Siemens VDO Pro Cockpit User manual

Siemens VDO Limited Warranty

VDO North America warrants all merchandise against defects in factory workmanship and materials for a period of 24 months after purchase. This

warranty applies to the first retail purchaser and covers only those products exposed to normal use or service. Provisions of this warranty shall not

apply to a VDO product used for a purpose for which it is not designed, or which has been altered in any way that would be detrimental to the

performance or life of the product, or misapplication, misuse, negligence or accident. On any part or product found to be defective after examination

by VDO North America, VDO North America will only repair or replace the merchandise through the original selling dealer or on a direct basis. VDO

North America assumes no responsibility for diagnosis, removal and/or installation labor, loss of vehicle use, loss of time, inconvenience or any other

consequential expenses. The warranties herin are in lieu of any other expressed or implied warranties, including any implied warranty of merchant-

ability or fitness, and any other obligation on the part of VDO North America, or selling dealer.

(NOTE: This is a Limited Warranty as defined by the Magnuson-Moss Warranty Act of 1975.)

Siemens VDO . http://sso-usa.siemensvdo.com . Phone: 1-800-265-1818

Mechanical Pressure Gauge

Installation Instructions

Instruction Sheet #0511 011 788

Rev. 07/03

INSTRUCTIONS FOR THE INSTALLATION OF THE MECHANICAL PRESSURE GAUGE

ARE CONTAINED HEREIN. USE IS RESTRICTED TO 12-VOLT NEGATIVE GROUND

ELECTRICAL SYSTEMS. LIGHT BULB, IF SUPPLIED, IS 12 VOLTS.

SiemensVDO®

Tools and Materials Needed For Installation:

16 Gauge stranded, insulated wire

Insulated ¼" spade connectors

2⁵⁄₈" hole saw

Drill and drill bit set

Half-round file

Tape measure or ruler

Small tools: wrench or nut driver, utility

knife, pliers, etc.

Tubing kit and various engine adapters To Begin, go to #➊

The bezel diameter is only a few mil-

limeters larger than the gauge itself.

With that in mind, measure and pre-

cisely mark the gauge location be-

fore cutting any holes!

CAUTION!!!

Item Description Quantity

1. Pressure Gauge (2⁵⁄₈" [65 mm] diameter) 1

2. Lamp Socket 1

3. Light Bulb 1

4. VDO Mounting Bracket and nuts 1

5. Installation Instructions 1

Parts List

Your VDO mechanical pressure gauge fea-

tures the latest illumination technology and

a rugged design to insure years of durable

and reliable operation. These instruments

require a tubing kit to complete installa-

General Information:

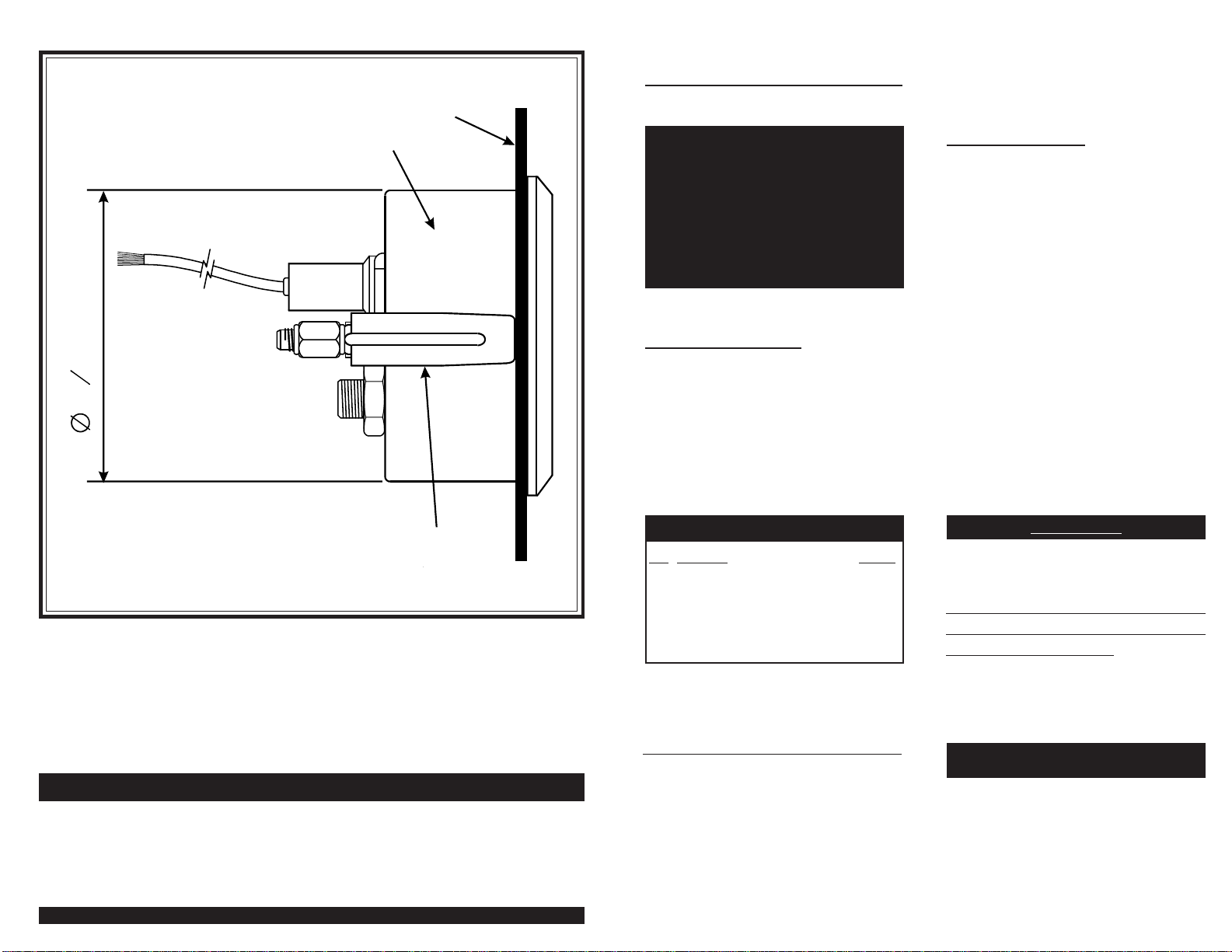

1. Select the location where you will mount

the gauge, and mark a center point for a

hole (or use a VDO Mounting Accessory

[1,2, & 3 hole chrome and black] or a VDO

Mounting Cup [chrome or black]).

2. Cut a 2 ⁵⁄₈" (65 mm) diameter hole for

the pressure gauge. Place the instrument

into the hole. If the gauge is too snug, use

a file to slightly enlarge the opening until

the gauge fits properly. See Diagram A.

4. Slip the mounting bracket over the

mounting bolts on the back of the gauge.

Screw on the accompanying nuts. Tighten

the nuts until the gauge can no longer be

rotated by hand. DO NOT OVER-

TIGHTEN!

Gauge Installation:

➊BEGIN HERE tion with various engines. You may pur-

chase such a kit (with different lengths of

tubing and of different styles) from your

VDO dealer.

CAUTION:

Read these instructions

thoroughly before making installation.

Donotdeviatefromassemblyor wiring

instructions. Alwaysdisconnectbattery

ground before making any electrical

connections. Ifindoubt,pleasecontact

yourdealerorVDOInstruments at1-800

265-1818.

