SIEB & MEYER Drive System SD3 Series Guide

Drive System SD3

Hardware Description

P-TD-0000486.3

2017-03-30

SIEB & MEYER W

Copyright

Translation of the original instructions, Copyright © 2017 SIEB & MEYER AG

All rights reserved.

This manual or extracts thereof may only be copied with the explicit authorization of

SIEB & MEYER AG.

Trademarks

All product, font and company names mentioned in this manual may be trademarks or registered

trademarks of their respective companies.

SIEB & MEYER worldwide

For questions regarding our products and technical problems please contact us.

SIEB & MEYER AG

Auf dem Schmaarkamp 21

21339 Lueneburg

Germany

Phone: +49 4131 203 0

Fax: +49 4131 203 2000

http://www.sieb-meyer.com

SIEB & MEYER Shenzhen Trading Co. Ltd.

Room A208, 2/F,

Internet Innovation and Creation services base

Building (2),

No.126, Wanxia road, Shekou, Nanshan district,

Shenzhen City, 518067

China

Phone: +86 755 2681 1417 / +86 755 2681 2487

Fax: +86 755 2681 2967

http://www.sieb-meyer.cn

SIEB & MEYER Asia Co. Ltd.

4 Fl, No. 532, Sec. 1

Min-Sheng N. Road

Kwei-Shan Hsiang

333 Tao-Yuan Hsien

Taiwan

Phone: +886 3 311 5560

Fax: +886 3 322 1224

http://www.sieb-meyer.com

SIEB & MEYER USA

3975 Port Union Road

Fairfield, OH 45014

USA

Phone: +1 513 563 0860

Fax: +1 513 563 7576

http://www.sieb-meyer.com

W

2 Drive System SD3 - Hardware Description

About this Manual 1

General Information 2

Safety Instructions 3

Unit Assembly Complying EMC 4

Description of the Device 5

Drive Amplifier 03631490xy 6

Option Modules 7

Connector Pin Assignment 8

Connection Examples 9

Status Display and Error Messages 10

Battery Change 11

General Information Regarding the Wiring 12

Safety Circuit / Restart Lock (STO) 13

Appendix 14

Index 15

WChapter Overview

Drive System SD3 - Hardware Description 3

Chapter Overview W

4 Drive System SD3 - Hardware Description

1 About this Manual ............................................................. 9

1.1 Illustration of Warnings ............................................................................... 9

1.2 Illustration of General Notices ................................................................... 10

1.3 Technical Symbols .................................................................................... 10

1.4 Abbreviations ............................................................................................ 10

2 General Information ........................................................ 11

2.1 Approval for the Markets in USA and Canada .......................................... 11

2.2 NRTL Requirements ................................................................................. 12

3 Safety Instructions ........................................................... 13

3.1 General Information .................................................................................. 13

3.2 Appropriate Use ........................................................................................ 14

3.3 Transport and Storage .............................................................................. 15

3.4 Installation ................................................................................................. 15

3.5 Electrical Connection ................................................................................ 16

3.6 Operation .................................................................................................. 17

3.7 Maintenance ............................................................................................. 17

3.8 Disposal .................................................................................................... 18

3.9 Legal Warranty .......................................................................................... 18

3.10 Standards and Regulations ....................................................................... 18

4 Unit Assembly Complying EMC ...................................... 21

4.1 Emitted Interference According to Category C3 ....................................... 21

5 Description of the Device ................................................ 23

5.1 General Device Description and Use ........................................................ 23

5.2 Block Diagram ........................................................................................... 25

5.3 Type Plate ................................................................................................. 26

5.4 Device Designation ................................................................................... 26

6 Drive Amplifier 03631490xy ............................................ 29

6.1 Dimensions ............................................................................................... 30

6.2 Technical Data .......................................................................................... 30

6.3 Memory Card for Device Software (microSD Card) .................................. 32

6.4 Connectors and Displays .......................................................................... 33

7 Option Modules ............................................................... 35

7.1 Option A ................................................................................................... 35

7.1.1 036 31 0044A1: EtherCAT Slave Interface .......................................................... 35

7.1.2 036 31 0044A2: CAN Bus Slave Interface ........................................................... 38

