Signal Audio Workshop Gainrider User manual

Gainrider Vacuum Tube

Dynamic Range Controller

OWNER’S MANUAL

Signal Audio Workshop

Abarbanel ST.53

Tel Aviv 66089 IsraelP.O.B 5169 TLV 61051Office: 972-3-6820892

Fax: 972-3-6824716

www.signal-audio.com

Gainrider Owner’s Manual

Content:

Preface ____________________________

Front Panel Controls __________________

Signal Chain ______________________________

Side Chain __________________________

RMS Detector ________________________

Crest Detector ____________________________

Tips & Tricks ____________________________

Installation _________________________

Maintenance & Calibration ________________

Gainrider PCB top view ______________________

Specifications _______________________

Warranty and Registration Form __________

3

4

5-6

6

7

7-8

8-9

9

10-11

12

13

14-15

www.signal-audio.com

2

Dear customer,

I am confident that working with the Gainrider

will open new worlds of manipulating audio

dynamics with a tool like no other. In order to

produce the full potential of this sophisticated tool I strongly

encourage you to read and understand this manual thoroughly.

I’d like to personally thank you for the confidence

that you have shown in Signal Audio Workshop

by purchasing the Gainrider. You acquired the

latest generation of dynamics processor which is

unequal in its design and specification.

At Signal Audio Workshop we consider the development and

assembly of our gear an art form and take great pride in the final

product. The Gainrider is a result of a five year development

period and 10 years of researching the dynamic behavior of music

and audio signals.

In an effort to innovate and achieve the Gainrider’s outstanding

capabilities we have revolutionized the SIDE CHAIN system with

unique features, superior reaction and accuracy that can provide

sophisticated dynamic range processing.

For the VCA circuitry we chose the VARIABLE BIAS topology for its

speed and superb sound performance. The same VCA topology

implemented in the legendary FAIRCHILD 670 and its close

relatives.

All the signal path stages are pure CLASS-A tubes circuitry and 3

transformers for each channel takes this uncompromising structure

to the highest level of sonic excellence.

I hope you will enjoy working with the Gainrider as much as we

enjoyed making it for you!

With Honor

Oded Levy

Signal Audio Workshop

3

Front Panel Controls

1. DC-T.H=DC-THRESHOLD: The input signal exceeded above this controlled

threshold level goes into compression.

2. LOG-RATIO: Being a variable bias compressor means that the ratio of the

signal being compressed gets higher with the amount of gain reduction.

Therefore this knob adjusts the ratio’s slope angle (from soft compression -

to hard limiting).

3. ATTACK time: Sets the time it will take the VCA’S RMS DETECTOR to

accomplish its desired compression.

4. RECOVERY time: Sets the time it will take the VCA’S RMS DETECTOR to

recover from compression.

5. CREST-LEVEL: In any regular compressor, having an attack time means

also that some amount of fast transients entered the VCA will not develop

gain reduction. The longer the RMS ATTACK the more short peak transients

missed by the VCA, for these purpose we implemented a CREST DETECTOR

that detects those peaks and allows you to mix them with the RMS signal

on its way to the VCA and you chose their level of mixing from 0% to

300% (why 300%? hear it ...)

6. CREST-RECOVERY: Enables you to give the CREST signal a private

recovery time.

7. OUT-LEVEL: Allows you to amplify the output level in order to makeup for

gain loses from compression.

8. IN-LEVEL: This is a variable input attenuator for both sides, ranging from

-20db to 0db, enables you to set compression amounts to both sides

simultaneously or altering the amount of signal to drive this tube

instrument.

9. BYPASS: It’s a HARD WIRED BYPASS switch for channel A.

10. ST-LINK: This switch engages both channels VCA signals for operating on

stereo signals (It still means that both sides need to be tuned equally).

11. MODE: This switch affects the signal path, it has two operations - NRM

MODE: both channels A and B are separate. This means, channel A is left

and B is right, or dual mono, (just like any other normal compressor). M.S.

MODE (used only with stereo signals): means that channel A is now

compressing the center of the stereo signal therefore it will be called L+R,

And channel B will compress the sides of the stereo signal therefore it will

be called L-R (as seen on front panel). The output levels unlike any other

compressor with M.S. mode, allows you to tune the level of the MONO

versus SIDES and controlling stereo image’s width.

12. GAIN REDUCTION Meter: Peak meter with 21 segments especially

designed to deflect these unique fast VCA movements.

