Siegmund System 16 User manual

System 16

16002766

System 28

28004643

Table press

EN

Online

Bernd Siegmund GmbH

Landsberger Strasse 180

86507 Oberottmarshausen

Tel. 0049 (0) 8203 / 96 07-0

Fax 0049 (0) 8203 /96 07-33

info@siegmund.com

www.siegmund.com

2

TABLE OF CONTENTS

Table of contents 3

1. About this instructions 4

1.1. Validity 4

1.2. Symbols and markings 4

1.3. Used symbols on the unit 5

2. Safety instructions 6

2.1. Intended usage 6

2.2. Common safety instructions 6

2.3. Secure handling 7

3. Scope of delivery 8

4. Assemby 9

4.1. Structural requirements 11

4.2. Operating 12

4.3. Clamping hydraulic, extending and retracting 14

4.3.1. Extending 14

4.3.2. Retracting 15

5. Trouble shooting 16

5.1. Overload safetys 17

6. Maintenance and inspection 18

6.1. Maintenance 18

6.2. Inspections 19

6.3. Fire protection 19

7. Disposal 20

8. Technical data 21

8.1. Hydraulic diagram 22

8.2. Type plate 23

9. Warranty 23

10. Installation instruction 23

11. Notes 24

EN

3

1. ABOUT THIS INSTRUCTIONS

1.1. VALIDITY

1.2. SYMBOLS AND MARKINGS

The assembly and operating instructions are part of the product clamping hydraulic L12.11V5 and its

versions. (Consecutively referred to as unit.)

For damages and secondary damages caused by inobservance of the assembly and operating instructions,

Bernd Siegmund GmbH (consecutively referred to as manufacturer) will not assume any liabilities and

warranties.

• Please pay attention to the assembly and operating instructions prior to usage of the unit.

• Please read the safety instructions!

• Keep the assembly and safety instructions during the service life of the unit safely.

• Keep the assembly and safety instructions accessible to the operating personnel.

• Pass over the assembly and operating instructions to any subsequent owner of the unit.

• Illustrations, measurements and descriptions in this instruction are noncommittal.

Subject to change without notice.

This assembly and operating instructions are valid for the products shown on the cover page only.

For assembling and operating of appropriate attachments, consider their assembly and operating

instructions accordingly.

Structure of written warnings

SIGNALWORD

Mode and source of the hazard (Physical damage)!

Possible effects (Optional).

→Procedure for damage avoidance.

INSTRUCTION

Instruction text.

• Instruction list.

→ Procedure.

4

Danger Levels in warning notes

Other symbols and markings

WARNING LEVEL CHANCE OF INCIDENCE

CONSEQUENCE BY INOBSERVANCE

DANGER Imminent Danger Death, serious physical damage

COUTION Possible Danger Possible physical damage

ADVICE Possible Danger Material damage

SYMBOL/MARKING MEANING

Requirement

→Action in one step

1.

2. Action with more steps in subsequent order

• Numeration (first level)

..., see capture xxx Page xx Cross Reference

1.3. SYMBOLS USED ON THE UNIT

Warning and order signs according to ASR A1.3 (old/new) / DIN 4844-2 / DIN7010

→ Indication of jamming possibility during operation

Total usage 1 x (see Pic. 1):

• Clamping spot/Lever/Lever Absorption

Caution of Hand Damage

NOTICE

→ Pay attention during usage, that all symbols are completely readable.

→ Possible clamping spots while retracting optional accessories should be marked by

the operator.

