Siddons Solarstream MAHRW015WAA User manual

www.siddonssolarstream.com

To be read in conjunction with the

Installation and User Manual for models:

ELECTRONIC SPLIT HEAT PUMP

OWNER'S MANUAL

For externally coiled tanks with

refrigeration line connections

Model MAHRW015WAA

AIR TO WATER HEAT PUMP

264SSAD, 264SSBD

327SSAD, 327SSBD

Notice

1.1 Save this manual for future reference.

1.2 In order to use this product better and more safely, please read this manual carefully before

installation and initial operation.

1.3 Children or persons with physical, sensory or mental disability should not play with nor operate

this appliance.

1.4 This appliance must be installed by qualified and experienced technicians/tradespeople.

Improper installation of this appliance may cause damage and danger.

1.5 This appliance must be installed in accordance with Australian wiring regulations including an

isolating switch from the supply mains and grounded power supply consistent with the power

requirements of this appliance.

1.6 The installation of this appliance must comply with the model's wiring chart in this manual and

its power requirements as stated on the rating label on the side of the heat pump.

1.7 Do not install this appliance close to flammable or explosive materials, or naked flames.

1.8 A filter in the mains water supply inlet is recommended and should be checked/cleaned

periodically.

1.9 Checking and cleaning of the evaporator fin coil is recommended for good air flow.

1.10 The battery should be removed from this appliance's controller at the end of its operating life

and disposed of safely.

