Sifam Tinsley Zeta 20 User manual

User Manual

Analog-Digital Insulation Tester

Zeta 20

IC 2-60-006-00-00550/REV. A/03/11/2014

Printed in India, Subject to change without Notice

Sifam Tinsley Instrumentation Ltd.

Central Buildings, Woodland Close,

Old Woods Trading Estate,

Torquey, Devan, England, TQ27BB

Website: www.sifamtinsley.com/uk

Contact Number: +44(O) 1803 615139

E-mail: info@tinsley.co.uk

Sifam Tinsley Instrumentation

3105, Creekside Village Drive,

Suite No 801,Kennesaw,

Georgia 30144

Contact Number: +1.404.736.4903

Web: www.sifamtinsley.com

P R E C I S I O N I N S T R U M E N T A T I O N

WARRANTY

Dear Customer,

You are now the privileged owner of Zeta 20 Analog-Digital / Multimeter a

product that ranks the first of its kind in the world. Company provides 12

months warranty from the original date of Purchase against defective

material and workmanship.

In the unlikely event of failure of the instrument / accessories within the

warranty period. Company will repair meter / accessories free of charge.

Please hand over the meter / accessories to the dealer / stockist from whom

you have purchased along with this card and relevant Cash Memo / Invoice.

This warranty entitles you to bring the meter / accessories at your cost to the

nearest stockist / dealer and collect it after repairs.

NO TRANSPORTATION CHARGES WILL BE REIMBURSED.

The warranty is not valid in following cases:

1. Warranty card duly signed and stamped and original Cash Memo / Invoice

is not sent along with Meter.

2. Complete warranty card is not presented to authorised person at the time

of repairs.

3. Meter / accessories is not used as per the instructions in the instruction

manual.

4. Defect caused by misuse, negligence, accidents, tampering and Acts of

God.

5. Improper repairing by any person not authorised by the company.

6. Modification, Alteration of any sort is made in electrical circuitry.

7. Seal provided inside/outside is broken.

Warranty of Zeta 20 accessories does not cover Fuses, Battery & Mains

Adapter.

In case of dispute to the validity of the warranty, the decision of Company

service center will be final.

If you bought this Meter directly from the company, and if you notice transit

damage, then you must obtain the insurance surveyors report and forward it

to Company .

Thank you.

(To be filled by authorized dealer)

Model No. :

Serial No. :

Date of Purchase :

Cash Memo / Invoice No. :

Dealer’s Signature :

Dealer’s Stamp :

Scope of Supply

1) Instrument 2) Cable Set

3) Spare Fuse 4) Safety Cover

5) 1.5 V Battery 6 Nos. - Rechargeable - Yes No

6) User Manual 7) Warranty Card

8) Crocodile Clips 9) Optional-mains

Adapter Yes No

10) Belt

13.3 Fuses

Application of high energy pulse during Insulation resistance

measurement or application of voltage during Continuity and Ohm

measurement will blow the fuse. If the fuse blows, eliminate the cause of

the overload before placing the instrument back in to operation !

Fuse Testing

* Set the function selector switch to any insulation measurement range.

* Open circuit the test leads.

* Press the “Test” button until “OL” or “FUSE” appears on display.

If display = “OL” : Fuse is OK.

If display = “FUSE” : Fuse is blown and needs replacement.

Note : Once “FUSE” is displayed all the functions are inhibited.

Immediately switch the Instrument OFF and replace the fuse.

Replacement of Fuses

* Open the instrument as described under battery replacement.

* Remove the defective fuse and replace it with a new fuse.

* Make sure that the new fuse makes good contact.

Specification :

Current Rating : 500 mA / 500V-6.3 mm x 32 mm with a breaking capacity

of 10kA.

Recommended fuse manufacturer : Siba

Part No. : 70-065-63/0.5A

Be absolutely sure that only the specified fuses are used !

The use of a fuse with different triggering characteristics,

a different nominal current or a different breaking capacity

exposes the operator, the system and the measuring

instrument to danger. The use of repaired fuses or short-

circuiting of the fuse holder is prohibited.

13.4 Housing

No special maintenance is required for the housing. Excessive

contamination has an adverse effect on isolation and reduces input

resistance. The surface must be kept clean for this reason. Use a slightly

dampened cloth for cleaning. Oil free petrol is recommended for

cleaning. Avoid the use cleansers, abrasives or solvents.

