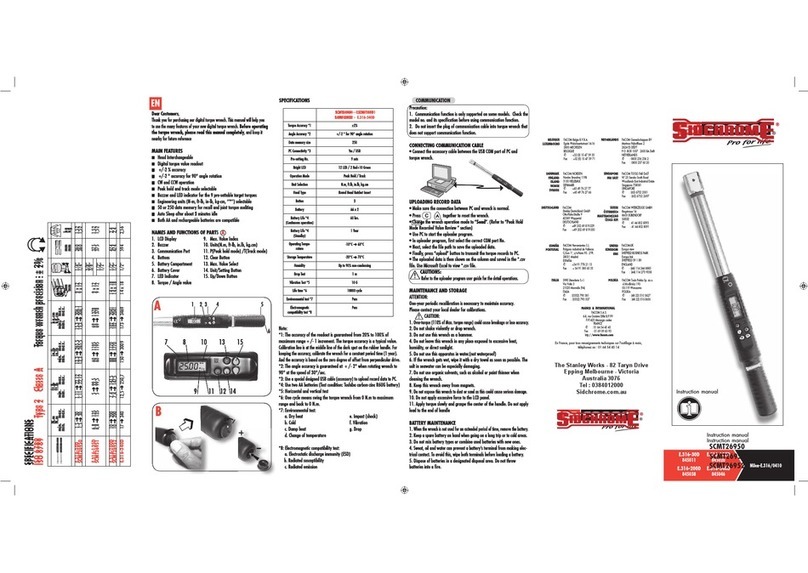

Sidchrome SCMTSA-1SHD User manual

NS.1800F

788272 NU-NS.1800F/0110

1’’ Air Impact Wrench SCMTSA-1SHD.2013.A

Before operating this tool, all operators should study this manual to understand and follow the safety warnings and instructions. Keep these instructions

with the tool for future reference. If you have any questions, contact your Sidchrome

®

representative or distributor.

1’’

WARNING

SCMTSA-1SHD

Operation and Maintenance Manual

TABLE OF CONTENTS

Introduction 3

Specications 3

Safety Instructions 4

Getting Started 5

Tool Components 6

Contact Information 8

2

WARRANTY

Sidchrome air tools are warranted for TWO (2) years from the date of purchase, excluding normally wearing parts such as

vanes, gaskets and o-rings;

1. Unless otherwise specied, this warranty does not cover:

(a) modied, abused, neglected, accidentally damaged or excessively worn products, or products that have become

damaged or defective as a result of improper use;

(b) repairs attempted or made by other than our regional repair centre or authorised warranty service centre;

(c) conditions or malfunctions caused by the reasonable eects of fair wear and tear or the malfunction of normally

wearing parts, which include but are not limited to: vanes, gaskets, o-rings, driver blades, bumpers, pistons and

piston rings;

(Warranty non-transferrable) is warranty is not transferrable beyond the original purchaser.

2. How to make a warranty claim

Unless otherwise specied, the process for making a warranty claim is as follows:

(a) Any product subject to a warranty claim should be returned to the place of purchase for assessment by a

Sidchrome Australia distributor or representative. You are responsible for returning the product to the place of

purchase unless the cost of returning, removing or transporting the product is signicant, in which case you

should contact Sidchrome Australia to make alternative arrangements.

(b) You must present proof of purchase when making a warranty claim.

(c) e claim under this warranty (you may have additional rights under the Australian Consumer Law) will be

assessed by a Sidchrome Australia distributor or representative on the basis of their product knowledge and

reasonable judgment and will be accepted if:

(i) a relevant defect is found;

(ii) the warranty claim is made during the relevant warranty period

(iii) none of the exclusions in cl 1. of this warranty apply.

(d) Upon acceptance of a claim under this warranty, Sidchrome Australia will send you a replacement product or

arrange for your product to be repaired free of charge.

(e) Any warranty related enquiries or claims may be directed to Sidchrome Australia at the address or contact details

listed below.

3. Repair notices

Goods presented for repair may be replaced by refurbished goods of the same type rather than being repaired.

Refurbished parts may be used to repair the goods.

e repair of your goods may result in the loss of any user-generated data. Please ensure that you have made a copy of any

data saved on your goods.

e Consumer Guarantee Statement

Our goods come with guarantees that cannot be excluded under Australian Consumer Law. You are entitled to a

replacement or refund for a major failure and compensation for any other reasonably foreseeable loss or damage. You are

also entitled to have the goods repaired or replaced if the goods fail to be of acceptable quality and the failure does not

amount to a major failure.