Content

1

1

1

1

2

2

3

7

4

4

4

5

5

5

5

5

6

10

12

13

I. Specification........................................................................

1. How it works................................................................................

2. Stainless Steel Hot Water Storage Tank.........................................

3. Flexible installation......................................................................

II. Electronic Split Heat Pump..................................................

1. Technical parameters for the main unit...........................................

2. Electronic Split Heat Pump Dimensions .........................................

3. Heat Pump check .........................................................................

III. Technical Guide..................................................................

1. Starting Current and Peak Current.................................................

2. Electrical wiring...........................................................................

3. Gas Levels and Pressures.............................................................

4. Electronic expansion valve............................................................

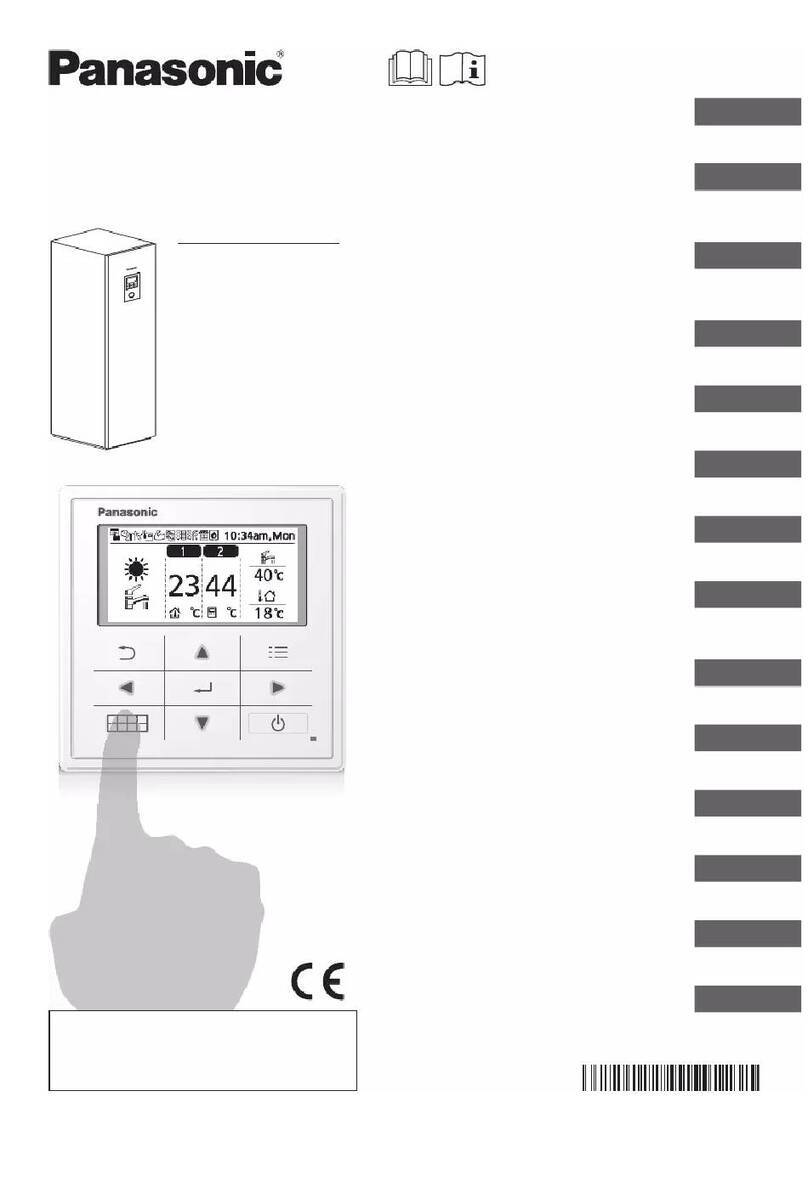

IV. Digital Controller................................................................

1. Operation & Adjustment of the Digital Controller..............................

2. Use of Digital Controller....................................................

3. Operation date setting...................................................................

V. System Malfunction Schedule..............................................

VI. Wiring diagram .. .......................................................... ......

RETROFITTING TO AN EXISTING SIDDONS COILED TANK

This new Electronic Split heat pump model has improved features over the previous mechanical heat pump.

New features include:

* Electronic tank sensor probe replacing the mechanical Klixon tank thermostat for regulating the on/off

function of the heat pump

* Electronic tank sensor probe replacing the mechanical Klixon tank thermostat for regulating the over

temperature function of the compressor; this can be reset by turning power to the heat pump on/off.

* Electronic tank sensor probe for activating the de-ice function; on older units from 2005, this will replace

the mechanical Klixon evaporator thermostat for regulating the de-ice function

* Pressure switches

* LED display unit that provides diagnostic information and monitoring of key operating parameters (refer

Section IV). Note, the LED display unit can be placed under the heat pump lid on top of the electrical

wiring post or placed onto a wall using the sensor extension lead provided with the heat pump)

REFRIGERANT: This Electronic Split heat pump is charged with 1.5KG of R134A refrigerant, whereas the

older style Mechanical Split heat pump is charged with 1.5kg of R417a refrigerant.

CONNECTING THE NEW HEAT PUMP

* Locate the heat pump at least 75mm clear of a wall on the air inlet side and at least 1m clear of a wall or

fence on the air outlet side.

* Ensure all refrigerant is purged from the existing system.

* Connect the existing refrigeration lines to the new refrigeration lines supplied with new electronic heat

pump by brazing them together.

* Ensure the new heat pump and tank and connected with no refrigerant leakage.

* Evacuate the air from the refrigeration lines and the 40m condenser coil wrapped around the tank.

* Fully open both refrigeration valves on the heat pump to charge the whole system.

* Mark the technical label on the tank, deleting reference to R417a refrigerant charge and write in R134a.

* The digital controller can be placed inside the heat pump box on top of the terminal block after the heat

pump has been set, clock and timer (if required) or it can be fixed onto a wall by using the extension lead

provided. Make sure the digital controller is protected from the weather.

* Fit the drain plug and connect a plastic hose to take the condensate water from the evaporator away to a

drain from underneath the heat pump. Angle the heat pump slightly towards the drain plug to enable the

condensate water to flow easily towards the drain plug. Periodically check the drain plug for any blockages.

* If the heat pump is mounted on a wall or on top of a roof, make sure the heat pump’s feet are mounted on

top of rubber pads to prevent vibration from being transmitted.

* It is fine to connect the heat pump to off-peak power but keep in mind the heat pump will operate about

25% more efficiently with a 10 degree rise in the ambient air temperature.

* We recommend installing a pool pump timer set between 12:00pm and 5.00pm if connecting to a

continuous tariff to ensure one operating cycle at the warmest time of day for greater efficiency.

