Sifam Tinsley Insu 5Dx User manual

Insu 5Dx

5KV Digital Insulaon Tester

User Manual

Insu 5Dx

1

Table of contents

1 PRECAUTIONS AND SAFETY MEASURES....................................................................................................2

1.1 Preliminary instrucons ................................................................................................................................ 2

1.2 During use ..................................................................................................................................................... 3

1.3 Aer use ....................................................................................................................................................... 3

1.4 Definion of measurement (overvoltage) category ........................................................................................ 3

2 GENERAL DESCRIPTION ............................................................................................................................4

2.1 Instrument features ...................................................................................................................................... 4

3 PREPARATION FOR USE............................................................................................................................4

3.1 Inial inspecons .......................................................................................................................................... 4

3.2 Power supply ................................................................................................................................................ 4

3.3 Calibraon .................................................................................................................................................... 4

3.4 Storage ......................................................................................................................................................... 4

4 OPERATING INSTRUCTIONS .....................................................................................................................5

4.1 Instrument descripon .................................................................................................................................. 5

4.2 Descripon of funcon keys .......................................................................................................................... 5

4.3 Descripon of display .................................................................................................................................... 6

4.4 Descripon of measuring leads...................................................................................................................... 7

4.5 GUARD lead .................................................................................................................................................. 7

4.6 Notes on the insulaon measurements ......................................................................................................... 7

4.7 Switch on the instrument .............................................................................................................................. 8

4.7.1 Configuraon of the test parameters for FIX mode ............................................................................. 8

4.8 Insulaon measurement in FIX mode ............................................................................................................ 9

4.8.1 Configuraon of the test parameters for FIX mode ............................................................................12

4.9 Insulaon measurement in ADJUST mode ....................................................................................................13

4.9.1 Configuraon of the test parameters for ADJUST mode .....................................................................16

4.10 Insulaon measurement in RAMP mode .......................................................................................................17

4.10.1 Configuraon of the test parameters for RAMP#1 mode ....................................................................21

4.10.2 Configuraon of the test parameters for RAMP#2 mode ....................................................................21

4.10.3 Configuraon of the test parameters for RAMP#3 mode ....................................................................22

4.11 Enable/Disable of SMOOTH funcon ............................................................................................................22

4.12 Anomalous situaons ...................................................................................................................................22

5 MANAGEMENT OF MEMORY DATA ........................................................................................................ 25

5.1 Save measurements .....................................................................................................................................25

5.2 Delete measurements ..................................................................................................................................25

5.3 Recall measurements ...................................................................................................................................26

6 RESET OF INSTRUMENT ......................................................................................................................... 26

7 CONNECTION OF THE INSTRUMENT TO PC............................................................................................. 26

8 MAINTENANCE ...................................................................................................................................... 27

8.1 General informaon .....................................................................................................................................27

8.2 Recharging internal baery ..........................................................................................................................27

8.3 Cleaning the instrument ...............................................................................................................................27

8.4 End of life .....................................................................................................................................................27

9 TECHNICAL SPECIFICATIONS .................................................................................................................. 28

9.1 Reference guidelines ....................................................................................................................................29

9.2 General characteriscs .................................................................................................................................29

9.3 Environment ................................................................................................................................................30

9.4.1. Environmental condions for use ......................................................................................................30

9.4 Accessories ..................................................................................................................................................30

9.4.1 Standard accessories .........................................................................................................................30

9.4.2 Oponal accessories ..........................................................................................................................30

10 SERVICE ................................................................................................................................................. 31

10.1 Service operaon .........................................................................................................................................31

11 THEORETICAL APPENDIX ........................................................................................................................ 32

11.1 Polarizaon Index (PI) ..................................................................................................................................32

11.2 Dielectric Absorbon Rao (DAR) .................................................................................................................32

2

1 PRECAUTIONS AND SAFETY MEASURES

The instrument has been designed in compliance with standards IEC/EN61557 and IEC/EN61010-1

regarding electronic measuring instruments.

CAUTION

For the operator’s safety and to prevent damaging the instrument, follow the

procedures described in this manual and carefully read all notes preceded by the

symbol .

Before and during measurements, carefully observe the following instrucons:

Do not perform any measurement in humid environments, in the presence of gas or explosive

or inflammable material or in dusty areas

Even when no measurements are being performed, avoid any contact with the circuit being

tested, with exposed metal parts, with unused measuring leads or circuits, etc

Do not perform any measurement when anomalies are found in the instrument, such as

deformaons, breaks, substance leaks, no display view, etc

Pay special aenon when measuring voltages above 25V in special environments (building

yards, swimming pools, etc.) and 50V in ordinary environments, as there is the danger of

electric shocks.

In this manual and on the instrument, the following symbols are used:

CAUTION: it is necessary to consult the instrucon manual to find the type of potenal

danger and the acons to be taken.

Observe the instrucons reported in the manual. An improper use could damage the

instrument and lead to dangerous situaons for the operator.

DC voltage or current.

AC voltage or current.

Dangerous voltages: risk of electric shocks.

Instrument with double insulaon.

1.1 PRELIMINARY INSTRUCTIONS

This instrument has been designed for use in an environment with polluon level 2

It may also be used to test industrial electrical systems up to overvoltage category IV 600V to

earth with maximum voltage 600V between inputs

Follow the usual safety rules to protect the operator from dangerous currents and protect the

instrument against improper use

Never use the instrument resng on the floor, it must be placed over flat horizontal surfaces

Only the accessories supplied with the instrument guarantee safety standards. They must be in

good condions and replaced, if necessary, with idencal models

Do not measure systems exceeding the current and voltage limit values specified

Do not perform measurements in environmental condions not within the limit values

indicated in this manual

Before connecng the probes to the circuit to be tested, check that the correct funcon is

selected.

3

1.2 DURING USE

Carefully read the following recommendaons and instrucons:

CAUTION

Failure to observe the cauons and/or instrucons may damage the instrument

and/or its components or generate a danger for the operator. If, during use, the low

baery symbol appears on the display, insert the supply cable into the Mains socket

to start baery recharge. During baery recharge, it is possible to perform

measurements.

Before selecng a new funcon, disconnect the measuring probes from the circuit

When the instrument is connected to the circuit being tested, never touch any unused lead

Avoid measuring resistance with external voltages; even if the instrument is protected, as an

excess voltage may cause instrument malfuncons

Prevent that the instrument receives voltage during measurement (e.g. a probe slipping from

the measuring point and touching a point under voltage)

Avoid inserng the plug of the supply cable into the Mains socket while measuring.