Warranty related enquiries and claims may be directed to:

Sidchrome Australia

82 Taryn Drive, Epping, Victoria 3076

http://www.sidchrome.com.au/contact

Australia

Phone 1800 338 002

Fax 1800 080 898

New Zealand

Phone 0800 4782 6539

Fax 0800 278 265

INTRODUCTION

e

Sidchrome

®SCMTSA-1SHD is a precision-built tool, designed for torque assembly and disassembly of threaded

fasteners. is tool will deliver ecient, dependable service when used correctly and with care. As with any ne power

tool, for best performance the manufacturer’s instructions must be followed. Please study this manual before operating

the tool and understand the safety warnings and cautions. e instructions on installation, operation and maintenance

should be read carefully, and the manuals kept for reference. NOTE: Additional safety measures may be required because

of your particular application of the tool. Contact your

Sidchrome

®representative or distributor with any questions

concerning the tool and its use.

Sidchrome®

82 Taryn Drive, Epping

Victoria, Australia 3076

1800 338 002

Sidchrome.com.au

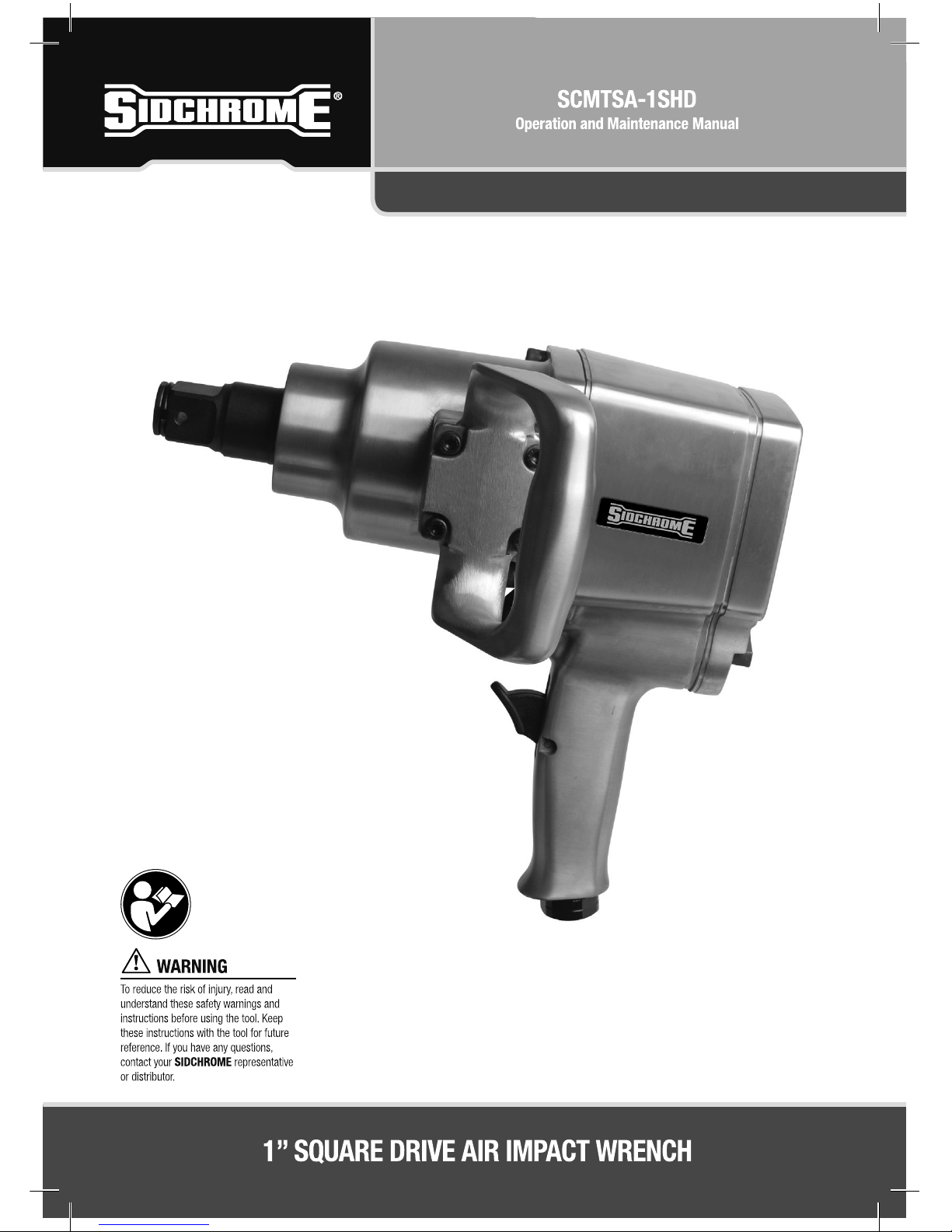

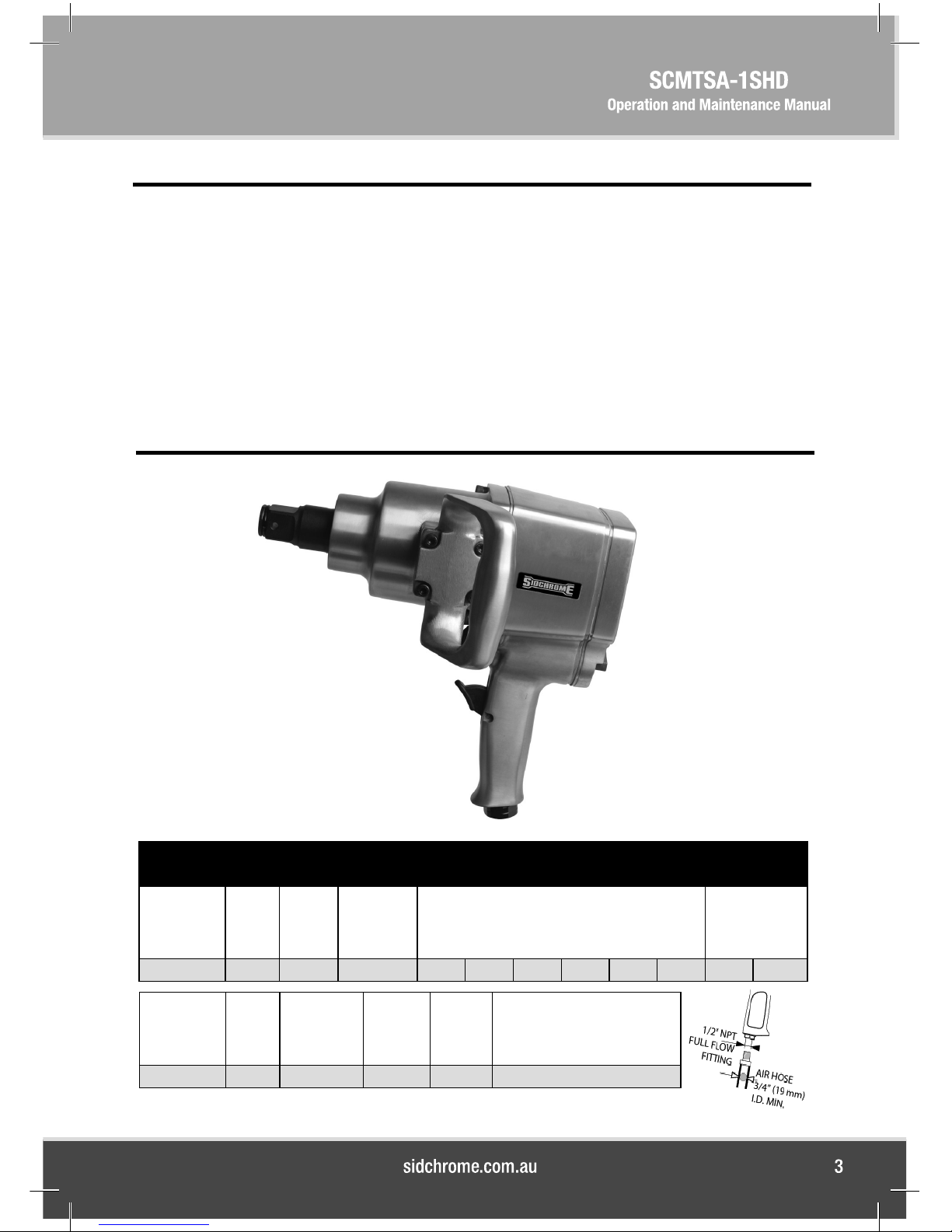

SPECIFICATIONS

Twin-Hammer

Impact Mechanism

Multiple Position

Power Regulator

3

Aluminum 2-pc

Construction

Variable Speed