Diagram A

Gauge Dimensions

PP

*DXJH

0RXQWLQJ

%UDFNHW

3D Q H O

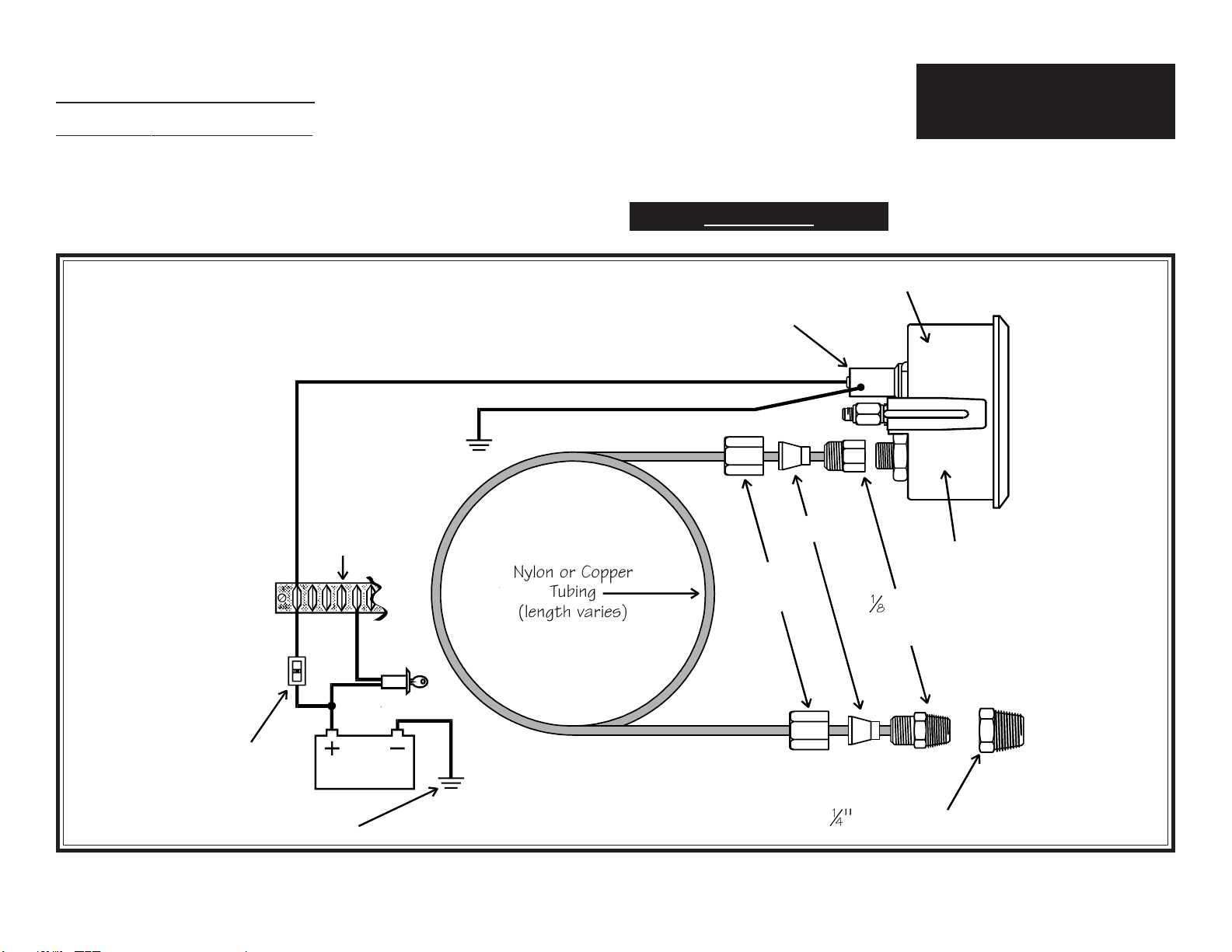

1. Route the tube from the gauge to the

engine. DO NOT CRIMP the tubing

closed during routing. A rubber grommet

is recommended around the tubing where

it passes through the firewall.

Diagram B

Gauge hookup and lamp wiring information

Gauge Hookup and Lamp Wiring:

2. Attach one end of the tubing to the

gauge using a 1/8" adapter, ferrule and seal-

ing nut, as shown in Diagram B.

3. Attach the other end of the tubing to

the engine using a ¹⁄₈" adapter, a ferrule and

a sealing nut. A ¼" adapter may be needed.

DO NOT OVERTIGHTEN THE SEAL-

ING NUTS OR YOU WILL DAMAGE

THE TUBING!

➋CONTINUE HERE 4. Run the wire from the gauge lamp socket

to the lighting circuit (a +12 volt source,

usually after the light switch fuse in the fuse

box). See Diagram B.

At this point, installation is complete.

Re-check the routing of the tube from the

gauge to the engine.

CAUTION:

Make sure the tube is absolutely free

from moving and/or hot engine com-

ponents, and that it is totally free of

kinks.

Start the engine and turn on the lights to

make sure the gauge illumination functions

properly. If it doesn't, recheck your con-

nections and your wiring. Check all tub-

ing connections for leaks.

1\ORQRU&RSSHU

7XELQJ

OHQJWKYDULHV

6HDOLQJ

1XWV

)HUUXOHV

%DWWHU\

/DPS6RFNHW

6HOIJURXQGHGWR

LQVWUXPHQWKRXVLQJ

*URXQG

)XVH

%R[

/LJKW

6ZLWFK

*URXQGWR

LQVWUXPHQW

KRXVLQJ

%HVXUHKRXVLQ

J

LVJURXQGHG

137

$GDSWRU

é$GDSWRU

3UHVVXUH

*

DXJH

Siemens VDO Limited Warranty

VDO North America warrants all merchandise against defects in factory workmanship and materials for a period of 24 months after purchase. This

warranty applies to the first retail purchaser and covers only those products exposed to normal use or service. Provisions of this warranty shall not

apply to a VDO product used for a purpose for which it is not designed, or which has been altered in any way that would be detrimental to the

performance or life of the product, or misapplication, misuse, negligence or accident. On any part or product found to be defective after examination

by VDO North America, VDO North America will only repair or replace the merchandise through the original selling dealer or on adirect basis. VDO

North America assumes no responsibility for diagnosis, removal and/or installation labor, loss of vehicle use, loss of time, inconvenience or any other

consequential expenses. The warranties herin are in lieu of any other expressed or implied warranties, including any implied warranty of merchant-

ability or fitness, and any other obligation on the part of VDO North America, or selling dealer.

(NOTE: This is a Limited Warranty as defined by the Magnuson-Moss Warranty Act of 1975.)

Siemens VDO .http://sso-usa.siemensvdo.com/ .Phone: 1-800-265-1818

Mechanical Vacuum Gauge

Installation Instructions

Instruction Sheet # 0 511 011 795

Rev. 07/03

INSTRUCTIONS FOR THE INSTALLATION OF THE MECHANICAL VACUUM GAUGE ARE

CONTAINED HEREIN. USE IS RESTRICTED TO 12-VOLT NEGATIVE GROUND

ELECTRICAL SYSTEMS. LIGHT BULB, IF SUPPLIED, IS 12 VOLTS.

Siemens VDO®

Tools and Materials Needed For Installation:

16 Gauge stranded, insulated wire

Insulated ¼" spade connectors

2⁵⁄₈" hole saw

Drill and drill bit set

Half-round file

Tape measure or ruler

Small tools: wrench or nut driver, utility

knife, pliers, etc.

Tubing kit and various engine adapters To Begin, go to #➊

The bezel diameter is only a few mil-

limeters larger than the gauge itself.

With that in mind, measure and pre-

cisely mark the gauge location be-

fore cutting any holes!

CAUTION!!!

Item Description Quantity

1. Vacuum Gauge (2⁵⁄₈" [52 mm] diameter) 1

2. Lamp Socket 1

3. Light Bulb 1

4. VDO Mounting Bracket and nuts 1

5. Installation Instructions 1

Parts List

Your VDO mechanical vacuum gauge fea-

tures the latest illumination technology and

a rugged design to insure years of durable

and reliable operation. These instruments

require a tubing kit to complete installa-

General Information:

1. Select the location where you will mount

the gauge, and mark a center point for a

hole (or use a VDO Mounting Accessory

[1,2, & 3 hole chrome and black] or a VDO

Mounting Cup [chrome or black]).

2. Cut a 2 ⁵⁄₈" (65 mm) diameter hole for

the vacuum gauge. Place the instrument

into the hole. If the gauge is too snug, use

a file to slightly enlarge the opening until

the gauge fits properly. See Diagram A.

4. Slip the mounting bracket over the

mounting bolts on the back of the gauge.

Screw on the accompanying nuts. Tighten

the nuts until the gauge can no longer be

rotated by hand. DO NOT OVER-

TIGHTEN!

Gauge Installation:

➊BEGIN HERE tion with various engines. You may pur-

chase such a kit (with different lengths of

tubing and of different styles) from your

VDO dealer.