1.3 AFTER USE

When measurements are completed, turn off the instrument by pressing the ON/OFF key.

1.4 DEFINITION OF MEASUREMENT (OVERVOLTAGE) CATEGORY

Standard "IEC/EN61010-1: Safety requirements for electrical equipment for measurement, control

and laboratory use, Part 1: General requirements", defines what is intended for measurement

category, commonly known as overvoltage category. In § 6.7.4: Measuring circuits, it reads:

Circuits are divided into the following measurement categories:

Measurement category IV is for measurements performed at the source of a low-voltage

installaon

Examples are electric counters and measurements on primary devices protecng against

overcurrents and on ripple adjusng units

Measurement category III is for measurements performed on installaons inside buildings

Examples are measurements performed on distribuon boards, circuit breakers, wiring

harnesses, including cables, bars, juncon boxes, switches, sockets of fixed installaons and

appliances designed for industrial use and other equipment, e.g. staonary motors connected

to fixed systems.

Measurement category II is for measurements performed on circuits directly connected to the

low-voltage installaon.

Examples are measurements performed on household appliances, portable tools and similar

equipment.

Measurement category I is for measurements performed on circuits not directly connected to

the MAINS.

Examples are measurements performed on circuits not derived from the MAINS and on circuits

derived from the MAINS provided with a special (internal) protecon. In this laer case, the

stress caused by the transients is variable; therefore, (OMISSIS) it is necessary that the user

knows the appliance’s resistance to transients.

4

2 GENERAL DESCRIPTION

The instrument You purchased, if used in compliance with the indicaons given in this manual,

guarantees accurate and reliable measurements and the utmost safety thanks to a development

of new concepon which ensures double insulaon and, consequently, compliance with the

requirements of overvoltage category IV.

2.1 INSTRUMENT FEATURES

Insulaon resistance measurement with nominal voltage which can be set up to 5kV

Dielectric leakage current measurement

Polarizaon Index (PI) measurement

Dielectric Absorpon Rao (DAR) measurement

Capacitance measurement.

AC/DC voltage measurement up to 600V

3 PREPARATION FOR USE

3.1 INITIAL INSPECTIONS

Before shipment, the instrument’s electronics and mechanics have been inspected. All possible

precauons have been taken in order for the instrument to be delivered without damage.

However, we recommend generally inspecng the instrument in order to detect any damage

suffered during transport. Should you detect any anomalies, immediately contact the forwarding

agent or the dealer.

Moreover, we recommend checking that the package contains all parts listed in § 9.4. Should you

find any discrepancy, please contact the dealer. Should it become necessary to return the

instrument, please follow the instrucons reported in § 10

3.2 POWER SUPPLY

The instrument is power-supplied through internal baeries which are recharged from the mains

by means of a baery charger integrated in the instrument itself. The symbol “ ” steadily

illuminated in the right boom part indicates that the baeries are flat and must be recharged . To

recharge the baeries, follow the instrucons given in § 8.2

CAUTION

Perform at least a complete recharging of internal baery in one year. If the

instrument is not used for one year, the baery can be damaged and could not be

completely recharging neither aer some charging/discharging cycles.

3.3 CALIBRATION

The instrument complies with the technical specifications reported in this manual. Its correct

operaon is guaranteed for one year from the date of purchase.

3.4 STORAGE

In order to guarantee accurate measurements and protect the instrument from possible failures,

aer a long storage period under extreme environmental condions, wait for the instrument to

return to a normal condion (see § 9.4.1).

5

4 OPERATING INSTRUCTIONS

4.1 INSTRUMENT DESCRIPTION

CAPTION:

1. Input bushings

2. Mains socket

3. RS232 connector

4. ON/OFF/ key

5. Mulfuncon arrow keys

6. FUNC/ERASE MEM key

7. MODE/CLEAR SMOOTH key

8. SET/DISPLAY MEM key

9. ESC/RECALL MEM key

10. SAVE key

11. START/STOP key

12. LCD display

Fig. 1: Instrument descripon

4.2 DESCRIPTION OF FUNCTION KEYS

Key Descripon

Mulfuncon arrow keys they have several funcons which are

described in detail below

ON/OFF/ key used for:

Switch on/off the instrument

Switch on the display’s backlighng for 20 seconds (short

pressing of the key with the instrument already on)

FUNC/ERASE MEM key used for:

Select the desired funcon

Delete the measurements saved during the display of memory

data

MODE/CLEAR SMOOTH key used for:

Change the internal modes (if there are more available modes)

The pressure of the key set the default value of the selected

parameter

SET/DISPLAY MEM key used for:

Set the test parameters of a funcon

The pressure of the key shows the dates of the measurement

saved inside the memory

6

ESC/RECALL MEM key used for:

Access to the data saved in the memory (if present)

From a parameter seng screen or memory data display screen,

pressing the key once allows returning to the previous screen

SAVE key used for:

Once a measurement has been completed, pressing the key once

allows saving the results in the memory

From a parameter seng screen, pressing the key once allows

saving the changes made to the parameters

START/STOP key used for:

Start and/or stop a measurement

Table 1: Descripon of funcon keys

4.3 DESCRIPTION OF DISPLAY

Symbol Descripon

Display group 1 shows:

Insulaon resistance

Dielectric leakage current

PI (Polarizaon Index)

DAR (Dielectric Absorpon Rao)

Capacitance

Display group 2 shows:

