SIEB & MEYER CNC 8.00 Series Manual

CNC 8x.00

Demo Kit

Installation and Setup

P-TD-0000431.2

2015-11-05

SIEB & MEYER W

Copyright

Translation of the original instructions, Copyright © 2015 SIEB & MEYER AG

All rights reserved.

This manual or extracts thereof may only be copied with the explicit authorization of

SIEB & MEYER AG.

Trademarks

All product, font and company names mentioned in this manual may be trademarks or registered

trademarks of their respective companies.

SIEB & MEYER worldwide

For questions regarding our products and technical problems please contact us.

SIEB & MEYER AG

Auf dem Schmaarkamp 21

21339 Lüneburg

Germany

Phone: +49 4131 203 0

Fax: +49 4131 203 2000

http://www.sieb-meyer.de

SIEB & MEYER Shenzhen Trading Co. Ltd.

Room 306, 3rd Floor, Building A1,

Dongjiaotou Industrial Area, Houhai Dadao,

Shekou, Nanshan District,

Shenzhen City, 518067

China

Phone: +86 755 2681 1417 / +86 755 2681 2487

Fax: +86 755 2681 2967

http://www.sieb-meyer.cn

SIEB & MEYER Asia Co. Ltd.

4 Fl, No. 532, Sec. 1

Min-Sheng N. Road

Kwei-Shan Hsiang

333 Tao-Yuan Hsien

Taiwan

Phone: +886 3 311 5560

Fax: +886 3 322 1224

http://www.sieb-meyer.com

SIEB & MEYER USA

3975 Port Union Road

Fairfield, OH 45014

USA

Phone: +1 513 563 0860

Fax: +1 513 563 7576

http://www.sieb-meyer.com

W

2 CNC 8x.00 - Demo Kit

1 Introduction ....................................................................... 5

1.1 Function ...................................................................................................... 5

1.2 Components ................................................................................................ 5

1.2.1 Hardware ................................................................................................................. 5

1.2.2 Software .................................................................................................................. 5

1.2.3 Files ......................................................................................................................... 6

2 Installation and Setup ........................................................ 7

2.1 Configuring a 2nd Network Card ................................................................. 7

2.1.1 Setting the IP Address for the 2nd Network Card ................................................... 7

2.1.1.1 Notes for Windows 7 ............................................................................................... 8

2.2 Connection of the Hardware ....................................................................... 9

2.2.1 Connection Example A ............................................................................................ 9

2.2.2 Connection Example B .......................................................................................... 10

2.3 Install Software, Calibrate, Load Program ................................................ 11

3 Troubleshooting .............................................................. 17

3.1 Network error ............................................................................................ 17

3.2 Tool Measurement Error ........................................................................... 18

WContent

CNC 8x.00 - Demo Kit 3

Content W

4 CNC 8x.00 - Demo Kit

1 Introduction

The CNC 8x.00 Demo Kit includes hardware and software components for production

planning on a separate work place.

This manual describes the Demo Kit for the CNC 84.00. You can apply the

described instructions to the CNC 82.00. Then, use the operating software of

the CNC 82.00 with the motion controller MC82.

1.1 Function

Compared with the operation of the CNC on a machine the Demo Kit offers only limited

functionalities. The motion controller is provided with a special dongle that does not

support normal operation of the motion controller on a machine.

After installation and setup of the CNC 8x.00 Demo Kit has been finished the CNC

works in the simulation mode.

1.2 Components

1.2.1 Hardware

The CNC 84.00 Demo Kit contains the following hardware components:

▶ Motion Controller MC84 in housing

▶ Ethernet cable X11 (Cross Over, Cat 5e)

▶ external power supply unit (input: 100 to 240 VAC / ~1.6 A / 50 to 60 Hz / output:

24 VAC/ 2.5 A) with connection cable X10

When delivered in countries where other mains plug standards apply than in

Germany, the external power supply unit is not part of delivery. In this case,

consider connection example B (p. 10). Otherwise, consider connection

example A (p. 9).

For PCs equipepd with one network card, only, you need an USB > Ethernet

adapter which is not part of delivery

You can for example use the USB 2.0 > LAN 10/100 Mb/s adapter by Delock

(article number of Delock: 61147).

