioning electrical devices as well as when carrying

out regular technical inspections in explosion-hazardous areas. Article 500 of the

National Electrical Code and ATEX Directive 2014/34/EU shall apply in particular.

Manufacturers and operators of machines using safety light curtains are responsi‐

ble for ensuring that all applicable safety regulations and guidelines are complied

with.

bThese operating instructions must be made available to the operator of the

machine on which the safety light curtain is used. Qualified safety personnel must

instruct the operator in how to use the device. The operator must also be directed

to read and follow the operating instructions.

DANGER

Risk of ignition

Failure to observe this instruction can result in a risk of ignition from potential sparking.

bEnsure that only accessories that are approved for explosion-hazardous areas are

used.

NOTE

SICK provides more information about the following explosion-proof connections:

•Joint between glass and cover

•Joint between cover and explosion-proof enclosure

2.2 Correct use

Overview

The deTec4 Ex safety light curtain is an electro-sensitive protective device (ESPE) and is

suitable for the following applications:

•Hazardous point protection

•Access protection

•Hazardous area protection

The deTec4 Ex safety light curtain is suitable for use in enclosed spaces only. It has

UL/cUL certification for the following hazardous areas defined in the National Electrical

Code® and Canadian Electrical Code®:

•Class I, groups C, D

•Class II, groups E, F, G

•Class III

The deTec4 Ex safety light curtain also complies with these standards: EN

60079-0:2012/A11:2013/IEC 60079-0 Edition 6.0, EN 60079-1:2014/ IEC 60079-1

Edition 7.0, EN 60079-31:2014/IEC 60079-31 Edition 2.0 and is certified for the fol‐

lowing hazardous areas:

•X II 2 G Ex db IIB T6

•X II 2 D Ex tb IIIC T56°C Db IP6X

SAFETY INFORMATION 2

8022883/2019-03-07 | SICK O P E R A T I N G I N S T R U C T I O N S | deTec4 Ex 11

Subject to change without notice

•Ex db IIB T6

•Ex tb IIIC T56°C Db IP6X

DEMKO 14 ATEX 1315X

IECEx UL 14.0034X

The deTec4 Ex safety light curtain does not emit any substances which hinder paint

coating, any volatile silicones or any solid parts or materials into its surroundings.

The deTec4 Ex safety light curtain must only be used within the limits of the prescribed

and specified technical data and operating conditions at all times.

Any instance of improper use, incorrect modification, or manipulation of the deTec4 Ex

safety light curtain shall void any warranty provided by SICK AG; furthermore, SICK AG

shall not accept any responsibility or liability for any resulting damage and consequen‐

tial damage.

Important information

DANGER

Hazard due to lack of effectiveness of the protective device

Persons and parts of the body to be protected may not be recognized in case of non-

observance.

The safety light curtain works as an indirect protective measure and cannot provide pro‐

tection from parts thrown out nor from emitted radiation. Transparent objects are not

detected.

bOnly use the safety light curtain as an indirect protective measure.

DANGER

Risk of ignition

Failure to observe this information could result in a risk of ignition.

bThe sender, receiver, and cables delivered with the safety light curtain are not

explosion-proof. The person purchasing, assembling, and using the safety light cur‐

tain is responsible for fitting the cables in suitable explosion-proof conduits and/or

cable glands to ensure the integrity of the system.

bThe type label on each individual explosion-proof enclosure contains information

on the device’s hazardous area class and group. Every device that penetrates the

explosion-proof enclosure must be suitable for the environment in which the explo‐

sion-proof enclosure is installed with regard to its hazardous area class and group

or zone.

DANGER

Risk of ignition

Failure to observe this information could result in a risk of ignition.

Only if the device is used outside North America:

bA cable gland must be mounted.

bThe cable gland must be certified for d and tb environments.

2 SAFETY INFORMATION

12 O P E R A T I N G I N S T R U C T I O N S | deTec4 Ex 8022883/2019-03-07 | SICK

Subject to change without notice

DANGER

Risk of ignition

Failure to observe this information could result in a risk of ignition.