CAUTION:

Read these instructions

thoroughly before making installation.

Donotdeviatefromassemblyor wiring

instructions. Alwaysdisconnectbattery

ground before making any electrical

connections. Ifindoubt,please contact

yourdealer orVDOInstruments at1-800-

265-1818.

Diagram A

Gauge Dimensions

PP

*DXJH

0RXQWLQJ

%UDFNHW

3D Q H O

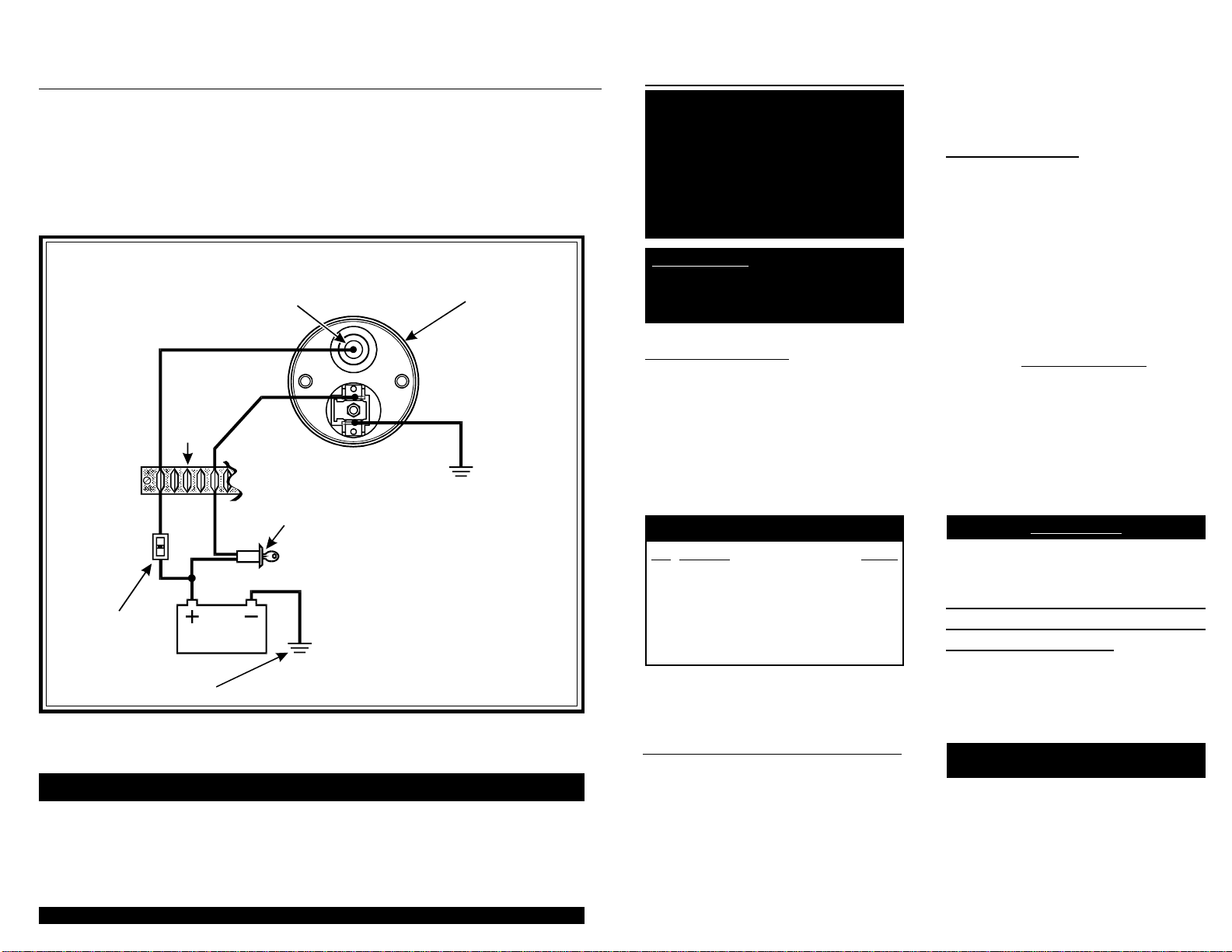

1. Route the tube from the gauge to the

engine. DO NOT CRIMP the tubing

closed during routing. A rubber grommet

is recommended around the tubing where

it passes through the firewall.

Diagram B

Gauge hookup and lamp wiring information

7)LWWLQJ

WR0DQLIROG

9DFXXP+RVH

9DFXXP*DXJH

1\ORQRU&RSSHU

7XELQJ

OHQJWKYDULHV

6HDOLQJ

1XWV

)HUUXOHV

%DWWHU\

/DPS6RFNHW

6HOIJURXQGHGWR

LQVWUXPHQWKRXVLQJ

*URXQG

)XVH

%R[

/LJKW

6ZLWFK

*URXQGWR

LQVWUXPHQW

KRXVLQJ

%HVXUHKRXVLQJ

LVJURXQGHG

137

$GDSWRU

Gauge Hookup and Lamp Wiring:

2. Attach one end of the tubing to the

gauge using a 1/8" adapter, ferrule and seal-

ing nut, as shown in Diagram B.

3. Attach the other end of the tubing to

the engine using a T-fitting, 1/8" adapter, a

ferrule and a sealing nut.

DO NOT OVERTIGHTEN THE SEAL-

ING NUTS OR YOU WILL DAMAGE

THE TUBING!

➋CONTINUE HERE 4. Run the wire from the gauge lamp socket

to the lighting circuit (a +12 volt source,

usually after the light switch fuse in the fuse

box). See Diagram B.

At this point, installation is complete.

Re-check the routing of the tube from the

gauge to the engine.

CAUTION:

Make sure the tube is absolutely free

from moving and/or hot engine com-

ponents, and that it is totally free of

kinks.

Start the engine and turn on the lights to

make sure the gauge illumination functions

properly. If it doesn't, recheck your con-

nections and your wiring. Check all tub-

ing connections for leaks.

Siemens VDO Limited Warranty

VDO North America warrants all merchandise against defects in factory workmanship and materials for a period of 24 months after purchase. This

warranty applies to the first retail purchaser and covers only those products exposed to normal use or service. Provisions of this warranty shall not

apply to a VDO product used for a purpose for which it is not designed, or which has been altered in any way that would be detrimental to the

performance or life of the product, or misapplication, misuse, negligence or accident. On any part or product found to be defective after examination

by VDO North America, VDO North America will only repair or replace the merchandise through the original selling dealer or on a direct basis. VDO

North America assumes no responsibility for diagnosis, removal and/or installation labor, loss of vehicle use, loss of time, inconvenience or any other

consequential expenses. The warranties herin are in lieu of any other expressed or implied warranties, including any implied warranty of merchant-

ability or fitness, and any other obligation on the part of VDO North America, or selling dealer.

(NOTE: This is a Limited Warranty as defined by the Magnuson-Moss Warranty Act of 1975.)

Siemens VDO .http://sso-usa.siemensvdo.com/ . Phone: 1-800-265-1818

Electric Temperature, Pressure,

Fuel Gauge or Voltmeter

Installation Instructions

Instruction Sheet # 0 511 011 812

Rev. 07/03

INSTRUCTIONS FOR THE INSTALLATION OF THE ELECTRIC TEMPERATURE,

PRESSURE, FUEL GAUGE AND/OR VOLTMETER ARE CONTAINED HEREIN. USE IS

RESTRICTED TO 12-VOLT NEGATIVE GROUND ELECTRICAL SYSTEMS. LIGHT BULB,

IF SUPPLIED, IS 12 VOLT.

Siemens VDO ®

Tools and Materials Needed For Installation:

16 Gauge stranded, insulated wire

Insulated ¼" spade connectors

2 ⁵⁄₈" hole saw

Drill and drill bit set

Half-round file

Tape measure or ruler

Small tools: wrench or nut driver, utility

knife, pliers, etc.

Various engine adapters

1. Select the location for the instrument

and cut either a 2 ⁵⁄₈" hole (or use a VDO

mounting accessory [1,2, & 3 hole chrome

and black] or VDO mounting cup [chrome

Gauge Installation:

To Begin, go to #➊

➊BEGIN HERE or black]).