5

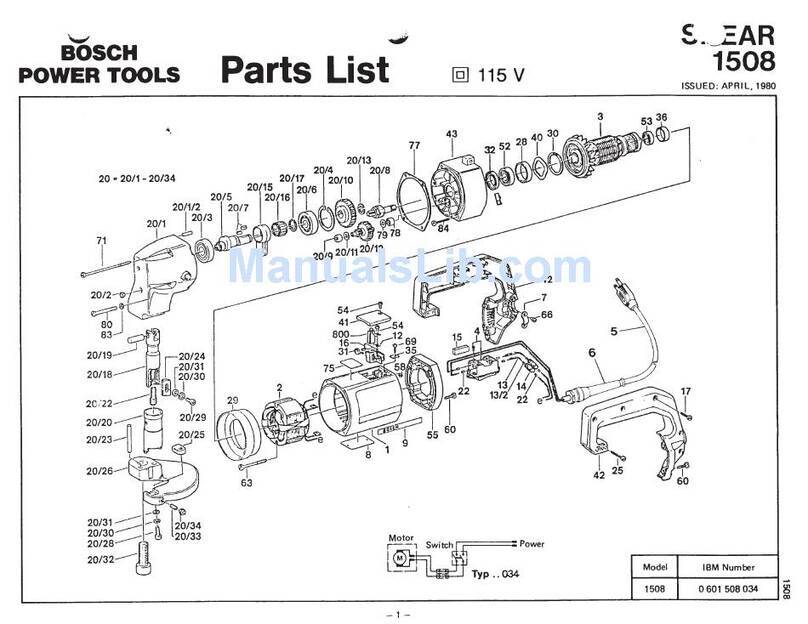

Pic. 1: Instructions (Pic. Shows Version 28)

Lever

Lever Absorption

Clamping Spot

Clamping

2. SAFETY INSTRUCTIONS

Pay attention to the following instructions to avoid malfunction material

damages and physical damages

2.1. INTENDED USE

2.2. COMMON SAFETY INSTRUCTIONS

The intended use of the unit is the clamping of work pieces with a clamping force of max 25.000 N inside

an external absorption. The unit itself is unable to absorb any radial forces.

• The unit is used in a dry internal area with normal room temperature.

• The unit is not suitable for lifting and bearing loads.

• The unit is not approved for EX protected areas.

• The unit is not approved for the use inside machine tools.

• The unit is designed for central power transmission of the piston rod.

Pressure holding time 30 minutes.

• Protection of work pieces (position/overhead clamping) against dropping out is not allowed inside

a fixture or machine

→ Keep packing material away from children. Danger of choking!

→ Read this assembly and operating instructions carefully prior to initial operation.

→ Secure the proper installation of the unit in the destined application prior to initial operation or

maintenance work.

6

→ Correct handling and paying attention to the assembly and operating instructions are essential for

the productivity reliability and work security.

→ If the unit shows damages or leakings, it shoud be shut down immediately.

→ The maximum intendet clamping force is 25 KN, it must not be exceed. Exceedings can leed to

serious damage on the unit and physical damages.

→ The unit is equipped with a bursting element. While using the unit as alignment as well as while

applying external forces, the bursting element will provide safety to the user.

→ The manufacturer declares liability exclusion for physical and material damage caused by

incorrect use of the unit.

→ Alterations of the original condition of the unit or self-made repairs will result in expiration

of any warranty.

→ Never work below clamped loads, if additional security measures are not provided. Please regard,

woring below clamed loads is always dangerous even if additional security is applied.

→ Do not repair the unit by yourself, repair work should be done by a qualified technician.

2.3. SECURE HANDLING

→ While using the unit, please check that the piston rod is holohedral and centered effecting the used

absorption and that the alignment points are secured. A outcentered stress can lead to damages on

the unit and danger to individuals.

→ While retracting the piston rod, the operator and other persons must stay out of the danger zone.

→ Pay attention to the warning instructions of the manufacturer.

→ The unit should be operated by people trained in the use of the unit only

.

→ Before using the unit, free your hands of all things (Tools, for instance) causing potential injuries.

→ Remove possibly leaking oil immediately. Slip danger.

→ Operate unit with the provided levers, hand lever and lowering lever only.

→ Transport the unit in retracted condition only.

→ Don’t store the unit loosely, store it secure to avoid tilding and falling dawn.

→ The Unit consists partly of moving parts. If not used properly, there may be danger of squeezing.

7

1

CAUTION

Slight risk of injury

• During transportation, don’t carry the unit on the rubber grommt of the lever.

It could loosen and the unit may fall down.

• Wear safety clothes and safety equipment while operating hydraulic units.

• Wear protective gloves and safety shoes while working with the unit.

• Don’t stay directly over the pump handle to avoid being hit from a possible

kickback of the handle. Stay sideways to the pump to keep your body out of the

moving path of the handle.

• Consider the marked clamping spots (Pic. 1).