7.2 Option B – Option Modules ...................................................................... 40

7.2.1 036 31 0045B1: Digital and Analog Inputs and Outputs ...................................... 40

8 Connector Pin Assignment .............................................. 43

8.1 Operation of the Terminal Connectors ...................................................... 43

8.1.1 Spring-cage Connection ........................................................................................ 43

8.1.2 Click & Lock System (STCL Connectors) ............................................................. 43

8.1.3 Push-in Technology .............................................................................................. 44

WContent

Drive System SD3 - Hardware Description 5

8.2 X1 – microSD Card Reader ...................................................................... 44

8.3 X14 – Ethernet .......................................................................................... 45

8.4 X15 – USB-Host ........................................................................................ 46

8.5 X16 – USB Device .................................................................................... 46

8.6 X17 – Motor Feedback .............................................................................. 46

8.7 X18 – Encoder 0 ....................................................................................... 48

8.8 X19 – Encoder 1 ....................................................................................... 48

8.9 X20 – Digital Inputs/Outputs ..................................................................... 49

8.10 X21 – Analog Inputs/Outputs .................................................................... 50

8.11 X26/ X27 – SERVOLINK 4 ........................................................................ 50

8.11.1 Assembly of Optical Fiber Cables ......................................................................... 51

8.12 X44 – Mains Supply .................................................................................. 52

8.13 X45 – Motor Connection ........................................................................... 53

8.14 X63 – External Ballast Resistor ................................................................. 53

8.15 X100 – Safety (STO) ................................................................................. 54

9 Connection Examples ..................................................... 55

9.1 X17 – Motor Feedback .............................................................................. 55

9.1.1 EnDat 2.1 with Sine Signals (1 Vpp) ...................................................................... 55

9.1.2 EnDat 2.2 .............................................................................................................. 56

9.1.3 BiSS Interface ....................................................................................................... 56

9.1.4 Resolver ................................................................................................................ 57

9.2 X18 – Encoder 0 ....................................................................................... 58

9.2.1 Encoder 0 .............................................................................................................. 58

9.2.2 EnDat 2.2 .............................................................................................................. 59

9.2.3 BiSS Interface ....................................................................................................... 59

9.3 X19 – Encoder 1 ....................................................................................... 60

9.4 X20Digital Inputs and Outputs .................................................................. 61

9.5 X21 – Analog Inputs/Outputs .................................................................... 62

9.5.1 Analog Outputs ..................................................................................................... 62

9.5.2 Analog Inputs ........................................................................................................ 63

9.6 X26/X27 – SERVOLINK ............................................................................ 63

9.7 X45 – Motor Phases .................................................................................. 64

9.8 X63 – External Ballast Resistor ................................................................. 65

9.9 X100 – safety circuit (STO) ....................................................................... 65

9.9.1 Wiring with OSSD ................................................................................................. 65

9.9.2 Wiring without OSSD ............................................................................................ 65

10 Status Display and Error Messages ................................ 67

10.1 LED Status Display of the Ethernet Interface ........................................... 67

10.2 7-segment Display .................................................................................... 67

11 Battery Change ............................................................... 69

12 General Information Regarding the Wiring ...................... 71

12.1 Mains Connection ..................................................................................... 71

12.2 Cable Requirements ................................................................................. 71

12.2.1 Motor Cable ........................................................................................................... 73

12.2.2 Communication Cable ........................................................................................... 74

12.2.3 Cables for the Rotor Position Detection ................................................................ 75

Content W

6 Drive System SD3 - Hardware Description

12.2.4 Cables for the External Ballast Resistor ................................................................ 75

13 Safety Circuit / Restart Lock (STO) ................................. 77

13.1 Functional Description of the Restart Lock ............................................... 78

13.2 Wiring Example ......................................................................................... 79

13.3 Requirements and Standards ................................................................... 80

14 Appendix ......................................................................... 83

14.A Manufacturers ........................................................................................... 83

14.A.1 SIEB & MEYER Accessories ................................................................................ 83

14.A.1.1 Connectors of the Series SD3 ............................................................................... 83

14.A.1.2 Line Filters for Frequency Converter/Power Electronics ....................................... 83

14.A.2 Phoenix Contact .................................................................................................... 84

15 Index ............................................................................... 85

WContent

Drive System SD3 - Hardware Description 7

Content W

8 Drive System SD3 - Hardware Description

1 About this Manual

This chapter descirbes symbols, signal words and abbreviations used in this manual.