4

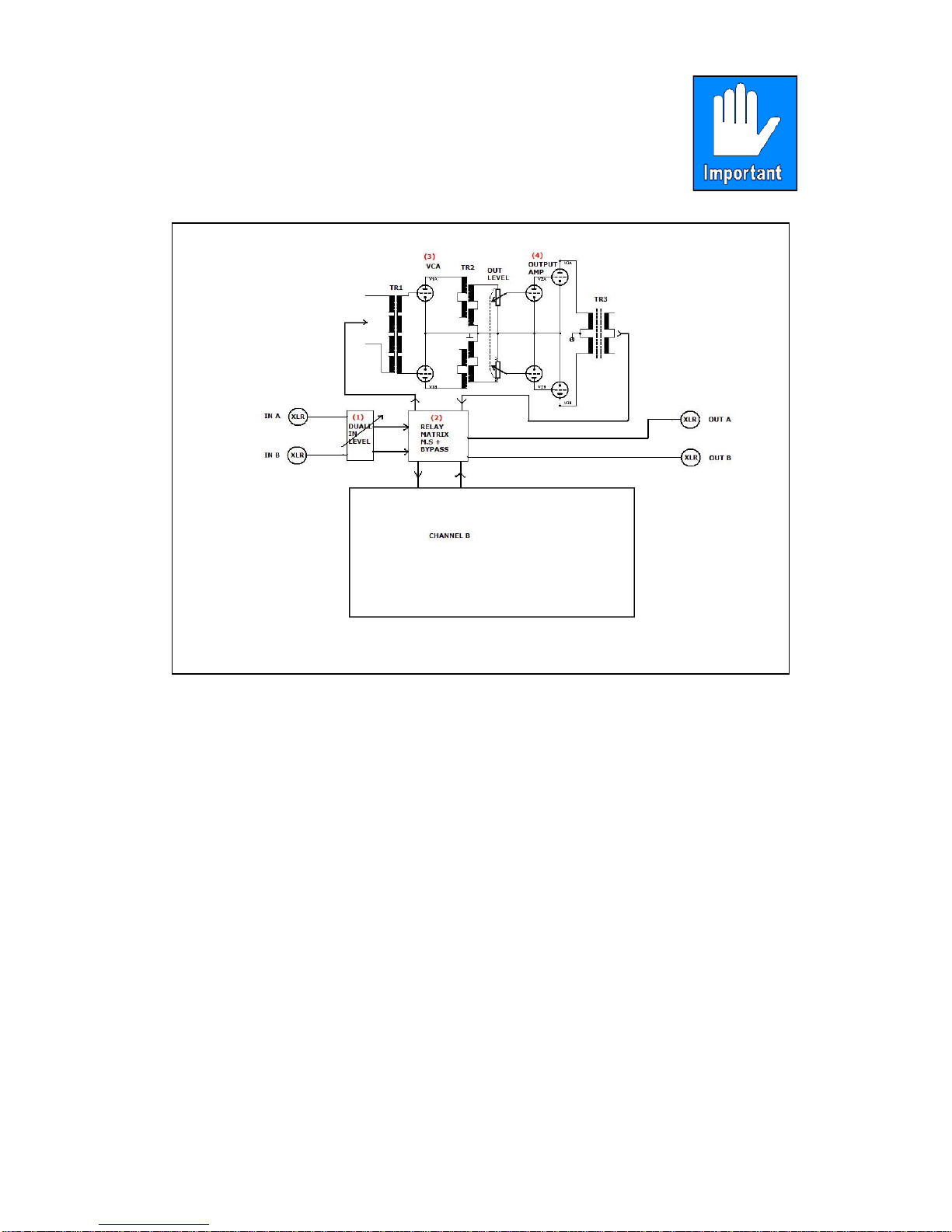

Signal Chain

This chapter details the signal chain structure in order

to help you better understand the Gainrider

capabilities.

(1) DUAL IN LEVEL:

This is a variable input attenuator for both sides, ranging from

-20db to 0db. It enables you to set compression amounts to

both sides simultaneously or altering the amount of signal to

drive into the Gainrider tubes.

(2) RELAY MATRIX:

The passive relay matrix is in charge of functions like:

BYPASS+M.S.\NORM modes. Carefully planed to preserve

signals quality at all operating modes.

(3) VCA STAGE:

The first stage of amplification is the VCA stage, made from two

custom wound transformers and 6BQ7 sharp cutoff tube. An

inter-stage transformer is essential in order to reach high speed

gain reduction capabilities with minimum artifacts.

5

(4) OUTPUT AMPLIFIER:

The output amplifier is made from 12AX7 and 6CG7 tubes that

drive the output transformer. This stage supplies the makeup

gain needed and drives the output transformer.