2. Insert the gauge and secure it.

DO NOT OVERTIGHTEN.

(Refer to Diagram A)

NOTE: On all oil and water temperature

gauges, 14-gauge wire is required for gauge

ground; it must be a dedicated ground to

insure gauge accuracy and to eliminate any

erratic gauge readings.

1. Run wires from the instrument location

through the firewall to:

a) the positive (+) terminal on

the battery (after the ignition

switch, and after the fuse box);

b) the light switch (also after the

fuse in the fuse box);

Wiring the Gauge:

Ù

[text continues at #Ë]

IMPORTANT: Mounting dimensions

vary for different gauges. Please be cer-

tain to follow the instructions for your

specific gauge as described below.

The bezel diameter is only a few mil-

limeters larger than the gauge itself.

With that in mind, measure and pre-

cisely mark the gauge location be-

fore cutting any holes!

CAUTION!!!

Item Description Quantity

1. Temperature, Pressure, Fuel Gauge or

Voltmeter

(2⁵⁄₈" [65 mm] diameter) 1

2. Lamp Socket 1

3. Light Bulb 1

4. Mounting bracket 1

5. Installation Instructions 1

Parts List

CAUTION:

Read these instructions

thoroughly before making installation.

Donotdeviatefromassemblyor wiring

instructions. Alwaysdisconnectbattery

ground before making any electrical

connections. Ifindoubt,please contact

yourdealer orVDOInstruments at1-800-

265-1818.

➌FINISH HERE

4. Ground the sender wire. On all pres-

sure and fuel gauges, the pointer will go

to 0. On all temperature gauges, the

pointer will go to the extreme right.

NOTE: Items 2,3, & 4 will be in the re-

verse operating condition when you are using

SW senders.

If these four functions occur as stated, the

instrument is in proper working order. If

the gauges do not respond as described

above, you probably have a faulty sender

or other sender problem.

Diagram D

Proper wiring of the Voltmeter

%DWWHU\

9ROWPHWHU

/DPS6RFNHW

6HOIJURXQGHGWR

LQVWUXPHQWKRXVLQJ

*URXQG

)XVH

%R[

/LJKW

6ZLWFK

6ZLWFKHG

Y

+

–

*URXQGWR

FKDVVLV

Diagram A

Gauge dimensions

PP

*DXJH

0RXQWLQJ

%UDFNHW

3DQHO

➋CONTINUE HERE

c) a good, dedicated ground lo-

cation (i.e., where the negative

() battery pole is connected to

the chassis of the vehicle); and

d) from the instrument sender

terminal to the terminal on the

sending unit.

2. Connect the appropriate positive (+),

ground (negative []), and signal wires to

the gauge and gauge lamp socket as shown

in Diagram B or C.

3. If you are using a VDO sender with a

built-in warning contact terminal, run a

wire (again, minimum 16-gauge, stranded)

from the sender terminal marked WK to

one terminal on the warning light.

Run another wire from the other warning

light terminal to a switched ignition source.

NOTE: Do not use teflon tape on the sender

threads which act as an electrical ground source

for the unit.

Water temperature senders work best if

they are installed near the thermostat hous-

ing. Oil temperature senders can be used

to replace the manufacturers oil pan drain

plug. The oil pressure sender is installed

in the same location as the factory sender

or warning light switch.

Remember: These gauges measure ohm

resistance which is created by the sender.

The ohm range of the sender and gauge

MUST MATCH or the gauge will not be

accurate. VDO sells many gauges which

work with other manufacturers senders;

but you must know the correct sender ohm

range before you buy any of these gauges.

Diagram B

Proper wiring of the Temperature, Pressure or Fuel Gauge

Make sure the instrument is wired prop-

erly, then:

1. On all electric instruments, the pointer

will be to the extreme left when power is

off.

2. On pressure instruments, the pointer

will go to 0 when the power is turned on.

On temperature gauges, the pointer will

indicate current fluid temperature when

power is turned on. When power is ap-

plied to fuel gauges, the pointer will show

how much fuel is currently in the tank.

3. Pull the sender wire off the sender. On

pressure and fuel gauges, pointers go to the

extreme right; pointers go to the extreme

left on temperature instruments.

%DWWHU\

6LJQDO

*DXJH

*URXQGWR

FKDVVLV

/DPS6RFNHW

6HOIJURXQGHGWR

LQVWUXPHQWKRXVLQJ

*URXQG

)XVH

%R[

/LJKW

6ZLWFK

6ZLWFKHG

Y

s

+

*URXQG

6HQGHU

7HPSHUDWXUH

RU

RU

3UHVVXUH

)XHO

Troubleshooting:

Ù

[text continues at #Ì]

Web Site: http://sso-usa.siemensvdo.com/

Page 1

Tachometer Installation and Operation Instructions

For Street Eliminator, Comp Eliminator, Pro Eliminator, and Top Eliminator Tachometers

THE INSTRUCTIONS FOR INSTALLATION AND ELECTRICAL WIRING FOR THESE TACHOMETERS FOLLOW. USE IS RESTRICTED TO 12 VOLT NEGATIVE GROUND ELECTRICAL SYSTEMS.

Item Description Quantity

Parts List

1. Tachometer 1

2. Decals, 2 x 4 (not contingency decals) 2

3. 18-Gauge Wire, 4 1

4. 3-Conductor Shielded Wire, 10 1

5. Posi-Lock Connectors 4

6. Rubber Mounting Grommet 1

7. Contoured Mounting Foot 1

Tachometer Installation

CAUTION: Read these instructions thoroughly before mak-

ing installation. Do not deviate from assembly or wiring in-

structions. Always disconnect battery ground before making

any electrical connections. If in doubt, please contact your

dealer or VDO Instruments at 1-800-265-1818.

Installing the tachometer is a three-step process. First, you

must program the tachometer to match the number of cylin-

ders your engine has and the type of ignition your are using.

Next, you must determine where to mount the tachometer

and which optional mounting brackets, if any, you need.

Finally, after mounting the tachometer, you must wire it.