1.2.2 Software

The following software is required for the CNC 84.00 Demo Kit:

▶ Operating software of the CNC 84.00

Contact the SIEB & MEYER service department to get the installation file (cnc-

WIntroduction

CNC 8x.00 - Demo Kit 5

1

1.2.3 Files

The following files are provided with the Demo Kit:

▶ DEMO-KIT.PAR: test parameters for the setup

▶ STARTUP.TXT: text file with CNC commands for setup

▶ SIEB-MEYER-Format-5000.SM5: part program for the simulated execution

Introduction W

6 CNC 8x.00 - Demo Kit

1

2 Installation and Setup

2.1 Configuring a 2nd Network Card

Top operate the CNCs of the series CNC 8x.00 via a network, you must install a 2nd

network card into your PC. Then, you can connect the CNC via X11 with the network

connection of the 2nd network card in your PC.

Alternatively, you can use a standard USB > Ethernet adapter, e.g.

USB 2.0 > LAN 10/100 Mb/s adapter by Delock, article no. 61147 (commercialy avail‐

able).

This chapter describes how to configure a 2nd network card.

Consider the documentation of the PC manufacturer when installing the 2nd

network card in your PC.

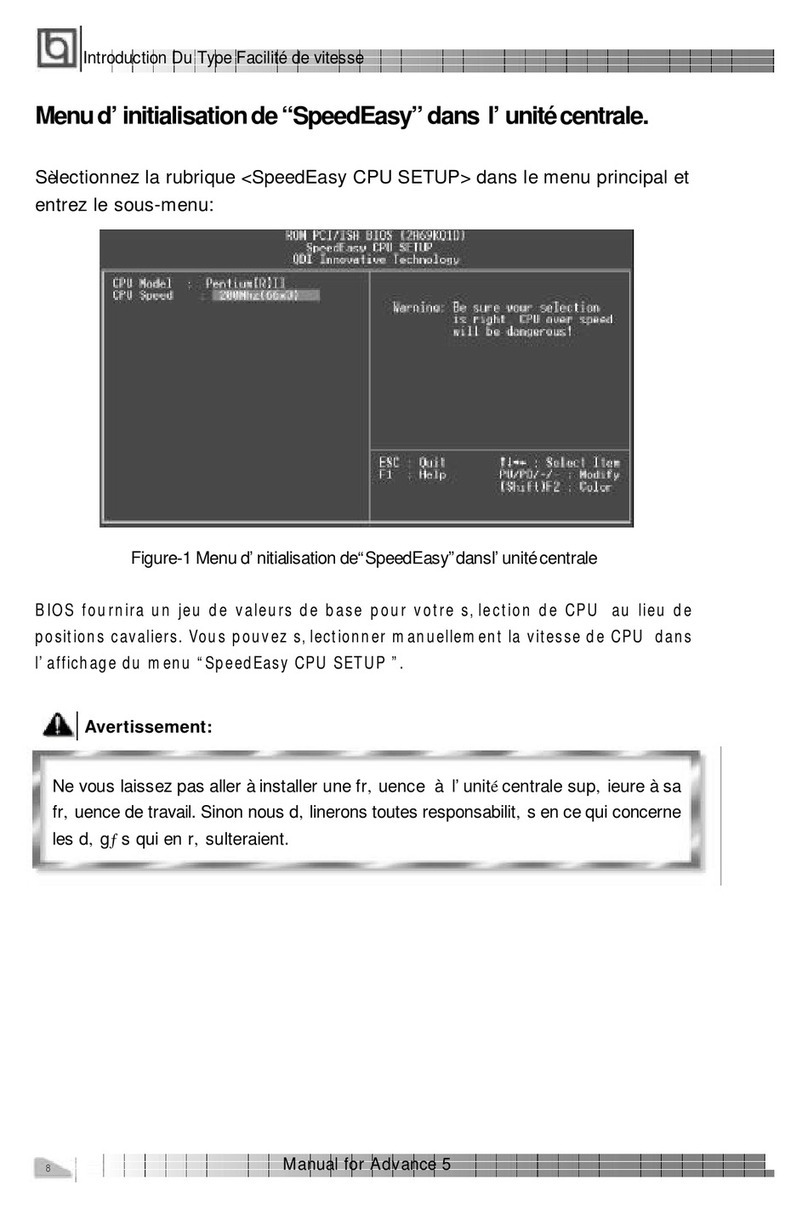

2.1.1 Setting the IP Address for the 2nd Network Card

Procedure

This section describes the procedure with the example of Windows XP.