The over sized custom wound output transformer is designed to

supply the unit’s line output power needed with maximum

signal integrity, especially when it comes to low frequency

T.H.D.

All signal stages are internally balanced with Tube class-

A topology.

Side chain

The SIDE CHAIN circuitry is pure solid state in order to achieve the

precision and speed needed for the Crest Detection.

Looking at the block diagram you can see that at some point after the

Ratio amp, the signal splits into two paths. One is the RMS signal

path (4), with functions like ATTACK and RELEASE, while the other is

the CREST which forms in the COMPARATIVE DETECTOR stage (6).

Then it goes to a second detector that sets the timing of the CREST

material (CREST REL) (7).

Next, there is the blending process back with the RMS material where

the CREST LEVEL determines the CREST amount.

We implemented the 0-300% scale on the CREST LEVEL knob in

order to enable high levels of CREST material to mix with the RMS. In

this instance, the Gainrider can generate a rhythmic effect caused by

CREST signals taking control over the slow movements of the RMS

material. This unique phenomena happens because the CREST

material is mostly originated from the peaks that forms the rhythm of

all conventional music.

6

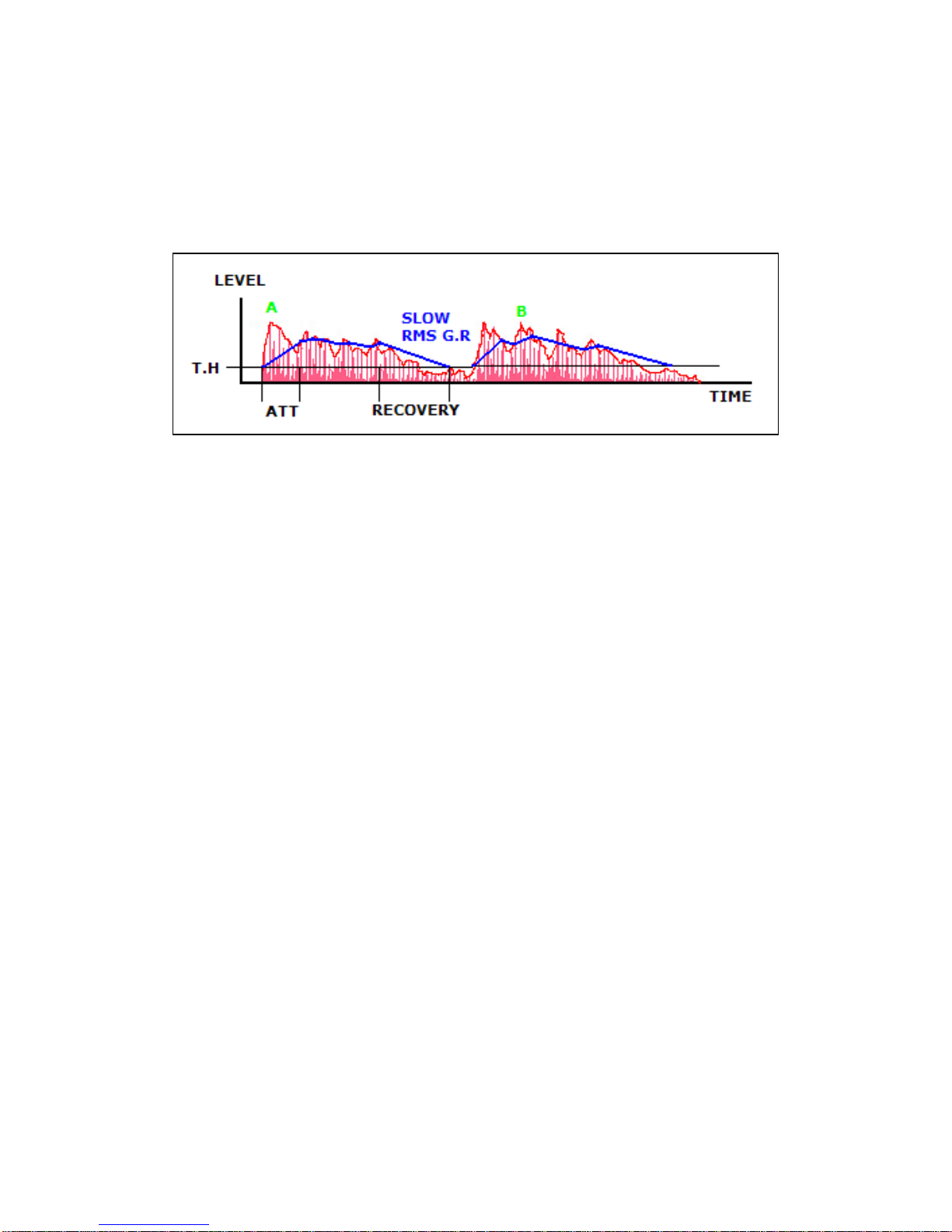

RMS Detector

In order to better understand the dynamic behavior of the Gainrider

we need to understand the way it is developing Gain reduction in

comparison to the input signals envelope.