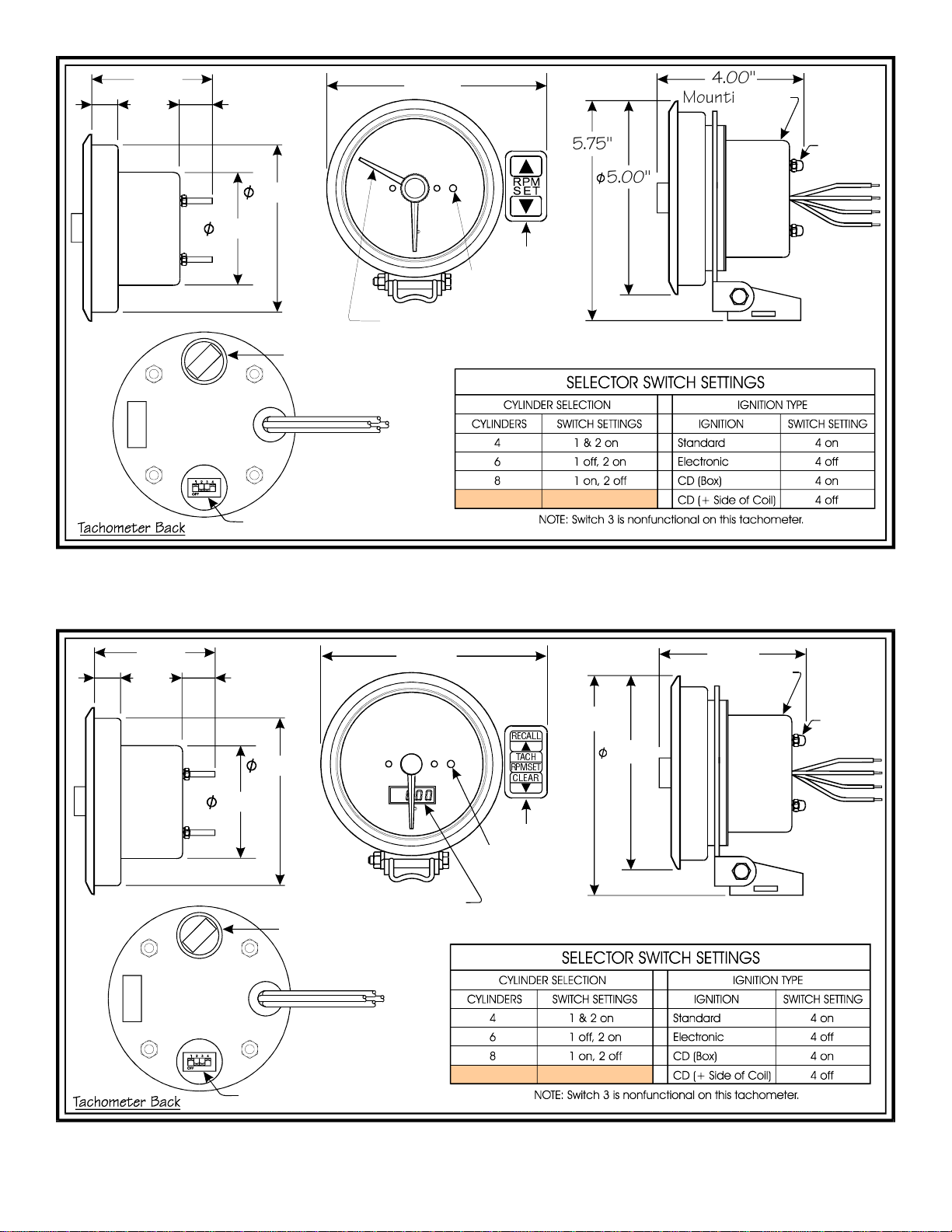

I. Programming the Tachometer

1. Start by removing the four (4) cap nuts and washers on

the back of the tachometer. (For the Street Eliminator, see

Diagram A; for the Comp Eliminator, Diagram B; for the

Pro Eliminator, Diagram C; and for the Top Eliminator,

Diagram D.)

2. Before removing the mounting cup, spray the five wires

with any of the following products: WD40, ARMOR-ALL,

or any rubber/vinyl protectorant. This will allow the wires

to slide through the rubber grommet.

3. Take off the back cap. Set the selector switches to match

the cylinder and ignition type you are using. Switches 1 & 2

will input the number of cylinders your engine has. Switch 3

applies only to the Top Eliminator. It allows you to choose

either 50 or 200 seconds of recording memory. We recom-

mend that you use the shortest memory practical for your

application. Switch 4 is used to input the type of ignition

system on which you are installing the tachometerelec-

tronic, CDI, or standard. For the selector switch settings

that apply to the model of Eliminator Tachometer you are

installing, consult either Diagram A, B, C, or D. Each ta-

chometer is preset to eight cylinder engines and electronic

ignitions (and the Top Eliminator to 50 seconds). You must

change the selector switches to match the number of cylin-

ders and the ignition your are using, or the tachometer will

not work properly. Should you ever need to replace the Type

194 light bulb, remove the back cap as you would to set the

Selector Switches.

Diagram A

Street Eliminator Dimensions and Switch Settings

Magneto Interface Box #340 030

Remote Keypad Cable, 6 #240 207

Flush Dash Mounting Bracket #240 104

On-Dash Mounting Bracket #240 103

Optional Items Which May Be Needed:

Part # 0 511 012 253 Rev. 07/03

®

&'%R[

6KLIW3RLQWHU

0RXQWLQJ&XS

&DS1XW

7\SH%XOE

6HOHFWRU6ZLWFKHV

Siemens VDO Instruments

Page 2

Diagram B

Comp Eliminator Dimensions and Switch Settings

Diagram C

Pro Eliminator Dimensions and Switch Settings

6KLIW3RLQWHU

.H\SDG

6KLIW/LJKW

.H\SDG

6KLIW/LJKW

'LJLWDO'LVSOD\

5(&$//

7$&+

&/($5

5306(7

0RXQWLQJ&XS

&DS1XW

0RXQWLQJ&XS

&DS1XW

7\SH%XOE

6HOHFWRU6ZLWFKHV

7\SH%XOE

6HOHFWRU6ZLWFKHV

Page 3

For competition dash mounting, the rubber mounting grom-

met supplied can be used. This requires a 3½" hole. Re-

move the rubber grommet from the mounting ring and place

the tachometer into the hole. The mounting cup can be

used for a mounting bracket. Mounting without the grom-

met requires a 33

/

16

"hole. If the dash panel is ½" thick or

less, the mounting cup can be used for a bracket. Or, use a

modified in-dash bracket #240 104.

1. Select a location to mount the tachometer. Eliminator

Tachometers can be mounted in four different ways, depend-

ing on your preference. They can be: ¶ Column or roll bar

mounted. A short contoured foot is included so you can

mount the tachometer this way. · In-dash shock mounted.

¸ In-dash flush mounted with an optional U-bracket (#240

104). ¹Top-dash mounted with an optional long foot (#240

103) for stability.

Diagram D

Top Eliminator Dimensions and Switch Settings

4. After you have correctly positioned the selector switches

to exactly match your cylinder and ignition type, reassemble

the mounting cup to the rear of the tachometer with the

four (4) cap nuts.

II. Mounting the Tachometer

2. Mount the tachometer, making sure it does not rest against

glass, the windshield post, or the roll bar. (NOTE: To en-

sure proper operation, don't mount the tachometer too close

to any electrical items like an ignition system box, coils, or

an electrical fuel pump. The wires from these shouldn't be

routed by the tachometer, either.) Recommended installa-

tion is on the steering column using a band clamp available

at any local auto parts store. In some instances the drilling

of new holes for the repositioning of the keypad may be nec-

essary. For mounting on the dash, use the optional long

mounting bracket #240 103. Use the holes provided in the

bracket to secure the tachometer. Flush dash mounting re-

quires a 4¾" hole and the optional U-bracket #240 104.

3. The keypad can be remote mounted using the optional 6'

remote cable #240 207. Remove the keypad from the mount-

ing ring, then remove the mounting cup. Unplug the cable

from the back of the tach housing. Insert the male end of

the extension cable into the back of the tach. Then insert

the male end of the control pad cable into the female end of

the extension cable. Reattach the mounting cup, then mount

the keypad in the location of your choice.

1. Remove the key from the ignition and disconnect the

negative terminal from the battery post.

III. Wiring the Tachometer

2. Wire the tachometer to the vehicle as shown in Diagram

H on Page 4. Please understand that proper wiring must be

maintained throughout your vehicle. If it isnt, the tachom-

eter may pick up signals that have been produced by electri-

cal devices other than the ignition system. Dont coil up

excess tachometer wires during installation. Cut wires and

cables to length, and route them making sure they cant be

0RXQWLQJ&XS

&DS1XW

7\SH%XOE

6HOHFWRU6ZLWFKHV

.H\SDG

6KLIW/LJKW

'LJLWDO'LVSOD\

5(&$//

7$&+

&/($5

530 6(7

Page 4

5('

:+,7(

%/$&.

5('

:+,7(

%/$&.

6+,(/'

7RS 9LHZ

7R

0DJQHWR 7R

7DFKRPHWHU

&211(&7 $7 0$*1(72 (1' &211(&7 $7 7$&+20(7(5 (1'

5('

:+,7(

%/$&.

6+,(/'

5('

%/$&.

:+,7(

7R 6ZLWFKHG 3RZHU WR %DWWHU\

7R 0DJQHWR 2XWSXW 7DFK 6LJQDO

7R *URXQG

7R 6KLHOG RQ 6LJQDO :LUH WR *URXQG

7R 7DFK 5HG 3RZHU

7R 7DFK %ODFN *URXQG

7R 7DFK *UHHQ 6LJQDO

pinched by pedals or levers. When running cables through

areas like firewalls, eliminate wire chafing by using chassis

grommets. Proper battery voltagefrom 10.5 to 16.5 volts

must be maintained in the vehicle during operation. Dont

use solid core ignition wires. Ignition wires must be in good

condition. If erratic tachometer readings occur, check all wires

for proper resistance values. Youll note that we have included

shielded cable and Posi-Lock Connectors for your tachom-

eter installation. We highly recommend that you use these

to help insure proper operation. Splice the wires from the

tachometer to the shielded cable using the Posi-Lock Con-

nectors as shown in Diagram E.