CONNECTING THE SENSOR PROBE TO THE TANK

You will need to fit the tank water temperature sensor probe against the storage tank wall, underneath the

insulating foam and seal with silicone. Here are the key installation points:

* Make a small hole with a screwdriver hard against the storage tank 50-75mm long to fit the probe tightly

* Push the sensor probe in right to the end of the hole

* Seal the hole with silicone to ensure the probe gets a good reading from the tank wall, unaffected by the air

* Secure the sensor probe lead so it cannot fall out of position

* Fine tuning adjustment to the probe cut off/on settings can be made if necessary (refer Section IV)

I¡General

1

2. Hot Water Storage Tank

1. How it works

3. Flexible installation

The condenser coil for the Siddons Solarstream model MAHRW015WAA, with 1.5 horsepower

rotary compressor, is designed to operate with a 40m x 3/8inch copper condenser coil wrapped

around a stainless steel storage tank, insulated on the casing side with at least 50mm of foam

insulation and conductive on the water side, or equivalent. The coil should either be tightly

wrapped around the storage tank or an equivalent internal coil can be used if the inlet water has low

mineral content, typically water coming from reservoir from a mountain catchment, such as exists

in Tasmania, Melbourne, Canberra and Sydney. For other locations, check with your local plumber.

The split system allows flexible design options and with the storage tank installed inside or outside.

It is best for the heat pump to be installed outside and made accessible for any maintenance. Also

the outlet fan should have at least 1m unimpeded distance for the air to blow out.

Installations may vary from the side by side configuration of heat pump and water tank to placement

of the heat pump up to 9 metres distant from the water tank including up to 3 metres above such as

installation of the heat pump on a roof with water tank on the ground.

The Heat Pump comes pre-charged with 1.5kg of ozone friendly R134a refrigerant. This is sufficient

to charge a side by side system with 2m connection lines after it has been connected. For Heat

Pumps installed with extension lines, the refrigerant charge should be slightly greater than 1.5kg,

allow 30 grams extra per additional metre to ensure the correct refrigeration charge in the system.

2

MODEL

COOLING

HEATING

RATED CAPACITY

RATED CURRENT

RATED POWER INPUT

EER

STAR RATING

HEATING CAPACITY

RATED CURRENT

RATED POWER INPUT

EER

STAR RATING

W

A

W

WW

W

A

W

WW

MAHRW015WAA

3500

4.7

1080

3.15

3500

4.5

1020

3.2

4.5

4

POWER SUPPLY

MAX OPERATION CURRENT

NOISE LEVEL INDOOR/OUTDOOR

VOLUMETRIC CAPACITY

DEHUMIDIFICATION CAPACITY

REFRIGERANT TYPE/CHARGE

Ph/V/Hz

A

dB(A)

3

m /h

L/h

/(g)

1/~220-240/50

10.2

53

620

1.5

R134a /1500(g)

INDOOR/OUTDOOR UNIT

DIMENSION (mm)

NET WEIGHT INDOOR/OUTDOOR

COMPRESSOR TYPE

LCD REMOTE CONTROL

TEMPERATURE SETTING RANGE

OPERATION MODES

FAN SPEEDS

24-HOUR ON/OFF TIMER

W

D

H

Kg

Liquid

Gas

¡

780

258

540

Kg 10/40

CONNECTION PIPE SIZE mm(inch)

COMPRESSOR TYPE

LCD REMOTE CONTROL

TEMPERATURE SETTING RANGE

OPERATION MODES

FAN SPEEDS

24-HOUR ON/OFF TIMER

UP/DOWN LOUVER

LEFT/RIGHT LOUVER

HI-POWER

SLEEP MODE

DRY MODE

LED DISPLAY ON FRONT PANEL

LIQUID

GAS

6.35(1/4)

9.52(3/8)

Rotary

Y

OC16-30

4

3

Y

Automatic

Manual

Y

Y

Y

Y

2

M

model

brand

TB36G

Mitsubishi

SOFT START

APPLICATION AREA*

Compressor

N

18-30

1. Technical parameters for the main unit

II Electronic Split Heat Pump

A

B

C

D

Size

Units: mm

MAHRW

280

505

805

542

B

A

C

D

015WAA

2. Electronic Split Heat Pump Dimensions

The heat comes apart easily. Firstly remove the lid, then unscrew the brace on

top of the fan to the front panel, then the screws along the base of the casing

working from the front RHS corner along the base to the left to the back plate

on the opposite corner. Unscrew the two screws connecting the back plate.

3

4

3. Heat Pump checks

Flare Nuts

Ensure the flare nuts are tight, use two spanners and apply pressure, one spanner countering

the force of the other.

