2. INTRODUCTION & SPECIFICATION

IMPORTANT: These instructions contain the information you require to prepare your machine for welding, together with a maintenance and a troubleshooting sec-

tion. The instructions are not intended to teach you how to weld. If you have no experience, we recommend that you seek training from an expert source. MIG

welding is relatively easy, but does require a steady hand and supervised practice on scrap metal, as it is only with continued practice that you will achieve the

desired results.

INTRODUCTION: Your Seigen Mig welder features a heavy-duty, high output transformer and forced air cooling to ensure the highest level of

performance. Suitable for welding with CO², Argon or CO²/Argon mix. Contoured grip, non live torch is comfortable in the hand, thus

ensuring a steadier weld bead. Includes, industrial gas regulator, starter spool of 0.6mm mild steel wire, 0.6 and 0.8 contact tips and gas cup. To weld steel you will

need CO²gas which is not supplied with machine. (To weld aluminium, order a roll of 0.8mm aluminium wire, a packet of 0.8mm contact tips, and a bottle of Argon

gas).

3. ASSEMBLY & PREPARATION

Stock Code:S0816 Welding Current.....................30 - 150A

Wire Capacity - steel ................................0.7 - 5.0kg

Wire Capacity - aluminium............................0.5 - 2.0kg

Duty Cycle .....100% @ 50A, 75% @ 55A, 50% @ 66A, 20% @ 105A

Cooling System .....................................Forced Air

Gas Type .........................CO²/Argon mix & Argon & CO²

Torch ..............................................Non-live

Power Input ........................................230V 1ph

Absorbed power........................................4.1kW

Stock Code:S0817 Welding Current.....................30 - 180A

Wire Capacity - steel ................................0.7 - 5.0kg

Wire Capacity - aluminium............................0.5 - 2.0kg

Duty Cycle .....100% @ 56A, 75% @ 65A, 60% @ 73A, 15% @ 145A

Cooling System .....................................Forced Air

Gas Type .........................CO²/Argon mix & Argon & CO²

Torch ..............................................Non-live

Power Input ........................................230V 1ph

Absorbed power........................................5.7kW

3.1. Assembly.

3.1.1 Depending on the model you have it may be necessary to assemble the wheels as follows. Slide the rear

axle through the loops on the underside of the rear tray. Slide a wheel onto each end of the axle and retain with the

washers and split pins provided. Attach the front foot to the underside of the welder using the screws provided.

Where castor wheels are specified these should be bolted to the underside of the welder using the fixings provided.

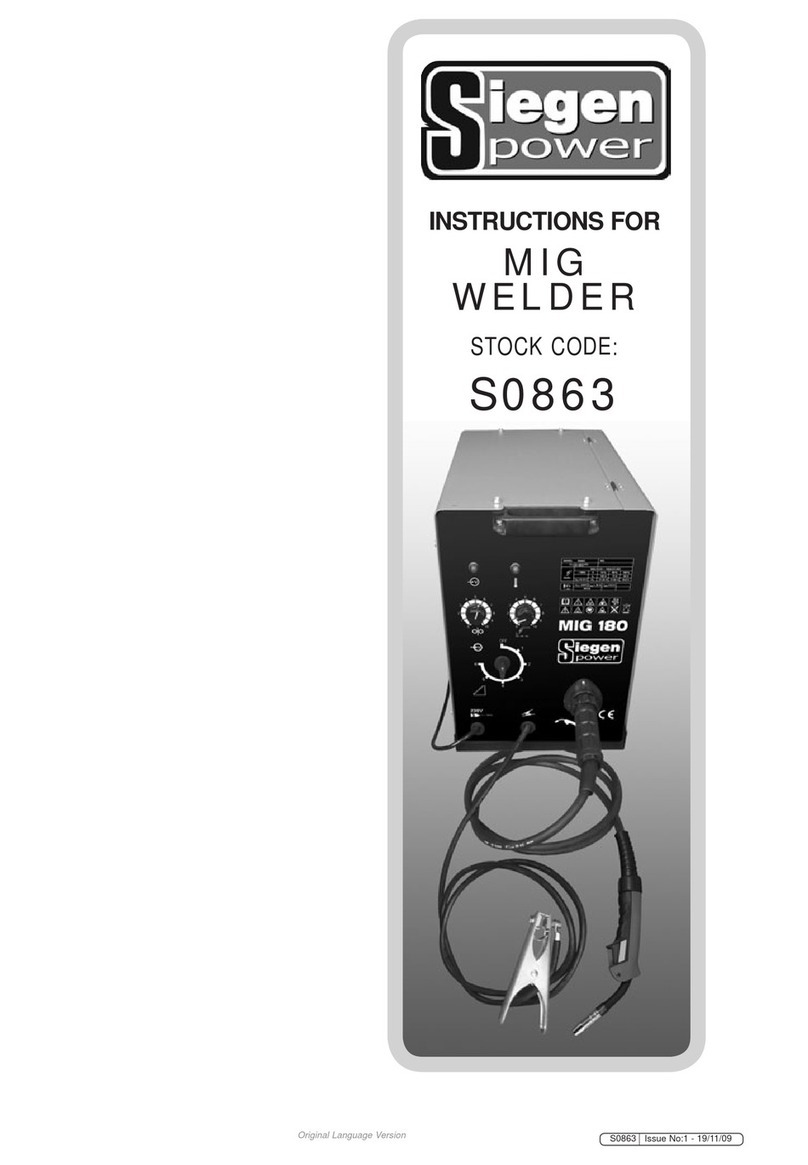

3.2. Connecting the gas cylinder (See Section 4.3 regarding gas types)

3.2.1. Place the lower end of the gas cylinder on to the rear tray, between the two wheels. See fig.2-C. Allow the upper part