More documentation can be downloaded from the SIEB & MEYER website

under http://www.sieb-meyer.de/downloads.html.

1.1 Illustration of Warnings

Depending on their degree of risk, warnings are classified into different levels. In the

manual, the different levels and types of dangers are represented as follows:

[1] Risk level (signal word/warning color)

Classification of the risk

[2] Safety symbol

Risk of injury

[3] Risk symbol

Graphic representation of the source of risk

Risk levels

Risk Level Description

Indicates an imminently hazardous situation which, if not avoided, will

result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, could

result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, may result

in minor or moderate injury or property damage.

Indicates a hazardous situation which, if not avoided, may result in property

damage.

Risk symbols

Risk symbol Description

General hazardous situation

Risk of injury due to electric shock

Risk of injury due to hot surfaces

WAbout this Manual

Drive System SD3 - Hardware Description 9

1

Risk symbol Description

Potentially risk of injury when working on machines with open covers/

doors

Risk of injury due to flying objects

Destruction risk of electrostatically sensitive components

Risk of property damage

1.2 Illustration of General Notices

Symbol Description

Hint with additional, further information

Tip with suggestions and useful information

1.3 Technical Symbols

Symbol Description

LED indicator: LED on

LED indicator: LED off

LED indicator: LED flashes

1.4 Abbreviations

n.c. not connected

STO safety function: Safe Torque Off

VCC voltage at the common collector

About this Manual W

10 Drive System SD3 - Hardware Description

1

2 General Information

This manual describes the drive systems of the series SD3. These devices allow oper‐

ation of high-dynamic servo motors as well as synchronous and asynchronous high-

frequency spindles.

The devices can be equipped with interfaces for different sensor systems allowing to

drive motors with resolvers as well as SinCos, EnDat, Hall, linear Hall, incremental,

field plate sensors and BiSS interfaces. Motor systems without any sensors are also

supported, whereas different customized control methods are available.

For real-time requirements optional fieldbus modules (e.g. EtherCAT) are available.

This manual provides information on:

▶ Safety instructions and application advice

▶ Notes about the electromagnetic compatibility

▶ Description of the device (block diagram, type plate, module designation)

▶ Technical data, dimensions

▶ Connector pin assignment

▶ Wiring examples

▶ Status and error messages

▶ General information regarding the wiring (cables and line cross-sections)

▶ Safety circuit and restart lock

▶ External protection, ballast circuit

This manual has the following demands on the trained staff of machine manufacturers:

Transport: only by skilled employees familiar with handling electrostatically

sensitive components.

Installation: only by experts with electromechanical experience

Initial operation: only by experts with experience in the fields of electrical engi‐

neering / drive technology

Information concerning the initial operation and parameterization of the digital

drive amplifier can be found in the manual of the software

drivemaster3

.

More documentation can be downloaded from the SIEB & MEYER website

under http://www.sieb-meyer.de/downloads.html.

2.1 Approval for the Markets in USA and Canada

Using products in public buildings or industrial environments in the USA or Canada

must be conform withe the applicable national regulations. In particular electric prod‐

ucts and machines are subject to testing and certification obligations and shall be

labeled specifically.

The Occupational Safety and Health Administration (OSHA) only accepts devices that

have been approved by an authorized NRTL laboratory (Nationally Recognized Testing

Laboratory) and labeled with an appropriate test mark. An NRTL authorized by OSHA

checks the legitimate status of the test mark by inspectors of the manufacturing sites,

for example.

