SIG E-FORCE ARF User manual

are in your battery pack -- i.e. if you are using a lithium-polymer

battery pack, be sure you use a charger designed for li-polys.

NEVER use a nicad or nimh charger to charge lithium batteries,

and vice versa. Doing so can be very dangerous!

2) Make sure you use a "peak detection" charger. This is a

charger that automatically senses when the battery is completely

charged (peaked) and then shuts itself off. A peak detection

charger not only prevents overcharging of batteries, (which will

damage them in time), but it also insures that you are getting the

maximum charge into the batteries, so that you will realize

maximum power and duration from the motor.

RADIO EQUIPMENT

The E-FORCE gets its great flight performance from many factors,

but one of the most important factors is its light weight. The lighter

the final weight is, the better this airplane will fly! Since this model

is factory built and covered, you can only realistically control the

finished, ready-to-fly weight by choosing the most appropriate

radio equipment for a model of this size. In short, the flight

performance of your E-FORCE will be directly controlled by the

weight of the radio equipment you choose to put in it. Maximum

performance can only be achieved with light weight components.

RECEIVER (not supplied): A small or "micro" size receiver

should be used in this model due to weight and size constraints.

In our flight tests of the E-FORCE, we have used the following dual

conversion receivers:

receiver weight

FMA M5 11 grams

Hitec Electron 6 19 grams

SERVOS (not supplied): You will need 4 mini servos for the

E-FORCE - 1 for the elevator, 1 for rudder, and 2 for ailerons.

Standard servos, the ones that come with most sport radio

systems, are too big and too heavy for the E-FORCE. You will

need smaller servos. In our flight tests of the E-FORCE, we have

used the following servos with excellent results:

servo weight torque

Hitec HS-55 7.9 grams 15 in/oz

Airtronics 94091 9.0 grams 18 in/oz

Note: Any other brand of servo that is in the same size and torque

range will also work just fine.

SERVO CHORDS (not supplied): You will need two 6" Servo

Extension Chords - one for the elevator servo and one for the

rudder servo.

COVERING MATERIAL

Your E-FORCE has been professionally covered with SIG

AEROKOTE-LITE®iron-on plastic covering material. This is a low

temperature covering material that is very tough and light weight,

weighing only 5.9 grams per sq. ft.

The colors used on this model are AEROKOTE-LITE®

#SIGSGX100 Brilliant White, and

#SIGSGX060 Transparent Purple

Wrinkles In The Covering! After you remove the covered model

parts from their plastic bags, you may notice within the first couple

days that some of the covering material may become slack or

wrinkled. If that's the case, there is no need to be alarmed. The

covering is not defective! Your E-FORCE was covered in a part of

the world which has consistantly high humidity, and some of that

moisture is retained in the balsa wood when the parts were put in

1

INTRODUCTION

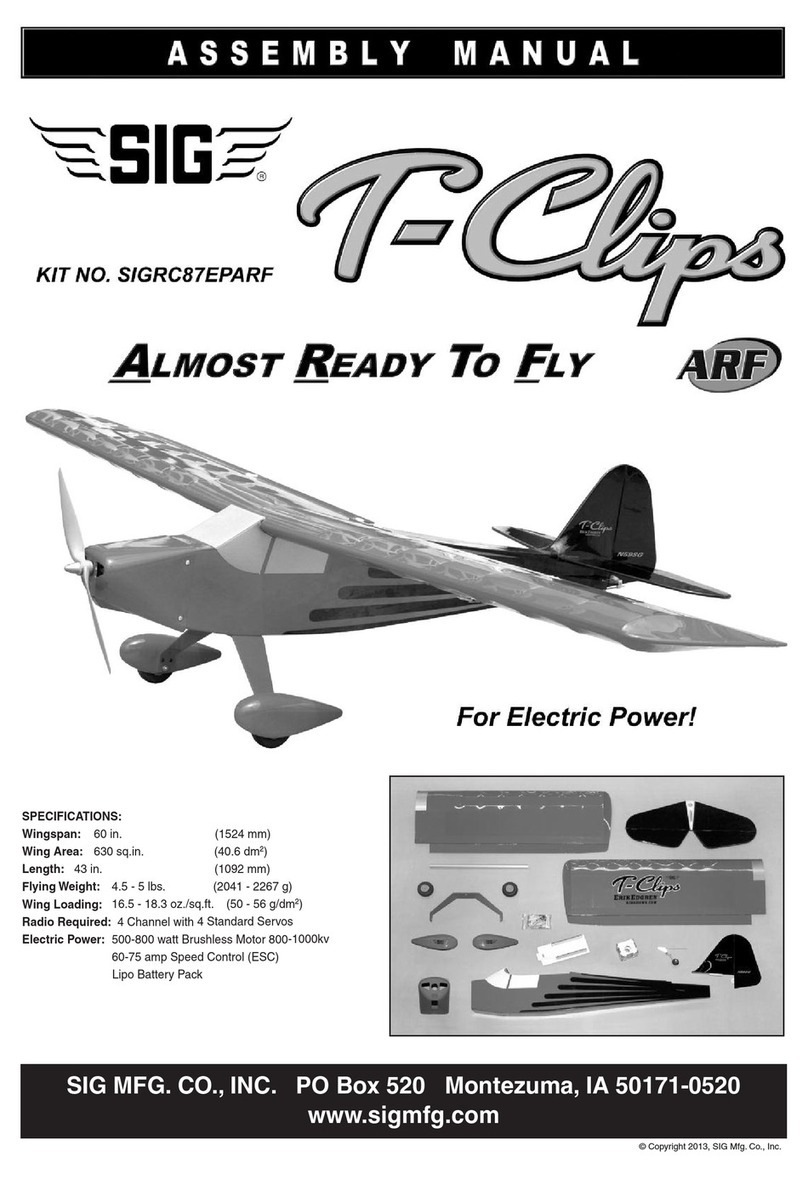

Congratulations on your purchase of the SIG E-FORCE ARF. The

E-FORCE was designed for one purpose - to provide an all wood

electric powered 3D aerobatic ARF. This is no "throw away"

