Sielco Elettronica D1-15A User manual

D1-15A analog module

User’s guide

D1-15A analog module

User’s guide

Version: 11 February 2003

Sielco Elettronica S.r.l.

via Edison 209 20019 Settimo Milanese (MI ) – Italia

http://www.sielcoelettronica.com

info@sielcoelettronica.com

Tel.+39 ( 0 )2 48916252

Fax +39( 0) 2 45329627

Contents

1 Installation.................................................................................................................1

1.1 Packaging check .......................................................................................................... 1

1.2 Dimensions.................................................................................................................. 2

1.3 Fixing method ............................................................................................................. 2

1.4 Physical module description........................................................................................ 3

1.5 Supply.......................................................................................................................... 4

1.6 Inputs........................................................................................................................... 5

1.6.1 Analog inputs for linear sensors................................................................... 5

1.7 Serial communication.................................................................................................. 6

1.7.1 Serial link ..................................................................................................... 6

1.7.2 Communication protocol.............................................................................. 7

1.7.3 Device identification .................................................................................... 7

1.7.4 Serial cable ................................................................................................... 8

1.8 Earth wiring and shielding .......................................................................................... 8

1.8.1 Earth wiring.................................................................................................. 8

1.8.2 Linear sensor wiring..................................................................................... 8

2 Operation...................................................................................................................9

2.1 Application .................................................................................................................. 9

A Gates list................................................................................................................. 10

A.1 Numeric Gates (Holding Registers) ......................................................................... 10

1.1 Packaging check

1

1 Installation

1.1 Packaging check

Before starting installation, it is necessary to check that the packaging

contents is in compliance with your order. In the packaging there must be:

- # 1 D1-15A series module

- # 1 instruction manual

Check that the model code is in compliance with the ordered code and

verify that the manual edition correspond to the purchase year.

The models are:

D1-15A 6 voltage sensors (from 0 to 10 V) or current sensors (from 0

to 20 mA), individually selectable by jumpers

Analog inputs have the following features:

- Precision : ±0,05 % full scale

- Resolution : 15 bit

- Input impedance (0-20mA): 20 ohm

D1 series modules are covered by 1 year of warranty except for damages

caused by tampering or wrong wiring.

The label on the modules backside certificates the purchase date.

1 Installation

2

1.2 Dimensions

The D1-15A modules dimensions are shown in figure 1.1.

Figure 1.1 - D1-15A module dimensions

1.3 Fixing method

All D1 series products are provided by a plastic support for fixing on

normalized DIN EN rail and by a shielding serigraphed cover.

On the cover there are schematic mounting indications; in grey areas are

shown the interface circuits that are inside the module, in yellow areas

common use sensors and actuators to be connected externally.

The cover serigraph provides only a general wiring diagram and cannot

show every possible connection cases; for this reason it is necessary to

read carefully this manual before starting module installation.

Do not use excessive pressure on the cover, mounting or dismounting the

module on the rail. Remember to do these operations with supply voltage

switched off or not connected.

1.4 Physical module description

3

1.4 Physical module description

Figure 1.2 - D1-15A scheme

1 Installation

4

Description

[C1] RS422/485 serial channel connector

[C2] +24 Vdc supply connector

[M1] Analog inputs screws

[M2] Analog sensors inputs screws

DIPSW Protocol and device address selection dipswitch

Led LA Supply led

Led LM Selftest led (normally blinking)

Led TX Transmitted data led

Led RX Received data led

422 485 RS422 or RS485 line selection jumper

[C1] - RS422/485 serial channel connector

RS422

RS485

1

RX– 1

N.C.

2

RX+ 2

N.C.

3

TX– 3

TX–/RX–

4

TX+ 4

TX+/RX+

[C2] - +24 Vdc supply connector

POWER

1

+24 Vdc

2

FIELD GND

3

MECH. GND

1.5 Supply

The module needs a 24 Vdc (18V < Vdc < 36V) supply by [C2] connector

and absorb a maximum current Icc=70 mA at 24 Vdc.

The negative power supply must be connected to pin #2 of [C2] connector.

After power is turned on, check that LA led is on.

1.6 Inputs

5

1.6 Inputs

1.6.1 Analog inputs for linear sensors

To D1-15A series modules can be connected 0-10V or 0-20mA/4-20mA

linear sensors. Input channels can be configured individually as voltage or

current using jumpers from J15 to J20 (closed for current inputs).

