until the desired burn rate is achieved. Be careful to retain

a flame as this will produce clean combustion, clean glass

and highest efficiencies.

6. When ashes get 4 to 5 inches deep in the firebox, and

when the fire has burned down and cooled, remove excess

ashes. Leave about an inch of ash in the bottom of the

firebox to help maintain a hot charcoal bed.

Maintaining Catalytic Conditions -During the start-up of

a cold stove, a medium stove, a medium to high air setting

must be maintained for about 20 minutes. This ensures

that the stove, catalyst, fuel, and chimney area all at proper

operating temperature. Even though it is possible to have

smoke temperature reach 600 degrees within two or three

minutes after af ire is started, the combustor and the

chimney are not yet warm enough. At the end of the burn

cycle; it’s possible that the amount of buring charcoal

mightnot provide sufficient temperatures for the catalyst.

During the refueling, we recommend that the stove be fired

hard for at least 10 minutes to ensure that the satalyst and

chimney are properly warmed up. If you have a long or

large diameter chimney, or if it is very cold outside, run the

stove on high for a longer period.

Whenever loading the stove, KEEP THE BYPASS OPEN!

NEVER remove the combustors to clean them. If there

seems to be excessive fly ash on the combustors, use the

blower side of your vacuum claener to blow ash out. Be

cerain you never vacuum ash into your vacuum cleaner.

Always replace the mixers after brushing the combustors.

Combustor Life and Replacement - Sierra uses only

“12,000 Hour Long Life Combustors.” The combustor will

still be functioning at 7-% of its effectiveness after 12,000

hours of use. Depending on the frequency of stove use, it

will last for four to twelve years before needing

replacement.

OVERNIGHT BURNING

To hold a fire overnight, load the firebox with a full supply

of wood which has a minimum diameter of six inches.

Wood still in "the round" will burn longer than split wood.

After experimenting with the slide draft for a few days, you

will discover the correct setting for your home. If the fire is

out in the morning and wood is burned up, open the slide

draft a little more the next night.

MORE FUEL AND OPERATION TIPS

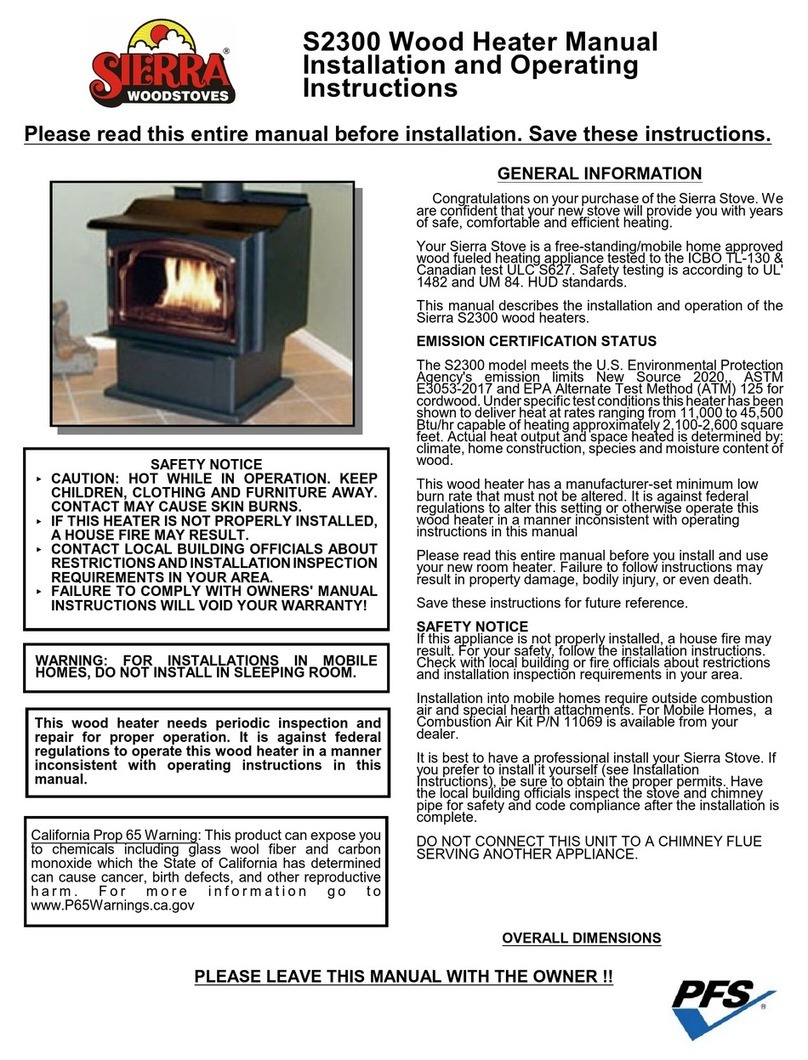

Fuel Sizes: S8000II uses 17" to 19" wood side to side. The

ideal fuel load is about 24 lbs. Producing about 17,000 to

72,600 Btu/Hr.