Compressor Sitting Squarely

This image shows the Heat

Pump without the casing

revealing the compressor.

Note the compressor sits in a

tray under its own weight and

can occasionally shift its

alignment during transit and/or

installation.

If there is any metallic vibrating

or rattling sound present, try

shifting the compressor with

your hands to ensure it squarely

seated in the tray.

III¡Technical Guide

1. Starting Current and Peak Current

When the Heat Pump starts up for the first time, when the tank has cold water, the power

input will be approximately 700 watts / 220 volts = 3.1 amps. The current will gradually

rise over the heating cycle until it reaches the maximum power input of 1.38kW/230

volts = 6.2 amps, just before the thermostat cuts out the Heat Pump compressor. The

power input ranges between 0.8kw to 1.38kW, 1.1kW average, and will produce Heat

Output of 3.3kW at 20 deg C and 4.4kW at 30 deg C ambient temperature at lower humidity.

The unit should use dedicated power supply and power supply voltage line corresponding with rated

voltage, 220-240 volts. The power cable must be a copper cable, the cable diameter must be sufficient for the

maximum starting current of around 26 Amps.

The unit power supply circuit must have a grounding wire, which should connect with a reliable

external ground wire, and the external ground wire is effective. Wiring construction must be installed

by professional technicians refer to circuit diagram.

Power lines and signal line layout should be neat, rational, strong and weak lines separate and can

not interfere with each other, while not contacted with the connecting pipe and the valve body.

When power lines and control lines parallel, the wires were placed in each tube, also leave appropriate

distance between the lines.

Heat Pump electrical wire connection: take the power line, remote control three core lines, and water

tank temperature sensor probe, and pass themthrough the wiring hole set into the electrical box, then

connect to the appropriate terminals according to wiring diagram.

Unit control panel Code MK4068, Fuse specifications: 5A/250V.

Electric wire selection

2. Electrical wiring

220V/1PH/50Hz 1.0 2

mm 1.0 2

mm 1.0 2

mm 0.5 2

mm 0.5 2

mm

Host power

Mode Phase line Zero line Ground line Max.line

length (m) Signal line Tem. Sensor

Max.line

length (m)

MAHRW015WAA

15 50

Notes:

1). Use PVC insulated copper wire for above wiring

2). If the line is longer than the maximum line length, please contact Siddons.

5

3. Gas Levels and Pressures

For a standard side by side system, the heat pump is pre-charged with 1.5 kg of R134a refrigeration.

The high pressure hot gas line will start at around 1,100 kPa at 20 deg C and lower in colder

temperatures, such as 900kPa at 10 deg C, and reach around 2,600 kPa at cut out temperature

(60 deg C water temp) irrespective of the ambient temperature.

4. Electronic expansion valve

The electronic Split heat pump has an electronic expansion valve which will automatically control

the refrigerant flowrate, adjusting therefrigeration system to work optimally in all ambient air

conditions and through the heating cycle by constantly adjusting the refrigerant flow rate.

1. Operation & Adjustment of the Digital Controller

Caution:

Apart from adjusting the time, timer, hot water temperature or restart dead-band settings,

only an authorised technician should make adjustments to the other parameters depending

on local climatic conditions and usage circumstances, or as instructed by SIDDONS.

IV Digital Controller

6

2. Use of Digital Controller

1.1 Optional Mounting and Fixing of the Remote Controller:

2.1 User Interface and Functions:

Heat pump on/off

button

Operating status

SET

IN

NO

ROOM

OUT

VALVE

ELEC

TEMP

HUM

1

2

FAN

C

%

C

%

Buttons lock icon

CLOCK T IMER

Defrost Mode (continuous flashing)

Water heating mode

Manual water supply flow and return mode

(flashing)

Automatic water supply flow and return

mode (on but not flashing)

Electric heater mode - N/A

Timer 1 (heat pump on/off timer setting)

Timer 2 ( water supply flow and return mode

on/off timer setting)

Manual electric heater

on/off button - N/A

Open the controller

(push tabs in)

Timer setting button

Clock setting button

Water cooing mode - N/A

Additional water pump - N/A

Heat pump fan only - N/A

The remote controller is designed for standard wiring and to fit a standard electrical box

with dimensions 86 x 86mm, fixed hole distance 60mm. The illustration below shows how

to open and fix the controller and base box. You may request from SIDDONS extension

wiring for the remote controller and a blank panel to fit onto the casing after relocating the

controller.

