SIGMAKOKI JS-300 User manual

-1-

JOY STICK

User’s Manual

JS-300(Ver2.0)

For Your Safety:3

Ⅰ.Before You Begin

1-1.Overview:5

1-2.Connecting Method:5

Ⅱ.Notes on Use

2-1.Parts of the JS-300:6

2-2.Operating method:7

2-3.Checking and Setting Memory Swithes 9

Ⅲ.Specifications

3-1.Specifications:10

3-2.Exterior Dimensions:10

CONTENTS

-2-

Notes regarding these materials

・ These materials are intended as a reference to assist our customers in the use of

the SIGMAKOKI CO., LTD. Product best suited to the customer’s application; they

do not convey any license under any intellectual property rights, or any other rights,

belonging to SIGMAKOKI CO., LTD. or a third party.

・ SIGMAKOKI CO., LTD. assumes no responsibility for any damage, or infringement

of any third-party’s rights, originating in the use of any product data, diagram, charts,

programs, or algorithms contained in these materials.

・ All information contained in these materials, including product data, diagrams,

charts, programs and algorithms represents information on products at the time of

publication of these materials, and are subject to change by SIGMAKOKI CO.,LTD.

without notice due to product improvements or other reasons.

・ When using any or all of the information contained in these materials, including

product data, diagrams, charts, programs, and algorithm, please be sure to evaluate

all information and products. SIGMAKOKI CO., LTD. assumes no responsibility for

any damage, liability or other loss resulting from the information contained herein.

・ SIGMAKOKI CO., LTD. products are not designed or manufactured for use in

equipment or system that is used under circumstances in which human life is

potentially at stake. SIGMAKOKI CO., LTD. products cannot be used for any

specific purposes, such as apparatus or systems for transportation, vehicular,

medical, aerospace, nuclear, or undersea repeater use.

・ The prior written approval of SIGMAKOKI CO., LTD. is necessary to reprint or

reproduce in whole or in part these materials.

・ If these products or technologies are subject to the Japanese export control

restrictions, they must be exported under a license Japanese government and

cannot be imported into a country other than the approved destination.

Any diversion or reexport contrary to the export control laws and regulations of

Japan and/ or the country of destination is prohibited.

-3-

For Your Safety

Before using this product, read this manual and all warnings or cautions in the documentation

provided.

Only Factory Authorized Personnel should be changes and/or ad ust the parts of controller.

The Symbols Used in This Manual

! WARNING ! CAUTION

This symbol marks warnings that should be read

and used to prevent serious in ury or death.

This symbol indicates where caution should be

used to avoid possible in ury to yourself or others,

or damage to property.

The above indications are used together with the following symbols to indicate the exact nature of the

warning or caution.

Examples of Symbols Accompanying Warnings and Cautions

△Symbols enclosed in a triangle indicate warnings and cautions. The

exact nature of the warning or caution is indicated by the symbol

inside (the symbol at left indicates risk of electrocution).

○Symbols enclosed in a circle mark indicate rohibitions(actions that

must not be erformed).The exact nature of the rohibition is

indicates by the symbol inside or next to the circle mark (the symbol

at left indicates that the roduct must not be disassembled).

●Symbols inside a black circle mark actions that must be erformed

to ensure safety. The exact nature of the action that must be

erformed is indicated by the symbol inside (the symbol at left is used

in cases in which the AC ada ter must be un lugged to ensure safety).

Symbols on the product

The symbol mark on the roduct calls your attention. Please refer to the manual, in the

case that you o erate the art of the symbol mark on the roduct.

This symbol labeled on the ortion calls your attention.

!

-4-

Disclaimer of Liability

① SIGMAKOKI CO., LTD. does not accept liability for damages resulting from the use of this

product or the inability to use this product.

② SIGMAKOKI CO., LTD. does not accept liability for damages resulting from the use of this

product that deviates from that described in the manual.

③ SIGMAKOKI CO., LTD. does not accept liability for damages resulting from the use of this

product in extraordinary conditions, including fire, earthquakes, and other acts of God, action by

any third party, other accidents, and deliberate or accidental misuse.

④ If the equipment is used in a manner not specified by the SIGMAKOKI CO., LTD., the protection

provided by the equipment may be impaired.

WARNING

● Do not use this product in the presence of flammable gas, explosives, or corrosive substances, in

areas exposed to high levels of moisture or humidity, in poorly ventilated areas, or near flammable

materials.

● Do not connect or check the product while the power is on.

● Installation and connection should be performed only by a qualified technician.

● Do not bend, pull, damage, or modify the power or connecting cables.

● Do not touch the products internal parts.

● Connect the earth terminal to ground.

● Should the product overheat, or should you notice an unusual smell, heat, or unusual noises coming

from the product, turn off the power immediately.

● Do not turn on the power in the event that it has received a strong physical shock as the result of a

fall or other accident.