Trigger

Model # Square

Drive

Blow

Rate

Breakaway

Torque

in bpm ft-lbs / Nm

SCMTSA-ϭSHD 1 720 3000 / 4068 103.4 3* 114.4 3* 103.0 3* 16.7 2.15**

Model # Free

Speed

Average Air

Consumption

Working

Pressure Weight

rpm cfm / l/min psi / bar lbs / kg

SCMTSA-ϭSHD 4400 8.6 / 243 90 / 6.2 22.7 / 10.3

* = measurement uncertainty in dB(A) ** = measurement uncertainty in m/s²

SPECIFICATIONS

Noise Level Vibration

Level

Pressure dB(A) Power dB(A) Pressure dB(C)

11.9 x 8.1 x 11.4 / 301 x 205 x 290

m/s²

Dimensions

in / mm

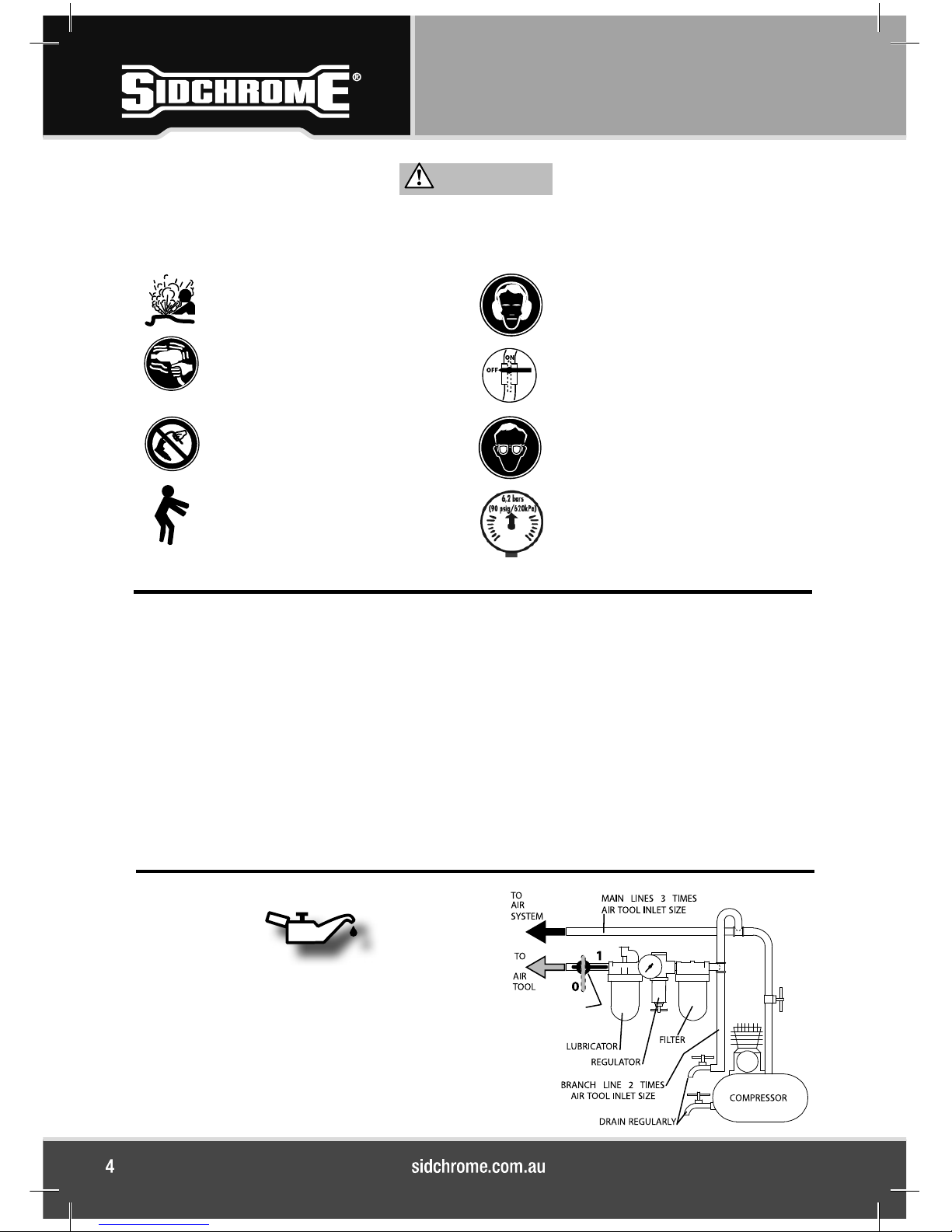

WARNING

Do not use damaged, frayed or deteriorated air

hoses and ttings.