For a 0-10V output sensor connection connect, for each set of three screws,

positive sensor signal to the screw called IN and the negative sensor signal

to the 0V one, as shown in figure 1.3.

0 -10 V

1

2

3

+24 IN 0V

+ -

Figure 1.3 - 0-10V linear sensor wiring

For a current output sensor connection, it is necessary to distinguish 2

cases:

A) linear sensor supplied by the D1-15A module; supply the sensor

through the screw called +24V and connect the sensor signal to screw

called IN (fig. 1.4A);

B) linear sensor esternally supplied; supply the sensor through an

external power source and connect its negative to the screw called 0V

and connect sensor signal to the screw called IN (fig. 1.4B).

Figure 1.4 - Connection of 4-20 mA linear sensors supplied by the D1-15A

module (case A) or by an external power source (case B)

1 Installation

6

In case of disturbance, can be useful to use shielded cable and connect the

cable shield to the screw called 0V.

1.7 Serial communication

1.7.1 Serial link

To connect to D1 modules, it is necessary to use a RS422/485 serial

interface that usually are not standard equipment in personal computers.

SIELCO produces C1-25 model, a RS232-RS422/485 serial interface

converter with triple optical isolation that can be connected to PC serial

port (COM) and to D1-15 [C1] connector as shown in table 1.1.

C1-25 D1-15A

# RS-422 RS-422 #

1 GND ←→ GND 2 C2

2 RX– ←→ TX– 3 C1

3 RX+ ←→ TX+ 4 C1

4 TX– ←→ RX– 1 C1

5 TX+ ←→ RX+ 2 C1

6 0 V

7 +24 V

C1-25 D1-15A

# RS-485 RS-485 #

1 GND ←→ GND 2 C2

2 n.c. n.c. 1 C1

3 n.c. n.c. 2 C1

4 TX–/RX– ←→ TX–/RX– 3 C1

5 TX+/RX+ ←→ TX+/RX+ 4 C1

6 0 V

7 +24 V

Table 1.1 - C1-25 - D1-15A (RS 422/485) wiring

D1-15A modules are provided with configurable serial interface

RS422/485, normally configurated as RS485. To change configuration you

have to move the 422/485 jumper placed upper on the printed circuit

board.

1.7 Serial communication

7

1.7.2 Communication protocol

Software communication protocol is realised according to ModBus ASCII

or RTU standard: protocol selection is made by #2 selector of dipswitch

(ON=RTU, OFF=ASCII).

The baudrate selection is made by #1 selector of dipswitch (ON=19200,

OFF=9600).

ASCII protocol features

Baud rate 9600 / 19200

Data bits 7

Parity bit even

Stop bit 1

RTU protocol features

Baud rate 9600 / 19200

Data bits 8

Parity bit none

Stop bit 1

NOTE

At power on, the device waits 4 seconds to communicate.

1.7.3 Device identification

To D1-15A can be assigned an identification address between 1 and 31

through binary notation, using selector from 4 to 8 of dipswitch (see table

1.2).

ADDRESS

1 2 3 4 5 6 7 8

BAUD PROT.

252423222120

ON

19200

RTU

OFF

9600 ASCII

Table 1.2 - Address configuration using dipswitch

NOTE

Address 0 is reserved.

1 Installation

8

1.7.4 Serial cable

Use shielded cable with one (RS-485) or two (RS-422) twisted pair in

compliance with EIA RS-485 or EIA RS-422; using the shield for ground.

Recommended cable: Belden 9841 (RS-485);9842 (RS-422)

Maximum signal loss: 6 dB

Maximum line capacitance: 100 nf

Maximum line length: 1200 m

Line impedance: tra 100 e 120 ohm

1.8 Earth wiring and shielding

1.8.1 Earth wiring

It is suggested to make the following earth:

- device mechanical ground (pin #3 of [C2] connector) goes

directly to earth;

- the power supply negative signal (pin #2 of [C1] connector)

must be connected to a local earth.

It is important that device grounds are connected to earth independently; it

is also important to avoid to share the same wire path with power devices

as inverter, drives etc.