Nominal test voltage

Generated test voltage

Display group 3 shows the duraon me of the test

Bargraph

Modes available test : FIX, ADJUST and RAMP

, , “Flash”, Alarm (values over limits), “Warning” symbols

, , “Low baery", “Mains supply", “Timer” symbols

“Number of test cycles” symbol

Table 2: Descripon of symbols of display

7

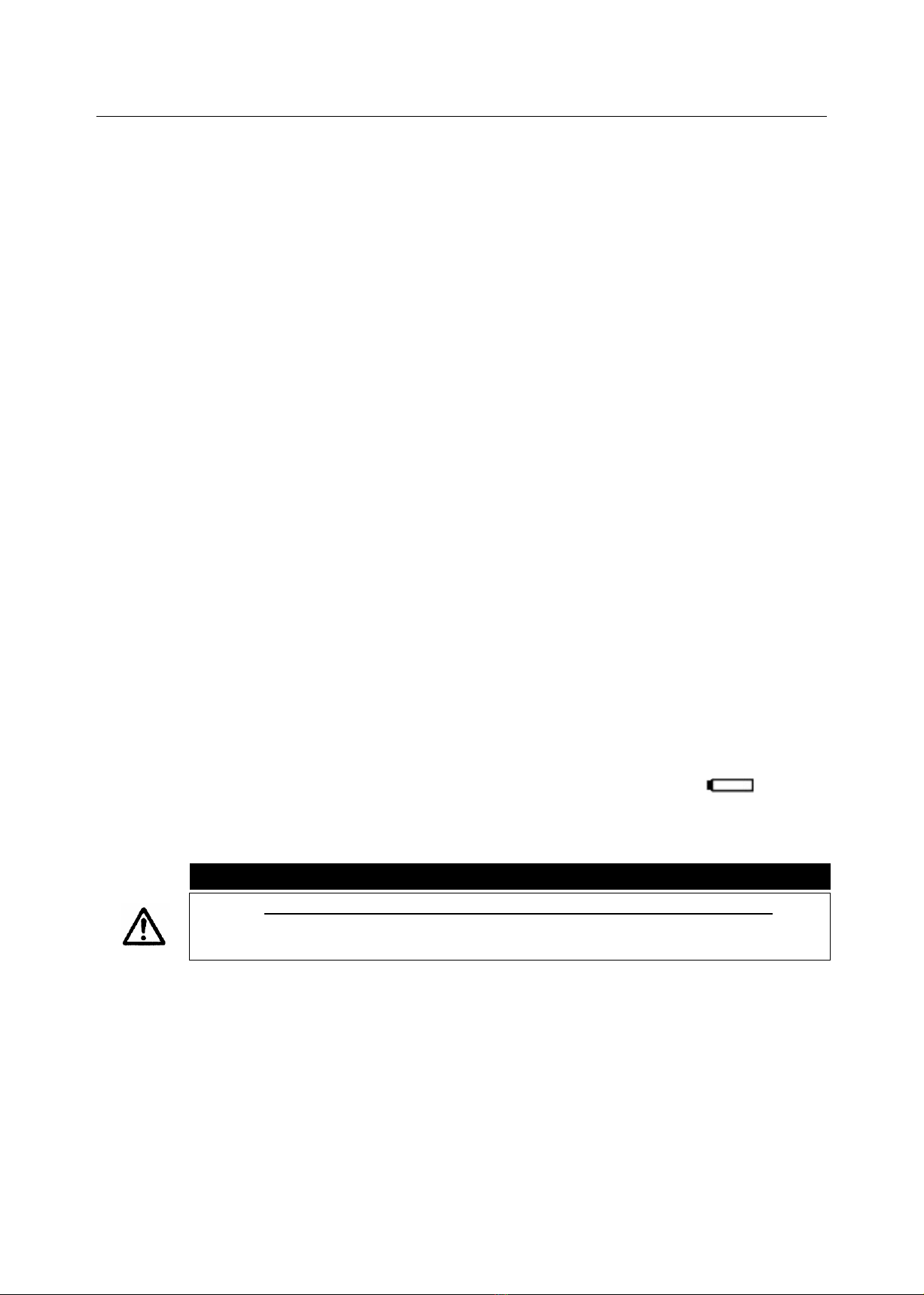

4.4 DESCRIPTION OF MEASURING LEADS

CAPTION:

1. Hand protecon

2. Safety areas

Fig. 2: Measuring leads

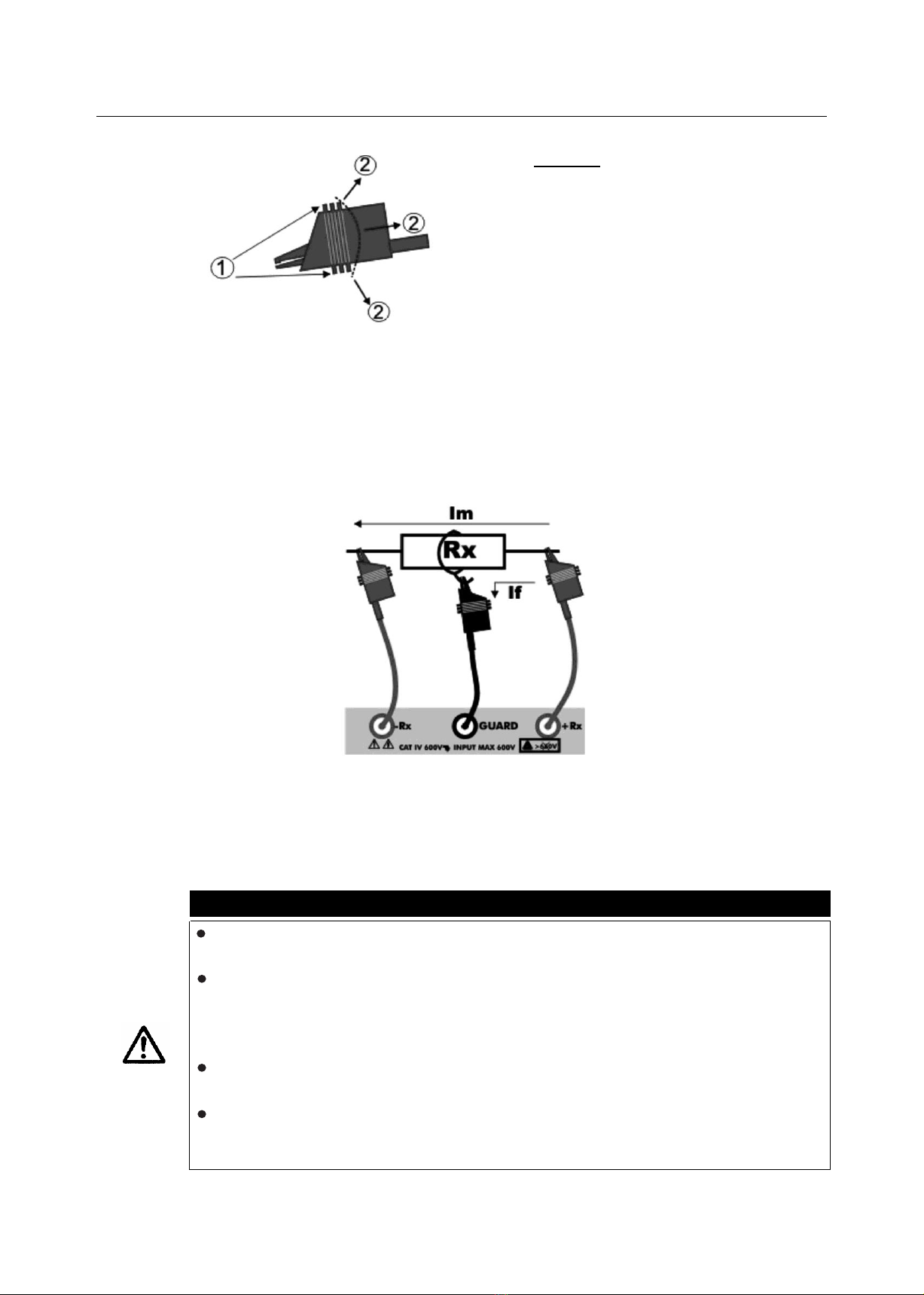

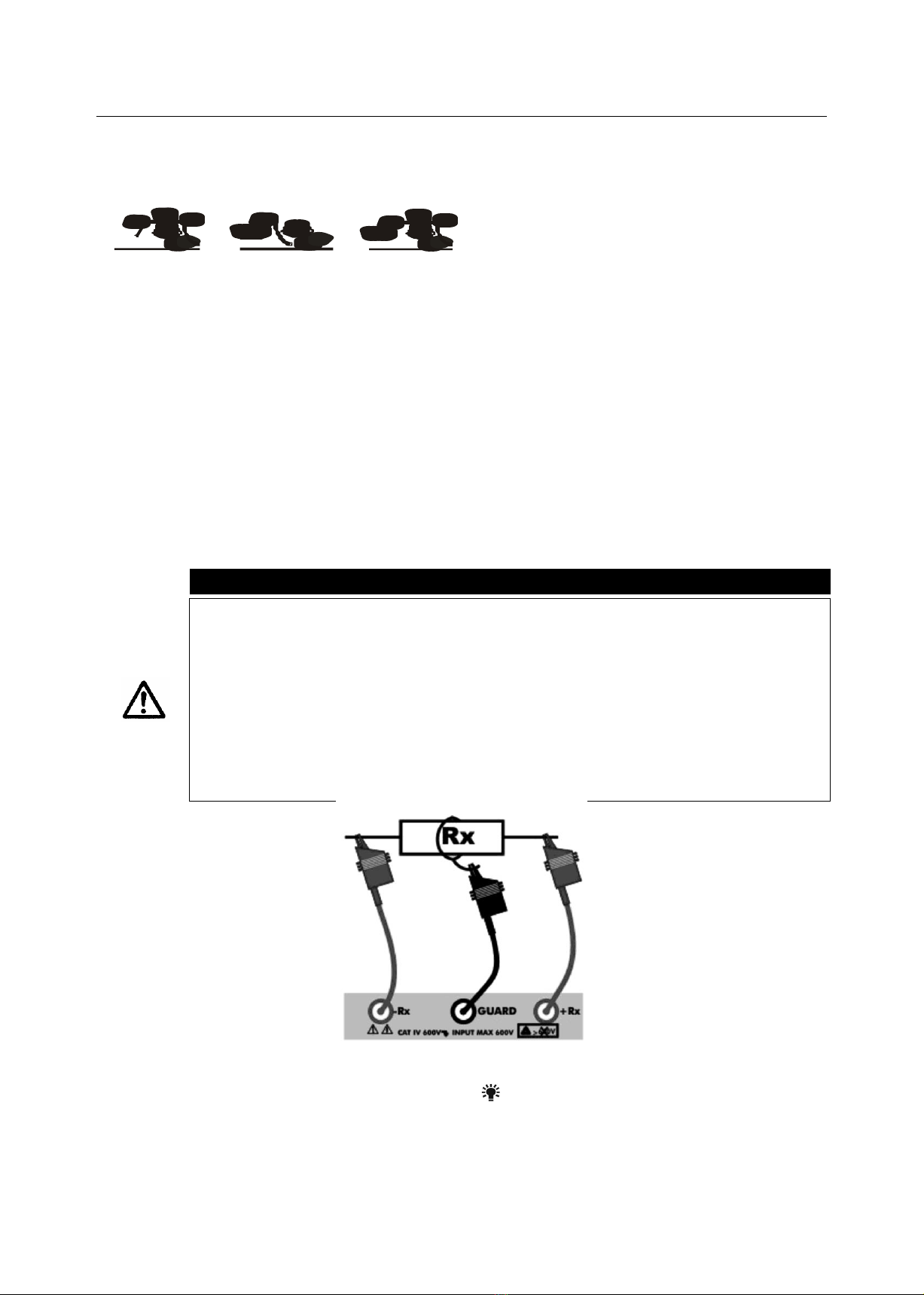

4.5 GUARD LEAD

In some cases, measurements could be affected by surface currents. By applying voltage to an

insulaon to be measured, there may be two disnct currents: one flowing in the test piece, the

other flowing on its surface. In case you want to measure only the resistance due to current Im

flowing in the test piece Rx (which is the significant one), it is necessary to absorb the surface

current If using another lead.

Fig. 3: Currents flowing in the test piece

4.6 NOTES ON THE INSULATION MEASUREMENTS

Measuring a high resistance such as the insulaon resistance is very difficult as the value of the

currents considered may be very low. When measuring, to prevent making mistakes, it is therefore

necessary to take the following precauons:

CAUTION

Keep the measuring leads suspended above the path or, anyway, make sure the

leads do not make contact in more of one point

While measuring high resistances, the area around the measuring instrument and

the appliance being tested must be free. It is recommended to use the mer

funcon so that the operator may keep at due distance from the leads and from

the resistance to be tested

It is recommended to use the GUARD lead to measure resistances of some tens of

GΩ or higher

While use the instrument with main supply, it's important to check that the

earthed resistance pole to measure is connected to the instrument Rx+

Terminal

8

4.7 SWITCH ON THE INSTRUMENT

Aer switch on, the instrument gives a short

acousc signal and, for approximately one

second, all segments of the display appear.

Then, the instrument shows the firmware

version, then it sets to the last measuring mode

selected before turning off.

4.7.1 Configuraon of the test parameters for FIX mode

If no test is being carried out, the instrument automacally turns off aer approximately 5

minutes aer the last me a key was pressed. To reacvate the instrument, it is necessary to turn

it on again by pressing the relevant key.

9

4.8 INSULATION MEASUREMENT IN FIX MODE

This measurement mode, performed in compliance with IEC/ EN61557-2 guideline, allows a quick

selecon of the test voltage among the values: 250, 500, 1000, 2500, and 5000VDC.