foamie! Constructed of laser-cut balsa, the sturdy light weight

structure is designed to stand up to the rigors of 3D maneuvers

and turn in spectacular performances, flight after flight.

Assembly of your E-FORCE ARF is fast and simple when

following the detailed instructions in this manual. A low parts

count and professional engineering ensure quick and easy

assembly. All parts are CAD-drawn, laser-cut, and jig assembled,

which means that everything fits the way it should! We urge you

to read this instruction manual completely before starting

assembly, to familiarize yourself with the parts and the assembly

sequence.

ELECTRIC POWER SYSTEM

MOTOR (supplied):The E-FORCE ARF includes a super-torquey

Himax HC2808-0980 brushless outrunner motor.This light weight

motor produces more than a 1:1 power to weight ratio that will

blast the E-FORCE from zero to insane in just about a heartbeat!

Technical Specifications Himax HC2808-0980 Motor:

Kv=980, Rm=.220, lo=0.4, current=3-8A, 12A max 15 seconds

PROPELLER (supplied): A 9.25 x 5 electric style propeller is

included in the kit.

ESC ELECTRONIC SPEED CONTROL (not supplied): A 10-12

amp Brushless ESC is recommended for the E-FORCE. Note that

3 Brass Connectors (female) are provided in this kit to connect

your ESC to the motor. You will need to purchase appropriate

connectors of your choice to connect your ESC to your battery

pack (see ESC INSTALLATION further back in this manual).

BATTERY PACK (not supplied): We recommend a 3S (3 cells in

series), 11.1v, 900mah Lithium Polymer battery pack. Properly

charged, this battery pack delivers excellent power and duration

for the E-FORCE power system.

Note: We do not recommend other types or sizes of battery packs

without thorough bench and field testing. Flight performance can

suffer greatly with the wrong battery pack. In some cases the

airplane won't fly at all with the an improper pack. Use the

recommended battery pack to insure good performance.

BATTERY CHARGER (not supplied): To get the maximum

capacity and performance from your battery pack, it is essential to

use a proper battery charger.

1) Make sure your charger is designed for the type of cells that

the bags. When exposed to drier air, the wood loses the excess

moisture, dimensionally shrinking slightly in the process. In turn,

this shrinkage may cause some slight relaxing of the covering,

causing wrinkles to appear.

Any wrinkles that appear in the covering are easy to remove by

applying a little heat from a small modeler's heat iron. Because of

this model's small size, we do not recommend using a heat gun to

tighten up loose covering. A typical hobby type covering iron will

work just fine. Even better is a small modeler's "trim seal" iron,

which is perfect for controlling the heat applied to a specific area.

Using a small trim iron also minimizes the possibility of warping

the thin control surface parts.

For reshrinking AEROKOTE-LITE®set your iron temperature

to approximately 140O-180OF (60O-82OC).

First, use the hot iron to go over all the s

eams and color joints in

the covering, making sure they are all sealed down and well

adhered. Then, hold the hot iron over the wrinkle to lightly shrink

the material - do not press on it. Once the covering is tight, lightly

iron it back down to the wood. Use caution whenever the hot iron

gets close to a seam in the covering. Over-heating a seam can

cause the covering to creep, exposing th

e wood underneath.

REQUIRED TOOLS

For proper assembly, we suggest you have the following tools and

materials available:

❑A selection of glues - thin, medium, and thick SIG CA, and

SIG Epoxy Glue (5-minute and 30-minute)

❑Fine point CA applicator tips

❑Screwdrivers

❑Pliers - Needle Nose and Flat Nose

❑Wire Cutters

❑Drill with Assorted Drill Bits

❑Pin Vise for small diameter drill bits

❑Small T-Pins

❑Sandpaper

❑Hobby Knife with sharp #11 blades

❑Scissors

❑Covering Iron and Trim Seal Tool

❑Paper Towels

❑Rubbing Alcohol (for cleaning off excess epoxy glue)

KIT INVENTORY

The following is a complete list of all parts contained in this kit.

Before beginning assembly, we suggest that you take the time to

inventory the parts in your kit.

1 bag ❑(1) Fuselage, with

❑(1) Electric Motor installed

❑(1) Wire Tail Skid installed

❑(1) Fin installed

❑(1) Velcro installed for battery mounting

1 bag ❑(1) Wing

1 bag ❑(1) Right Aileron

❑(1) Left Aileron

1 bag ❑(1) Stabilizer

❑(1) Elevator

❑(4) CA Hinges, installed but not glued

1 bag ❑(1) Rudder

1 bag ❑(1) Tall Landing Gear Wire

❑(1) Short Landing Gear Wire

❑(2) Main Wheels

❑(2) Wheel Collars with Set Screws

❑(2) Nylon Wheel Spacers

❑(2) Plastic Tie Straps

1 bag ❑(4) Nylon Control Horns

❑(4) Nylon Pushrod Keepers

❑(4) Pre-Bent Pushrod Wires

❑(11) CA Hinges

1 bag ❑(1) 9.25 x 5 Propeller

1 bag ❑(3) Brass Connectors (female)

❑(1) L-Wrench

❑(1) Prop Shaft Assembly, consisting of:

(1) Collet

(1) Drive Washer

(1) Spinner Nut

1 bag ❑(1) Decal Sheet

NOTE: In this manual, any references to right or left, refer to your

right or left as if you were seated in the cockpit of the airplane.