1.8.2 Linear sensor wiring

Follow these shielding rules particularly in environment noise affected by

power devices (motor driver , power contact etc.).

- use shielded and twisted cables for sensors connection;

- keep connection cables as short as possible;

- it's better to make differents canalizations for analog signals

and power signal conductors;

- connect all sensors cable metal shields at pin 3 of [C2]

connector;

2.1 Application

9

2 Operation

2.1 Application

D1-15A module is provided with 6 analog inputs

Analog signals can be voltage (0-10 V) or current (0-20 mA); in the first

case the acquired value is recorded on a range from 0 to 10000; for

example the value of 7500 means 7.500 Volt (V1, …, V6 gates). In current

input case, the acquired value is recorded on a range from 0 to 20000 and

for example the value of 12000 means 12.000 mA(C1, …, C6 gates).

Numeric values are available through the numeric reading gates (N1, …,

N6 gates).

Error gates indicate the presence of an input signal reading

"Restart number" gate is only for diagnostic use and gives an indication of

the electrical disturbances presence.

A Gates list

10

A Gates list

A.1 Numeric Gates (Holding Registers)

Address Description ID Byte Limits R/W

00 Restart number Rs 1 0: 255 R/W

08 Channel #1 numeric value N1 2 0 - 32767 R

09 Channel #2 numeric value N2 2 0 - 32767 R

10 Channel #3 numeric value N3 2 0 - 32767 R

11 Channel #4 numeric value N4 2 0 - 32767 R

12 Channel #5 numeric value N5 2 0 - 32767 R

13 Channel #6 numeric value N6 2 0 - 32767 R

14 Channel #1 voltage value (mV) V1 2 0 - 10000 R

15 Channel #2 voltage value (mV) V2 2 0 - 10000 R

16 Channel #3 voltage value (mV) V3 2 0 - 10000 R

17 Channel #4 voltage value (mV) V4 2 0 - 10000 R

18 Channel #5 voltage value (mV) V5 2 0 - 10000 R

19 Channel #6 voltage value (mV) V6 2 0 - 10000 R

20 Channel #1 current value (µA) C1 2 0 - 20000 R

21 Channel #2 current value (µA) C2 2 0 - 20000 R

22 Channel #3 current value (µA) C3 2 0 - 20000 R

23 Channel #4 current value (µA) C4 2 0 - 20000 R

24 Channel #5 current value (µA) C5 2 0 - 20000 R

25 Channel #6 current value (µA) C6 2 0 - 20000 R

25 Analog errors eA 1 00h:FFh R

A.1 Numeric Gates (Holding Registers)

11

Analog errors – eA

(for each bit: 0 = OK / 1 = KO)