Complete the installation by pressing the

digital controller down firmly to reengage

the tabs.

Put the digital controller into the base box and

tighten the two setting screws.

Illustration 3

Illustration 4

Illustration 1

Illustration 2

Use a flat screwdriver to press down the two

tabs and lift open the face covering.

Remove the top covering leftwards to

disengage two top tabs.

7

2.2 Initial Power On and Standby Status

After first powering on, the remote controller will show the full screen display. After 10 seconds, it will

show the Standby status with storage tank temperature, ambient air temperature and clock showing.

Initialization status

CC

ELEC

CLOC K TI ME R

Standby status

2.3 ON/OFF Control

ON/OFF button. Press this button to power on and off. In the ON mode, the remote controller

displays the operation mode, clock, timing status, bottom of water tank temperature and ambient temperature.

Notice: When the heat pump is turned on for the first time, the default 3 minute delay is not operational,

but will revert from the second time it is turned on.

Hot water

tank temperature

Ambient

temperature.

CC

ELEC

CLOC K TI ME R

OUT

OUT

2.4 Electric Heater Control

NOTE: The electric heater control is not applicable to Australian BOLT-ON Heat Pump models.

A: Independent electric heater mode:

Under the turn off status, press the button, you can turn on the independent electric heater mode the

sign of display on the interface like the picture 1. press the button again turn off the independent

electric heater mode like the picture 2.

B: Auxiliary electric heater mode:

Under the turn on status, press the button, you can turn on the auxiliary electric heater mode, the sign

of display on the interface like the picture 1. When the delay time which is begin when you turn on the

unit is longer than the parameter of 3 setting, the electric heater signal will output. Press the button again

turn off the auxiliary electric heater mode like the picture 2.

ELEC

IN

CC

ELEC

CLOC K TI ME R

IN

CC

CLOC K TI ME R

picture 1 picture 2

IN

CC

ElEC

CLOC K TI ME R

IN

CC

ElEC

CLOC K TI ME R

picture 1 picture 2

ELEC

ELEC

ELEC

OUT OUT

OUT OUT

ELEC

NO

ROOM

OUT

VALVE

1

2

C

%

C

%

CLOC K TI ME R

IN

ELEC

SET

TEMP

HUM

FAN

8

2.6 Clock Setting

Under power-on or stand by status, press to adjust the clock. The hour and minute display

flickers. Press again and the hour display flickers. Use to adjust the hour. Press

again. The minute display flickers. Use to adjust the minutes. Press again to

quit clock adjustment.

CLOCK

ELEC

CLOC K TI MER CLOCK T IM ER

CLOC K TI MER

2.5 Turning On/Off the Ring Main Water Circulating Pump Manually.

Press the button for 5s to turn on the water supply pump. The sign will display on the

interface as in picture 1. Press the button again to turn off the water supply pump as in picture 2.

IN

CC

ELEC

CLOC K TI MER

IN

CC

CLOC K TI MER

picture 1 picture 2

OUT OUT

OUT OUT OUT

1

ROOM

1

ROOM

1

ROOM

1

ROOM

1

ROOM

1

ROOM

1

ROOM

ELE C

CLOCK

TIMER

CLOCK

TIMER

CLOCK

TIMER

CLOCK

TIMER

CLOCK

TIMER

CLOCK

TIMER

CLOCK

TIMER

2.7 Timer 1 ON/OFF Setting

Press button for hour, minutes and timing. The ON symbol flickers. Press again, the

hour display flickers. Press the button to adjust the setting of the hour. Press button

again, and the minute display flickers. Press buttons to adjust the minutes. Press

button again and the hour and timer OFF symbol flickers. Press again and the hour display

flickers, press button to adjust the hour setting. Press button again, and the minute

display flickers. Press buttons to adjust the minute setting. Press button to exit the

timer ON/OFF setting. The following example shows the heat pump set to turn on at 8:30 every

morning, and turn off at 23:30 every night (Timer 1 turns the heat pump ON/OFF).