Diagram G

Wiring With and Without a Light Switch

Diagram F

Magneto Interface Box Wiring Instructions

Magneto Interface Box

#340 030

To

Magneto Tachometer

To

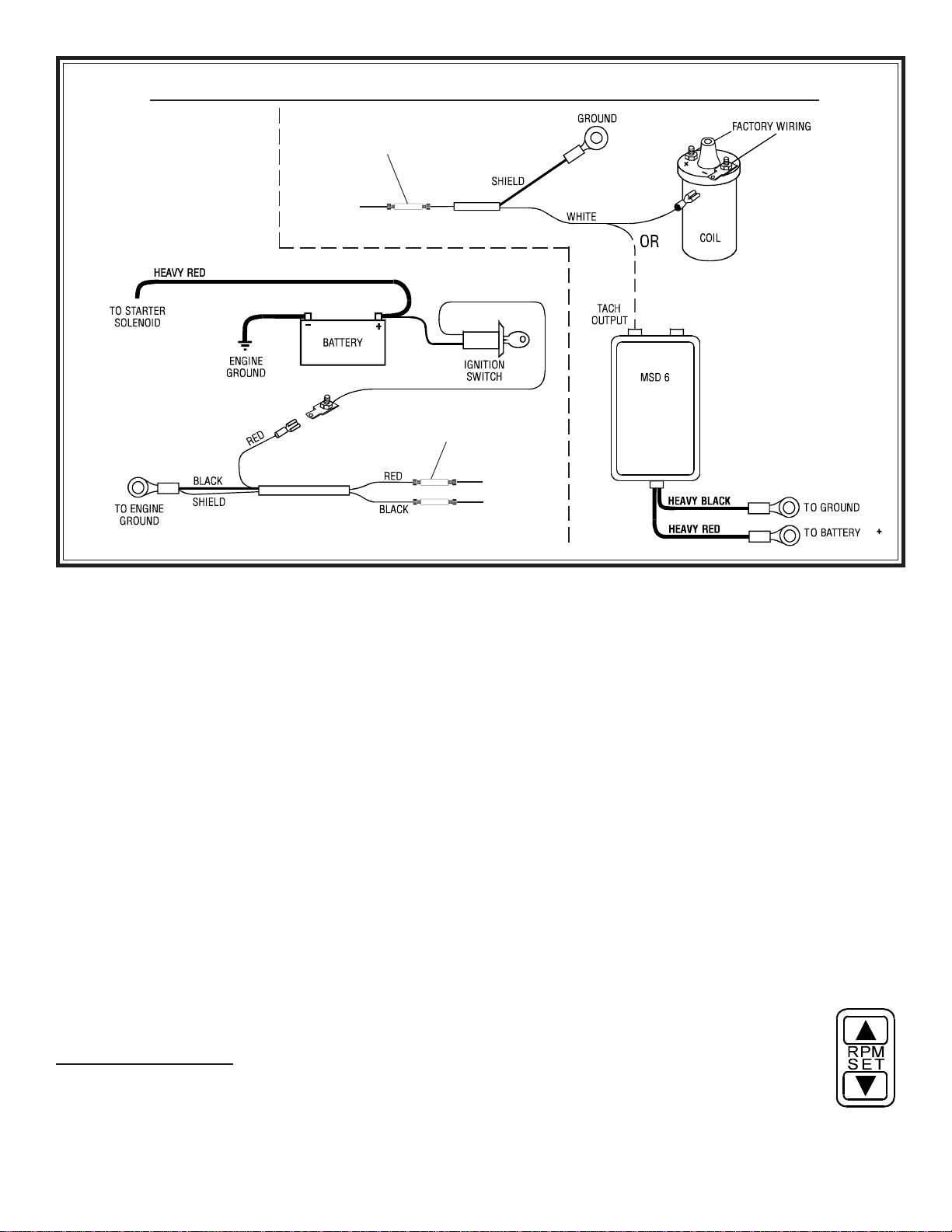

Diagram H

General Wiring Information

Diagram E

Connect tach wires to insulated cable with Posi-Locks

CdbY`gYbUU^TcQR_ed

9^cUbdUQSXgYbUY^d_Q]Q\UU^T

Uh`_cY^W_^\iRQbUgYbU

8Q^TdYWXdU^]Q\UU^Tc

Y^d_U^Tc_VRQbbU\

¯

°

±

3. Refer to your engine manual and/or the manufacturers

manual for the location of the tachometer signal connection

for a voltage-triggered tachometer. Typical connections are

found in the box below. Wire to a magneto ignition using the

optional Magneto Interface Box as shown in Diagram F.

For racing applications, connect both the red wire for power

and the white wire for illumination to the red wire in the

shielded cable used to connect the tach to the ignition.

This will cause the tachometer to stay illuminated continu-

ously during operation, but will help insure the shielding of

the tachometer. For non-racing applications, or applications

with a low risk of radio-frequency or electromagnetic inter-

ference, the white wire from the tachometer can be wired di-

rectly to the light switch for illumination only when the lights

are turned on. Refer to the wiring in Diagram G.

<(//2:

'2 127 86(

5('

%/$&.

*5((1

:+,7(

5('

%/$&.

:+,7(

:+,7(

6+,(/'('

&$%/(

/,*+7

6:,7&+

:,7+ /,*+7 6:,7&+

<(//2:

'2 127 86(

5('

5('5('5('

%/$&.

%/$&.

%/$&.%/$&.

*5((1

:+,7(

:+,7(

6+,(/'('

&$%/(

12,6( ),/7(5

,1387 287387

:,7+ 12,6( ),/7(5

:,7+287 /,*+7 6:,7&+

<(//2:

'2 127 86(

5('

%/$&.

*5((1

:+,7(

5('

%/$&.

:+,7(

6+,(/'('

&$%/(

:,7+287 /,*+7 6:,7&+

IGNITION

Standard

CD

Electronic

TYPE

points / breakerless

points

breakerless

MSD, ACCEL,

MALLORY, DDIS

(distributorless),etc.

CONNECTIONS

negative terminal on coil

points connection to CD box

positive terminal on coil

Tach output terminal on ignition

box, or points connection to

ignition box, or negative coil

Page 5

CONNECTING TO AN MSD-7AL IGNITION

1. Connect the tach using the 10' shielded cable included

with the tachometer. Peel approximately 3 to 4 inches of the

outside covering and aluminum shielding from the gray cable.

This will reveal four individual wires. Three will be insu-

lated and one will be uninsulated.

Diagram I

Wiring to MSD-7AL Ignition

2. Strip ½" of the insulation from the black, red and white

covered wires.

4. On the end of the white insulated wire, which will be

used for the tach signal, install a ¼" female spade terminal.

3. Combine the black and uninsulated wires, which will be

used for the ground, into a 5

16 " ring terminal.

5. Complete the ignition end of the cable by installing a ¼"

flange spade terminal on the red wire that will be used for

power.

6. Now connect the cable to the MSD-7AL box as shown

below in Diagram I. Connect the O ring with the black

and uninsulated wire to the terminal labeled GROUND.

7. Slide the female terminal with the white insulated wire

onto the terminal labelled TACH.

8. Place the U connector with the red wire on the

terminal labeled IGNITION. Make sure all of your con-

nections are tight and clean.

10. Peel back approximately 1½" of the gray cover, and the

shield, from the tachometer end of the shielded cable. Cut

the uninsulated wire down to the base of the shielding. Do

notUNDER ANY CIRCUMSTANCESconnect the

shield to the tachometer.

9. Route the shielded cable through the car as desired. Make

sure no wires can be pinched by pedals, levers, etc. Then

cut the cable to length, leaving a little extra for error.

11. Strip about ½" of insulation from the ends of the wires.

Strip the same amount of insulation from the tachometer

wires. We strongly recommend using the provided Posi-

Lockconnectors for splicing the tachometer wires to the

shielded cable. Install them now. Refer to Diagram E.

12. Connect the black wire from the tachometer to the black

wire of the shielded cable (GROUND).

13. Connect the green wire from the tachometer to the white

wire in the shielded cable (TACH SIGNAL).

14. Finally, connect the red wire from the tachometer to the

red wire in the shielded cable. The remaining white

tachomter wire is for illumination, and is connected as

+ TACH

TACH

SIGNAL

Posi-Lock Connector

Page 6

Diagram J

Wiring from the Tachometer to the Ignition Coil or MSD-6

described on Page 4, in the text and in Diagram G.