Only if the device is used in North America:

bAny conduit openings that are not in use must be sealed. Sealing fittings must turn

at least five (5) full revolutions and be at least 3.175 mm thick (1/8 of an inch).

bConduit sealing fittings must be applied in each installed conduit run (located a

maximum of 457 mm (18 inches) away from the explosion-proof enclosure) in

order to comply with the provisions of the most recent version of the National Elec‐

trical Code, Article 501.15 and/or 502.15, and all other applicable regulations.

Foreseeable misuse

Among others, the deTec4 Ex safety light curtain is not suitable for the following appli‐

cations:

•Outdoors

•Underwater

•At altitudes over 3,000 m above sea level

•In environments with enhanced ionizing radiation

2.3 Requirements for the qualification of personnel

The safety light curtain must be configured, installed, connected, commissioned and

serviced only by qualified safety personnel.

Project planning

For project planning, a person is considered competent when he/she has expertise and

experience in the selection and use of protective devices on machines and is familiar

with the relevant technical rules and national work safety regulations.

Mechanical mounting

For mechanical mounting, a person is considered competent when he/she has the

expertise and experience in the relevant field and is sufficiently familiar with the appli‐

cation of the protective device on the machine that he/she can assess its operational

safety status.

Electrical installation

For electrical installation, a person is considered competent when he/she has the

expertise and experience in the relevant field and is sufficiently familiar with the appli‐

cation of the protective device on the machine that he/she can assess its operational

safety status.

Configuration

For configuration, a person is considered competent when he/she has the expertise

and experience in the relevant field and is sufficiently familiar with the application of

the protective device on the machine that he/she can assess its work safety aspects.

Commissioning

For commissioning, a person is considered competent when he/she has the expertise

and experience in the relevant field and is sufficiently familiar with the application of

the protective device on the machine that he/she can assess its operational safety sta‐

tus.

SAFETY INFORMATION 2

8022883/2019-03-07 | SICK O P E R A T I N G I N S T R U C T I O N S | deTec4 Ex 13

Subject to change without notice

Operation and maintenance

For operation and maintenance, a person is considered competent when he/she has

the expertise and experience in the relevant field and is sufficiently familiar with the

application of the protective device on the machine and has been instructed by the

machine operator in its operation.

Maintenance and thorough checks may only be carried out by qualified and trained per‐

sonnel, who are familiar with the regulations and provisions for potentially explosive

atmospheres, in particular with:

•Ignition protection types

•Installation regulations

•Regulations on distances which must be complied with.

An operator must clean the safety light curtain. Additional information for the operator

of the machine: see "Operation", page 73, and see "Regular cleaning", page 76.

2 SAFETY INFORMATION

14 O P E R A T I N G I N S T R U C T I O N S | deTec4 Ex 8022883/2019-03-07 | SICK

Subject to change without notice

3 Product description

This chapter provides information on the operation of the safety light curtain and shows

examples of its range of use.

3.1 Structure and function

Overview

The deTec4 Ex safety light curtain is an electro-sensitive protective device (ESPE) con‐

sisting of a sender and receiver.

A series of parallel infrared light beams form a protective field between sender and

receiver that protects the hazardous area (hazardous point, access, and hazardous

area protection). When one or more light beams are completely interrupted, the safety

light curtain reports the interruption in the light path to the secure output signal switch‐

ing devices (OSSDs) by a signal change. The machine or its control must safely analyze

the signals (for example using a safe control or safety relays) and stop the dangerous

state.

Sender and receiver automatically synchronize themselves optically. An electrical con‐

nection between both components is not required, but is advantageous.

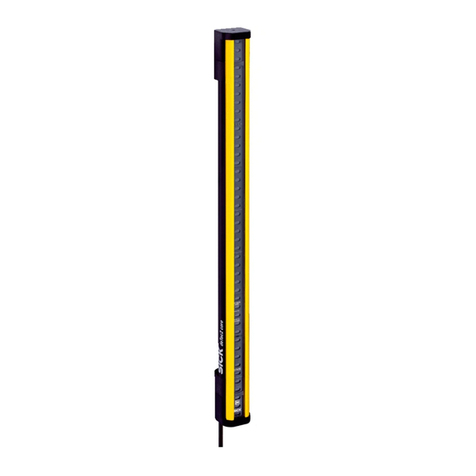

Figure 2: Sender and receiver

Protective field height

The protective field height indicates the range within which the test rod belonging to the

safety light curtain is reliably detected.