CAUTION

The instrument may be used on installaons of overvoltage category CAT IV 600V

to earth with maximum voltage 600V between inputs. Do not connect the

instrument to installaons with voltages exceeding the limit values indicated in

this manual. If these limit values are exceeded, the operator may be exposed to

electrical shocks and the instrument could get damaged

Always connect the measuring leads to the instrument and to the alligator clips

with the accessories disconnected from the system

It is recommended to hold the alligator clip respecng the safety area marked by

the hand protecon (see § 4.4)

Fig. 4: Instrument connecon

1. Turn on the instrument by press ON/OFF/ key

2. Press the FUNC/ERASE MEM key to select the “FIX” mode

3. The display shows a screen similar to that

reported here to the side, which contains:

The FIX selected mode

The bargraph set to zero

The "--- TΩ" indicaon

The selected test voltage

The test me value

The plug symbol (if the instrument is

supplied from the mains)

The baery symbol steadily

illuminated or flashing (if baeries are

flat or are being recharged)

The TIMER symbol if the duraon of

the test has been set

10

4. By pressing the arrow keys, the

instrument shows a screen similar to that

reported here to the side, which contains

the value of the input voltage.

5. Press the MODE/CLEAR SMOOTH key to set one of the following test voltages: 250V, 500V,

1000V, 2500V, 5000V

6. Insert the measuring leads into the relevant input leads of the instrument -Rx, +Rx and

GUARD, if necessary (see § 4.5 and Fig. 4)

CAUTION

Make sure that there is no voltage at the ends of the measuring points before

connecng them to the measuring leads.

7. Connect the alligator clips to the part of the system to be tested

8. Press the START/STOP key to perform measurement

CAUTION

The display shows the message "Measuring..." which indicates that the instrument is

performing the measurement. During this whole phase:

Do not disconnect the measuring leads of the instrument from the conductor

being tested; the conductor could remain live at a dangerous voltage because of

possible stray capacitances in the circuit tested;

Never insert the power cord into the Mains socket

9. During measurement, the instrument

gives a short acousc signal every second

and the display shows a screen similar to

that reported here to the side, which

contains:

The FIX selected mode

The bargraph proporonal to the

measured resistance value

The numerical indicaon of the

measured resistance

The applied test voltage

The symbol of the alarm bell (if the measured value is not within the set limits and/or if

the value of the test voltage is lower than the set nominal value)

The value of the test me elapsed or remaining (if a test has been set)

The plug symbol (if the instrument is supplied from the mains)

The baery symbol steadily illuminated or flashing (if baeries are flat or are being

recharged)

The mer symbol if the duraon of the test has been preset

The two "flash" symbols to indicate a dangerous voltage

The message "MEASURING..."

11

While measuring, it is also possible to display the leakage current, the DAR (Dielectric Absorpon

Rao if test duraon > 1 minute), the PI (Polarizaon Index if test duraon > 10 minutes) which

cyclically show when pressing the arrow keys (see § 11.1)

10. If no measuring me was set when seng the parameters or if you want to stop the test in

advance before the set me elapses, press the START/STOP key

11a. Once measurement is complete and any

capacitance has been discharged, the

instrument shows:

The value of the measured insulaon

resistance;

The value of the generated voltage;

The duraon of the test

If the measured resistance value is

between the (MIN - MAX) limits

previously set, the instrument shows

OK and gives a double acousc signal

(see § 4.10.1)

OR

11b. Once measurement is complete and any

capacitance has been discharged, the

instrument shows:

The value of the measured insulaon

resistance

The value of the generated voltage

The duraon of the test

If the measured resistance value is not

between the (MIN - MAX) limits

previously set, the instrument shows

NOT OK, the alarm bell and gives a

long acousc signal (see § 4.10.1)

12. Once measurement is complete, it is also possible to display the leakage current, the DAR

(Dielectric Absorpon Rao), the PI (Polarizaon Index) and the cap acitance which cyclically

show when pressing the arrow keys (see § 11.1)

CAUTION

If the measured resistance value < 5.0MΩ , the screen displaying the capacitance

shows three hyphens “---“, to indicate that it was impossible to measure the

capacitance, and the symbol

If, when scrolling the results obtained, the capacitance value is > 1nF, it is

recommended to repeat the measurement by acvang the SMOOTH funcon

(see § 4.11)

13. Measures can be saved by pressing the SAVE key twice (see § 5.1)

12

4.8.1 Configuraon of the test parameters for FIX mode

a. By cyclically pressing the SET/DISPLAY MEM key, it is possible to select the following

parameters:

Minimum value of the insulaon (MIN) in a range between 0,01MΩ - MAX

Maximum value of the insulaon (MAX) in a range between (MIN) - 10TΩ

Test me value in a range between (00min:05sec) - (99min:59 sec)

b. Press the arrow keys to change the value of the parameters (a long pressing of the keys

allows a rapid change of the values)

c. Press the MODE/CLEAR SMOOTH key to remove the limit values set for the parameters. The

display shows the message "no" to indicate that there is no limit set.

d. Aer seng, press the SAVE key to save the changes made or press the ESC/RECALL MEM

key to exit without saving and return to the previous screen

13

4.9 INSULATION MEASUREMENT IN ADJUST MODE

This funcon is performed in compliance with IEC/ EN61557-2 guideline. The ADJUST mode allows

the fine adjustment of the test voltage between 100 - 5000VDC.

CAUTION

The instrument may be used on installaons of overvoltage category CAT IV 600V

to earth with maximum voltage 600V between inputs. Do not connect the

instrument to installaons with voltages exceeding the limit values indicated in

this manual. If these limit values are exceeded, the operator may be exposed to

electrical shocks and the instrument could get damaged

Always connect the measuring leads to the instrument and to the alligator clips

with the accessories disconnected from the system

We recommend holding the alligator clip respecng the safety area marked by

the hand protecon (see § 4.4)