● Do not touch the stage while operation.

● Use dry clothes only for cleaning the equipment.

!

-5-

Chapter 1: Before You Begin

1-1. Overview

The JS-300 is a joystick with representational function.

It can be connected to our stage controller, S OT-30* series and S OT-702.

The joystick, connected to the controller via a cable, provides remote operation. This

means that the joystick allows you to work near the motorized stage while checking its

behavior even if the controller and the motorized stage are away from each other.

1-2. Connecting method

The Joystick (JS-300) is connected to the controller with MDR14-CA cable.

① Connect a standard cable (MDR14-CA-*) to the connector on the rear panel of the

JS-300.

② Connect the cable from the JS-300 to the “JOYSTICK” connector on the front panel of

the S OT-30X series and S OT-702 controller. (In the case of S OT-702, it becomes

the rear panel part.)

③ Turn power switch of the controller on.

And confirm that the open message is displayed correctly. If it can not be displayed,

reconfirm if connection of cable is done correctly.

Be sure the controller is off when you connect the oystick. You may not able to

use the buttons on oystick if you connect or disconnect either device while the

controller is on.

-6-

Chapter 2: Notes on Use

2-1. Parts of the JS-300

①LCD panel

②MODE button

④ZERO button

⑤Axis select button

⑥Joystick

⑦M-ORG button

⑧Third axis operation switch

⑨SPEED button

⑩STOP button

③E-ORG button

MODE

-7-

2-2. Operating method

①LCD panel

Display the position coordinates for each axis and the operating mode.

Display Digit : 16 digit × 4 lines

②MODE button

Change an operation mode of the controller.

OST→MANUAL・・・

Refer to a User’s Manual of S OT-302GS/S OT-304GS for various modes.

NOTE) IN S OT-702, the MODE change is invalid.

③E-ORG button

Position stage at logical origin “0” for all axes.

The LED indicator lights up when the stage is moving and lights off when the stage is at

logical position.

④ZERO button

Reset position coordinates for all axes to zero.

⑤Axis select button

Selects the axis operated by joystick as “ 1 and 2 axis” or “3 and 4 axis”.

The LED indicator lights up when “3 and 4 axis” can be operated by joystick.

NOTE) This button is only usable with S OT-304GS.

⑥Joystick

Enables operation of “1 and 2 axis” or “3 and 4 axis”.

A move of the joystick continuously moves the stage continuously.

Releasing the stick stops the stage.

Move the oystick again after putting the oystick in neutral for over a second

when

inverting moving direction of each axis. It may not work without the

required operation.

-8-

⑦M-ORG button

Moves the stage to its mechanical origin.

The LED indicator lights up when the stage is moving and lights off when the stage is at

mechanical origin position.

⑧Third axis operation switch

Use the switch to operate third axis.

Push the switch to Top : + direction

Push the switch to Bottom : - direction

NOTE) This button is only usable with S OT-304GS.

⑨SPEED button

Cycle through “SPEED 1/2/3/4” settings stored in controller’s memory switches (1→2→3→

4→1・・・).

Change the number of lightning of LED indicator by the SPEED button every time

pushing the button. Its number of lightning of LED indicator enables you to check current

moving speed.

Example) Four LED indicator lightning : SPEED setting 4

⑩STOP button

Stop all operating motorized stages immediately.

Refer to the manual of each controller for stopped condition.

-9-

2-3. Checking and Setting Memory Switches

Changing of the memory switch of S OT-302GS/S OT-304GS controller is possible in

JS-300(Ver2.0).

(*) For more information about memory switch, refer to User’s manual of

S OT-302GS/S OT-304GS.

(NOTE) This function is only usable with S OT-302GS and S OT-304GS.

○

Changing Memory switch settings

To display the memory switch settings screen in MANUAL mode, press the “MODE” and “E-ORG” buttons

simultaneously. Memory switch settings can be changed using the buttons on the JS-300.

Button Function

Joystick UP side Cycle through items in descending order (No.2⇒

1⇒86⇒85)

Joystick down side Cycle through items in ascending order (No.85⇒

86⇒1⇒2)

Joystick right side For numeric options, move cursor to right digit

Joystick left side For numeric options, move cursor to left digit

①Cycle through options for the current item (or

increase the value of numeric options)

MODE + ZERO

②After changes to settings have been completed,

save changes to settings and exit

①Cycle through options for the current item (or

decrease the value of numeric options)

SPEED

②After changes to settings have been completed,

cancel changes to settings and exit

①Press to end changes to settings (a

confirmation screen will be displayed)

MODE

②Exit confirmation screen and return to

memory switch settings screen

MODE + M-ORG Restore memory switch settings to factory

defaults

-10-

Chapter 3: Specifications

3-1. Specifications

Power source DC5V ±10% ( from controller)