▶ Start the PC.

▶Select "Start ÿ Settings ÿ Control Panel ÿ Network connections" .

▶ Double click on the symbol for the second network card.

The window "Local Area Connection Status" appears.

Fig. 1: Connection status and properties of the second network card

Click on the button <Properties>.

The window "Local Area Connection Properties "appears.

Activate the option "Internet protocol (TCP/IPv4)" via the corresponding check

box. All other option are deactivated.

Ensure that only the option "Internet protocol version 4 (TCP/IPv4)" has been

activated, "Internet protocol version 6 (TCP/IPv6)" must not be activated!

Click on the button <Properties>.

WInstallation and Setup

CNC 8x.00 - Demo Kit 7

2

The window "Internet Protocol (TCP/IP) Properties" appears. Enter the IP

address of the 2nd network card into this window. You must ensure that both

network cards have different IP addresses.

Fig. 2: Enter IP address

IP address (PC) 192.168.50.2 (default)

Subnet mask: 255.255.255.0 (default)

Click on the button <Properties> to apply your entries.

The default IP address of the network card in the Motion Controller is:

192.168.50.1.

2.1.1.1 Notes for Windows 7

Starting from Windows 7 the TCP/IP stack of Windows has changed. This means that

Windows requires a quite long period (about 1min.) to re-establish a network connec‐

tion that was cut before (for example after a reset of the CPU card).

You can reduce the waitng time by binding the MAC address to its IP address.

Proceed as described in the following:

▶ Enter "

show mac

" in the buggy terminal.

The MAC address appears, e.g. "mac: 00:01:84:01:0C:2F".

▶ Start the prompt as administrator and enter the following text:

"

arp -s <IP address of the card> <MAC address of the card>

" bzw. mit o.g.

Adressen "

arp -s 192.168.50.1 00-01-84-01-0c-2f

"

Installation and Setup W

8 CNC 8x.00 - Demo Kit

2

2.2 Connection of the Hardware

2.2.1 Connection Example A

This connection example shows the connection of the motion controller, if delivered

with external power supply unit and network cable.

1. Connect the power cable to the external power supply unit and connect it to

mains.

2. Connect the power supply cable with X10 of the motion controller.

3. Connect the provided Ethernet cable with connector X11 of the motion controller

and with the network connection of the 2nd. network card of the PC or with the

LAN connector of the USB > Ethernet adapter.

Fig. 3: Connection of the Demo Kit hardware: connection example A

WInstallation and Setup

CNC 8x.00 - Demo Kit 9

2

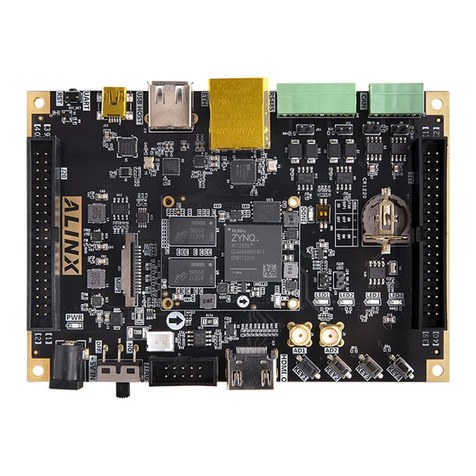

2.2.2 Connection Example B

This connection example shows the connection of the motion controller, if delivered

with external power supply unit and network cable.

1. Mount a cable for the connection of the voltage supply to X10 according to the pin

assignment in the figure.

2. Connect the power supply cable with X10 of the motion controller and the adapter

to the mains socket.

3. Mount a cable for the connection of the PC according to the pin assignemt in the

figure (Cross Over, Cat 5e).