Fig. 5: Instrument connecon

1. Turn on the instrument by pressing the relevant key

2. Press the FUNC/ERASE MEM key to select the “ADJUST” mode

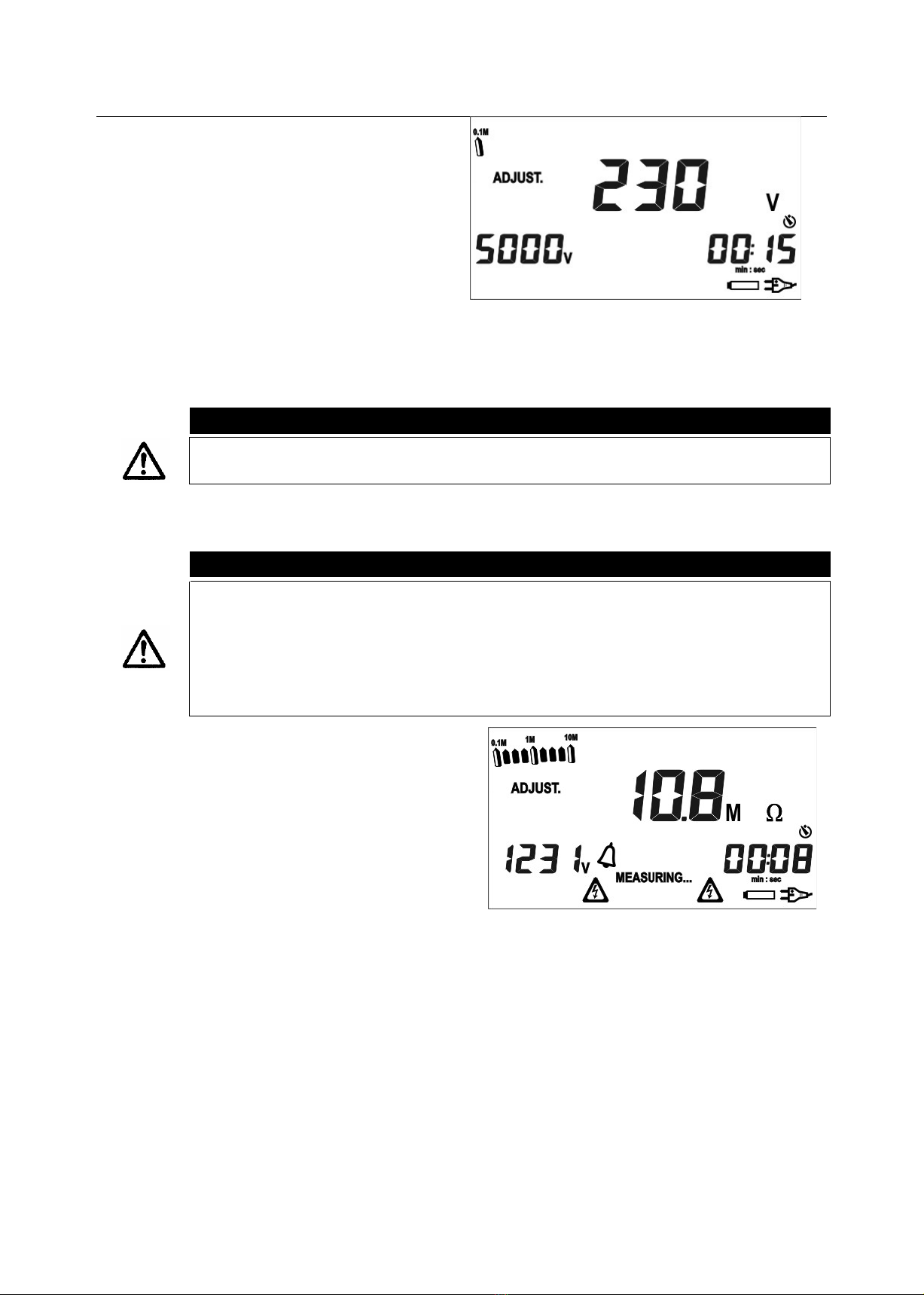

3. The display shows a screen similar to that

reported here to the side, which contains:

The ADJUST funcon selected

The bar graph set to zero

The indicaon "--- TΩ"

The test voltage

The value of the test me

The plug symbol (if the instrument is

supplied from the mains)

The baery symbol steadily

illuminated or flashing (if baeries are

flat or are being recharged)

The mer symbol if the duraon of the

test has been preset

14

4. By pressing the arrow keys, the

instrument shows a screen similar to that

reported here to the side, which contains

the value of the input voltage.

5. Make sure that the set test voltage is the desired one. Should it not be the case, please refer

to § 4.9.1 to change it

6. Insert the measuring leads into the relevant input leads of the instrument -Rx, +Rx and

GUARD, if necessary (see § 4.5 and Fig.5)

CAUTION

Make sure that there is no voltage at the ends of the measuring points before

connecng them to the measuring leads.

7. Connect the alligator clips to the part of the system to be tested.

8. Press the START/STOP key to perform measurement

CAUTION

The display shows the message “Measuring…” which indicates that the instrument is

performing the measurement. During this whole phase:

Do not disconnect the measuring leads of the instrument from the conductor

being tested; the conductor could remain live at a dangerous voltage because of

possible stray capacitances in the circuit tested

Never insert the power cord into the Mains socket

9.

During measurement, the instrument gives a

short acousc signal every second and the

display shows a screen similar to that

reported here to the side, which contains:

The ADJUST funcon selected

The bar graph proporonal to the

measured resistance value

The numerical indicaon of the

measured resistance

The actual test voltage

The symbol of the alarm bell (if the measured value is not within the set limits and/or if

the value of the test voltage is lower than the set nominal value)

The value of the test me elapsed or remaining (if a test has been set)

The plug symbol (if the instrument is supplied from the mains)

The baery symbol steadily illuminated or flashing (if baeries are flat or are being

recharged)

The mer symbol if the duraon of the test has been preset

The two “flash” symbols to indicate a dangerous voltage

The message “MEASURING…”

15

While measuring, it is also possible to display the leakage current, the DAR (Dielectric

Absorpon Rao if test duraon > 1 minute), the PI (Polarizaon Index if test duraon > 10

minutes) which cyclically show when pressing the arrow keys (see §11.1)