TÜV SÜD Product Service is an NRTL approved by OSHA and undertakes product

certifications for industrial controls, electric drives and other products. The following

links lists the approved NRTL laboratories:

WGeneral Information

Drive System SD3 - Hardware Description 11

2

https://www.osha.gov/dts/otpca/nrtl/nrtllist.html

The tested devices are labeled with the following symbol:

The project 036 31 490XX is tested accoring to the harmonized standard IEC /

UL 61800-5-1: “Standard for Adjustable Speed Electrical Power Drive Systems –

Part 5-1: Safety Requirements – Electrical, Thermal and Energy”

▶ Date: 20.10.2016

▶ Current converter, converter: 036 31 490 EC, 036 31 490 IC, 036 31 490 EF,

036 31 490 IF

▶ Certificate number: U8V 16 10 96098 002

▶ Certificate data base:

https://www.tuev-sued.de/industrie-konsumprodukte/zertifikatsdatenbank

http://www.tuev-sued.de/industry-and-consumer-products/-services/nationally-

recognized-testing-laboratory-nrtl

http://www.tuev-sued.de/industrie-konsumprodukte/branchenloesungen/industrie‐

produkte-elektronik/frequenzumrichter

2.2 NRTL Requirements

Points of Exceptions of the Test Procedure and Conditions of Acceptability

Conditions of Acceptability:

▶ When installing, requirements of mentioned Test Standards and Installation Guide

have to be fulfilled.

▶ The equipments are intended for use in end-use application within final enclosure

to maintain a pollution degree 2 or equivalent environment.

▶ The final enclosure has to fulfill the requirements for the protection in case of

direct contact.

▶ Maximum Surrounding Air Temperature: +40 °C.

▶ The Terminal blocks are suitable for factory wiring only.

▶ The following Branch Circuit Protection must be installed in the end application.

▶ All Branch Circuit Protection shall have characteristic B.

▶ The diameter of the protective earthing conductor shall be 10 mm² (AWG 8) or

higher.

Technical Considerations:

▶ The equipment under test was tested for use at the maximum ambient tempera‐

ture permitted by the manufacturer's specification of: 40 °C.

▶ The operation altitude of the equipment is specified for 1000 m.

▶ The equipment under test was tested with the maximum version (three-phase

version).

General Information W

12 Drive System SD3 - Hardware Description

2

3 Safety Instructions

These safety instructions include important information regarding your safety

and must be observed during installation and operation of SIEB & MEYER.

Read them carefully and keep them for later use.

Also adhere to safety instructions in the product documentation and on the

device.

3.1 General Information

WARNING

Risk of serious injuries and material damage

Any works regarding installation, initial operation and maintenance must be carried

out by trained staff only.Furthermore, electricians which connect feed-in systems

must be approved by the local DSO (distribution system operator).

Trained staff, according to this fundamental safety instruction, are persons familiar

with the installation, mounting, initial and permanent operation of the product and

they are qualified appropriately for the work. The standards DIN VDE 0100 and

DIN VDE 0110 as well as the national accident prevention regulations shall be

considered!

When installing feed-in systems adhere to all applicable regulations, special safety

instructions and technical connection conditions of the local DSO.

DANGER

Material may be damaged and persons be injured seriously:

▶ when covers are removed illegally,

▶ improper use

▶ when either the installation or the operation is incorrect

Observe the corresponding notes and information in the product documentation of

your device.

WARNING

Risk of injuries and material damage due to illegal modifications

Only change the settings of the device after having contacted SIEB & MEYER.

All Information and advice attached to the device, such as safety instructions or danger

warnings and technical data (type plate) are:

▶ not to be removed

▶ not to be damaged

▶ to be kept readably (no covers, no paint over or the like)

WSafety Instructions

Drive System SD3 - Hardware Description 13

3

3.2 Appropriate Use

Use the device according to its appropriate use only. Consider the corresponding infor‐

mation regarding the application fields of the device in the product documentation.

Terms according to DIN EN 61800

Before initial operation, make sure that the machine will not expose danger (e.g.

runaway moves). The conformity with the safety standards DIN EN 60204-1 and DIN

EN 61800-5-1 must be ensured.

The manufacturer of the system or the machine has to meet the requirements of the

legal values regarding the Electromagnetic Compatibility (EMC). SIEB & MEYER units

can be operated in industrial areas, provided that the attached EMC information has

been taken into consideration.

SIEB & MEYER takes care in its own EMC laboratory over their products to meet the

respective standards, when they are installed properly.

Installation of the device differing from the product documentation and the manual

"EMC Guidelines" means that the machine manufacturer has to carry out new meas‐

urements to comply with the regulations.

SIEB & MEYER devices meet the requirements of the Low-Voltage Directive

2014/35/EU. The harmonized standards of DIN EN 50178 and DIN EN 60204-1 in

combination with the standards DIN EN 60947 and DIN EN 61800-5-1 are applied

consequently.