bit 0 10V reference

bit 1 Analog #1

bit 2 Analog #2

bit 3 Analog #3

bit 4 Analog #4

bit 5 Analog #5

bit 6 Analog #6

bit 7 Analog #7

Table of contents

Other Sielco Elettronica Control Unit manuals

Popular Control Unit manuals by other brands

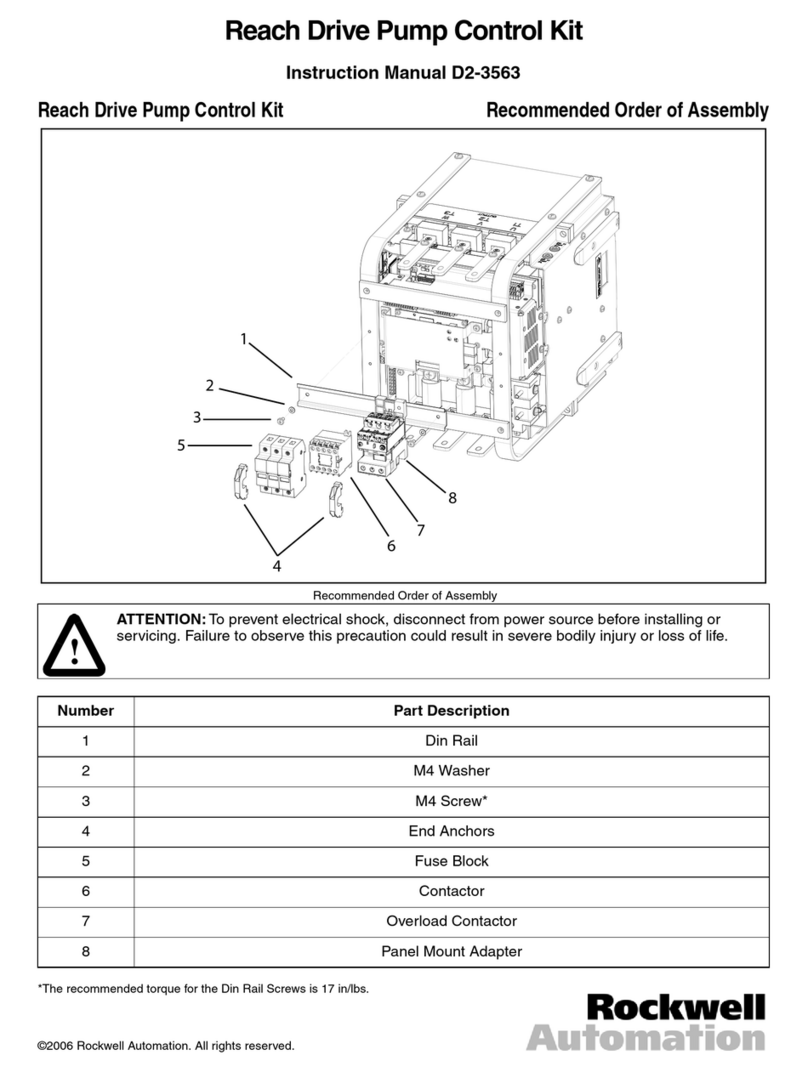

Rockwell Automation

Rockwell Automation D2-3563 instruction manual

Sharp

Sharp NU-JC410 installation manual