BASIC ASSEMBLY

❑1) Carefully slide the wing in place in the fuselage. Measure

carefully to make sure you have the wing properly centered and

square with the fuselage.

❑2) Once you have the wing properly aligned, use a felt-tip pen

to mark the exact fuselage location on the surfaces of the wing.

2

3

Run the pen tight against the side of the fuselage, from the

leading edge of the wing all the way to the trailing edge. Mark both

sides of the fuselage on both the top and bottom of the wing. Then

remove the wing for the next step.

❑3) Next, you need to remove the covering material from the

wing between the marked lines. Start by using a sharp hobby

knife or single-edge razor blade to cut through the covering

material just inside the marked lines. Be very careful to cut the

covering material only - not the balsa wood structure underneath.

After you've cut through the covering material, peel the unwanted

covering off the wing.

❑4)

Now glue the wing permanently in place in the fuselage, being

very careful to get it in perfect alignment before the glue dries.

❑5) As provided in the kit, the elevator is only temporarily

attached to the stabilizer with 4 unglued CA hinges in the pre-cut

slots. Separate the stabilizer and elevators and set the hinges

aside for now. Then use your covering iron to make sure the

covering material is securely adhered to the trailing edge of the

stab and the leading edge of the elevators.

❑6) Slide the stabilizer in place in the fuselage. Measure

carefully to make sure you have the stabilizer properly centered

and square with the fuselage. Also check the alignment of the

stabilizer to the wing, checking both the top and rear views. If

necessary, alter the stab cutout in the fuselage to allow you to get

the stab in proper alignment.

❑7) Once you have the stabilizer properly aligned, use a felt-tip

pen to mark the fuselage location on the top and bottom surfaces

of the stabilizer. Remove the stabilizer from the fuselage, and then

carefully remove the covering material between the lines.

❑8)

Glue the stabilizer permanently in place in the fuselage, being

very careful to get it in perfect alignment before the glue dries.

HINGING

❑9)

Assemble the elevators back onto the stabilizer with the four

CA Hinges. Make sure the pre-drilled holes in the left elevator for

the control horn end up on the left side of the fuselage, (left side as

if you were seated in the cockpit of the airplane). Push the

elevators firmly up against the back of the stab. Also check to

make sure the elevator is centered on the span of the stab. Set the

proper amount of gap between the stab and elevators by

deflecting the elevator about 45

O

each way. This will automatically

set the proper hinge gap. Keep in mind that for best control

response the gap should be as small as possible, but big enough

to allow full movement of the elevator. Make sure everything is

functioning properly before proceeding to the next step.

❑10) With a fine applicator tip on your glue bottle, carefully place

2 drops ofThin CA glue directly onto the first hinge in the gap. You

will notice that the glue wicks into the wood and the hinge. Quickly

turn the model over and apply 2 drops of glue to the other side of

4

the hinge. Continue this process until you have glued both sides

of all the elevator hinges. Keep a rag handy to wipe off any excess

Thin CA glue.

Note: If you get some glue smears on the plastic covering, don't

worry about them right now. Once all the hinges are glued, you

can go back to clean the smears off with a little CA Debonder on

a rag or paper towel.

Let the glue dry a minimum of 10 minutes before flexing the

hinges. At first you might notice a little stiffness in the joint. This

will go away after the hinges have been flexed back and forth a

couple dozen times.

VERY IMPORTANT:

It's critical that you only make one

application of glue to each side of a CA hinge. If you apply

additional glue to the hinge after the first application of glue is

already dry, the second application of glue will merely puddle in the

hinge gap and make the hinge too stiff to operate properly. The

excess glue can also weaken the hinge! When properly glued, the

portion of the hinge that you see in the hinge gap should have a

dry appearance, not wet. A dry appearance indicates that almost

all of the glue has properly soaked into the hinge and wood. A wet

appearance indicates that excess glue is puddled in the hinge gap.

Excess glue can become brittle with age and cut the hinge. Also,

NEVER USE CA ACCELERATOR (KICKER) ON CA HINGES!

❑11) Hinge the rudder to the back of the fin/fuselage with three

CA Hinges, in the same manner that you did the elevators.

❑12) Hinge the ailerons to the back of the wing with four CA

Hinges per aileron. Use the same proceedure you did for hinging

the elevators and rudder.

LANDING GEAR

❑13) Notice that one of the landing gear wires is taller than the

other. The taller wire installs in the upper hole in the fuselage side,

and the shorter wire goes into the 2nd hole down. Insert the wires

in the holes, one wire on each side of the fuselage, (it doesn't

matter which wire goes on which side of the fuselage).

❑14) Secure the wires to the fuselage with the two Plastic Tie

Straps provided. Snug the tie straps as tight as possible and then

cut off the excess length.