TIMER TIMER

TIMER

TIMERTIMER

TIMER

TIMER

ELEC

ELEC EL EC

ELE C EL EC ELE C ELE C ELE C ELE C

CLOCK

CLOCK

CLOCK

CLOCK CLOCK

2.8h Timer 2 ON/OFF Setting

Press for 5s to adjust the hours and minutes setting. The ON symbol flickers. Press again,

the hour display flickers. Press the button to adjust the setting of the hour. Press button

again, the minute display flickers. Press buttons to adjust the minutes. Press

button again and the hour and timer OFF symbol flickers. Press again and the hour display

flickers, press button to adjust the hours. Press button again and the minute display

flickers. Press buttons to adjust the minutes. Then press button to exit the timer ON/OFF

setting. The following example shows the heat pump set to turn on at 8:30 every

morning, and turn off at 23:30 every night (Timer 1 turns the heat pump ON/OFF).

TIMER TIMER

TIMER

TIMER

TIMER

TIMER

TIMER

9

2

ROOM

2

ROOM

2

ROOM

2

ROOM

2

ROOM

2

ROOM

2

ROOM

2.9 Cancellation of Timer Setting Operation

Press button, then press button to cancel Timer 1.

Press for 5 seconds, then press button to cancel Timer 2.

2.10 Parameter Setting

In the standby mode, press at the same time to interface with the parameters 0-17 and A-G.

Choose the parameter you want to modify, then press and at the same time to change the

parameter setting, then press at the same time to modify the parameter value, then press

and at the same time to confirm the modification.

Note: 1. The parameters can not be modified in boot-up mode. They need to be modified

in standby mode.

2. If you stop operations for 10 seconds, you will quit the parameter setting mode.

ELEC

ELEC

CLOCK

TIMER

CLOCK

TIMER

CLOCK

TIMER

ELEC

Parameter 4

Not applicable on this

model

Parameter 3

Not applicable on this

model

Parameter 2

Not applicable on this

model

Parameter 1

Compressor restart

dead-band differential

temperature range.

Range: 2¡ to 15¡.

Default: 12¡

Parameter 0

Hot water tank temperature

Range: 10¡ to 60¡.

Default: 60¡

Note: temperature rise above

sensor probe approx 5¡

Parameter 9

Defrost time maximum time

Range: 1 to 12 min.

Default: 8 min

Parameter 8

Defrost exit temperature

Range: 2¡ to 30¡.

Default: 13¡

Parameter 7

Defrost enter temperature

Range: -30¡ to 0¡.

Default: -7¡

Parameter 6

Defrost cycle time out

Range: 30 to 90 min.

Default: 45 min

Parameter 5

Not applicable on this

model

Parameter 13

The electric expansion

valve operation step setting

for the manual control style

default setting :35

(measure valve=35*10)

Parameter 12

Electronic expansion valves

control the selection

0:mannual control

1:automatic control

default setting:1

Parameter 11

The Target superheat

temp. Alternative

range:-F(-15)¡ to F(15)¡.

default setting:5¡

Parameter 10

Not applicable on this

model

CLOCK

TIME R

ELEC

CLOCK

TIME R

ELEC

CLOCK

TIME R

ELEC

ELEC

CLOCK

TIMER

ELEC

CLOCK

TIMER

ELEC

CLOCK

TIMER

ELEC

CLOCK

TIMER

ELEC

CLOCK

TIMER

ELEC

CLOCK

TIMER

CLOCK

TIME R

ELEC

CLOCK

TIME R

ELEC

CLOCK

TIME R

ELEC

CLOCK

TIME R

ELEC

CLOCK

TIME R

ELEC

CLOCK

TIME R

ELEC

CLOCK

TIME R

ELEC

CLOCK

TIME R

ELEC

CLOCK

TIME R

ELEC

CLOCK

TIME R

ELEC

CLOCK

TIME R

ELEC

Parameter 14

Unloading valve type

Alternative range:-15(-F) to

-14(-E)

Default: -F

CLOCK

TIME R

ELEC

10

Parameter16£The ambient

temp.setting for the unit

enter the ambient temp.

