H48.PSKLMS001EN/22.11.2013 Page 5

Important Instructions

– Please pay attention to our “Hardware for Sliding Doors and Windows” product information.

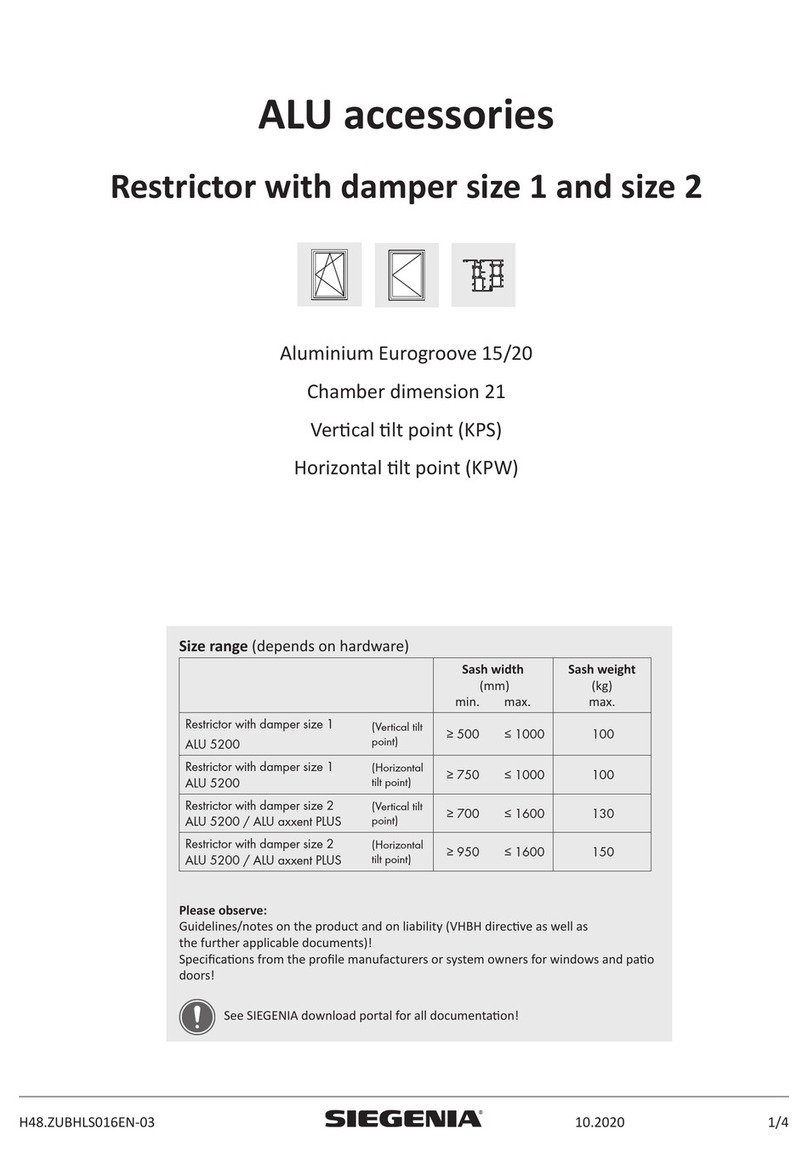

– For the PSK PORTAL 160 Plus LM fitting from SIEGENIA the size ranges detailed on page 1 apply.

Furthermore, the specifications provided by the profile manufacturers or system owners also apply, especially any information regarding

possible restrictions on sash dimensions, sash weight and lock spacing.

Observe any special manufacturing specifications or processing guidelines explicitly. The specifications given for screw-in speeds and torques

must be adhered to.

– If the parallel tilt & slide element is subjected to excessive strain, the sash can, in the worst case, jump and fall out of its guide and, in doing so,

cause serious injuries.

If it is expected that the parallel tilt & slide element will be subject to excessive strain from being closed with force (use in schools,

nursery schools, etc.), appropriate measures must be taken to prevent this from happening.

For example:

– move the stop to reduce the opening width or

– install a lockable handle to prevent unauthorised use.

In case of doubt, be sure to contact your SIEGENIA sales consultant.

– The fittings specified in these assembly instructions are electro-galvanised and finished using a special technique; they

comply with DIN EN 1670. They must not be used in environments where the air contains aggressive or corrosive components, or salt.