Air powered tools can vibrate in use. Vibration,

repetitive motions or uncomfortable positions may

be harmful to your hands and arms. Stop using any

tool if discomfort, tingling feeling or pain occurs.

Seek medical advice before resuming use.

Do not carry the tool by the hose.

Keep body stance balanced and firm. Do not over-

reach when operating this tool.

IMPORTANT SAFETY INFORMATION ENCLOSED.

READ THIS MANUAL BEFORE OPERATING THE MACHINE.

FAILURE TO OBSERVE THE FOLLOWING WARNINGS COULD RESULT IN INJURY.

Always wear hearing protection when operating

this tool.

Always turn o the air supply and disconnect the air

supply hose before installing, removing or adjusting

any accessory on this tool, or before performing any

maintenance on this tool.

Always wear eye protection when operating or perfor-

ming maintenance on this tool.

Operate at 90 psig (6.2 bar / 620 kPa) Maximum air

pressure.

EMERGENCY

GATE VALVE

PLACING TOOL IN SERVICE

LUBRICATION

Always use an air line lubricator with this tool. Aer every

eight hours of operation, if a lubricator is not used on the

compressed air network, inject 1.5 cc of approved air tool oil

through the tool’s inlet connection. Recommended air tool

oil available from Sidchrome SCMTSATO-250.

SAFE OPERATION

• Always wear eye protection when operating or performing maintenance on this tool.

• Always wear hearing protection when operating this tool.

• Keep hands, loose clothing and long hair away from rotating end of tool.

• Anticipate and be alert for sudden changes in motion during start up and operation of any power tool.

• Keep body stance balanced and rm. Do not overreach when operating this tool.

• Air powered tools can vibrate in use. Vibration, repetitive motions or uncomfortable positions may be harmful to

your hands and arms. Stop using any tool if discomfort, tingling feeling or pain occurs. Seek medical advice before

resuming use.

• Use accessories recommended by Sidchrome®.

• is tool is not designed for working in explosive atmospheres.

• is tool is not insulated against electric shock.

• Always turn o the air supply and disconnect the air supply hose before installing, removing or adjusting any

accessory on this tool, or before performing any maintenance on this tool.

GETTING STARTED

• Always operate, inspect and maintain this tool in accordance with all regulations (local, state, federal and country)

that may apply to hand-held / hand-operated pneumatic tools.

• For safety, top performance, and maximum durability of parts, operate this tool at 90 psig (6.2 bar / 620 kPa) maxi-

mum air pressure at the inlet with 3/4’’ (19mm) inside diameter air supply hose.

• Always turn o the air supply and disconnect the air supply hose before installing, removing or adjusting any

accessory on this tool, or before performing any maintenance on this tool.

• Do not use damaged, frayed or deteriorated air hoses and ttings.

• Be sure all hoses and ttings are the correct size and are tightly secured.

• Always use clean, dry air at 90 psig maximum air pressure. Dust, corrosive fumes and/or excessive moisture can

ruin the motor of an air tool.

• Do not lubricate tools with ammable or volatile liquids such as kerosene, diesel or jet fuel.

• Do not remove any labels. Replace any damaged label.

• e use of a hose whip is recommended. A coupler connected directly to the air inlet increases tool bulk and

decreases tool maneuverability.

• For maximum performance, the coupler on the wall should be the next size larger than the coupler used on the

tool. e coupler closest to the tool should not be less than the proper air supply hose size.