Too low protection

Alternative range:

-30¡ to 0¡Default: -15¡

(The minus sign can not

display)

Parameter B£Water

outlet temperature

Parameter A£Hot water

tank temperature

Range: -9¡ to 99¡

Actual testing value

Parameter C£

System coil temperature

Range: -9¡ to 99¡

Actual testing value

Parameter D£

System suction

temperature

Range: -9¡ to 99¡

Actual testing value

Parameter E£

Not applicable on this

model

Parameter F£

Ambient temperature

Range: -9¡ to 99¡

Actual testing value

Parameter G£

The electric expansion valve

opening Range: 15*10¡35*10

Actual testing value

Parameter17£The paramter

is set for recovering

refrigerant or adding

refrigerant

0:The unit normal running

1:The unit enter recovering or

adding refrigerant mode

Default: 0

¢

Note: After recovering refrigerant or adding refrigerant,you must reset the paramter 17 to 0,or else the unit

can not heating.

¢

£

The hot water tank temperature setting

of auxiliary electric heater mode

The temp. of start high-temperature

disinfection per week setting

10 60

2 15

10 90

0 90 min

60 90

0 90 min

30 90 min

-30 0

2 30

1 12 min

1~20

-F(15) F(15)

15*10 35*10

60

12

55

30 min

70

30 min

45 min

-7

13

8 min

6

5

1

(35*10)

Defrost cycle setting

Enter defrost temperature setting

Exit defrost temperature setting

Exit defrost max. time cycle setting

High-temperature disinfection maintain time

Tank temperature difference value for the

compressor restart setting

Domestic hot water tank temperature setting

The unit's operation data can be set on the wire controller.

Please set according to the table below.

3. Operation Data Setting

0

1

2

3

4

5

6

7

8

9

10

11

12

13

Parameter Content description range default Adjust

Adjustable

Adjusted by technicians

Not applicable

Not applicable

Not applicable

Not applicable

Adjusted by technicians

Adjusted by technicians

Adjusted by technicians

Adjusted by technicians

Not applicable

Adjusted by technicians

Adjusted by technicians

Adjusted by technicians

Electric heating start time delay the

time after the unit turn on

1

1

1

The electric expansion operation step setting

for the electric expansion manual control style

Difference temp. Value between solar

and tank for Solar pump start setting

The target superheat temperature setting

for the electric expansion valve.

The control style selection of the electronic

expansion valve

¢

0: manual control

1:automatic control

Alternative range: -9¡ to 99¡

Actual testing value

CLOCK

TIME R

ELEC

CLOCK

TIME R

ELEC

CLOCK

TIME R

ELEC

CLOCK

TIME R

ELEC

CLOCK

TIME R

ELEC

CLOCK

TIME R

ELEC

CLOCK

TIME R

ELEC

CLOCK

TIME R

ELEC

CLOCK

TIME R

ELEC

Parameter15£

Water tank temp.

Supplement setting

CLOCK

TIME R

ELEC

11

-30 ~0

15

16

17

A

B

C

D

E

F

G

Adjusted by technicians

Adjusted by technicians

Actual testing value

Actual testing value

Actual testing value

Actual testing value

Not applicable

Actual testing value

Actual testing value

Hot water tank temperature

Water outlet temperature

System coil temperature

System suction temperature

Solar collector temperature

Ambient temperature

-9 99

-9 99

-9 99

-9 99

-9 99

-9 99

15*10 35*10

The ambient temp.setting for the unit enter

the ambient temp.too low protection

¢

Note:

: Applies to the heat pump with Aux. electric heater.

: Applies to the heat pump with Solar collector. Not applicable.

: The minus sign can t display.

If you stop operating the controller for 10 seconds, it will log out automatically.

The electric expansion valve opening

0: normal running

1: recover or add refrigerant

0

The paramteris set for recovering old

refrigerant or adding new refrigerant

The ambient setting for the ele.c expansion

valve turn back to the manual control style

Water tank temp. supplement setting

14

15

Adjusted by technicians

Not applicable

1

3

2

-F(15) 30

-15(-F) -14(-E)

0

-F

12

V. System Malfunction Schedule

Check for lack of water or air in the cycle heating system heat

exchanger and discharge the air. Check if the water temperature is

too high. Check if the refrigerant charge is too great. Check whether

the high pressure switch has been damaged.

EE1

EE2

EE3

EE4

Check for lack of refrigerant. Check whether the low pressure switch

has been damaged or wire has become disconnected.

System high pressure

protection

System low pressure

protection

Aux.electric heater

overheat protection

Check whether communication wires have been disconnected or

there is a connection error.