Quectel

Quectel MC60-TE-A user guide

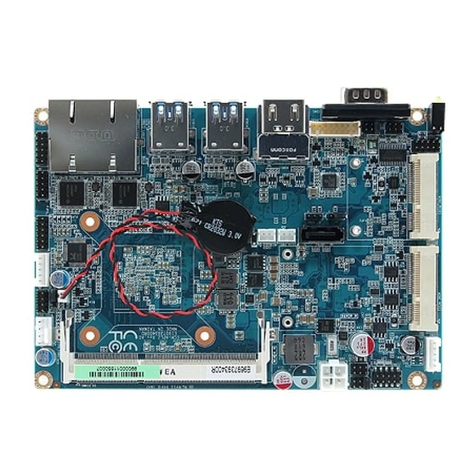

Avalue Technology

Avalue Technology ECM-APL2-A user manual

Walther Systemtechnik

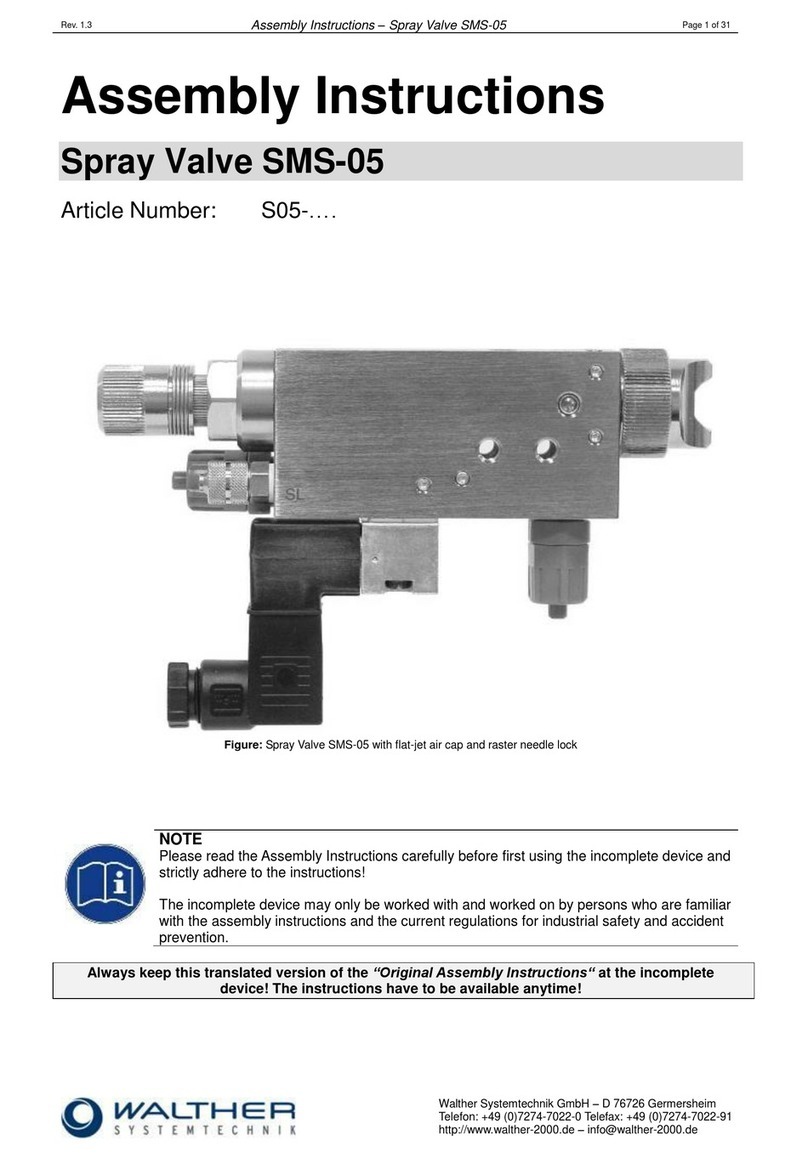

Walther Systemtechnik SMS-05 Assembly instructions

Marshall Excelsior

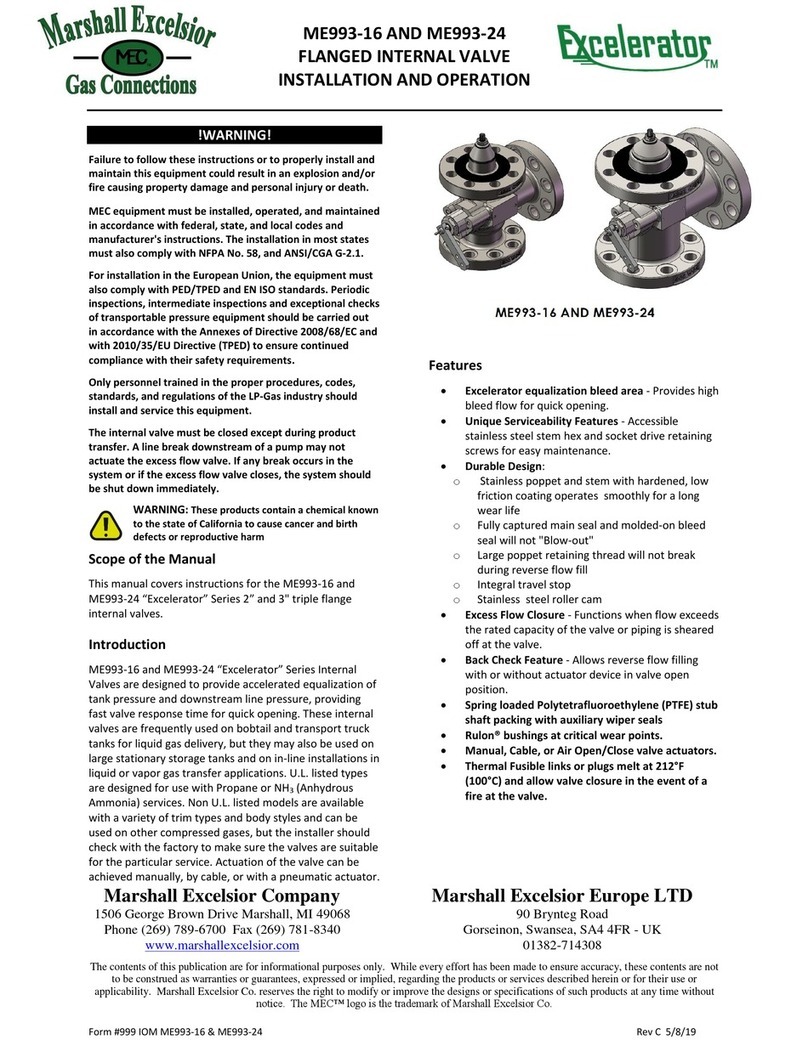

Marshall Excelsior Excelerator ME993-16 Installation and operation