5

11.9” (301mm)

11.4” (290mm)

8.1” (205mm)

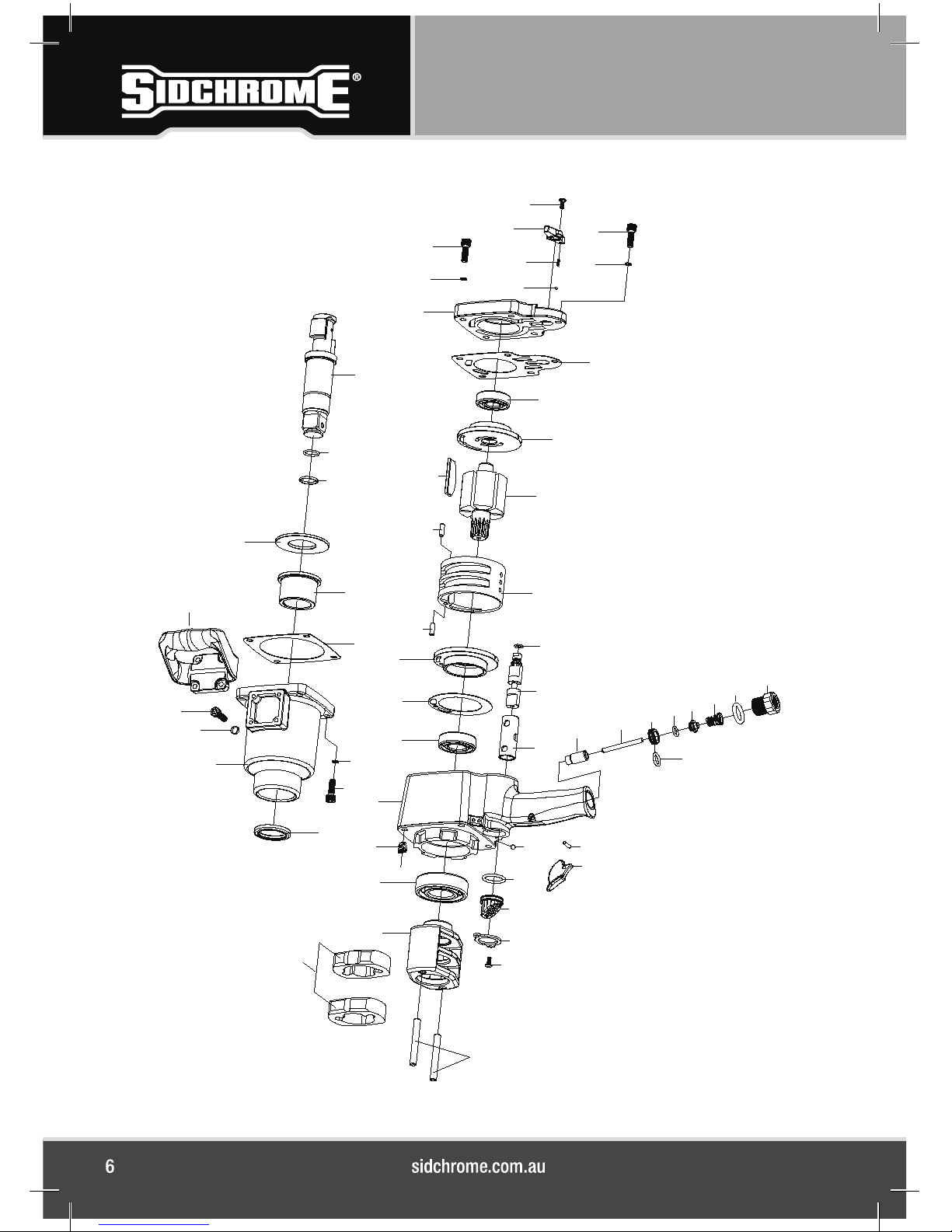

6

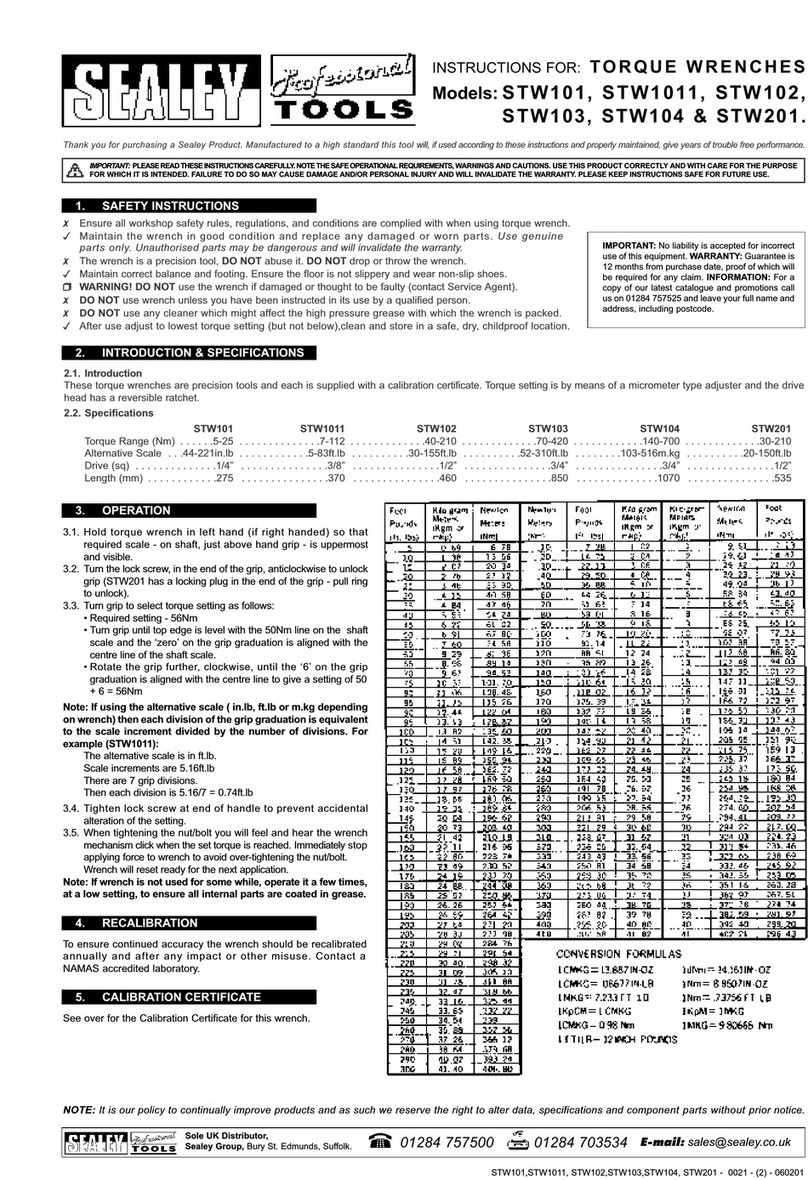

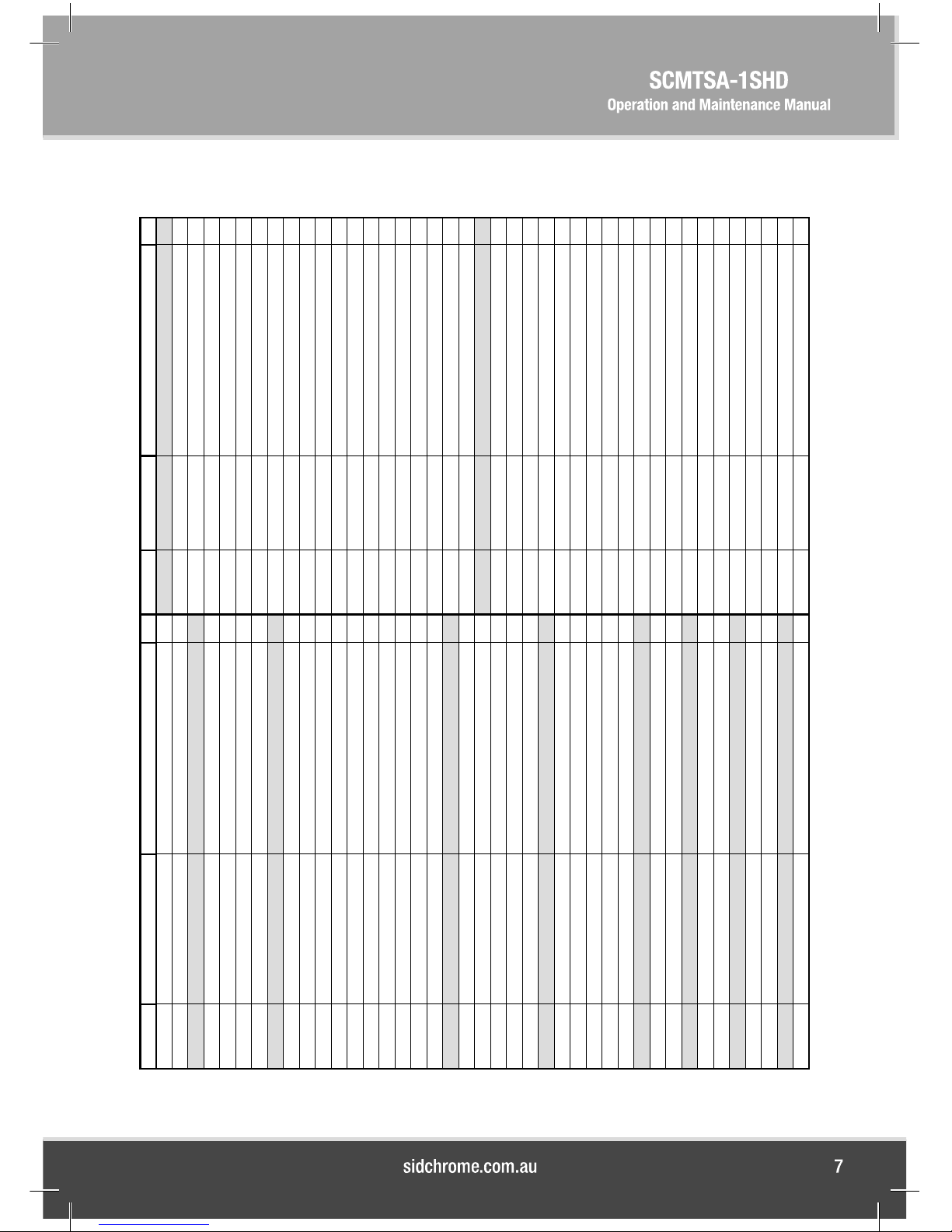

30

16

41

61

19A

18 19

121A

21

24

22

48

27 23

38A

26

28

49

29A

29

42

45

44A

44

9A

2A

5

9

10

4

3

2

12

13

33

17

15

31 32

633A

87

34

40

36

35

46A

46

43

47

37

52

62

21 21B

63

7

ITEM # PART # DESCRIPTION QTY ITEM # PART # DESCRIPTION QTY

SCMTSA-1SHD 1" Impact Wrench

1 31M200043

BACKHEAD 1

A31D100020

ANVIL ASSEMBLY 12 31Y200050 THROTTLE VALVE SEAT 1

38A 31D200038 ANVIL 13 31R200171 THROTTLE VALVE PLUNGER 1

48 31R200192

O-RING 14 31Y200051 THROTTLE VALVE 1

49 31R200193