❑15) Main wheel installation:

a) Slide one of the Nylon Wheel Spacers onto the axle of the

landing gear wire.

b) Put the Wheel on the axle.

c) Install the Wheel Collar on the axle up close to the wheel,

but not actually touching it. Leave a little room so the wheel

can turn freely. Tighten the wheel collar set screw.

d) Repeat steps a, b, and c to install the opposite wheel.

CONTROL HORNS

❑16) Prepare the four Nylon Control Horns for installation:

a) Drill out the 3 holes in each horn with a 3/64" or #56 dia.

drill bit, so that they will accept the pushrod wires.

b) Use a sharp razor blade or hobby knife to cut the 2 pegs on

each control horn to approximately half of their original

length. This is done to insure that the pegs don’t protrude all

the way through the control surfaces.

❑17) Install a Nylon Control Horn on top of the left elevator:

a) Begin by using a sharp blade to remove the small strip of

covering material between the 2 holes that are pre-drilled in

the left elevator for the control horn.

b) Apply a small drop of Thick CA glue to the two pegs and to

the bottom of the base of the control horn.

c)

Firmly press the horn into the two pre-drilled holes in the

elevator, until the base of the horn bottoms out on the

elevator surface. If any glue oozes out onto the covering, it

can be easily removed with CA Debonder, after the glue dries.

5

❑18) Repeat the proceedures in Step 17 to install a Nylon Control

Horn on the left side of the rudder.

❑19) Repeat the proceedures in Step 17 to install a Nylon Control

Horn on the bottom of each aileron.

MOUNTING THE SERVOS

For this section you will need 4 mini servos and appropriate

extension chords (see radio notes at beginning of this book).

❑20) Prepare your elevator and rudder servos for installation by

plugging a 6" long servo extension chord onto the end of each

servo wire. Secure these connections with a piece of plastic tape,

(not supplied), so that they cannot come apart in flight.

❑21) Mount the elevator and rudder servos in the fuselage, using

the screws that came with the servo. Note that the tops of both

servos should be on the left side of the airplane (where the

control horns are), while the servo wires should be on the right

side of the fuselage.

❑22)

Note that there is a channel built into the fuselage to house

the elevator and rudder servo wires and route them forward to the

radio compartment in the wing. The entrance hole to this channel

is on the right side of the fuselage, right in front of the rudder servo.

a) Start by feeding the elevator servo wire into the entrance

hole. Keep pushing the wire forward through the channel until it

becomes visible in the channel exit hole, which is on the left side

of the fuselage, under the wing. Grab hold of the servo plug and

pull it out of the exit hole.

b)

With the elevator servo wire already inside the channel, it's

going to be a bit trickier to get the rudder servo wire fed through the

channel. You won't be able to simply push the rudder servo wire

through the channel, like you did the first one. We recommend

getting a piece of string and tying a small flat metal washer (or

other small weight) to one end of the string. Tie the other end of

the string to the plug on the end of the rudder servo wire. Hold the

airplane nose down and drop the washer end of the string through

the channel - you may have to shake the airplane slightly to get the

washer to go past the elevator servo wire and plug that are already

in the channel. When the washer appears in the channel exit hole

at the wing, grab it and bring it outside of the hole.

c) Gently pull on the string to feed the rudder servo wire

through the channel. When it gets hung up on the elevator servo

wire inside the channel, (which it will), alternate gentle tugs on the

string and on the elevator servo wire, shaking the airplane slightly

in the process, until you get the rudder servo wire to come through

the channel. Don't get frustrated! It may take a few tries, but it will

come through eventually.

possible. Note: It is easier to make this bend if you temporarily

remove the pushrod wire from the servo.

e) The excess length of pushrod wire can now be cutoff,

leaving a 3/16" end leg to pass through the control horn

hole. Use a good sharp pair of wire cutters to do this. Clean

off any burs on the end of the wire, caused by the cutting.

f) Reinstall the Z-bend end of the pushrod into the servo

output arm. Insert the 90° bent end of the pushrod into the

middle hole in the control horn. Slide the nylon pushrod

keeper up to the control horn and snap its tab end over the

exposed wire on the opposite side of the control horn.

g) Remove the pieces of tape holding the elevator in neutral

position.

❑25) Repeat the proceedures in Step 24 to bend and install

pushrods for the rudder and ailerons.

NOTE: Later, when you hook up and turn on your full radio

system for the first time, you may find that the length of the

pushrod wires did not come out exactly perfect, leaving the

control surfaces slightly out of neutral position. If so, you can

make small corrections to the overall pushrod length by slight

tweaking of the V-shaped adjustment bend that is provided in the

middle of each pushrod wire.

❑23) Mount 2 servos in the wing for the ailerons, using the screws

that came with the servos.

INSTALL PUSHRODS

Note: The 4 Pre-Bent Pushrod Wires supplied in this kit are all

identical in length and shape.

❑24) In preparation for installing a pushrod to the elevator, center

the elevator servo output arm in neutral position. Use a small

piece of tape to hold the elevators in neutral position.

a) Slide one of the Nylon Pushrod Keepers over the plain

unbent end of the pushrod wire.

b) Insert the Z-bend end of the pushrod wire into the middle

hole of the servo output arm. Note: If the holes in your servo

arms are too small for the wire, drill out the holes with a #60

or 3/64" dia. drill bit.

c) Hold the pushrod wire against the side of the nylon control

horn and use a fine tip pen to mark the exact position of the

control horn hole onto the wire.

d) Use a pair of pliers to firmly grasp the pushrod wire at the

mark just made, and then bend the plain end of the wire 90O

away from the fuselage. Make the bend as sharp as 6

c) Turn on the transmitter and then plug the battery pack onto

the ESC.

d) Slowly advance the throttle stick on the transmitter. The

motor should start turning. If not, your throttle channel

needs to be reversed on the transmitter.

e) Now make sure the motor shaft is moving in the correct

direction. When viewing the fuselage from the rear to the

front - as if you were sitting in the cockpit - the motor shaft

should turn clockwise when throttle is applied. If not, you've

got the polarity of the motor-to-esc or esc-to-battery wiring

reversed.