– Select your complete set of fittings only from the SIEGENIA range of fittings. Damage could otherwise occur, for which we accept no liability.

– All fittings must be properly mounted as per the description on pages 10 to 20. Do not overtighten the screws.

– The parallel tilt & slide elements may be surface treated only before the fittings are assembled. Treating these surfaces at a later stage can

reduce the functional capacity of the fittings. In such cases we are not obliged to provide a guarantee.

– When inserting blocks, be sure to observe technical guideline no. 3 published by the German Glazing Trade

[Glaserhandwerk], “Blocking glazing units” [Klotzung von Verglasungseinheiten].

– Never use acid cure sealants as they may cause the fittings to corrode.

– Keep the sliding bump (on the running rail) and all rebates free from deposits and dirt, especially from remnants of cement and plaster. Avoid

exposing the fittings directly to water and do not let cleaning agents come into contact with the fittings.

– Attach the instruction label (sliding direction DIN left

or DIN right) to the integrated parallel tilt & slide sash in a clearly

visible location.

The instruction label is located in “Carton PSK 160 LM.”

Remove the applicable segment from the respective label and

stick it to the window sash.

Disclaimer of liability

We assume no liability for loss of function of or damage to the fittings (or to the fitted parallel tilt & slide

elements) resulting from insufficient tendering, failure to follow these assembly instructions or force being applied to the fittings

(e.g. through improper use).

Hebelstellung PZ mit Hebel innen und außen

Handle position PZ with handle inside and outside

Position de avec poignée

intérieure et extérieure

poignée à cylindre

PSK PORTAL

DIN rechts

DIN right

DIN droit

04 87

Bitte den passenden Aufkleber ablösen und gut sichtbar am Parallel-Schiebe-Kippflügel anbringen.

Please remove suitable sticker and affix it in a clearly visible way to the sash of the installed parallel-tilt-sliding unit.

Retirer l´auto-collant pertinent et le placer bien visiblement sur le vanail coulissant.

Hebelstellung Standard

Handle position basic

Position standard del poignée

Hebelstellung wie Dreh-Kippbes hlag

Handle position as turn and tilt

Position de la poignée selon OB

Schiebestellung

Sliding position

Position coulissante

Verschlußstellung

Locked position

Position fermée

Kippstellung

Tilt position

Position pivotante

Schiebestellung

Sliding position

Position coulissante

Verschlußstellung

Locked position

Position fermée

Kippstellung

Tilt position

Position pivotante

Schiebestellung

Sliding position

Position coulissante

Verschlußstellung

Locked position

Position fermée

Kippstellung

Tilt position

Position pivotante

Hebelstellung PZ mit Hebel innen und außen

Handle position PZ with handle inside and outside

Position de avec poignée

intérieure et extérieure

poignée à cylindre

PSK PORTAL

DIN links

DIN left

DIN gauche

Material-Nr. 7004 88

Bitte den passenden Aufkleber ablösen und gut sichtbar am Parallel-Schiebe-Kippflügel anbringen.

Please remove suitable sticker and affix it in a clearly visible way to the sash of the installed parallel-tilt-sliding unit.

Retirer l´auto-collant pertinent et le placer bien visiblement sur le vanail coulissant.