"Hard" wood (oak, maple, ash, nut trees, etc.) is better for

overnight burning than "soft" wood (fir, cedar, pine, spruce,

etc.)

PLAN AHEAD: PUT IN NEXT YEAR'S WOOD NOW!

Creosote Formation and the Need For Removal

Unseasoned or wet wood contains large amounts of

moisture. When this wood is heated in the fire, the water is

vaporized and driven off as steam at about 212 to 300

degrees Fahrenheit. As the temperature of the wood

reaches 300-600 degrees Fahrenheit the flammable liquid

in the wood fiber cells is vaporized and it too is driven off

as a steamy smoke.

If the temperature is high enough and there is a sufficient

amount of oxygen present, the steamy flammable wood

gases will ignite and burn. The burning of these gases is

what is referred to as "secondary combustion" and appears

as the rolling orange flame above the wood.

When there is an insufficient amount of either heat or

oxygen present in the stove, this wet and steamy smoke

does not ignite and burn. Instead it is drawn through the

exhaust vent and into the chimney. As this steam begins to

cool down in the flue it condenses as droplets of moisture

on the inside walls of the chimney. This becomes creosote

which is flammable and is the fuel which burns in a flue

fire. It is necessary to periodically clean these deposits

from your stove pipe and chimney.

Creosote deposits are dangerous and are deemed a

flue fire waiting to happen!

Visually check your chimney monthly. If creosote

deposits are more than 1/4" thick, remove them.

VII. CATALYTIC INSPECTION AND REPLACEMENT

It is important to periodically monitor the operation of the

catalytic combustors to ensure they are functioning

properly and to determine when they need to be replaced.

A non-functioning combustor will result in a loss of heating

efficiency, and an increase in creosote and emissions.

• The combustors should be visually inspected at least

three times during the heting seson to determine if

physical degradation has occurred. Remove the catalytic

cassette by loosing the two 3/8" nuts. Look for cracks,

cell blockage, excessive fly ash and general

deterioration.

You can get an indication of whether the catalyst is working

by comparing the amount of smoke leaving the chimney.

1. Leaving the bypass open, go outside and observe the

amount of smoke leaving the chimney.

2. Close the bypass, go outside and observe the amount of

smoke leaving the chimney.

Significantly more smoke should be seen when the

bypass is open and the exhaust is not being routed

through the combustors. Be careful not to confuse

smoke with steam from wet wood.

After inspecting the combustors and it it determined that

they are defective, they must be replaced. Read the

catalytic warranty information carefully.

3. Inspect the bypass gasket regularly. A bright light or

flashlight is useful for locating any areas that are not

sealed.

MAINTENANCE

The following tips on maintenance will help you keep the

Sierra Stove performing in an attractive and efficient

manner.

CHIMNEYS AND CREOSOTE

Formation and Need for Removal - Creosote is one of the

facts of life for wood burners. When wood is burned slowly,

it produces tar and other organic vapor which combines with

expelled moisture (even “dry” wood contains approximately

20% moisture) to form creosote. The creosote vapors

condense in the relatively cool chimney connectors and flue

of a slow-burning fire. As a result, creosote residue

accumulates on the flue lining. Large amounts of this tough,

gummy, tar-like substance can pile up quickly and virtually

choke a stove pipe. When ignited, this creosote makes an

extremely hot and dangerous fire.

Be sure to examine the chimney connector pipe and the

chimney above it every few weeks so you can determine

the rate of creosote build up.

Any excessive build up of creosote (more than 1/4")

will then be apparent and

must be removed for continued safe operation.

The chimney must be inspected from the top of the

chimney. For a thorough cleaning and inspection, your

SIERRA woodstove should be removed from the hearth.

If creosote has accumulated, it should be removed to

reduce the risk of a chimney fire. Creosote formations can

be chipped away from flue openings with a sturdy metal

blade such as a heavy duty scraper.

CAUTION: The acid content can cause burns to skin

and eyes, so wear protective glasses and gloves.

13