3. SCOPE OF DELIVERY

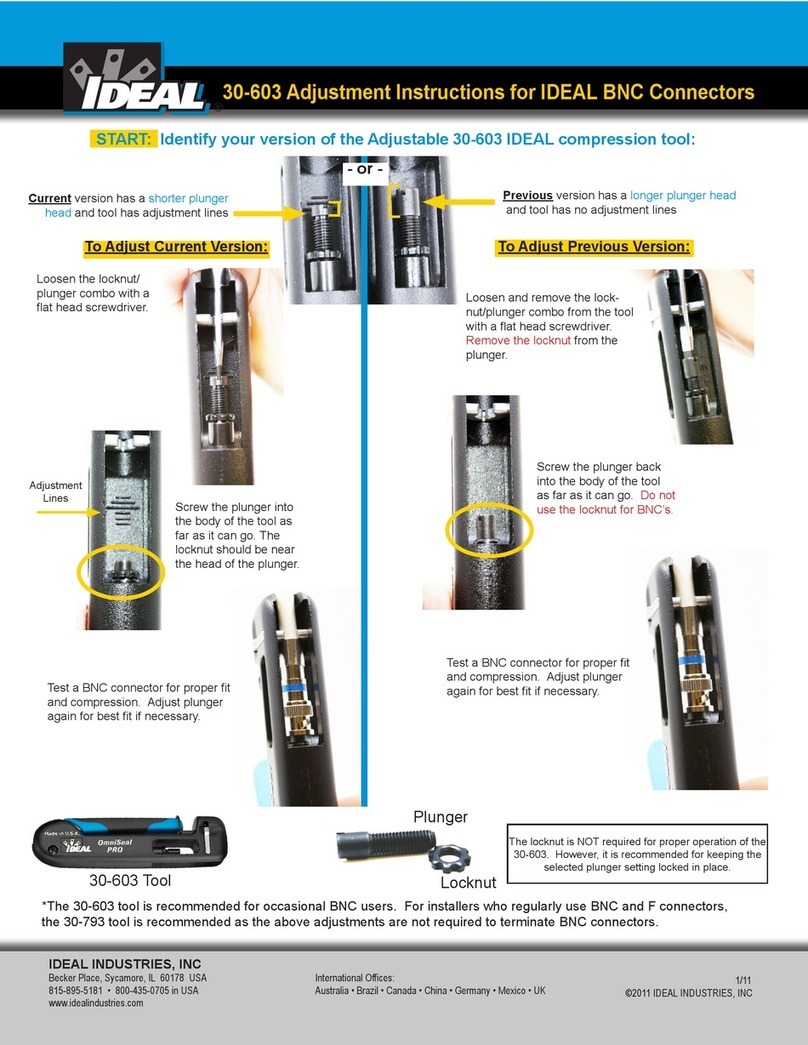

Pic. 2: Example scope of delivery Version 28

(Picture shows the unit without customer specification)

Tab. 1: Scope of delivery and description

PART NO. DESCRIPTION QUANTITY

1Clamping hydraulic 1

Optional attachment parts on request

8

NOTICE

Mounting absorptions are not included in the scope of delivery and should be coordinated

individually with the manufacturer.