Technical data and the connection specification can be found in the respective product

documents.

Line filters

If adequate interference suppression measures are applied and the appropriate use in

industrial applications of the device is ensured SIEB & MEYER devices comply with

the EMC Directive EMC Directive 2014/30/EU in terms of the EMC Product Standard

(PDS) DIN EN 61800-3.

The use of line filters helps reaching the following:

▶ Resistance to interference. The electronic system is protected against high-

frequency disturbances, possibly infiltrated via the mains cable.

▶ Protection against radiation. High-frequency disturbances are reduced to legally

authorized measure. This prevents effects of the transients to adjacent compo‐

nents or devices.

▶ Products, not equipped with an integrated AC supply line filter must be operated

with an upstream line filter.

▶ Using SIEB & MEYER devices in residential or business areas as well in small

businesses requires additional interference suppression.

For detailed information refer to the manual "EMG Guidelines", chapter "EMC

Product Standard DIN EN 61800-3 for PDS".

Refer to the product documentation of your device to find out whether or not

your device is equipped with a line filter. For detailed information on line

filters refer to the manual "EMC Guidelines".

Safety Instructions W

14 Drive System SD3 - Hardware Description

3

3.3 Transport and Storage

Avoid improper mechanical load of the device. The following points must especially be

taken into consideration:

▶ Protect the device against mechanical damage (max. acceleration = 40 m/s²).

▶ Protect the device against dirt and humidity.

Make sure that dust plugs are plugged on optical fiber connectors equipped with

them during transport of the device. Otherwise, recommissioning is potentially not

possible.

▶ Never touch electronic components.

The following climatic conditions apply to the storage. If required, appropriate meas‐

ures must be taken to ensure these climatic conditions (installation of heating/air condi‐

tioning systems etc.):

▶ The storage area must be clean (dust-free, if possible), dry and well-ventilated.

▶ Storage in the open is not permitted.

▶ The storage temperature must be in the range of −25 °C to +55 °C (−13 °F to

+131 °F). Shortly it may be +70 °C (+158 °F).

▶ The relative humidity on the storage premises must be in the range of 5 % to 75 %

(no bedewing).

▶ Sudden changes of the temperature or the humidity should be prevented.

▶ Avoid stacking of the devices during transport and storage.

The maximum storage period is 2 years. Electrolytic capacitors produce high leakage

currents when a voltage is applied after a long storage period without applied voltage

and must be reformed. For this, the operating voltage is applied via a 1 kΩ series

resistor for one hour. Please contact the SIEB & MEYER service department for

details.

3.4 Installation

NOTICE

Damage of electrostatically sensitive components due to improper handling

Never touch electronic components.

Consider specific mounting instructions for your device.

Operating conditions:

The following requirements are to be considered for the installation and the operation

of the device. Noncompliance with theses requirements is regarded as abnormal oper‐

ating condition:

▶ The device is conceived according to DIN EN 61800-1 / DIN EN 50178 for the dirt

level 2.

▶ The units can be loaded to their maximum up to a height of 1000 m above MSL

(3281 ft above MSL).

For an operation in areas higher than 1000 m (3281 ft) above MSL the capacity

must be reduced by 15 % per 1000 m (3281 ft).

▶ The device must be protected against harmful gas, oil vapor and salty air at the

place of installation.

▶ The ambient air must not contain aggressive, grinding, electrically conductive or

flammable substances as well as any amount of dust.

WSafety Instructions

Drive System SD3 - Hardware Description 15

3

▶ The maximum relative humidity during operation is 85% (no condensation).

▶ The admissible ambient temperature during operation is +5 °C to +40 °C (+41 °F

to +104 °F). Extreme and sudden changes of the temperature should be

prevented.

─ Devices with polyester film at the front panel: The polyester films must not be

exposed to direct sunlight for extended periods of time. In conditions of high

humidity (>80 %) the ambient temperature must not exceed +40 °C (+104 °F).

The polyester films must not come in contact with benzyl alcohol or methylene

chloride.

▶ Make sure that the aeration elements are free and open, so that the air circulation

is not restricted.