Protective field width

The protective field width is the dimension of the light path between sender and

receiver. The maximum protective field width is limited by the scanning range.

PRODUCT DESCRIPTION 3

8022883/2019-03-07 | SICK O P E R A T I N G I N S T R U C T I O N S | deTec4 Ex 15

Subject to change without notice

Resolution

The resolution describes the size of the smallest object detected by the safety light cur‐

tain in the protective field. The resolution corresponds to the diameter of the test rod

belonging to the safety light curtain.

The safety light curtain has a resolution of 30 mm. This resolution provides hand pro‐

tection.

Scanning range

The scanning range is the maximum protective field width.

The scanning range is reduced by using deflector mirrors.

Further topics

•"Flexible control cabinet cabling and status indication on both sides", page 18

•"Data sheet", page 89

•"Deflector mirrors", page 100

3.2 Product characteristics

3.2.1 Device overview

!

§

"

$

Figure 3: Device overview

!Sender or receiver

"System plug

§Terminal compartment

$System connection

3.2.2 Automatic calibration of the protective field width

When switched on, the safety light curtain automatically calibrates to the protective

field width.

3.2.3 Beam coding.

Depending on its configuration, the safety light curtain operates with 1 of 3 beam cod‐

ings: uncoded, code 1 or code 2. The beam coding “uncoded” allows for particularly

short response times. In order to avoid mutual interference between 2 neighboring

safety light curtains, one can be operated with code 1 and the other with code 2.

3 PRODUCT DESCRIPTION

16 O P E R A T I N G I N S T R U C T I O N S | deTec4 Ex 8022883/2019-03-07 | SICK

Subject to change without notice

3.2.4 Alignment aid

A laser alignment aid is installed in the sender of the safety light curtain. The laser

alignment aid can be switched on to perform a simple alignment of the sender.

Diagnostic LEDs are installed in the receiver of the safety light curtain. For a simple

alignment of the receiver, diagnostic LEDs 1, 2, 3 and 4 indicate the alignment quality

once the safety light curtain has been switched on.

Diagnostic LEDs 5 and 6 light up if the topmost beam (far from system plug) is synchro‐

nized. Diagnostic LEDs 7 and 8 light up if the bottommost beam (near system plug) is

synchronized.

3.2.5 Restart interlock

The safety light curtain has an integrated restart interlock. The function can be config‐

ured during commissioning.

A restart interlock prevents the machine from starting again once the protective device

has been triggered. The operator must first press a reset pushbutton to allow the pro‐

tective device to resume its monitoring function. The operator can then restart the

machine.

3.2.6 External device monitoring (EDM)

The safety light curtain has integrated external device monitoring. The function can be

configured during commissioning.

The external device monitoring (EDM) monitors the status of downstream contactors.

In order to use the external device monitoring, positively guided contactors must be

used to switch off the machine. If the auxiliary contacts of the positively guided contac‐

tors are connected to the external device monitoring, the external device monitoring

checks whether the contactors drop off when the OSSDs are switched off.

3.2.7 Application diagnostic output

The safety light curtain has an application diagnostic output on the system connection.

Depending on the configuration, the application diagnostic output signals a certain sta‐

tus of the safety light curtain, e.g. if the reset pushbutton must be engaged or if there is

a weak signal at the receiver.

For a signal of the safety light curtain to be displayed, a light can be connected to the

application diagnostic output or the signal can be transmitted to the machine con‐

troller.

3.2.8 System plug

Overview

The following system plugs are available for the safety light curtain:

•SP1 system plug

The system plugs are available in the following versions:

•System plug (flying leads, 8-wire)

The following functions are available depending on the system plug used:

•Beam coding

•Restart interlock

•External device monitoring (EDM)

•Application diagnostic output

PRODUCT DESCRIPTION 3

8022883/2019-03-07 | SICK O P E R A T I N G I N S T R U C T I O N S | deTec4 Ex 17

Subject to change without notice

3.2.9 Flexible control cabinet cabling and status indication on both sides

The safety light curtain can be connected to the control cabinet in different ways as

required:

•Separate connecting cables for sender and receiver

•Separate connecting cables for sender and receiver with connection in the control

cabinet

The OSSD status and the status of the protective field are indicated via LEDs on the

sender and receiver when the following applies:

•The sender and receiver are connected to one another in the control cabinet

If the sender and receiver are not connected to each other, this status information is

only indicated at the receiver.