CONNECTING TO THE IGNITION COIL OR MSD-6

1. When connecting to the negative post of the ignition coil

or to the MSD-6 box, run the shielded cableincluded with

the tachometerfor the TACH SIGNAL, the POWER and

the GROUND wires.

I. Street Eliminator Operation

The Eliminator series consists of four different tachometers

the Street Eliminator, the Comp Eliminator, the Pro Elimi-

nator, and the Top Eliminator. Each is designed to give the

ultimate flexibility in operation and function. Operation of

these state-of-the-art tachometers is profiled in this section.

Tachometer Operation

This tachometer is designed for those individuals whose needs

include only engine RPM monitoring with a manual shift

pointer. This orange pointer, in the center of the tachom-

eter, can be used as a shift point indicator, a reminder not to

exceed a certain RPM, or as a stall point indicator.

1. To operate, move the shift pointer by simply turning the

easy-to-hold knob in the center of the tachometer face to

the RPM you wish to highlight.

This tachometer features the same manual shift pointer as

the Street Eliminator, as well as a super bright red LED shift

light. The Comp Eliminator shift pointer works the same

way as the Street Eliminator shift pointer. See the above

section for details. To set the LED shift light:

II. Comp Eliminator Operation

1. Press the RPM set button on the key pad.

2. Press the up arrow until the red pointer indi-

cates the RPM at which you would like the shift

light to illuminate.

3. To lower the RPM, press the down arrow.

4. Once you have chosen your desired RPM, push the RPM

set button in the center of the keypad again. The microprossor

2. Ground the shielded wire at the coil. Leave the shield

unconnected at the tachometer. Do not, UNDER ANY CIR-

CUMSTANCES, connect the shielding to the tachometer.

3. Connect the red tachometer POWER wire to the igni-

tion power, as seen above in Diagram J. Under normal cir-

cumstances, this connection should work properly. How-

ever, the power may need to be run through a separate

shielded cable directly from the battery, in order to escape as

much noise as possible. If this is the case, a 3-Amp, in-line

fuse and separate power switch should be used. Again, refer

to Diagram J, above.

YOU MUST USE TWO SETS OF SHIELDED WIRE FOR THIS INSTALLATION!

SHIELDED CABLE #1

SHIELDED CABLE #2

TACH SIGNAL

+

–TACH

POWER

Posi-Lock

Connector

Posi-Lock

Connector

Page 7

will now store the RPM you have selected, and return the

tachometer to the functional mode.

III. Pro Eliminator Operation

The Pro Eliminator not only gives you the advantages of an

LED shift light, but also allows you to set your RPM in pre-

cise increments of 10 RPM. And, the Pro Eliminator will

record and store the highest RPM your engine reaches during

the tachometers memory cyclethat is, since the last time

you cleared the memory. Set your shift point as follows:

1. Press the RPM SET button on the keypad. This will lift

the pointer from the LED display window.

5(&$//

7$&+

&/($5

5306(7

3. Should you

need to lower the

shift point, simply

press the down arrow.

2. Press the up arrow until the LED indi-

cates the desired

RPM shift point.

4. To return the tachometer to the operation mode, push

the button marked RPM SET again. The microprocessor

will store the shift point you set.

5. To activate the recall function and reveal the highest RPM

level reached during the memory cycle, press the RECALL

button on the keypad. The digital display will show the peak

RPM level achieved since you last pushed the CLEAR but-

ton. This display will last two seconds. To keep the peak

RPM level displayed longer than two seconds, press and hold

down the RECALL button. The display will disappear when

you release the RECALL button.

IV. Top Eliminator Operation

VDO Instruments Top Eliminator is the ultimate recording

tachometer. In addition to all of the previously mentioned

benefits in our other Eliminator tachometers, the Top Elimi-

nator enables you to record and play back the tachometer

readings for an entire 50-second or 200-second time period.

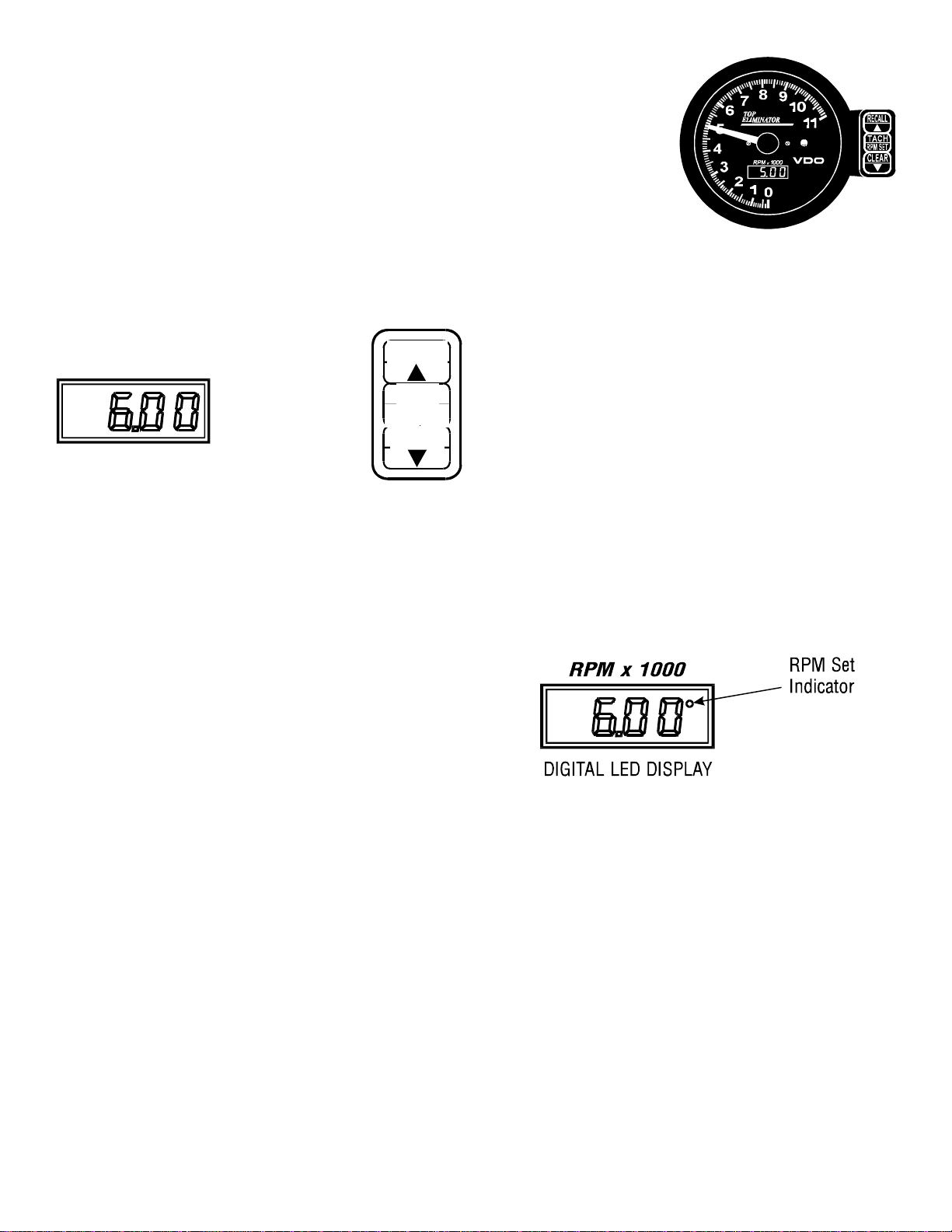

The tachometer has four modes of operation:

1. Normal tach mode (TACH); the tachometer is in the

normal TACH mode when first turned on. The LED

display will show 6.00.

2. Shift light RPM set mode (RPM SET); the RPM SET

mode is used for setting the RPM level for the shift

light.

3. Recording mode; the tachometer is capable of record-

ing 50 seconds or 200 seconds of the tachometers ac-

tivity.

4. Playback mode (RECALL); the tachometer will play

back the recording it made of the tachometer run in

slow motionshowing elapsed time and RPM values.

1. A 4-digit LED display

at the six oclock position.