4. INSTALLATION

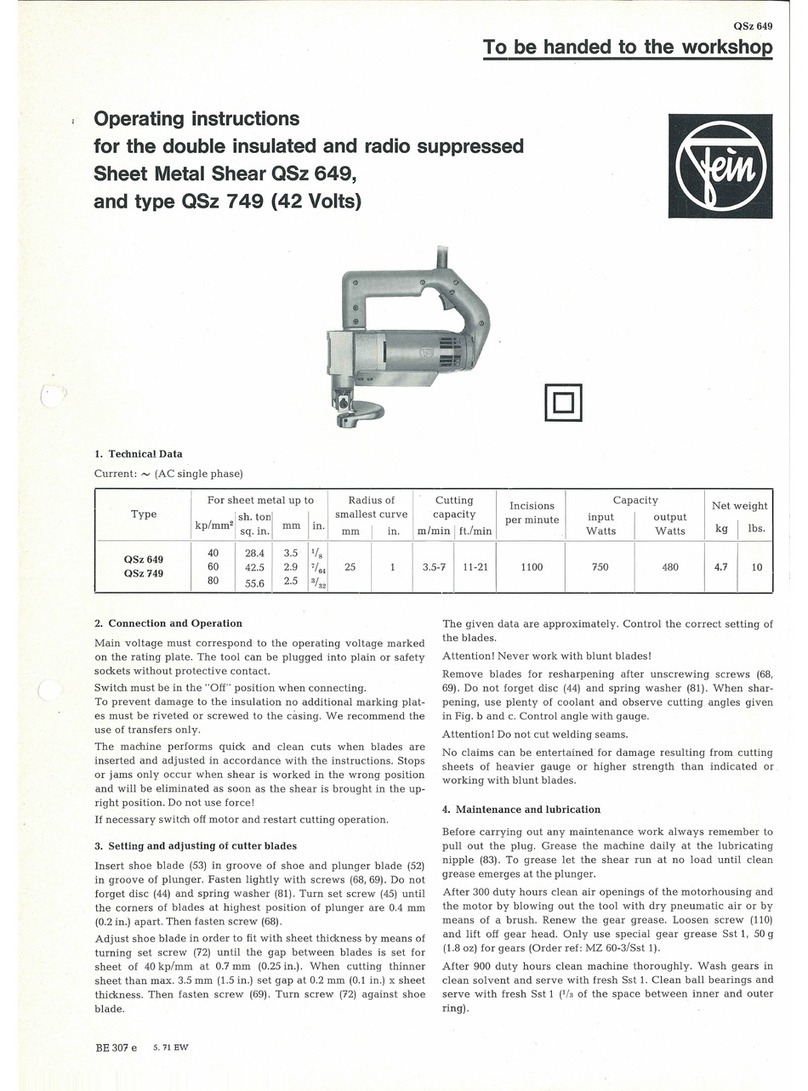

The lever is split in two parts for smoother handling (Pic. 3).

Please use the machined area of coverage on the lever to firmly screw it on to the absorption.

Use strong alignments and absorptions according to the emerging forces.

For mounting absorptions, use the mounting positions shown in Picture 4 only.

In case you need other alignment spots, please contact the manufacturer.

M10 standard thread

Spanner flat 13 mm

Spanner flat lever

Pic. 3: Lever assembly

NOTICE

• The unit is designed to apply axial thrust. The unit is not suitable for special applications

with aberrant forces (Cross forces) and o center support and the manufacturer disclaims

any liability.

• Pay attention to clean component parts if you are mounting and dismounting the lever

repeatedly. Unclean threads may result in a higher wear and/or damage on the thread.

• Comply with the accident prevention regulations when mounting the unit.

9

60

85

25

30

25

44 -0,2

44 -0,2

-0,05

28 -0,1

36,5

36,5

50+0,1

100+0,05

146

50+0,05 50 +0,05

146

16

28 H10

H10

22

44 -0,2

30

12

-0,05

16-0,1

M6 x 12 tief (5x)

12

16

24

29

12

M12

SW30

ø32

CAUTION

Danger of physical damage, caused by oil spillage

Danger of physical damage, caused by loosened lever

• Don’t drill additional holes in to the unit to install additional absorptions!

• Wear safety glasses to avoid eye injuries!

• The hand lever is moving. Pay attention when mounting the unit to avoid

squeezing of skin parts.

• Wear safety gloves when mounting the unit to avoid personal injuries

.

• Always pay attention that the lever is screwed down firmly. A loose fitting lever

is increasing the risk of physical damage.

Version 28 Version 16

Front Absorption

Piston rod, wrench size 30 mm

Pic. 4: Illustrations

10

The front absorption on Version 16 and Version 28 is designed rotatable. By turning in any direction,

one can switch between two different alignment positions. The alignment is locking 90° shifted.

Pic. 5: Illustration

4.1. STRUCTURAL REQUIREMENTS

• Prior to installation, make sure that the installation measurements and installation conditions

are matching the components of the unit.

• Mount the unit only to the intended absorptions of the unit (Pic. 4).

• Use sufficient dimensioned clamping bolts.

• The clamping bolts must be fitted with clearance in to the absorptions of the unit.

• Don’t apply additional forces to the unit during the installation.

• Construction dimensions see Pic. 6.

• When designing the complete system, consider the EN 1005-3.

• Require the appropriate installation drawing from the manufacturer prior to installation of

you customized unit.

11

Version 16

1:5 Version 28

1:5

238

16

ø32

pumpen

ca. 75°

ca. 324

ca. 20°

senken

100

~287

256

146

60

2460

Pic. 6: Construction Dimensions

4.2. OPERATING

Operate the unit with the hand grip of the pump lever and with the down lever.