Further topics

•"Connection diagrams", page 38

3.2.10 Status indicators

Overview

The sender and receiver LEDs indicate the operational status of the safety light curtain.

Sender indicators

!

"

§

Figure 4: Sender indicators

The sender has one laser alignment aid and at least two light emitting diodes, which

indicate the operational status:

3 PRODUCT DESCRIPTION

18 O P E R A T I N G I N S T R U C T I O N S | deTec4 Ex 8022883/2019-03-07 | SICK

Subject to change without notice

Position LED color Function Labeling

!Red/yellow/green Field indicator 1);

shows the status of

the protective field

and additional infor‐

mation about the sta‐

tus display

–

"– Laser alignment aid –

§Red/yellow/green Status indicator STATE

1) Safety light curtains with protective field height > 300 mm have several light emitting diodes for the field

indicator.

Receiver indicators

!

§

"

1234

5 6 7 8

Figure 5: Receiver indicators

At least ten light emitting diodes on the receiver indicate the operational status:

Position LED color Function Labeling

!Red/yellow/green Field indicator 1);

shows the status of

the protective field

and additional infor‐

mation about the sta‐

tus display

–

"Blue/red/yellow/white Diagnostics 1, 2, 3, 4, 5, 6, 7, 8

§Red/green OSSD status OSSD

1) Safety light curtains with protective field height > 300 mm have several light emitting diodes for the field

indicator.

Further topics

•"Diagnostic LEDs", page 79

3.2.10.1 Indication of diagnostic LEDs

Table 1: Colors and their meaning

Color Color Meaning

OWhite Configuration status

PRODUCT DESCRIPTION 3

8022883/2019-03-07 | SICK O P E R A T I N G I N S T R U C T I O N S | deTec4 Ex 19

Subject to change without notice

Color Color Meaning

OBlue Alignment quality

ORed Fault indicator

OYellow Warning

o LED off. Ö LED flashes. O LED illuminates.

Table 2: Indication of the configuration status

Diagnostic LEDs Color Configuration

1O White External device monitoring (EDM) is config‐

ured.

2O White Reserved

3O White Beam coding is configured.

4O White Restart interlock is configured.

5O White Reserved

6O White Reserved

7O White Reserved

8O White Reserved

o LED off. Ö LED flashes. O LED illuminates.

Table 3: Indication of the alignment quality

Diagnostic LEDs Color Meaning

1 ... 4 O Blue Indication of the alignment quality.

If only one diagnostic LED lights up, the align‐

ment is insufficient. If all 4 diagnostic LEDs

light up, the alignment is excellent.

5, 6 O Blue The topmost beam (far from system plug) is

synchronized.

7, 8 O Blue The bottommost beam (near system plug) is

synchronized.

o LED off. Ö LED flashes. O LED illuminates.

Table 4: Fault indicator

Diagnostic LEDs Color Meaning

1 ... 8 O Red A red illuminated diagnostic LED signals the

function at which an error has occurred.

1 ... 8 Ö Red A red flashing diagnostic LED signals the rea‐

son for the error.

o LED off. Ö LED flashes. O LED illuminates.

Example: If diagnostic LED 1 lights up red and diagnostic LED 5 flashes red, there is an

EDM error.

Table 5: Warnings

Diagnostics LED Color Meaning

1 ... 8 O Yellow A yellow illuminated diagnostic LED signals

which function is affected.

1 ... 8 Ö Yellow A yellow flashing diagnostic LED signals the

reason for the warning.

o LED off. Ö LED flashes. O LED illuminates.

3 PRODUCT DESCRIPTION

20 O P E R A T I N G I N S T R U C T I O N S | deTec4 Ex 8022883/2019-03-07 | SICK

Subject to change without notice

Other manuals for deTec4 Core

16

Table of contents

Other SICK Security System manuals