19

Zeta 20

MΩ

50V

100V

250V

500V1KV

V

7

TEST

ON

OFF

ESC

STORE

V MΩ

Ω

fused

600V CAT II / 300V CAT III

6

5

4

3

2

1

600V

MIN MAX 400

100kM

600

10kM

VAC VDC

ON

200

1MG

800

1kM

F

A

G

M

k

100k

1000

10MG

8

L

L

ZERO

8

(optional)

MIN MAX 400

100kM

600

10kM

VAC VDC

ON

200

1MG

800

1kM

F

A

G

M

k

100k

1000

10MG

8

L

L

ZERO

20

17

9 19 10 11 12

13

18 14 15 16

2

3

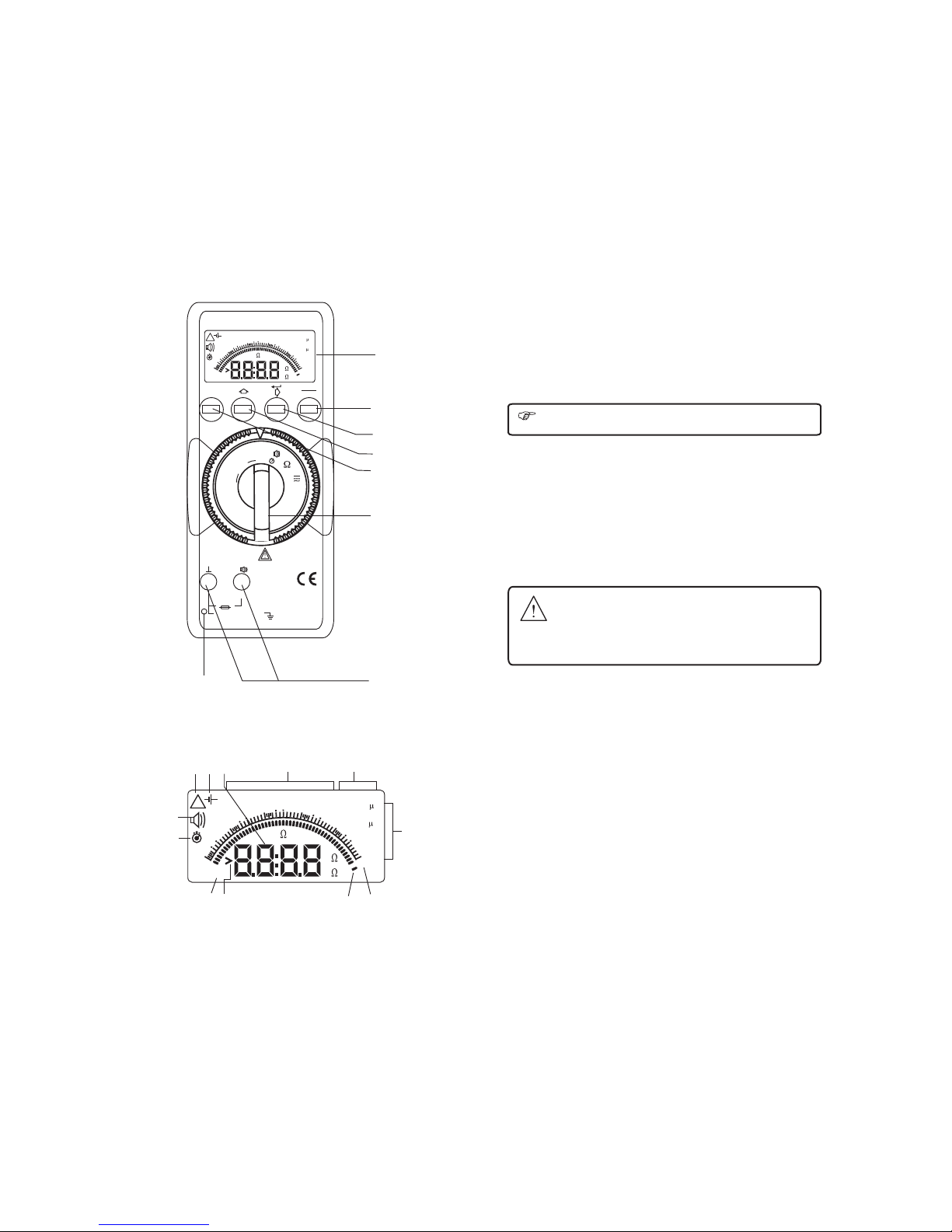

(1) Liquid Crystal Display (11) Symbols for displaying the

(2) ON/OFF push button selected functions

(3) Push button (12) Display for selected function

(4) Push button (13) Display for the unit of

(5) TEST Push button measured quantity

(6) Function selector switch (14) Over range Indication

(7) Terminal sockets (15) Pointer for Analog indication

(8) External Power supply jack (Optional)