Hebelstellung Standard

Handle position basic

Position standard del poignée

Hebelstellung wie Dreh-Kippbes hlag

Handle position as turn and tilt

Position de la poignée selon OB

Schiebestellung

Sliding position

Position coulissante

Verschlußstellung

Locked position

Position fermée

Kippstellung

Tilt position

Position pivotante

Schiebestellung

Sliding position

Position coulissante

Verschlußstellung

Locked position

Position fermée

Kippstellung

Tilt position

Position pivotante

Schiebestellung

Sliding position

Position coulissante

Verschlußstellung

Locked position

Position fermée

Kippstellung

Tilt position

Position pivotante

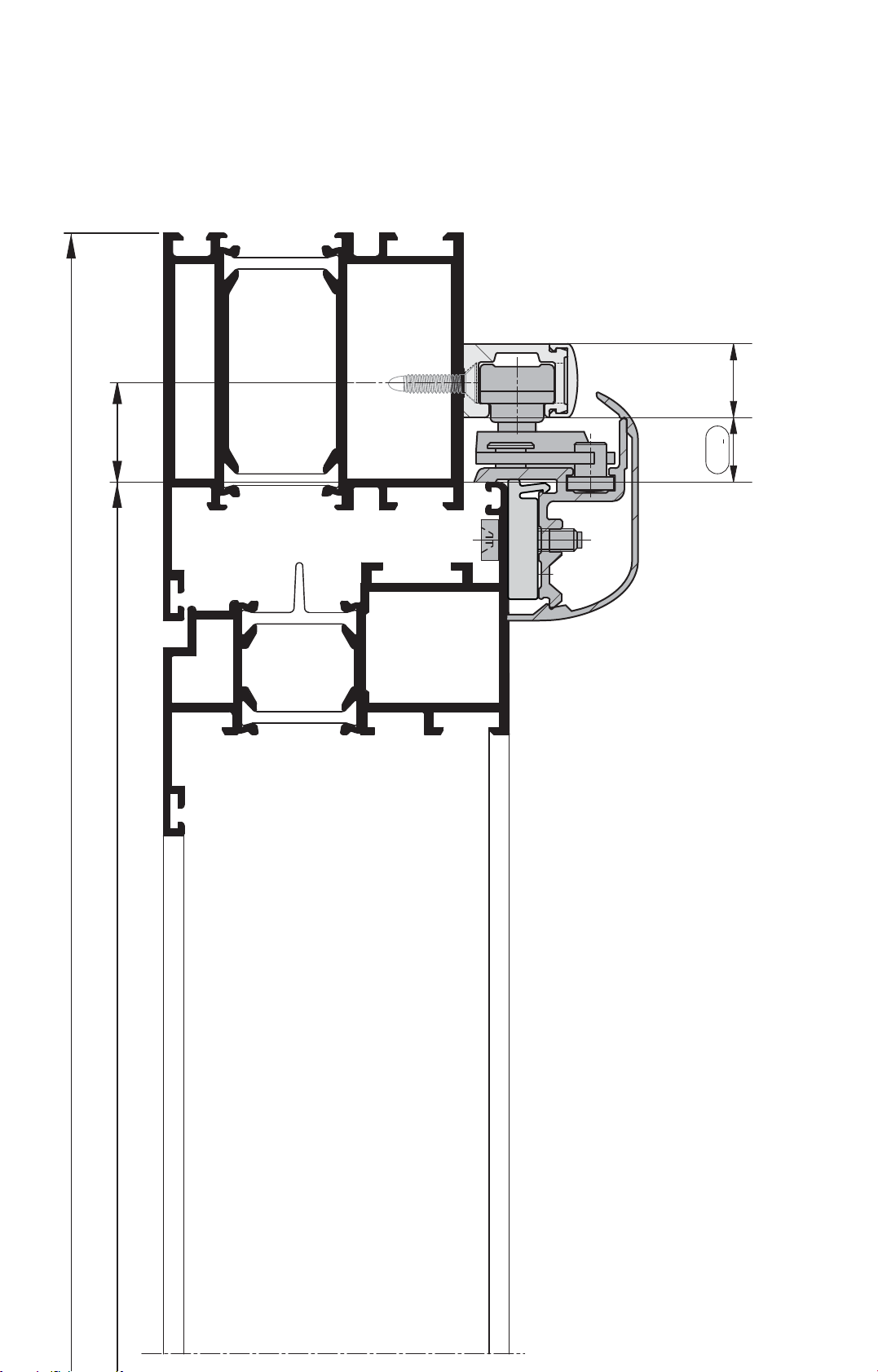

FGuidingrail

FB Sash width

FFB Sash rebate width

FFH Sash rebate height

FH Sash height

G Handle height

HRear

LBogiewheels

MMiddle

MV Centre lock

OKFF Finished floor level

PZ Profile cylinder

RAB Exterior width of frame

RAH Exterior height of frame

RFB Frame rebate width

SHeavyversion

S-ES Steel-enhanced security

SW Key dimension

ORH Over rebate height

VFront

VS Locking side

VSU Locking side, bottom

ZV Central locking part

Abbreviations

The following abbreviations are used in these assembly instructions:

Important instructions, abbreviationsPSK PORTAL 160 PLUS LM