10. If no measuring me was set when seng the parameters or if you want to stop the test in

advance before the set me elapses, press the START/STOP key

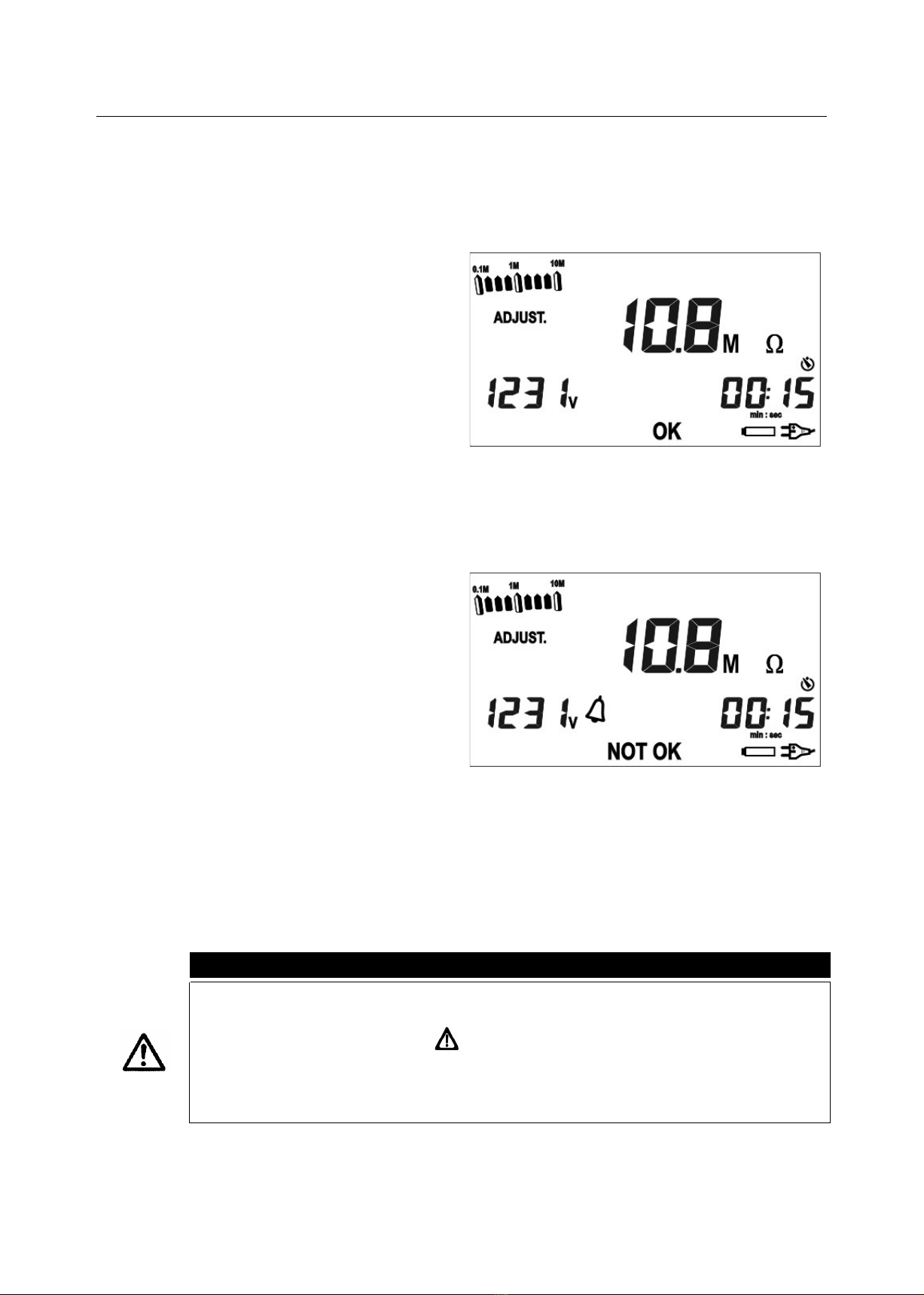

11a. Once measurement is complete and any

capacitance has been discharged, the

instrument shows:

The value of the measured insulaon

resistance

The value of the generated voltage

The duraon of the test

If the measured resistance value is

between the (MIN - MAX) limits

previously set, the instrument shows

OK and gives a double acousc signal

(see § 4.9.1)

OR

11b. Once measurement is complete and any

capacitance has been discharged, the

instrument shows:

The value of the measured insulaon

resistance

The value of the generated voltage

The duraon of the test

If the measured resistance value is not

between the (MIN - MAX) limits

previously set, the instrument shows

NOT OK, the alarm bell and gives a

long acousc signal (see § 4.9.1)

12. Once measurement is complete, it is also possible to display the leakage current, the DAR

(Dielectric Absorpon Rao), the PI (Polarizaon Index) and the capacitance which cyclically

show when pressing the arrow keys (see § 11.1)

CAUTION

If the measured resistance value < 5,0MΩ , the screen displaying the capacitance

shows three hyphens “---“, to indicate that it was impossible to measure the

capacitance, and the symbol

If, when scrolling the results obtained, the capacitance value is > 1nF, it is

recommended to repeat the measurement by acvang the SMOOTH funcon

(see § 4.11)

13. Measures can be saved by pressing the SAVE key twice (see § 5.1)

16

4.9.1 Configuraon of the test parameters for ADJUST mode

a. By cyclically pressing the SET/DISPLAY MEM key, it is possible to select the following

parameters:

Minimum value of the insulaon (MIN) in a range between 0.01MΩ - MAX

Maximum value of the insulaon (MAX) in a range between (MIN) - 10TΩ

Value of the test voltage in a range between 100V - 5000V (can be set in steps of 25V up

to 1000V and in steps of 50V from 1000V to 5000V)

Test me value in a range between (00min:05sec) - (99min:59 sec).

b. Press the arrow keys to change the value of the parameters (a long pressing of the keys

allows a rapid change of the values).

c. Press the MODE/CLEAR SMOOTH key to remove the limit values set for the parameters. The

display shows the message "no" to indicate that there is no limit set. Only when seng the

value of the test voltage, by pressing the MODE/CLEAR SMOOTH key, the voltage sets to

the default value of 1000V.

d. Aer seng, press the SAVE key to save the changes made or press the ESC/RECALL MEM

key to exit without saving and return to the previous screen

17

4.10 INSULATION MEASUREMENT IN RAMP MODE

This funcon is performed in compliance with standard IEC/ EN61557-2. The RAMP mode allows

choosing among three different types of ramps:

RAMP#1 RAMP#2 RAMP#3

For each type of ramp, it is possible to set the duraon, the test voltage and the number of mes

the ramp is repeated (§ 4.10.1, § 4.10.2, § 4.10.3).

RAMP#1: Voltage starts from 0V, reaches the value V1 in a me interval T, keeps the value

V1 for a me T1, and finally returns to 0 (with possible discharge of the residual

voltage).

RAMP#2: Voltage starts from 0V, which is kept for a me T0, reaches the value V1 in a me

interval T, and finally returns to 0 (with possible discharge of the residual voltage).

RAMP#3: Voltage starts from 0V, which is kept for a me T0, reaches the value V1 in a me

interval T, keeps to value V1 for a me T1, and finally returns to 0 (with possible

discharge of the residual voltage).