RECEIVER INSTALLATION

❑32) Plug the elevator and rudder servo leads into the receiver.

Note: Typically the elevator servo plugs into receiver slot #2 and

the rudder servo into slot #4. Consult your radio system manual.

❑33) There are two ways to hook up dual aileron servos,

depending upon what kind of radio system you have:

a) COMPUTER RADIO SYSTEM: If you have a computer

radio with a 6-channel receiver, you can plug the two aileron

servos into seperate receiver slots and the computer radio

will do the mixing for you. Note:

Typically with a computer

radio system the dual aileron servos will plug into receiver slots

#1 and #6. Consult your radio system manual.

b) NON-COMPUTER RADIO SYSTEM: If you do not have a

"computer" radio, you will need to get a "Y-Harness" chord,

(not supplied), to link the two aileron servos together. The

single end of the Y-Harness is then plugged into the normal

aileron slot in the receiver. Note:

Typically the normal aileron

slot for a single servo setup is receiver slot #1. Consult your

radio system manual.

❑34) Test the servos for proper operation:

a) Make sure your transmitter aileron, elevator, and rudder trim

levers are in neutral position, and that the throttle stick is in

the full "low throttle" position. Then turn on your transmitter.

b) Hook a charged battery pack up to the ESC. The elevator,

rudder, and aileron servos should now be working.

c) Move the transmitter sticks and check for proper response

and correct direction of servo movement. Use the servo-

reversing feature of your transmitter, if needed, to make the

servos move in the correct direction.

d) If necessary reposition the servo output arms on the

elevator and rudder servos as close to 90Oto the servo case

as possible. Be sure to reinstall the output arm retaining

screws after making the adjustment.

e) With the radio still on and the servo arms squared up, note

the exact neutral positions of the control surfaces. Adjust

the V-bend in the pushrods if necessary to get the control

surfaces properly centered.

❑35) Stuff all the servo wires and the receiver neatly inside the

wing. Notice in the next photo that we put the receiver and all the

wires in the left wing bay. Optional:

You can use a piece ofVelcro®

tape on the bottom of the receiver, or a strip of Scotch®tape across

the wing opening, to keep the receiver from falling out in flight.

❑36) Use small pieces of clear tape (not supplied) to fasten the

receiver antenna onto the bottom of the profile fuselage.

BATTERY PACK INSTALLATION

❑37) When you are ready to fly, the battery pack is carried in the

opening in the fuselage, and it is secured in place with a Velcro®

strap. The use of Velcro®makes the battery pack easy to remove

for re-charging between flights.

7

COMPLETE THE RADIO INSTALLATION

For this section you will need a 10-12amp brushless ESC, micro

receiver, and battery pack (see notes at the beginning of this

manual about esc, receiver, and battery specifications).

ESC INSTALLATION

❑26) Solder the 3 Brass Connectors (female) that are provided in

this kit onto the motor leads of your ESC.

❑27) Solder your choice of battery pack connectors (not supplied)

onto the battery leads of your ESC.

Note:

Your ESC probably did not come with battery pack

connectors pre-installed, nor are battery pack connectors supplied in

the kit. That is because there are several good connectors on the

market for this size electric motor installation, and most R/C fliers

quickly develope their own preference and want to stick with it so that

all of their similar sized battery packs are interchangeable. So the

choice of battery connectors is left up to you. Note in the picture that

we used a Kavan K2 Connector, #KAV6321. Other suitable choices

would be Deans Ultra or Sermos connectors.

❑28) Connect the ESC to the motor, being very careful to get the

polarity correct (red to red, black to black, etc.).

❑29) Mount the ESC to the side of the fuselage with Velcro®tape

as shown in the next photo. Use clear plastic tape as needed to

hold the motor wires in place against the fuselage side.

❑30) Mount the propeller securely to the motor shaft.

SAFETYWARNING:

With the propeller now mounted to the motor,

it is very important that you always remain aware of the position of

the throttle stick on your transmitter, especially when there is a

battery plugged into the airborne system. The motor/geardrive unit

used in this model is powerful enough to cause damage to people or

property if it is activated prematurely, accidently, or unexpectedly.

With an electric airplane, we recommended that you get in the habit

of always keeping the throttle stick in the "low throttle" position, even

when the transmitter is in storage. Be sure to recheck the throttle

stick position before plugging in the airborne battery pack, and also

again before turning on the airborne on/off switch. Under no

circumstances should you hold this model by the nose when the

battery is plugged in or the radio system is turned on. Never plug in

your flight battery until you are on the flight line, ready to fly.

❑ 31) Test the motor for proper operation:

a) Plug the ESC into the receiver. Note:

Typically the ESC plugs

into receiver slot #3 - but this may not be true in all cases. Some

brands of radios may be different. Consult your radio system manual.

b) Make sure the throttle stick on the transmitter is in the low

throttle position.