The above drawing shows an envelope of signal before compression

(RED).

On the left we can see the Threshold level (Black line), two parts of

envelope exceed this level line, generating Gain Reduction (G.R. -

blue). As you can see the G.R. curve has Attack and Recovery times

effected by front panel settings.

The blue curve is called RMS SLOW G.R. curve, as being significantly

slower then envelopes rise and fall times This is the classic method of

compression used by conventional compressor/limiters.

Areas A and B (green), are fast transients that are too fast for the

RMS mechanism to notice. Those transients are called CREST

transients.

Conventional compressor/limiter does not offer a way to manipulate

crest material except for, maybe chopping the peaks with a limiter.

CREST Detector:

As seen on previous chapter there are a lot of fast envelope

movements that any conventional compressor can’t track while

configuring SLOW RMS compression.

We refer these movements as CREST material and its rise and fall

times are much faster then the RMS envelope. Therefore we

developed a special detector to detect the FAST CREST G.R.

7

The picture above shows in green the CREST material that exceeded

T.H. level. You can see that sometimes it is above the RMS level and

sometimes lower then RMS.

The CREST signal has a very short attack time and a manually tuned

recovery time which is significantly shorter then RMS recovery time.

Mixing the two signals into the VCA gives us much better control over

dynamic range transients that appears on music program material.

You can refer this type of processing as having a very fast

compressor and a slower one mixed together in such a way that the

fast movements are modulating the slow one or even ride on them,

Therefore the name Gainrider.

The results of such mechanism are a much more natural and musical

VCA’s behavior and with much more proximity then other tools.

Tips & Tricks

1. Tuning CREST LEVEL will be done only after the initial RMS

ATTACK & RECOVERY are tuned according to program material.

You should always remember that the CREST is a by-product of

the RMS G.R. therefore altering RMS changes also the amount of

CREST to be created. Therefore always start with tuning RMS

ATTACK and RELEASE and then add the CREST LEVEL as needed.

2. As a rule of thumb: when tuning Release time it is always better to

have the timing somehow reflect the rhythm of the processed

material.

This way the compression applied will have enough time to recover

from its last RMS Gain reduction.

3. When working in M.S. mode do not work with ST-LINK on, since

there isn’t any rhythmic connection between the two channels.

4. Widening or narrowing of stereo image can easily be done on M.S.

mode even without compression, with the tuning of the OUT-LEVEL

controls you can compare the results to bypass when switching

both channels simultaneously.

8

5. When using M.S. we strongly recommend you to further judge the

resulted material with phase meter and ST/MONO monitoring.

Installation:

1. Make sure that the unit operates on the correct mains voltage

(230/115 VAC) before applying mains voltage.

2. Always install this unit in a properly grounded environment.

3. Do not expose the unit to humidity or dusty environment.

4. Do not expose the unit to heat sources and unventilated places.

Connections:

All audio connections are transformer floating balanced through XLR

connectors with the following pin list:

Signal Audio Workshop is not responsible for

damages created by improper installation.

PIN 1 GND

PIN 2 HOT

PIN 3 COLD

9

Maintenance & Calibration

Cleaning:

Do not clean the unit with water or with water soaked cloth.

Cleaning is best made with dry dusting brush and vacuum cleaner.

Dust and moisture are the primer enemy of switches and contacts

within this unit. Avoiding them as much as you can will prolong the

unit’s life significantly.

Maintenance:

There are no user’s serviceable parts inside the unit.

Opening and servicing this unit by anyone who is not authorized Signal

Audio Workshop service technician will void the warranty.

We recommend replacement of vacuum tubes only when the unit has

proven to not function correctly and according to the type of problem

discovered.

We recommend replacing the VCA tube when VCA balance can no

longer be obtained, after replacing VCA tube a full calibration

procedure must be done.

VCA balance check and calibration is recommended to be preformed

once a year.