4. Connect the provided Ethernet cable with connector X11 of the motion controller

and with the network connection of the 2nd. network card of the PC or with the

LAN connector of the USB > Ethernet adapter.

Fig. 4: Connection of the Demo Kit hardware: connection example B

Installation and Setup W

10 CNC 8x.00 - Demo Kit

2

2.3 Install Software, Calibrate, Load Program

1. Operating software of the CNC 84.00

Contact the SIEB & MEYER service department to get the installation file (cnc-

The installation file is named for example

"setup CNC84 11.12.007.exe"

.

2. Install the software. Double click on the installation file and follow the instructions

of the InstallShield Wizard.

During installation activate the check box for a desktop link.

Desktop

For detailed information on installation of th operating software refer to the manual

"CNC 8x.00 – Installation".

3. During software installation the following directories are created on the hard disk

of your PC.

─ C:\CNC84

─ C:\SM_WCNC

─ C:\SMWDATA

4. Copy the provided files into the following directories:

─ DEMOKIT.PAR → C:\SM_WCNC\SOFTC1\SM_MOT

─ STARTUP.TXT → C:\SMWDATA

─ SIEB&MEYER-Format.SM5 → C:\SMWDATA

5. Click on the desktop icon "CNC 84" to start the operating software.

6. After software start you are prompted to log on. Enter the user name "SERVICE"

and the password "WORKER".

Fig. 5: Enter user name

WInstallation and Setup

CNC 8x.00 - Demo Kit 11

2

Fig. 6: Enter password

7. If a test mode prompt appears during login, click on "No"

Fig. 7: Do not start CNC in the test mode

8. Load the parameters from the provided parameter file "DEMOKIT.PAR".

Installation and Setup W

12 CNC 8x.00 - Demo Kit

2

Fig. 8: Parameter file

9. Click on "System ÿ File and directory setting ÿ Info and startup files". The

following window opens:

Fig. 9: Select startup file

10. Click on the button on the on the right to the field "Startup file" [A]. The file browser

of the operating software opens. Select the provided file "STARTUP.TXT". After

you have selected the file appears in the field "Startup file".

WInstallation and Setup

CNC 8x.00 - Demo Kit 13

2

11. Press the space bar of the PC keyboard to start calibration. After calibration you

are prompted to load a program.

Fig. 10: Calibration finished. Load production program.

12. Load the provided part program "SIEB&MEYER-Format.SM5" into the operating

software. Press <F2> on the PC keyboard or click on the button with the floppy

disk symbol [A]. The file browser of the operating software opens.

Installation and Setup W

14 CNC 8x.00 - Demo Kit

2

Fig. 11: Load production program

13. Select the part program "SIEB&MEYER-Format.SM5". Double click on the file

name or click on the button on right to the file and path name [B]. The programm is

loaded into the main storage of the CNC.

14. Press the space bar on the PC keyboard to start the simulated execution of the

part program. The software generates the graphic of the part program.

Fig. 12: Graphic of the part program

15. Press the space bar on the PC keyboard twice. The CNC works in the simulation

mode.

WInstallation and Setup

CNC 8x.00 - Demo Kit 15

2

Fig. 13: Simulation mode

Fig. 14: Simulation mode

Installation and Setup W

16 CNC 8x.00 - Demo Kit

2

3 Troubleshooting

During setup of the CNC 8x.00 Demo Kit errors might occur.

3.1 Network error

Fig. 15: Network error

Remedy

▶ Check the cable connections of the motion controller: Check the mains connection

and the Ethernet connection.

▶ Open the settings of the used network card and enter the IP address as shown in

the message (see section 2.1.1 "Setting the IP Address for the 2nd Network Card",

p. 7).

WTroubleshooting

CNC 8x.00 - Demo Kit 17

3

3.2 Tool Measurement Error

Fig. 16: Error during tool measurement

Remedy

▶ The tool measurement simulation could not be finished correctly.

▶Check, whether the startup file has been selected correctly. Click on "System ÿ

File and directory setting ÿ Info and startup files". The following window opens:

Fig. 17: Select startup file

Troubleshooting W

18 CNC 8x.00 - Demo Kit

3

This manual suits for next models

2

Table of contents