This shows the RPM shift

point (e.g. 6.00 = 6000

RPM). The display will also

indicate when you are re-

cording and will show actual elapsed time in the playback mode.

Look at the tachometer

and you will notice three

distinctive features:

3. Once you have input the desired RPM level, push the

RPM SET button once again. The tachometer shuttles back

to the TACH operating mode, and the digital display now

indicates the new shift point. The dot in the upper right

corner of the display will disappear, and the pointer will re-

turn to the actual engine RPMs.

1. Push the TACH/RPM SET button. Pushing this button

toggles the tachometer between the normal TACH mode

and the RPM SET mode. In the RPM SET mode you can set

the RPM at which you want the shift light to illuminate. To

set this shift point, make sure the tachometer is in the RPM

SET mode. You can tell when tach is in this mode by looking

at the digital display. A small dot appears next to the last

digit on the right when the tach is in the RPM SET mode.

3. A keypad mounted on the right side of the tach. This

keypad is used to shuttle the tachometer between its four

modes, to set the RPM value of the shift light, to record ta-

chometer activity, and to activate the playback. To operate

the keypad and set the tachometer:

2. An ultra-bright LED shift light at the 3 oclock position.

This will turn on and stay on as long as your engine exceeds

the pre-set RPM shift point.

2. Push the up arrow (s) until you reach the RPM speed at

which you wish the LED shift light to illuminate. If you go too

far, push the down arrow (t) until you get the shift point ex-

actly where you want it (in exact increments or decrements of

10 RPM). Changing the shift point from 6.00 to 8.34, for ex-

ample, changes the shift point value up from 6000 to 8340 RPM.

The shift light will come on at exactly 8430 RPM.

When the tach is in the RPM SET mode, the functions illus-

trated on the bottom half of each keypad button become active

(s, t, and RPM SET). Also, the RPM indicator needle

moves out of the way so you can easily read the LED display.

Page 8

THE TACH POINTER JUMPS ERRATICALLY, THE

SHIFT LIGHT FLASHES RANDOMLY, OR THE DIS-

PLAY SHOWING THE SHIFT POINT GOES BLANK

AND THE POINTER GOES TO 4000-6000 RPM RE-

GARDLESS OF ACTUAL SPEED

4. To record and playback, press the RPM SET button. The

tachometer will return to the normal TACH operating mode.

The functions designated on the top half of each keypad but-

ton will now be active.

5. Press the CLEAR button to erace any previous recordings.

When the memory is erased the display will display three dots

(

. . .

) to indicate that the tach is recording. During this cycle,

the tach will record for either 50 or 200 seconds, whichever

length you selected when you programmed the tachometer.

When the tach has finished recording, the display will again

display the RPM value you set as your shift point.

6. Press the TACHRPM SET button during recording if

you wish to stop that function and return to the normal

TACH operating mode. You can turn off your engine before

recording has been completed without losing any informa-

tion. The tachometer also will remember your latest record-

ing even if you remove the power or battery leads.

7. Press the RECALL button to play back what you have

recorded. Playback occurs in slow motionone-third ac-

tual timeso you can really study the information. The LED

display will show elapsed time while the pointer is showing

the RPM cycle captured during the recording period. As an

example, a ten-second run requires thirty seconds to view;

but the digital display will show ten seconds as it links the

real time of the run to the recording.

8. Press the TACHRPM SET button during playback if

you wish to return to the normal TACH operating mode.

The stored information will be saved until the next time you

press the CLEAR button.

Troubleshooting

A. LOW BATTERY VOLTAGE. The operating voltage for

the Eliminator Tachometer is 10.5 volts 16.0 volts.

The cause of any combination of theseworsened under rac-

ing conditionsis extreme electrical noise attributed to:

If the tach is turned off during replay and the pointer was

over 4000 RPM, the pointer may swing to full scale. Just

turn on power to the tach and the pointer will reset.

WHEN THE POINTER STAYS AT FULL SCALE

B. INADEQUATE WIRING. All wiring should be kept as

direct as possible without having excess wires coiled behind

the dash. Avoid bundling power wires with signal wires and

having loose-ended power wires. These will act as transmit-

ting antennas for noise generated by the ignition system, fuel

pump, etc. The MSD crank trigger or mag pickup ignition

trigger should not be routed near spark plug wires or high

current wires.

C. IGNITION WIRES. Solid core metallic wires, old wires

with cracked insulation, or wires with improperly crimped ends

or breaks in the conductors emit large amounts of electro-

magnetic interference (EMI). Ignition wires can be checked

for defects with a standard ohmmeter. Heli-core wires (MSD)

will read 150 ohms per foot. ACCEL spiral core wire will

read 500750 ohms per foot. Standard resistor wires will

read 500010,000 ohms per foot.

Correct these problems first. If tach problems persist

A. WHEN CONNECTING TO MSD-7AL: Connect the

tach using the shielded cable provided. Connect the shield

and ground wire to the ground post on the MSD box or the

main MSD ground. Connect the power wire to the ignition

terminal on the MSD box, and the signal wire to the tach

output terminal on the MSD box. At the tach end, connect

the red wire to power, the green wire to signal, and the black

wire to ground (see Diagram I on Page 5). DO NOT connect

the shield to the tach under any circumstances.

B. WHEN CONNECTING TO THE IGNITION COIL OR

MSD-6: When connecting to the negative post of the igni-

tion coil or to the MSD-6, run a separate shielded wire for

the signal and the power/ground wires. The shielded wire

from the coil should be grounded at the coil and the shield-

ing left unconnected at the tach end. The power may need

to be run through a shielded wire directly from the battery to

escape as much noise as possible. If you wire in this way, in-

sert a 3-Amp in-line fuse and a separate power switch

( See Diagram J on Page 6).

C. If the shielded wire provided doesnt eliminate all noise

interference, a noise filter should be installed on the power/

ground wires, as close as possible to the tach. Noise filters

Radio Shack #270-051 or MSD #8830will eliminate any

remaining noise on the power wire from the ignition system,

fuel pump, alternator (if equipped), relays, etc. The tachs

white illumination wire may also need to be connected with

the red power wire after the noise filter. See Diagram G on

Page 4. These solutions should solve any problem you en-

counter. But if you still need assistance, call our Technical

Service Coordinator at 1-800-265-1818.

Siemens VDO Automotive Limited Warranty

Siemens VDO Automotive warrants all merchandise against defects in factory

workmanship and materials for a period of 24 months after purchase. This warr-

anty applies to the first retail purchaser and covers only those products exposed

to normal use or service. Provisions of this warranty shall not apply to a VDO

product used for a purpose for which it is not designed, or which has been

altered in any way that would be detrimental to the performance or life of the

product, or misapplication, misuse, negligence or accident. On any part or prod-

uct found to be defective after examination by Siemens VDO Automotive,

Siemens VDO Automotive will only repair or replacethe merchandise through the

oringinal dealer or on direct basis. Siemens VDO Automotive assumes no respon-

sibility for diagnosis, removal and/or installation labor, loss of vehicla use, loss

of time, inconvenience or any other consequential expenses. The warranties herin

are in lieu of any other expressed or implied warranties, including any implied

warranty of merchantabilty or fitness, and any other obligation on the part of

Siemens VDO Automotive, or selling dealer.

VDO Instruments .http://sso-usa.siemensvdo.com/ .Phone: 1-800-265-1818

Table of contents

Popular Measuring Instrument manuals by other brands

Powerfix Profi

Powerfix Profi 278296 Operation and safety notes

Test Equipment Depot

Test Equipment Depot GVT-427B user manual

Fieldpiece

Fieldpiece ACH Operator's manual

FLYSURFER

FLYSURFER VIRON3 user manual

GMW

GMW TG uni 1 operating manual

Downeaster

Downeaster Wind & Weather Medallion Series instruction manual

Hanna Instruments

Hanna Instruments HI96725C instruction manual

Nokeval

Nokeval KMR260 quick guide

HOKUYO AUTOMATIC

HOKUYO AUTOMATIC UBG-05LN instruction manual

Fluke

Fluke 96000 Series Operator's manual

Test Products International

Test Products International SP565 user manual

General Sleep

General Sleep Zmachine Insight+ DT-200 Service manual