For the larger decals we suggest the following method of

application:

a) Carefully cut out the decal with a hobby knife.

b) Peel the paper backing sheet completely off the decal, being

careful not to let the sticky side double over and adhere to

itself.

c) Use a product like SIG Pure Magic Model Airplane Cleaner,

Fantastic®, or Windex®to spray the area of the model that will

receive the decal. Then spray the adhesive side of the decal

as well.

d) Lightly place the decal onto the wet surface of the model. The

liquid cleaner solution will keep the decal from actually sticking

to the model until you have had time to shift it around into exact

position. Once in position, use a piece of stiff cardboard (or

sheet balsa, thin plywood, or a SIG SH678 EPOXY

SPREADER) to squeegee the excess liquid cleaner out from

under the decal. Squeegee repeatedly, removing all excess

liquid and any air bubbles. Mop up the liquid with a paper

towel. Allow to dry overnight.

e) When completely dry, wash off any soapy smears with a clean

wet rag.

Note: The individual lightning bolts were applied to the top of the

wing first (see photo above), using the “wet” method. Those

decals were then allowed to dry overnight. The next day, the

E-FORCE lettering were put on over the top of the lightning bolts,

again using the “wet” method (see photo below).

ADJUST CONTROL THROWS

❑38) Use a ruler to accurately measure and adjust the travel of

each control surface to the amounts shown below. Keep in mind

that these settings are meant to serve as a starting point. As you

gain experience flying your E-FORCE, you may want to adjust the

throws to suit your flying style. All measurements should be taken

at the widest part of the elevators, ailerons, and rudder.

Low Rate High 3D Rate

Ailerons 7/8" up 1-3/4" up

7/8" down 1-3/4" down

-20% expo -70% expo

Elevator 3/4" up 1-5/8" up

3/4" down 1-5/8" down

-20% expo -50% expo

Rudder 1-1/2" right 3-1/2" right

1-1/2" left 3-1/2" left

-20% expo -70% expo

Note: High Rate 3D Control Throws

The 3D control throws are only meant for extreme aerobatics.

They are not meant for normal flying. You should be competent

and comfortable flying your E-FORCE with normal control throws

before attempting 3D rates.

DECAL APPLICATION

The decals supplied with the E-FORCE are Mylar®stickers with an

extremely aggressive adhesive. These decals are not die-cut.

Each design must be cut from the sheet with a sharp #11 hobby

knife or a sharp scissors.

Small decals can be easily applied to the model by simply

removing the paper backing sheet, and then laying the decal in

position and pressing it in place with your finger. 8

BALANCE

While all airplanes must be balanced to achieve flight, the balance

of an aerobatic airplane like the E-FORCE is especially critical.

The final placement of the longitudinal Center of Gravity,

or Balance Point, will have a great effect on the aerobatic

performance of this airplane. Balancing this model should be

approached with patience and care.

Important: The model must be balanced with everything on

board, ready for flight. The flight battery must be installed in

the fuselage and the propeller must be mounted in place when

balancing the model.

BALANCE POINTS REFERENCE CHART

* Percentage of Mean Aerodynamic Chord

% of distance aft of

MAC* wing leading edge

29% 3.02"

30% 3.12"

31% 3.22"

32% 3.33"

33% 3.43"

35% 3.64"

37% 3.85"

For initial test flying and familiarization purposes, we suggest a

starting balance point of 33% MAC, which is approximately

3-7/16" behind the leading edge of the wing.

IMPORTANT NOTE: Balanced means the airplane sets perfectly

level when supported at the desired balance point - NOT slightly

nose down or nose up - PERFECTLY FLAT LEVEL!

As your experience with the E-FORCE increases, you can adjust

the balance point to suit yourself. In general, as the balance point

is moved aft, the airplane will become more responsive and less

stable in all axis. Some pilots like their models extremely reactive,

while others like to fly with more smoothness. If you never get into

3D flying, you will probably like the balance point at the intial

setting of 33%. In the end, the final balance point and control

throws you use will depend on how you like to fly.

INCIDENCE & THRUST ANGLES

The E-FORCE was built at the factory with the following specs:

Wing Incidence: 0O

Stab Incidence: 0O

Engine - Side View 0Odown

Engine - Top View 0Oright

PRE-FLIGHT NOTES

Be sure your flight battery pack is fully charged. Also be sure your

transmitter is fully charged. We highly recommend that you

perform a standard range check on your radio system - with and

without the motor running. Make sure your propeller is balanced

and has no nicks or cracks - never fly with a faulty propeller!

Finally, take a few minutes to give your model a thorough pre-flight

inspection. Make sure everything is secure and tight and

operating properly, before attempting to fly the model. Any

problems you have will not magically disappear at the field - they

will get worse!

FLYING

If you have carefully followed this assembly manual, test flying

your E-FORCE should be a lot of fun. Try to choose a calm day

with little or no wind for the first flight. Good conditions allow

you to better evaluate and more accurately adjust the trim

requirements for your airplane.

Always make it part of your pre-flight routine to check each control

on the airplane, making sure the surfaces are moving in the

correct directions. Also check each control linkage to be sure they

are secure and that nothing is loose.

THROTTLE MANAGEMENT:

The E-FORCE is not designed to fly

at high airspeeds. The key to its 3D aerobatic flying characteristics

is super light weight construction and extra large control surfaces.

Full throttle is only for takeoff and some aerobatic maneuvers. For

normal level flight, you should throttle back to cruising speed. Also,

never dive the E-FORCE at full throttle.