→ While operating the unit, wear safety gloves.

→ Utilize the complete support area and length of the pump lever to avoid ergonomic

unfavorable positions. (Lever coating).

→ Both levers are spring recessed, don’t let them snatch.

pump

about 75°

lower

approx. 20°

approx. 324

12

CAUTION

Obstructions during extending and lowering can lead to squeezing!

→ Prior to operating the operating lever, make sure no obstructions are blocking the

travelling distance.

NOTICE

Pay attention to clean and dry operating elements while operating the unit.

Lower lever

Pump lever

Support area

Pic. 7: Operating

13

ca. 75°

pumpen

ca. 20°

senken

4.3. CLAMPING HYDRAULIC, EXTENDING AND RETRACTING

Pic. 8: Functional area of the pump lever and lowering lever

4.3.1. EXTENDING

1. Push the pump lever in regular working speed up to the stopper in pumping direction.

Max. 75° (Pic. 8)

The piston rod executes a stroke movement. According to the travelled angle area, it will

lead to the max. stroke or proportionate smaller.

The possible pump area is limited by a stopper. Quit pumping on arriving at the stopper.

The pump lever is repressed by spring force in to the initial position. Relieve the lever.

The pumping chamber will be filled anew. The unit is ready for a new stroke movement.

According to the travelled angle area in the back movement the following possible stroke

movement will be up to the maximum stroke, or respectively shorter.

2. Ending the pump movement will result in ending the stroke drive. The position of the piston

rod will not change.

lower

approx. 20°

pump

about 75°

14

3. With reaching the upper stop position, no additional pressure will build up. The force on the

pump lever stays unchanged. The piston rod may move a little over the end position and will

then lower just about 2 mm. This is a normal operating condition.

The unit is in any positon (360°) applicable, utilizing the complete stroke length.

Should an angle or construction part on which you put pressure with the table press bend

more than 4 mm please stop putting on pressure.

NOTICE

Depending on pressure and stroke, the actuating force during pumping will change.

Adapt your working speed to the necessary power and your physical condition.

4.3.2.RETRACTING

When actuating the lowering lever, the unit will retract by spring return without actuation force.

1. Retracting and release of the work piece will be activated by pushing the lowering lever (Pic. 5).

There will be a release valve opened and the oil flows from the pressure chamber back to the

tank room. The unit lowers while the piston rod reverses.

2. When you release the lowering lever and turn the lever back, the lowering movement will stop.

The release of the lowering lever is activated by an integrated spring. The lowering movement

will end immediately, the piston rod stays in its current position.

Retracting is also position independent possible.

CAUTION

Physical damage trough sliding or squeezing danger

• Squeezing danger: While lowering, the piston rod will retract to the stopper.

Your hand and/or parts of your skin may be squeezed in.

max. 4 mm

Pressure

15

CAUTION

Obstructions during extending and lowering can lead to squeezing!

Squeezing danger: During lowering the piston rod will accelerate by applied forces.

High force and high speed can develop.

5. TROUBLESHOOTING

DISTURBANCE CAUSE SOLUTION

Short-term pressure build

up only

Over travel of the overflow Operator tries to create tension with far

extended piston rod.

Max. stroke reached The overflow is over traveled during

pressure build up. This results in an

immediate pressure loss. The piston

rod travels the length of the excess

to the overflow back, about 2 mm.

Pressure will not build up Safety valve is responding Ensure intended use!

Hydraulic unit polluted Keep the lowering valve open and try

pumping several times.

Repeat this procedure several times.

Pumping jerkily with open and closed

lowering valve. Produce strong internal

oil flow to flush pollutants of the valve

seating.

Repeat this procedure several times.

Unit does not hold the

pressure

Drain valve not fully closed Check drain valve if contamination

prevents complete closing.

16

FEHLER URSACHE LÖSUNG

Unit does not keep Pressure Hydraulic system may

be polluted

Pumping jerkily with open and closed

lowering valve. Produce strong internal

oil flow to flush pollutants of the valve

seating.

Repeat this procedure several times.

Temperature fluctuations The unit is a closed system which is

acting to temperature fluctuations

because of its tightness.

While cooling down (overnight, par

example) the clamping pressure may

change. The work piece may loosen!