SOCKET RETAINER 17 31Y200052 EXHAUST DEFLECTOR 1

8 31R200174

RETAINER 1

B31H100015

HAMMER CASE ASSEMBLY 19A 31R200137 SCREW 2

40

WASHER 110 31Y200053 AIR INLET 1

41

BUSHING 112 31R200176 TRIGGER PIN 1

42

GASKET 113 31Y200054 TRIGGER 1

43

HAMMER CASE 117 31Y200055 REVERSE VALVE 1

44 31R100001 SCREW ASSEMBLY (INCLUDES 44A) 419A 31R200181 SCREW 1

44A SPRING WASHER 427 31M200045 ROTOR 1

46 31R100003 SCREW ASSEMBLY (INCLUDES 46A) 428 31M200046 CYLINDER 1

46A SPRING WASHER 429 31R200209 SPRING PIN 1

47 OIL SEAL 129A 31R200183 SPRING PIN 1

45 31H200007

SIDE SPADE HANDLE 1

C31D100021

IMPACT ASSEMBLY 161 31Y200056 REVERSE VALVE KNOB 1

35

HAMMER PIN 2

36

HAMMER FRAME 1TK 31M100014 TUNE UP KIT

37

HAMMER 22A O-RING 1

A 31D100020

ANVIL ASSEMBLY 15 SPRING 1

6

O-RING 1

33 31H100026 HOUSING ASSEMBLY 19

O-RING 1

15

REVERSE VALVE BUSHING 116 O-RING 1

33A

STEEL BALL 418 STEEL BALL 1

52

BUSHING 119 SPRING 1

63

HELI-COIL 922 GASKET 1

23

BALL BEARING 1

24 31M100008 REAR END PLATE ASSEMBLY 126

ROTOR BLADE 6

23

BALL BEARING 131 BALL BEARING 1

32

GASKET 1

30 31M100010 FRONT END PLATE ASSEMBLY 134

BALL BEARING 1

31

BALL BEARING 142 GASKET 1

48

O-RING 1

21A 31R100001 SCREW ASSEMBLY 149

SOCKET RETAINER 1

21

SPRING WASHER 462 O-RING 1

21B 31R100002

SCREW ASSEMBLY 1

21 SPRING WASHER 1

Table of contents

Other Sidchrome Power Tools manuals