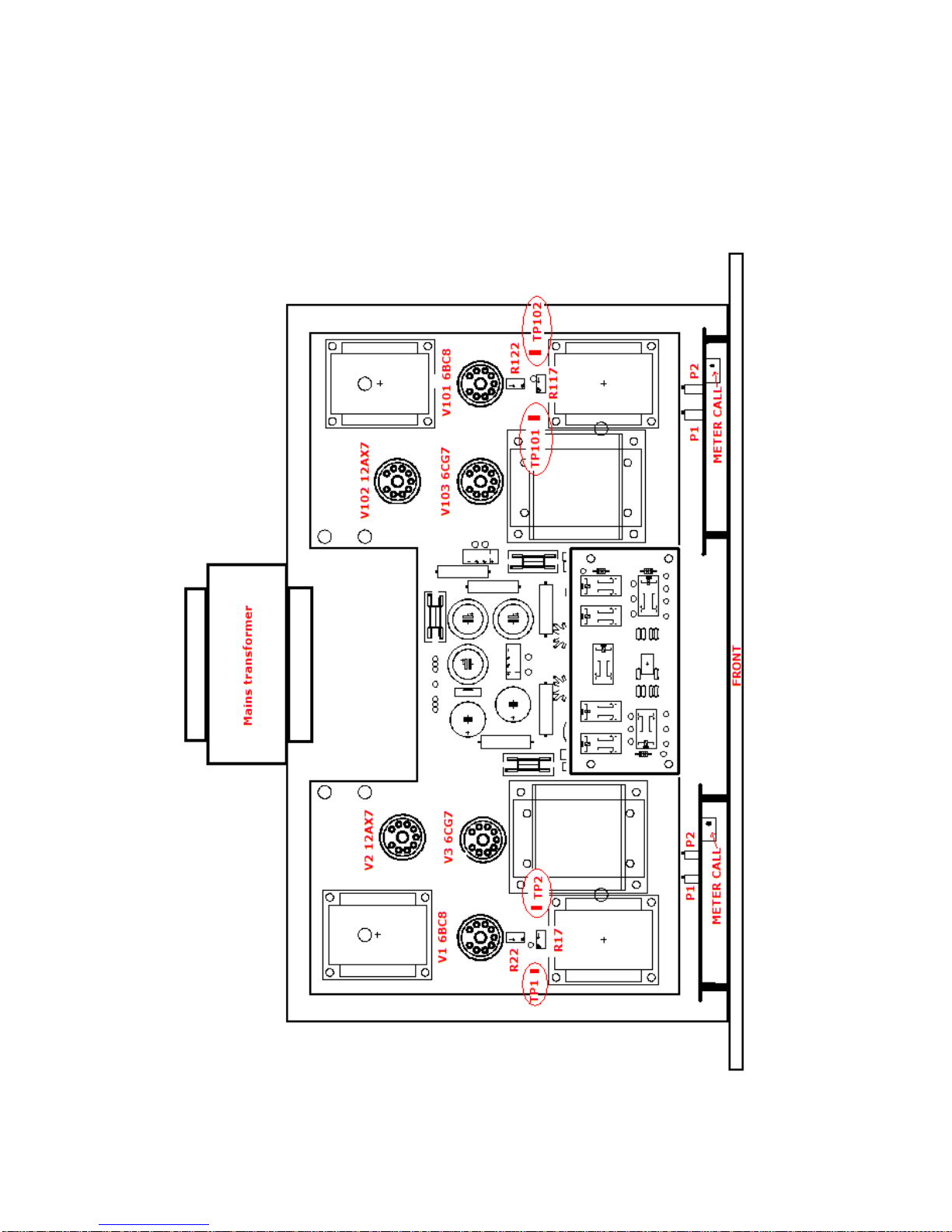

VCA Balance calibration:

Remove the top cover of the unit.

Connect the unit to mains voltage and allow it to worm up for 15

minutes.

Check with DC Voltmeter the voltage between TP1 and TP2 located on

the left side of the main board (see picture on page 12).

The voltage between these test points should be as close to 0V as

possible.

Calibrate the voltage for the lowest reading obtainable by tuning R22.

Repeat the same procedure for channel B with TP101 and TP102 and

R122.

Full calibration procedure:

Remove the top cover of the unit, Connect the unit to mains voltage

and allow it to worm up for 15 minutes.

1. Perform a VCA Balance calibration for both sides as previously

shown.

2. Preparations:

Tune the knobs on front panel on both channels by the following

order.

T.H., ATT, RECOVERY, OUT-LEVEL: fully clockwise.

10

RATIO, CREST LEVEL, CREST RECOVERY: fully counter

clockwise.

IN LEVEL: set to 12:00 o’clock. ST-LINK: off. BYPASS: IN.