(9) Symbol for (16) Scale for Analog Indication

“CONTINUOUSLY ON” (17) Activated stop watch Indicator

(10) Digital display with indication (18) Zero adjust indicator

of decimal point and polarity (19) Low battery indicator

(20) Buzzer indication

Contents Page

1 Safety Features and Precautions 4

2 Initial Start-Up 5

3 Selecting Measuring Functions 6

4 Liquid Crystal Display 6

4.1 Digital Display 6

4.2 Analog Display 6

4.3 Backlit 6

5 Insulation Resistance Measurement (M ) 7

5.1 Preparation for measurement 7

5.2 Insulation resistance measurement 7

5.2.1 Manual Insulation resistance measurement 7

5.2.2 Continuous measurement for a pre-selectable time 8

5.3 Conclusion of measurement and discharging 8

6 Additional Features 8

6.1 Pre-selectable limit checks (Go / No-Go option) 9

6.2 Storing the measured resistance value 9

6.3 Minimum value and Maximum value “MIN/MAX” 9

storage facility

7 Continuity Testing and Resistance Measurement 11

7.1 Continuity Testing 11

7.2 Low Ohm Measurement 11

7.3 Zero adjustment 11

8 Voltage Measurement (VAC/DC) 12

9 Default Live Circuit Warning 12

10 Stop Watch 13

11 Menu Structure 13

11.1 Description of Menu items 14

11.1.1 Setting the GoNoGo values 14

11.1.2 Setting the Timer values 14

11.1.3 To see the stored values 14

12 Specifications 15

13 Maintenance 18

13.1 Battery 18

13.2 Operation with mains Adapter (Optional) 18

13.3 Fuses 19

13.4 Housing 19

Ω

Mechanical Design

Protection Instrument :IP 50

For terminal socket : IP 20 according to

DIN VDE 0470 Part 1 / EN60529

Dimensions W x H x D

84mm x 195 mm x 35 mm

Weight 500 g including battery

13 Maintenance

Attention !

Disconnect the instrument from the measuring circuit before

opening the instrument to replace the battery or the fuse !

13.1 Battery

Before initial Start-up, or after long storage of your instrument, make sure

that no leakage has occurred at the instrument battery. Repeat this

inspection at regular intervals.

Battery symbol “ ” appears on the LCD in either of below conditions :

1. Battery voltage is <5.4 V. Battery replacement (recharging in case of

rechargeable battery) is necessary.

2. For a specific range depending on application

In either of above condition when the battery symbol is displayed, no

measurement can be done, and the battery symbol flashes.

Replacing the Batteries

* Lay the instrument on to its face, loosen the two screws at the rare

panel and lift out the housing base, starting at the bottom (a). The

housing base and the housing top are held together with snap hooks

at the top of the front panel.

* Remove all the cells from the battery holder and replace them with

new ones.

* Important for reassembly : first lay the housing base into place such

as shown in diagram below. Push the housing base and housing

top together, first at the bottom front (a) and then at the top front (b).

* Retighten the housing base with the two screws.

* Please dispose of the used cells properly.

13.2 Operation with Mains Adapter (Optional)

Use only Mains Adapter (Output : 12VDC, 1000mA) to power ON the

instrument.

During power supply via mains adapter in inserted batteries are cut off

electronically and thus can be left inside the instrument.

Note : There is no need of internal batteries when AC-DC Adapter

is connected to the instruments.

If re-chargeable batteries are used they must be charged outside

the instrument.

18

(b) (a)

Table of contents

Other Sifam Tinsley Test Equipment manuals

Popular Test Equipment manuals by other brands

Redtech

Redtech TRAILERteck T05 user manual

Venmar

Venmar AVS Constructo 1.0 HRV user guide

Test Instrument Solutions

Test Instrument Solutions SafetyPAT operating manual

Hanna Instruments

Hanna Instruments HI 38078 instruction manual

Kistler

Kistler 5495C Series instruction manual

Waygate Technologies

Waygate Technologies DM5E Basic quick start guide

StoneL

StoneL DeviceNet CK464002A manual

Seica

Seica RAPID 220 Site preparation guide

Kingfisher

Kingfisher KI7400 Series Training manual

Kurth Electronic

Kurth Electronic CCTS-03 operating manual

SMART

SMART KANAAD SBT XTREME 3G Series user manual

Agilent Technologies

Agilent Technologies BERT Serial Getting started