3.5 Electrical Connection

DANGER

Risk of serious injuries due to touch voltages

After electric devices have been switched off touch voltages may occur depending

on the device up to 4 minutes. Longer construction-related discharge times are

possible. Refer to the product documentation of your device.

All work at and within the units must only be carried out, when the units are turned

off, the mains supply is cut and the DC bus is completely discharged.

Never touch energized parts after a device has been switched. off.

Consider the applicable VDE regulations and accident prevention regulations (e.g.

VBG 1 and VBG 4).

DANGER

Risk of serious injuries due to improper connection to earth

Incorrect or insufficient connection of the system to ground may cause dangerous

currents.

Connection to earth must be realized according to the instructions in the product

documentation of your device.

The electrical installation must be carried out according to the relevant electrical codes

(e.g. appropriate wire gauges, fuse protection and connections of ground conductors

must be considered).

SIEB & MEYER device are conceived for connection to TN mains. For

detailed information regading the connection to TN mains or other mains

refer to the manual "EMC Guidelines", chapter "Connection to Different

Supply System Types".

Recommendations for the installation according to the EMC (e.g. shields, connection to

earth and line installations) can be found in the technical manuals of your device (only

for machine manufacturers). The manufacturer of the system or machine has to meet

the requirements of the legislation regarding the EMC.

➮ Consider that the mains supply must be protected via an overload release with

restricted guidance for each mains phase. The mains line should only be

connected, when the work is completed.

Safety Instructions W

16 Drive System SD3 - Hardware Description

3

➮ Before turning on the unit the first time, make sure that the connected machine will

not have runaway axes.

➮ Never connect capacitive loads to the output phases of the servo amplifiers and

frequency converters.

➮ Prevent cable loops. Therefore, the units must only be connected to earth at the

provided PE connection for the mains supply line and the racks only at the

provided earth screw.

DANGER

Connection of the power supply unit

This product may cause touch current in the protective earthing conductor. The

current in the protective earthing conductor can exceed 3.5 mA AC or 10 mA DC.

Pay attention to the local safety regulations for electric equipment with high

leakage currents, in particular the minimum cross-section of the protective earthing

conductor.

Operation with residual current device (RCD)

3.6 Operation

WARNING

Risk of serious injuries due to moving machine parts

During the operation of an installation with open doors or removed covers, persons

may seriously be injured by moving machine parts.

Keep the doors closed during the operation and do not remove covers.

WARNING

Risk of injuries and material damage due to flying parts

Persons may be injured or material be damaged, if screws of the front panels and

housing parts are not fastened.

Before the initial operation of the installation ensure that all screws are tightened.

Systems, into which servo amplifiers and frequency converters are mounted, possibly

must be equipped with additional protective devices according to the valid safety

instructions (e.g. law about technical material, rules for prevention of accidents, etc.).

3.7 Maintenance

The unit must be checked regularly for cleanness and functionality depending on the

ambient pollution. This applies in particular for installed fans.

WSafety Instructions

Drive System SD3 - Hardware Description 17

3

3.8 Disposal

Make sure to consider country-specific waste and disposal laws and statutes

for the disposal of packing material, used batteries and irreparable devices.

SIEB & MEYER products meet the requirements of the following directive:

▶ 2011/65/EU (EU-directive RoHS 2 on the restriction of the use of hazardous

substances in electrical and electronic equipment)

SIEB & MEYER products do not exceed the limits of the directive 2011/65/EU for

hazardous substances.

SIEB & MEYER products labeled with the adjacent symbol also meet

the regulations of the following directive:

▶ SJ/T 11364-2014 (China RoHS 2 on the restriction of the use of

hazardous substances in electrical and electronic equipment)

SIEB & MEYER products labeled with the symbol above do not exceed

the limits of the directive SJ/T 11364-2014 for hazardous substances.

3.9 Legal Warranty

SIEB & MEYER products are liable to a legal warranty of at least one year. Any claims

for the products beyond this warranty shall be declared in an additional contractual

agreement between SIEB & MEYER and the customer.