CAUTION

The instrument may be used on installaons of overvoltage category CAT IV 600V

to earth with maximum voltage 600V between inputs. Do not connect the

instrument to installaons with voltages exceeding the limit values indicated in

this manual. If these limit values are exceeded, the operator may be exposed to

electrical shocks and the instrument could get damaged

Always connect the measuring leads to the instrument and to the alligator clips

with the accessories disconnected from the system

It is recommended to hold the alligator clip respecng the safety area marked by

the hand protecon (see § 4.4)

Fig. 6: Instrument connecon

1. Turn on the instrument by press the ON/OFF/ key

2. Press the FUNC key to select the RAMP funcon

18

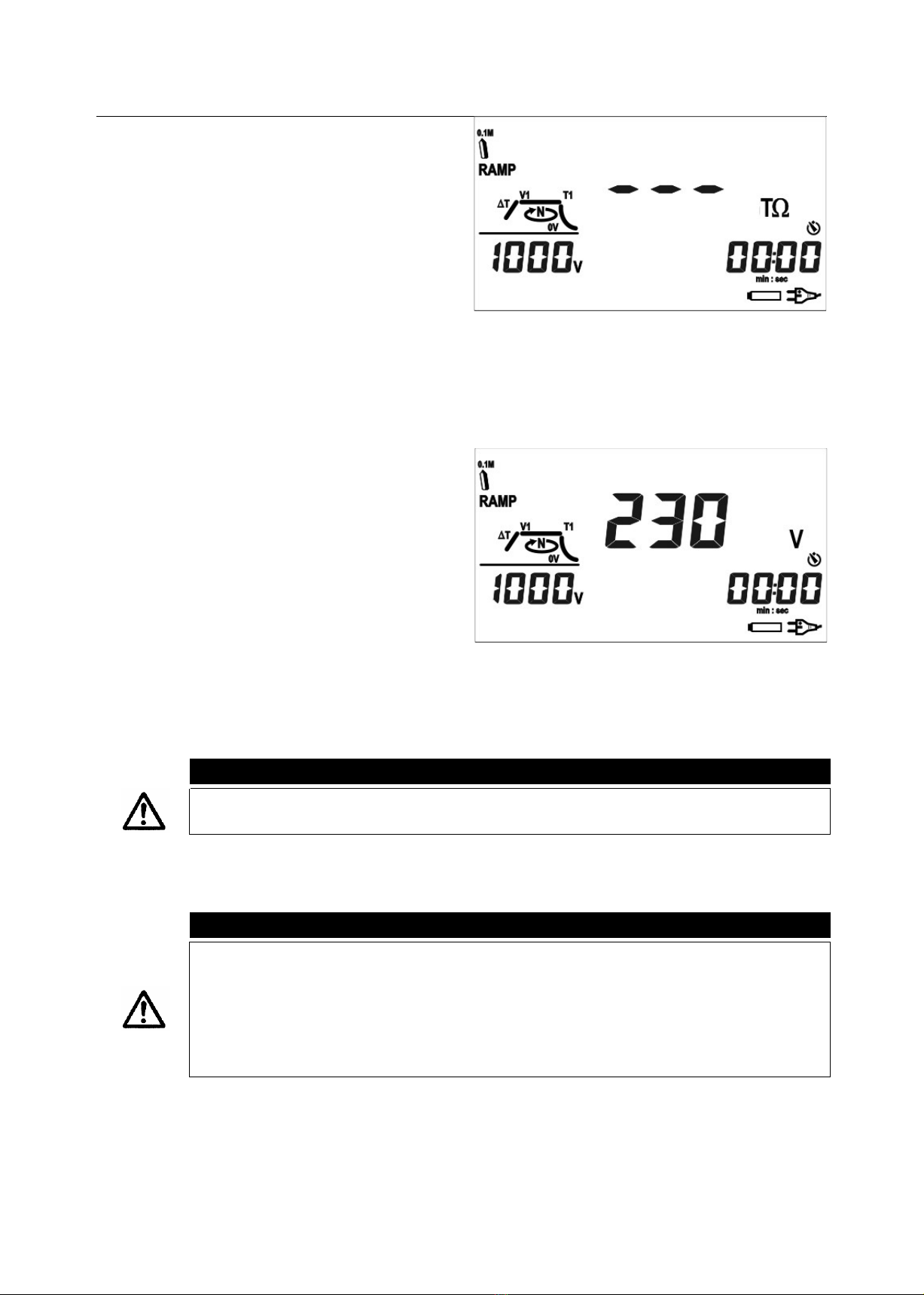

3. The display shows a screen similar to that

reported here to the side, which contains:

The RAMP type selected

The bar graph set to zero

The indicaon "--- T "

The set test voltage

The value of the test me

The plug symbol (if the instrument is

supplied from the mains)

The baery symbol steadily illuminated

or flashing (if baeries are flat or are

being recharged)

The mer symbol if the duraon of the

test has been preset.

4. By pressing the arrow keys, the instrument

shows a screen similar to that reported

here to the side, which contains the value

of the input voltage.

5. Insert the measuring leads into the relevant input leads of the instrument -Rx, +Rx and

GUARD, if necessary (see § 4.5 and Fig. 6)

CAUTION

Make sure that there is no voltage at the ends of the measuring points before

connecng them to the measuring leads.

6. Connect the alligator clips to the part of the system to be tested.

7. Press the START/STOP key to perform measurement.

CAUTION

The display shows the message "Measuring..." which indicates that the instrument is

performing the measurement. During this whole phase:

Do not disconnect the measuring leads of the instrument from the conductor

being tested; the conductor could remain live at a dangerous voltage because of

possible stray capacitances in the circuit tested

Never insert the power cord into the Mains socket

19

8. During measurement, the instrument gives

a short acousc signal every second and

the display shows a screen similar to that

reported here to the side, which contains:

The RAMP funcon selected

The bar graph proporonal to the

measured resistance value

The numerical indicaon of the

measured resistance

The segment relevant to the current ramp point, flashing

The actual test voltage (relevant to the current ramp point)

The symbol of the alarm bell (if the measured value is not within the set limits and/or if

the value of the test voltage is lower than the set nominal value)

The value of the remaining test me (relevant to the current ramp point)

The plug symbol (if the instrument is supplied from the mains)

The baery symbol steadily illuminated or flashing (if baeries are flat or are being

recharged)

The mer symbol

The two "flash" symbols to indicate a dangerous voltage

The message "MEASURING..."

While measuring, it is also possible to display the leakage current, the capacitance the

number N of the cycle the instrument is performing, which cyclically show when pressing

the arrow keys.

9. .. If you want to stop the test in advance before the set number N of cycles is reached, press

the START/STOP key.

10a. Once measurement is complete and any

capacitance has been discharged, the

instrument shows:

The value of the measured insulaon

resistance

The value of the actually generated

voltage V1

The value of the me relevant to

parameter T1

If the measured resistance value is

between the (MIN - MAX) limits

previously set, the instrument shows

OK and gives a double acoustic signal

(see § 4.10.1, § 4.10.2, § 4.10.3)

OR

Table of contents

Other Sifam Tinsley Test Equipment manuals