This is not a default of the unit!

Keep the surrounding temperature

constant.

Piston rod is bucking,

hardly retracting

Attachment parts may be

to heavy

The spring force is strongest at maxi-

mum stroke and declines at reduced

stroke accordingly. Reduce the weight

of the attachments.

Polluted piston rod Clean the piston rod.

Piston rod does not extend Safety valve is responding Maximum clamping pressure reached

No stroke without load Bursting element responding

See chapter 5.1

5.1. SAFETY VERSUS OVERLOAD

The unit is fitted with two systems safeguarding overload caused by excessive hydraulic pressure.

SYSTEM 1

Pressure safety with pressure control valve (DBV)

The pressure control valve secures the unit against excessive pressure, which is applied from the

operator with the hand grip. The DBV opens and prevents an excessive hydraulic pressure inside

the unit.

The DBV is closing automatically responding to relevant lower pressure. The unit stays functional.

17

SYSTEM 2

Pressure safety with bursting element

Bursting elements are pressure protections which secure pressure leading systems against dangerous

excess pressure. It occurs in bursting of a bursting disc, which is consisting of metal foil.

In case of the acting of an external force to the piston rod, by example an additional hydraulic,

an excessive distortion of the work piece, the pressure safety will be destroyed.

The bursting disc is responding to a force of 36000 N axial to the piston rod. The piston rod retracts

according to the effecting load completely and stays functional.

For replacement, please contact your distributor.

CAUTION

Manipulation on the safety valve!

→ The unit is on the side of the piston rod and on the pump piston side secured against

over loading through a safety valve. Manipulation may lead to damages on the unit

and/or physical damages to people.

6. MAINTENANCE AND REVISION

6.1. MAINTENANCE

The unit is basically maintenance free.

CAUTION

When leaking fluids, there is an increased fire hazard and an increased danger

of slipping!

→ Check the unit leak tightness prior to each utilization.

→ By noticing abnormalities, don’t utilize the unit and contact your distributor.

→ Check the unit about damages and defects.

→ Don’t use a damaged product.

→ Check the optical condition of the coating and the existing of the operating elements.

18

DANGER

Pre stressed spring!

Injuries caused by the pre stressed spring unit.

→Never open the unit without appropriate protection!

NOTICE

Damage of the unit trough self-repair!

→ Contact your distributor in case of repair.

→ Order spare parts through you distributor only.

→ Retain a specialist, trained on this unit.

NOTICE

This hydraulic unit is a closed system, there is no additional maintenance

required.

→ The unit doesn’t possess an oil filling screw.

→ The oil level cannot be checked .

NOTICE

→ Because of the aging effect of the seal material, the seals should be replaced

every 6 years.

→ Contact your distributor.

→ Do not open any screw on the unit for checking or refilling oil.

Replacement of the seals

Hydraulic fluids are predominantly inflammable. In case of leaking of the unit and contact of the fluid to

open fire or hot surfaces it can ignite.

Make sure that initial fire can be extinguished with a suitable extinguishing agent.

→ Suitable extinguishing agent: Foam, extinguishing powder, carbon dioxide, sand, water fog

→ Non suitable extinguishing agent (safety reason): Waterjet

6.2. REVISION

6.3. FIRE PROTECTION

19

Disposal of the hydraulic and oil

Packaging material should be conveyed to an environment friendly recycling.

7. DISPOSAL

DANGER

Pre stressed spring!

Injuries caused by the pre stressed spring unit.

→ Open the unit only if appropriate safety measures are applied to the

construction elements.

→ Retract the piston rod to reduce oil pressure and spring tension.

Pre stressed springs

F = 400 N

Pic. 9: Disassembling

→ Wear safety clothing and protection equipment while working with hydraulic devices (safety gloves,

eye protection).

→ Regard the accident prevention regulations while disassemble the unit.

→ The unit consists of different materials which can be homogeneous separated:

• Aluminium

• Steel, galvanized

• Steel, untreated

• Elastomer

• Plastics

• Oil

NOTICE

→ When opening the unit, oil is leaking. Please collect the oil in a suitable container.

→ Recycle used hydraulic oil environment friendly !

→ National regulations about environment protection and work safety are regulating the

disposal of oil and the handling of used oil. Pay attention to those regulations!

20

This manual suits for next models

3

Table of contents