Claims for damages are excluded:

▶ improper use of the device

▶ when the device has been installed nonstandard or improperly, especially by elec‐

tricians without license

▶ when the device has been employed although the protection equipment was

defective

▶ when the maximum permissible input voltage has been exceeded

▶ through improper operation

▶ when the device or its equipment have been modified

▶ when the device was affected by foreign material or force majeure

NOTICE

Due diligence of the machine manufacturer

A first programming carried out by SIEB & MEYER does not release the machine

manufacturer from his duty to check the programmed values for correctness.

3.10 Standards and Regulations

SIEB & MEYER devices comply with the following standards and directives:

▶ Low-Voltage Directive 2014/35/EU

▶ Machinery Directive 2006/42/EC

▶ EMC Directive 2014/30/EU

▶ DIN EN 61800

Safety Instructions W

18 Drive System SD3 - Hardware Description

3

If the mechanics or the electronics of the device are modified, the conformity

with the EC/EEC directives and thus the label will expire.

WSafety Instructions

Drive System SD3 - Hardware Description 19

3

Safety Instructions W

20 Drive System SD3 - Hardware Description

3

Table of contents

Other SIEB & MEYER Amplifier manuals

Popular Amplifier manuals by other brands

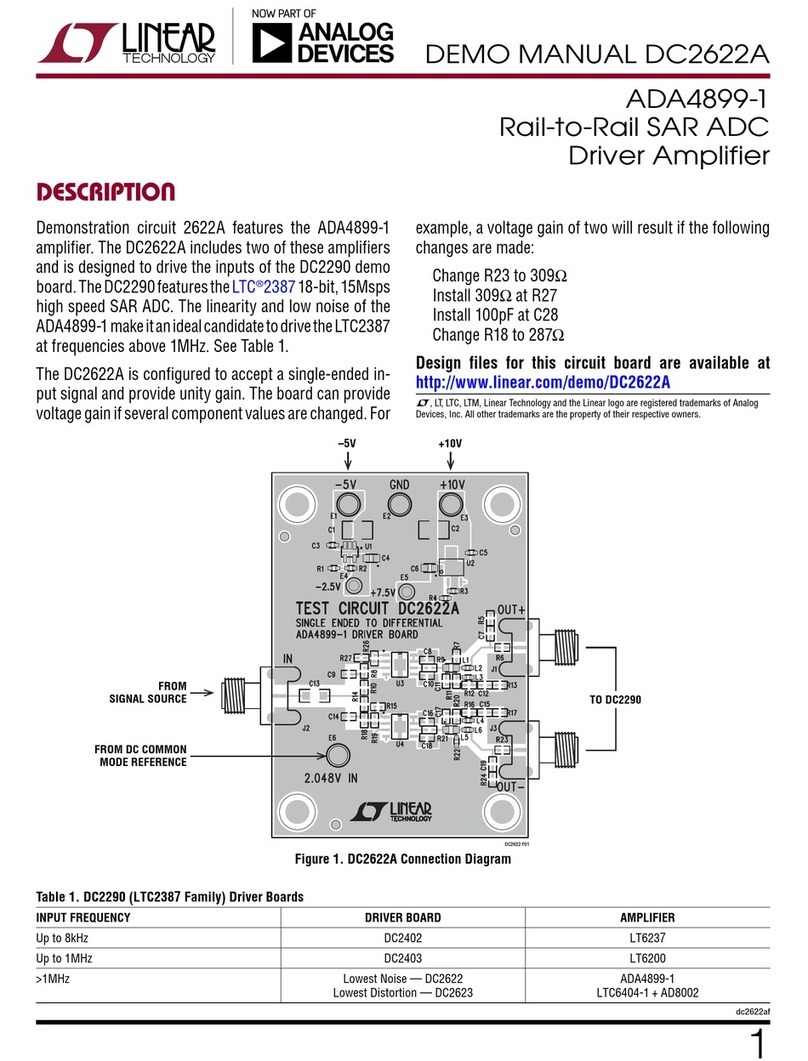

Linear Technology

Linear Technology DC2622A Demo Manual

Marshall Amplification

Marshall Amplification VDA-104-3GS-2 user manual

Niles

Niles SI-1230 Series 2 Installation & operation guide

Broadcast Tools

Broadcast Tools HPA-4 Installation and operation manual

Hubbell

Hubbell GAI-TRONICS 751-002ICS Quick installation guide

Bryston

Bryston BP 6 owner's manual