3. Connect DVM between chassis ground and test point C-IN-A

located on left of main board. Turn trimmers P1 and P2 located

on S.C. pcb of channel A to get minimum readings TYPICAL

READING -0.8V.

Repeat the same procedure on channel B with test point C-IN-B

and its S.C. pcb.

4. Connect 1khz tone at -4dbm to line in of channel A.

5. VCA OFFSET calibration: Connect channel A output to DBM

METER.

Calibrate trim P2 on the S.C. pcb (on the right) channel A to a

drop of -2.5dbm of output level. Do the same on channel B to

match the overall gain of channel A ( if the tubes were ideally

symmetric then -2.5dbm drop will equal the gains between the

two sides if not then compensate to equal gain of A versus B ).

6. VCA GAIN calibration: Change the Oscillators output level to

-8 dbm.

Turn T.H. knob counter clockwise, turn IN LEVEL, RATIO fully

clockwise.

Compare the output level of channel A on the dbm meter when

the T.H. is fully clockwise versus fully counter clockwise &

calibrate trimmer P1 Channel A till you get a -18dbm drop of

output level when T.H. is fully counter clockwise.

Calibrate the G.R. meter to read -18db of G.R.

Repeat the procedure on channel B.

7. T.H.D. MAX calibration: Connect a T.H.D meter to I/O of

channel A.

Tune the oscillator’s level to get -18db of Gain reduction on the

same knob settings. Calibrate trimmers R17 on main board to

give minimum T.H.D. readings on -18db of G.R.

Repeat the same procedure on channel B with R117.

8. Check and re trim the VCA balance of both channels with no

input signal connected.

9. Symmetry check: Check the maximum output gain of both

channels again for symmetry (without G.R.). Fine tune and

equal between them if needed by slightly trimming P2 (VCA

offset) on S.C. pcb in one of the channels.

Fine tune the VCA gain (P1) if needed to obtain best symmetry

of measured G.R. between both sides.

Fine tune the G.R. meter’s reading if needed to obtain best

symmetry of G.R. reading. For the symmetry tunings it is

best to connect the oscillator to both sides Line in with a

paralleled feeding cable.

11

Gainrider PCB top View

12

Specifications:

Electronics:

Input Impedance: 10Kohms Balanced, (PIN 2 HOT)

Output Impedance: >500 ohms Balanced, (PIN 2 HOT)

MAX Gain: 28 db

MAX Input level: 36dbu for 1% THD (WITH NO GR)

MAX Output level: 32dbu for 1% THD (WITH NO GR)

Noise Floor: -91db @ 22-22khz typical

Distortion: @ Unity gain 1Khz +4dbu INPUT,

THD+N=0.058% (WITH NO GR)

Frequency Response: -/+1db from 20HZ to 20Khz

Attack Time: 0.2 to 70msec

Recovery Time: 0.07 to 2 sec

Operating Voltage: 230Vac @ 50Hz / 115Vac @ 60Hz

Power consumption: 40watts

Dimensions: H=3 Rack Units, W=19” ,D=13.4”

All spec’s at RL=600Ohm.

Info subject to change without prior notice.

© All legal rights reserved to Signal Audio Workshop.

From In to Out, as follows for each channel.

Signal chain:

All Tube & Transformer balanced Signal chain as

described bellow:

Transformer input, 1 dual Triode VCA Tube,

Inter stage Transformer, 2 dual Triode Output

driver, Output Transformer.

Integrated M.S Matrix for M.S Stereo imaging.

Side chain:

Solid state Side Chain security.

Special 21 segment G.R Peak Meter.

13

Limited Warranty

This product is warranted to the original consumer purchaser to be free from defects in

materials and workmanship under normal installation, use and service for a period of

one (1) year from the date of purchase as shown on the purchaser’s receipt.

The obligation of Signal Audio Workshop under this warranty shall be limited to repair

or replacement (at our option), during the warranty period of any part which proves

defective in material or workmanship under normal installation, use and service,

provided the product is returned to Signal Audio Workshop, TRANSPORTATION

CHARGES PREPAID. Products returned to us or to an authorized Service Center must

be accompanied by a copy of the purchase receipt. In the absence of such purchase

receipt, the warranty period shall be one (1) year from the date of manufacture. This

warranty shall be invalid if the product is damaged as a result of defacement, misuse,

abuse, neglect, accident, shipping damage destruction or alteration of the serial

number, improper electrical voltages or currents, repair, alteration or maintenance by

any person or party other than our own service facility or an authorized Service Center,

or any violation of instructions furnished by us. This one-year warranty is in lieu of all

expressed warranties, obligations or liabilities.