EE8

Check whether the power supply is normal. Check whether the

current is greater than normal. Check whether the a/c contactor

connection is normal.

System is running in defrost mode.

Power phase

sequence protection

Communication failure

Not applicable

Unit defrosting status

١. Check whether the temperature thermistor of the upper part of

the water tank is connected loose or not .

upper part٢. Connect temperature thermistor of the of the water

tank tight or change the temperature thermistor.

١. Check whether the temperature thermistor of the is connectedcoil

loose or not .

٢. Connect temperature thermistor of coil tight or change the

temperature thermistor.

١. Check whether the exhaust temperature thermistor is connected

loose or not .

٢. Connect exhaust temperature thermistor tight or change the

exhaust temperature thermistor.

١. Check whether the ambient temperature thermistor is connected

loose or not .

٢. Connect ambient temperature thermistor tight or change the

ambient temperature thermistor

١.Check whether the temperature thermistor of the bottom of the

water tank is connected loose or not .

٢.Connect temperature thermistor of the bottom of the water tank

tight or change the temperature thermistor.

PP5

PP6

PP1

PP2

PP3

Malfunction and

Protection Name

Fault

code Solution

Hot water tank

temp. Sensor failure

Water outlet

temp.Sensor failure

System coil temp.

Sensor failure

System suction

temp. sensor failure

Solar collector

temp. sensor failure

Ambient temp. sensor

failure

PP4

Normal start

Standby

PP7 Water flow protection

1:Check for lack of water or air in the cycle heating system heat

exchanger and discharge the air.

2:Check whether the Grundfos water pump is working.

1. Check whether the resistor or temperature thermistor of the solar

collector is connected loose or not .

the solar 2. Connect resistor or temperature thermistor of the

collector tight or change the temperature thermistor.

VI¡Wiring diagram

Wiring diagram MK4068-0101 for Electronic Split model MAHRW015WAA

Wiring diagram MK4068-0101

Legend:

VA1: 4-way valve

VA2: Electric expansion valve

LP1: System low pressure switch

HP1: System high pressure switch

SW1: Power phase sequence

protection switch(close circuit)

SW2:Water flow switch(close circuit)

: 4 way valve coil

: Wire controller

SW3:Unit turn on/off switch(close circuit)

Fp1: Auxiliary electric heater

overload protection switch(close circuit)

T1 : Hot water tank temperature

T2 : 5K resistor

T3 : System coil temperature

T4 : System suction temperature

T5 : 5K resistor

T6 : Ambient temperature

AC-N

CN1

CN2

OUT3 OUT4 OUT5 OUT6

OT1

OT2

CN3

CN4

OUT7

Power input

(220V/1PH/50Hz)

R

C

S

×

White

OUT8

01

2 9

2 8

2 7

2 6

2 5

2 4

2 3

2 2

2 1

2 0

1 9

1 8

Red

Brown

Capacitance

G/Y

Black

Fan

Blue

G/Y

White

Red

Comp

L N

Brow n

Blue

Yell ow

Transformer

02 03 04 05 06 07 08 09 10 11 12 13 14 15 16 17

T1

SW1

T

FP1

LP1

HP1

SW2

SW3

T

T

T

T

T

T2 T3 T4 T5 T6

CN19

VA2

VA1

Red

Blue

Blue

Capacitance

13

MACON

AIR TO WATER HEAT PUMP

CODE:MK4068-01

Table of contents

Other Siddons Solarstream Heat Pump manuals

Popular Heat Pump manuals by other brands

Automatic Heating

Automatic Heating AHGR410AW Series Installation and instruction manual

Nibe

Nibe VVM 500 Service manual

Rheem

Rheem RP14 14 SEER installation instructions

Trane

Trane 4TWR5018E Installer's guide

Panasonic

Panasonic Aquarea WH-ADC0916H9E8 manual

Daikin

Daikin Alterma EDHQ011AA6V3 Operation manual

iDM

iDM TERRA SW Series Technical documentation, service manual

Carrier

Carrier 25HNB5 installation instructions

LG

LG MULTI F MAX Engineering manual

Trane

Trane WEATHERTRON 4TWX6 Use and care

Carrier

Carrier AQUAZONE 50PCH Installation and service instructions

Supreme Heating

Supreme Heating Heatseeker NovaS Installation & user manual