Once you've settled at cruising altitude and speed, adjust the trims

as needed to achieve hands off straight and level flight. Take it

easy with the E-FORCE for the first flight, gradually getting

acquainted with it as you gain confidence.

Each flight will be even more fun as you fine tune the trim of your

E-FORCE. Try a few loops and rolls. Inverted flight is easy,

requiring little down elevator for hold level flight. Next try some

snap rolls, spins, and knife edge flight. The E-FORCE should

perform all of these maneuvers with ease. Note any tendencies

that you can trim out when you're back on the ground. For

instance, if the E-FORCE has a tendancy to "pull" towards the

canopy during knife edge flight, try raising BOTH ailerons slightly.

If it pulls towards the landing gear, lower both ailerons. Fly it again

and note any difference. Always make changes slowly, in small

amounts, and only one change per flight. As with any aircraft,

getting consistently good results from the E-FORCE is usually a

matter of flight trim and practice.

For those of you interested in 3-D aerobatics, set up your radio to

take advantage of the huge control movements available from this

model. However, we would urge you to "sneak up" on such

control throws, making very sure you have them available to you

only on your high rate switches!

Caution: Never land your airplane in tall grass or weeds with the

motor running. Always throttle back completely if you land in such

terrain, or if you nose over after landing. Tall grass or a nose over

will stall the motor if it is running. A stalled motor can overheat the

ESC and batteries, causing them to fail.

JOIN THE CLUB

Although the E-FORCE is considered a "park flyer" and can be

flown in fairly confined spaces by accomplished pilots, it should

never be flown within five miles of an organized R/C aircraft flying

site. This one simple precaution can prevent the loss of your

model from radio interference. Do yourself a favor and join your

local R/C club - you'll almost always get assistance and good

advice, and you will even make a friend or two!

Please operate your airplane in a safe, responsible manner with

constant regard to other flyers, spectators, and property.

GOOD LUCK AND HAPPY LANDINGS!

9

10

WARNING! THIS IS NOT A TOY!

Flying machines of any form, either model-size or full-size, are not toys!

Because of the speeds that airplanes must achieve in order to fly, they are

capable of causing serious bodily harm and property damage if they crash.

IT IS YOUR RESPONSIBILITY AND YOURS ALONE to assemble this

model airplane correctly according to the plans and instructions, to ground

test the finished model before each flight to make sure it is completely

airworthy, and to always fly your model in a safe location and in a safe

manner. The first test flights should only be made by an experienced R/C

flyer, familiar with high performance R/C aircraft.

JOIN THE AMA

The governing body for radio-control model airplanes in the United States

is the ACADEMY OF MODEL AERONAUTICS, commonly called the AMA.

The AMA SAFETY CODE provides guidelines for the safe operation of R/C

model airplanes. While AMA membership is not necessarily mandatory, it

is required by most R/C flying clubs in the U.S. and provides you with

important liability insurance in case your R/C model should ever cause

serious property damage or personal injury to someone else.

ACADEMY OF MODEL AERONAUTICS

5161 East Memorial Drive

Muncie, IN 47302

Telephone: (765) 287-1256

AMA WEB SITE: www.modelaircraft.org

CUSTOMER SERVICE

SIG MANUFACTURING COMPANY, INC. is committed to your success in

both assembling and flying the E-FORCE ARF. Should you encounter any

problem building this kit or discover any missing or damaged parts, please

feel free to contact us by mail or telephone.

SIG MANUFACTURING COMPANY, INC.

401-7 South Front Street

Montezuma, IA 50171-0520

SIG MODELER’S ORDERLINE: 1-800-247-5008

(to order parts)

SIG MODELER’S HOTLINE: 1-641-623-0215

(for technical support)

SIG WEB SITE: www.sigmfg.com

LIMIT OF LIABILITY

The craftsmanship, attention to detail and actions of the builder/flyer of

this model airplane kit will ultimately determine the airworthiness, flight

performance and safety of the finished model. SIG MFG. CO.’s obligation

shall be to replace those parts of the kit proven to be defective or missing.

The user shall determine the suitability of the product for his or her

intended use and shall assume all risk and liability in connection therewith.

E-FORCE LOG BOOK

Date: Battery Pack:

Comments:

Table of contents

Other SIG Toy manuals

SIG

SIG Rascal 110 Technical manual

SIG

SIG KADET EP-42B User manual

SIG

SIG DORN IER Do 217 User manual

SIG

SIG KADET LT-40 User manual

SIG

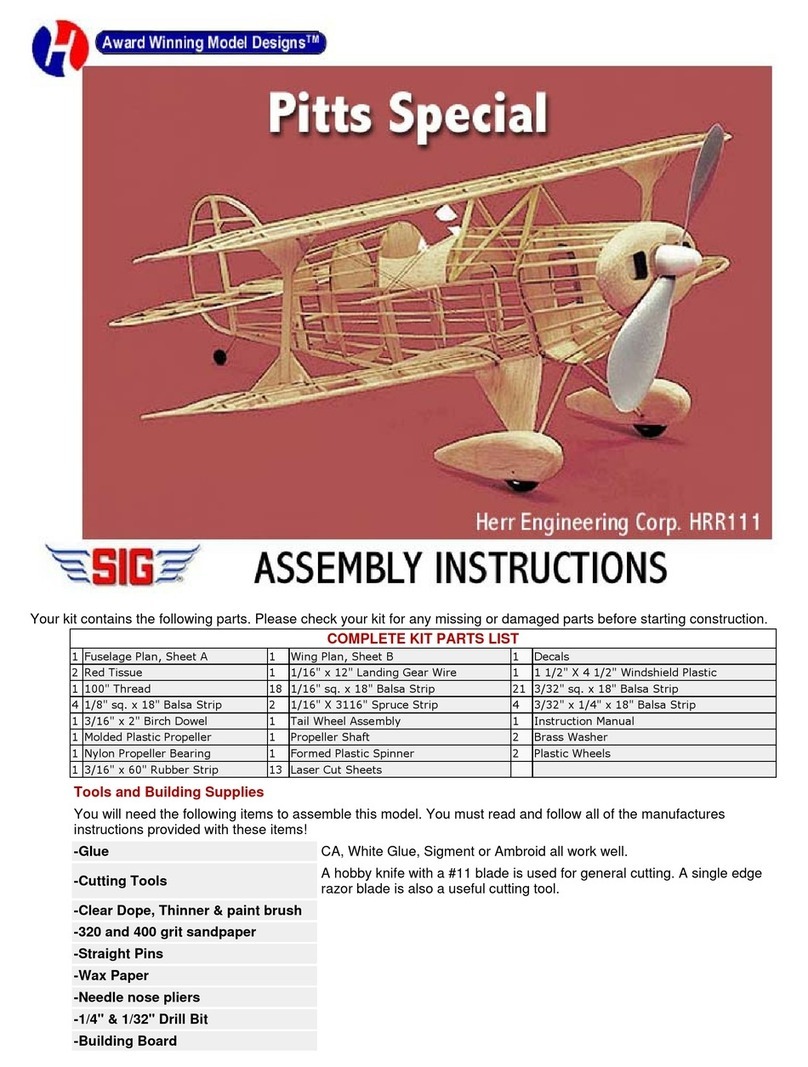

SIG HRR111 User manual

SIG

SIG SIGRC69 HOG BIPE User manual

SIG

SIG Customaire SIGFF26 Classic Series Instruction Manual

SIG

SIG King Kobra Instruction Manual

SIG

SIG KADET EP-42 User manual

SIG

SIG CAP 231EX User manual

SIG

SIG Rascal 72 EG User manual

SIG

SIG Rascal 110 User manual

SIG

SIG HERR FAIRCHILD 24 User manual

SIG

SIG EDGE 540T User manual

SIG

SIG KADET LT-40 EG User manual

SIG

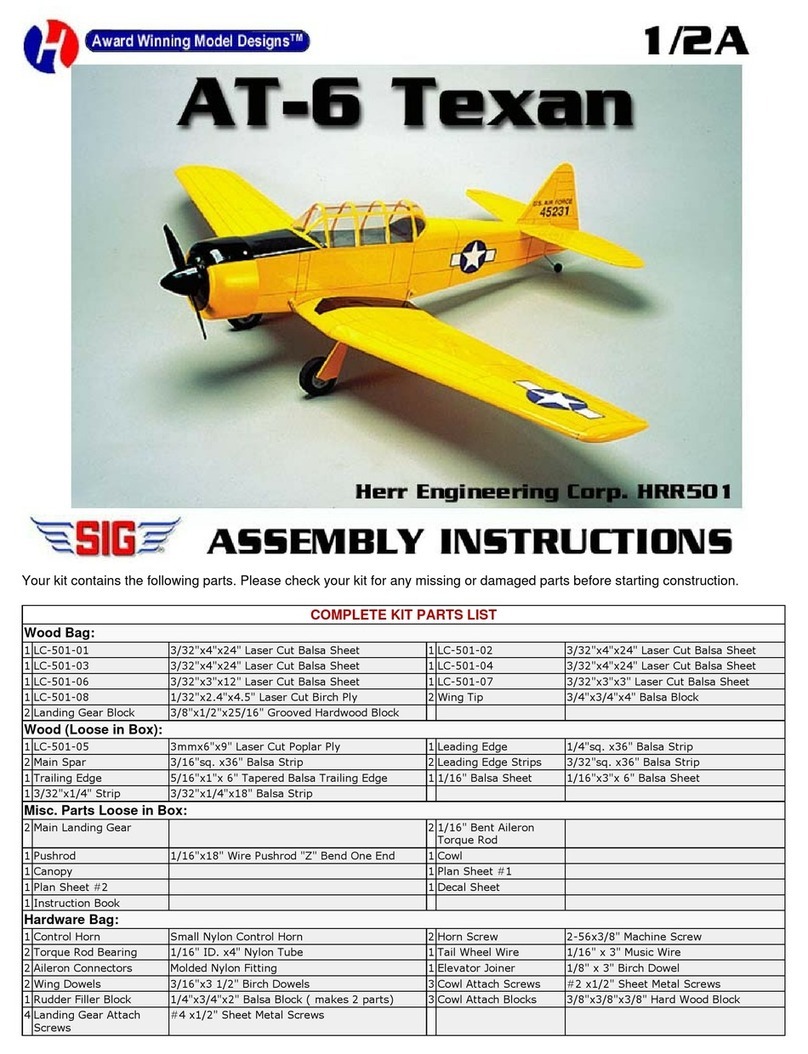

SIG HRR501 User manual

SIG

SIG Kadet Senorita EP User manual

SIG

SIG Piper J3 Cub Instruction Manual

SIG

SIG Cloud Ranger HHR508 User manual

SIG

SIG WACO SRE SIGRC101ARF User manual