of the cylinder to rest into the metal support. See fig.2-D. Secure the cylinder by hooking either end of the chain E

through the metal support as shown in fig.2.

3.3. Connecting the gas cylinder

3.3.1. When using Argon or Argon mixtures, you will need to use the “bull nose adaptor”. Fit the bull nose adaptor to the

cylinderwithaspanner.(IfyouintendtouseCO2gastheregulatorwilltdirectlyontothecylinder.)

332. Fitthegasregulatorontothebullnoseadaptorasshowning.1.

3.3.3 Pushtheblackgastubeprovided(seeg.2-A)ontothegasinletnozzleandretainitwiththewireclipprovidedas

showning.2-B.Pushtheotherendofthetubeontothegasoutletnozzleontheregulatorandretainitwiththeother

wireclipprovided.Seeg.1.

3.3.4. Whenyouarereadytoweldsettheregulatorowrateto5-8litres/mindependingonthematerialtobewelded,and

whethertherearedraughtswhicharestrongenoughtodisturbthegasow.

3.4. Fitting a reel of wire.

3.4.1 Depress the silver button behind the handle at the top of the control panel and open the top compartment. See 1 & 2

ing.3.Thewelderissuppliedwithaminispoolofmildsteelwire,butwillacceptspoolsofupto5kgwithoutmodication.

3.4.2. Referringtog.4,rotatethepressureknob(F)anti-clockwiseandremoveitfromthethreadedspindletogetherwith

the spring (E) and the top disc (D). Small reels of wire will run on the spindle itself. The larger 5kg wire reel will run

onthelargerdiameterangeatthebaseofthereelspindle(A).Placethewirereel(C)ontothespindleensuringthat

the wire withdraws from the spool in a forwards direction and on the same side of the compartment as the wire feed

unit. Place the plastic top disc (D) over the end of the spindle followed by the reel spring (E). Thread the pressure

knob (F) onto the end of the spindle and screw it down clockwise until the spring is partially compressed. The reel

take off pressure should be set to provide a mild braking effect to prevent overrun where loose coils of wire form on

thereel.Donotovertightenthisknobastoomuchbrakingwillconictwiththewiretensionsetonthewiredriveunit.

3.4.3. Referringtog.3turntheknobonthewirelockscrew(3)anti-clockwiseandunlatchitfromthepressureroller

moulding. Swing the pressure roller moulding (4) away from the drive roller.

3.4.4. Straighten 40-50mm of spool wire (do not allow wire to uncoil), and gently push wire through the plastic guide and

throughthe6or8mmfeedrollergroove(g.6)andintothetorchliner.Refertosection6.3onhowtoreversethe

roller for either 6 or 8mm wire.

DO NOT operate the welder if it or the cables are damaged and DO NOT attempt to fit any unapproved torches or other components to the welder.

DO NOT get welder wet or use in damp or wet locations or areas where there is condensation.

DANGER! DO NOT weld near flammable solids, liquids or gases andDO NOT weld containers or pipes which have held

flammable materials. Avoid welding materials which have been cleaned with chlorinated solvents or welding near such solvents.

DO NOT stand welder on a metal workbench, car bodywork or similar.

DO NOT touch any live metal parts of the torch or electrode while the machine is switched on.

DO NOT pull the welder by the cable, or the torch. Protect cables from sharp or abrasive items. DO NOT bend, strain or stand on cables or leads. Protect

from heat. Long lengths of slack must be gathered and neatly coiled. DO NOT place cables where they endanger others.

DO NOT touch the torch or workpiece immediately after welding as they will be very hot. Allow to cool.

DO NOT operate welder while under the influence of drugs, alcohol or intoxicating medication, or if tired.

When not in use store the welder in a safe, dry, childproof area.

1.3. GAS SAFETY

Store gas cylinders in a vertical position only and ensure the storage area is correctly secured.

DO NOT store gas cylinders in areas where the temperature may exceed 50°C. DO NOT use direct heat on a cylinder. Always keep gas cylinders cool.

DO NOT attempt to repair or modify any part of a gas cylinder or valve and DO NOT puncture or damage a cylinder.

DO NOT obscure or remove any official labels on a cylinder. Always check the gas identity before use.Avoid getting gas cylinders oily or greasy.

DO NOT lift a cylinder by the cap, guard or valve. Always keep caps and guards in place and close valve when not in use.

fig.1

fig.2

Original Language Version S0816, S0817 Issue: 2 - 10/02/10