ANY IMPLIED WARRANTIES, OBLIGATIONS, ORLIABILITIES, INCLUDING BUT

NOT LIMITED TO THE IMPLIED WARRANTIES OF MERCHANTABILITY AND

FITNESS FOR A PARTICU-LAR PURPOSE, SHALL BE LIMITED IN DURATION TO

THE ONE YEAR DURATION OF THIS WRITTEN LIMITED WARRANTY. Some states

do not allow limitations on how long an implied warranty lasts, so the above limitation

may not apply to you. IN NO EVENT SHALL WE BE LIABLE FOR ANY SPECIAL,

INCIDENTAL OR CONSEQUENTIAL DAMAGES FOR BREACH OF THIS OR ANY

OTHER WARRANTY, EXPRESSED OR IMPLIED, WHATSO-EVER.

Some states do not allow the exclusion or limitation of special, incidental or

consequential damages so the above limitation or exclusion may not apply to you. This

warranty gives you specific legal rights, and you may also have other rights which vary

from state to state.

14

Warranty Registration Form

Please take the time to fill out this registration Form and send it to

the address mentioned below. Or send this page threw e-mail to:

Signal Audio WorkshopAbarbanel ST.53

Tel Aviv 66089 IsraelP.O.B 5169 TLV 61051

Fax: 972-3-6824716or send it by

Registering your product will allow you to get full warranty service

plus product upgrades if there will be any at the warranty period,

according to Warranty rules.

We would like to seize these opportunity to thank you once again for

choosing Signal AWS.

PRODUCT INFO:

Model: __________________________________________________

Serial No: ________________________________________________

Manufacturing date: ________________________________________

Supplier: _________________________________________________

OWNER INFO:

Owner’s name: ____________________________________________

Company: ________________________________________________

Address: _________________________________________________

City: ____________________________________________________

State: ___________________________________________________

Zip: _____________________________________________________

Country: _________________________________________________

Phone: ___________________________________________________

Fax: _____________________________________________________

e-mail: ___________________________________________________

Comments:

__________________________________________________________

__________________________________________________________

__________________________________________________________

______________________________________________________

15

Table of contents

Popular Music Equipment manuals by other brands

Fishman

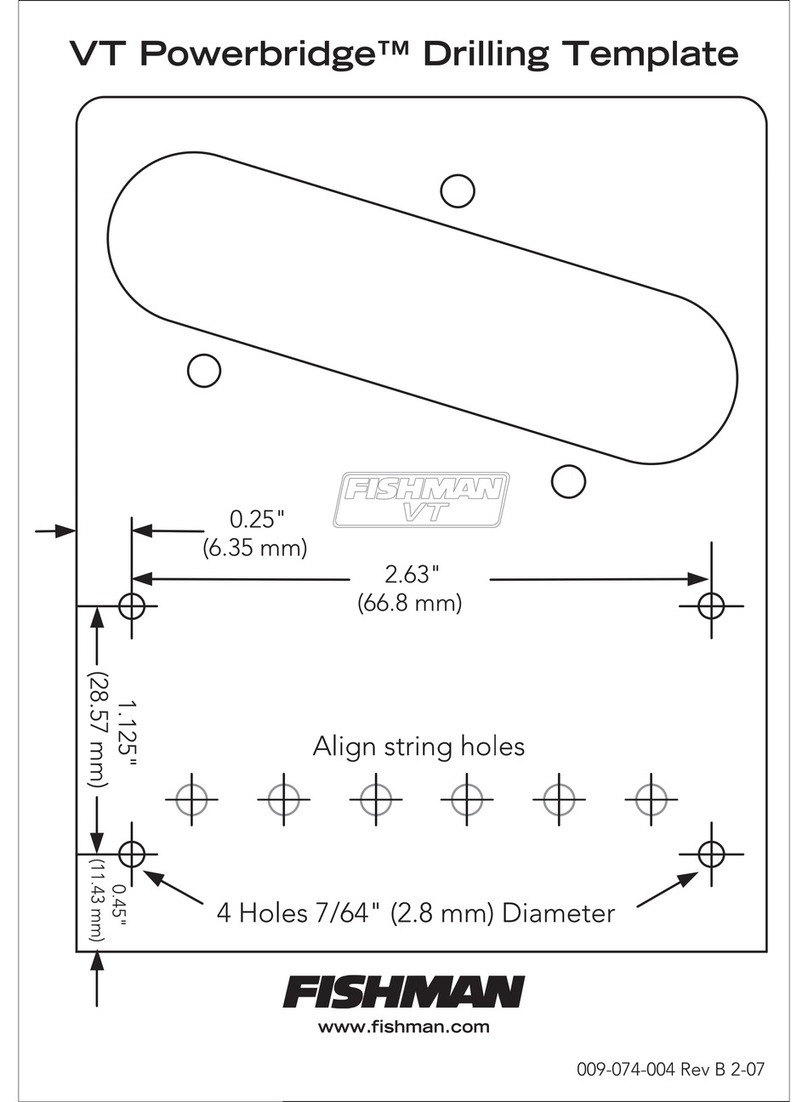

Fishman VT POWERBRIDGE - ROUTING Template manual

Roland

Roland VT-12 Specifications

Fishman

Fishman M-200 PRO MANDOLIN PICKUP installation guide

Gemini

Gemini KL-1 Operation manual

Marshall Amplification

Marshall Amplification Haze MHZ15 owner's manual

Alien Apparatus

Alien Apparatus Solo Performer Show Controller user guide

Harley Benton

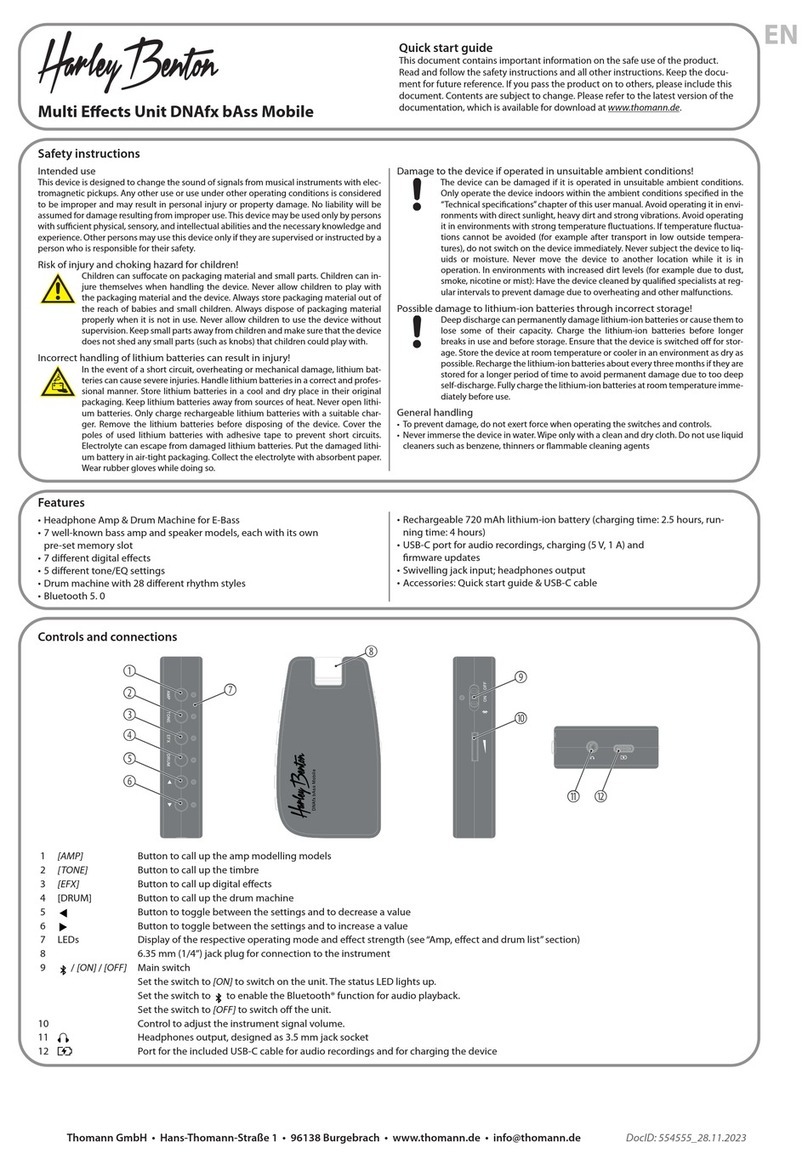

Harley Benton DNAfx bAss Mobile quick start guide

Zendrum

Zendrum Digital MIDI Controller owner's manual

Teac

Teac GT-R1 release note

Musicmakers

Musicmakers BALLAD HARP KIT Assembly instructions

PROEL

PROEL Axiom DSO480 user manual

Sweet Sound Electronics

Sweet Sound Electronics Mojo Vibe instruction manual