Operating temperature 5~40℃

Storage temperature -20~60℃

Ambient humidity 20~80%R (no condensation)

External dimensions 120W×160D×50 (excluding projections)

Weight 700g

Electrical burst immunity EN61000-4-4(2004) Level 2

Electrostatic discharge EN61000-4-2(1995)+A1(1998)+A2(2001) Level 2

3-2. Exterior Dimensions

-11-

SIGMAKOKI CO., LTD.

http://www.sigma-koki.com

Tokyo Head office

SIGMAKOKI Tokyo Head office 1-19-9, Midori, Sumida-

ku, Tokyo

130-0021, JAPAN

TEL:+81-3-5638-8228 FAX:+81-3-5638-6550 E-mail:international@sigma-

koki.com

Osaka Branch

4-9-28, Nishi-Nakajima, Yodogawa-ku, Osaka 532-0011, JAPAN

TEL:+81-6-6307-4835 FAX:+81-6-6307-4834

Kyushu Sales office

3-17, Hie-machi, Hakata-ku, Fukuoka-shi, Fukuoka 812-

0014,

JAPAN

TEL:+81-92-481-4300 FAX:+81-92-481-4310

Technology center

1-1 Yatsukaho, Hakusan-shi, Ishikawa-ken 924-0838, JAPAN

Table of contents

Popular Control Unit manuals by other brands

YASKAWA

YASKAWA JEPMC-OP3C01-E instructions

Revox

Revox Re:source Communicate Module user manual

Cisco

Cisco NM-1E2W Configuration note

Amersham Pharmacia Biotech

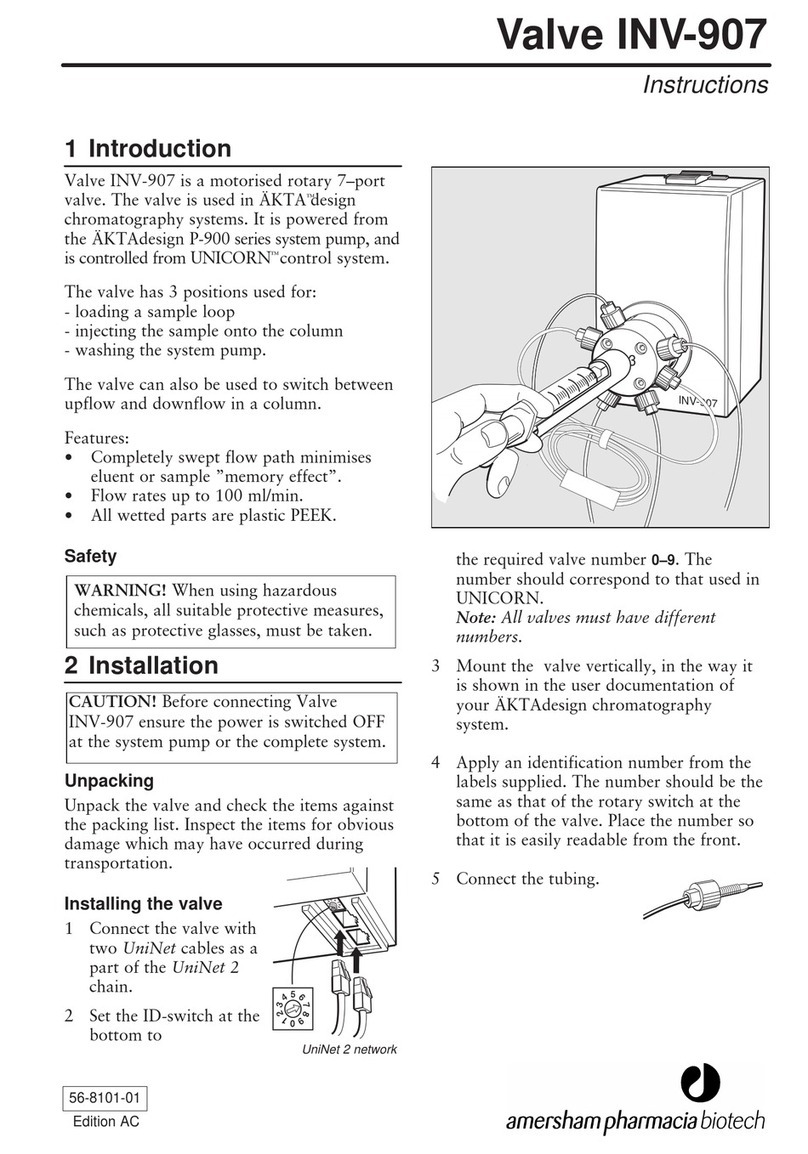

Amersham Pharmacia Biotech INV-907 instructions

Continental Refrigerator

Continental Refrigerator FE4CNX210 Manual and user guide

Arduino

Arduino MKR1000 Getting started