Signal NOXGEN III User manual

SIGNAL GROUP LTD

s/sales/masters/manuals/noxgman.doc Page 1of 17

SIGNAL NOXGEN III

NO2 CONVERTER TESTER

OPERATION MANUAL

NOX III/MAN

SIGNAL GROUP LTD

12 Doman Road

Camberley

Surrey

GU15 3DW

UK

Tel: +44(0) 1276 682841

Fax: +44(0) 1276 691302

e-mail: instruments@signal-group.com

site: www.signal-group.com

SIGNAL GROUP LTD

s/sales/masters/manuals/noxgman.doc Page 2of 17

COPYRIGHT

____________________________________________________________

All rights reserved. No part of this manual may be reproduced, stored in a retrieval

system or transmitted in any form or by any means -electronic, mechanical,

photocopying, recording or otherwise -without the prior written permission of The

Signal Group Ltd. While we believe that the information and guidance given in this

manual is correct, all parties must rely upon their own skill and judgement when making

use of it. The Signal Group Ltd. will not assume any liability to anyone for any loss or

damage caused by any error or omission in the manual, whether such omission is the

result of negligence or any other cause. Any and all such liability is disclaimed.

_____________________________________________________________

Issue Date Comments

108/85 First Issue

206/93 919

301/94 979

410/94 1045

502/99 1555

607/01 1740

SIGNAL GROUP LTD

s/sales/masters/manuals/noxgman.doc Page 3of 17

INDEX

PAGE

1.00 UNPACKING INSTRUCTIONS 3

2.00 INTRODUCTION 4

2.01 Principle of Operation 4

2.02 The Ozonizer 5

2.03 Flow Scheme Diagram 6

2.04 Remote Control Flow Scheme Diagram 7

3.00 INSTALLATION 8

3.01 General 8

3.02 Installation Drawing 9

3.03 Span Gas Connection 10

3.04 Oxygen/Air Inlet 10

3.05 Outlet 10

3.06 Mains Power 10

3.07 Remote Control Connections 11

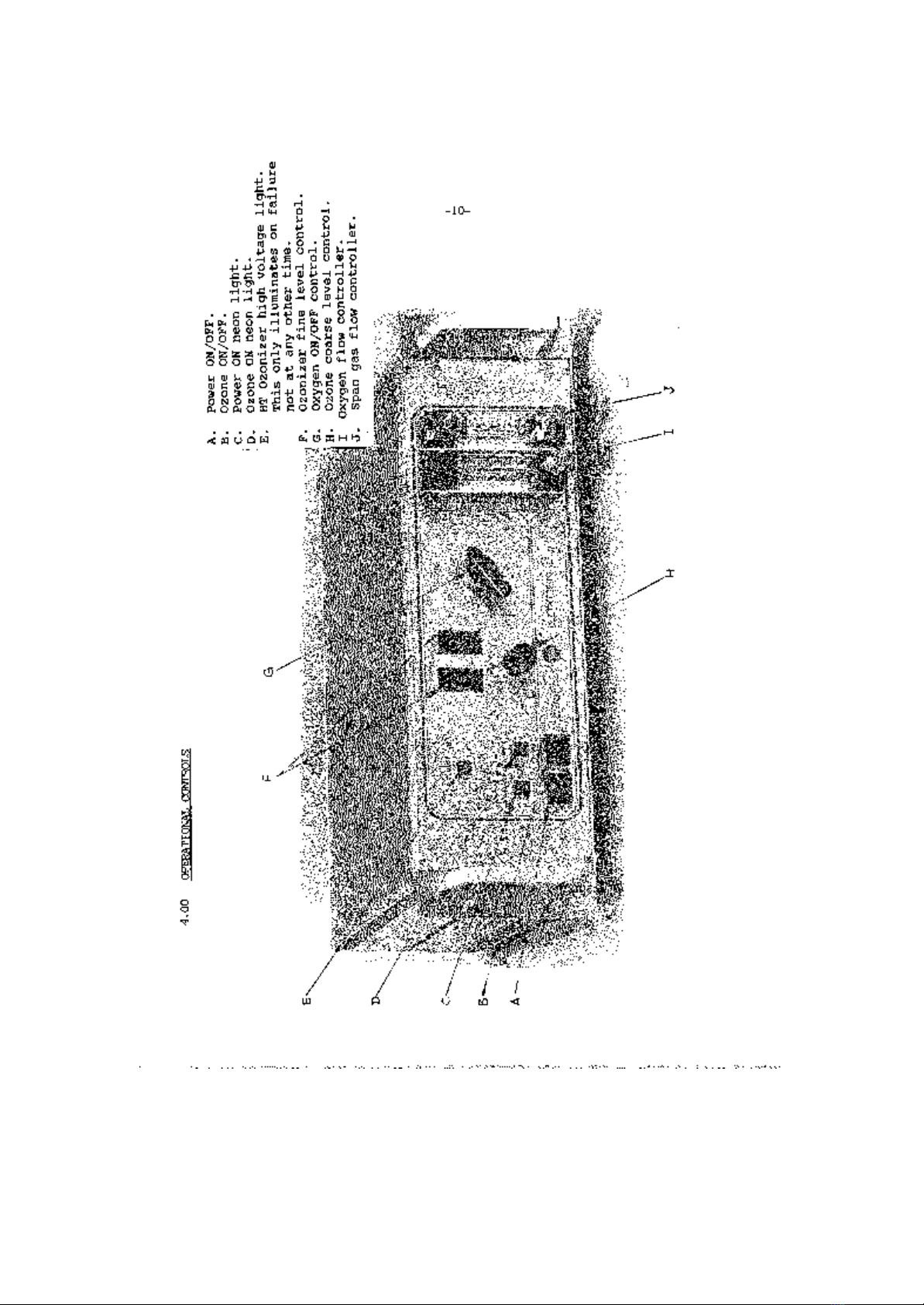

4.00 OPERATION CONTROLS 12

4.01 Operation 13

4.02 Remote Control Operation 15

SIGNAL GROUP LTD

s/sales/masters/manuals/noxgman.doc Page 4of 17

1.00 UNPACKING INSTRUCTIONS

This instrument is packed for general freight purposes. It should withstand the

occasional “bumps and knocks” which occur during transit.

Please check the instrument for damage however, and report any damage within

24 hours to the factory or its Sales Office or Distributor.

1. Before any connection is made, unscrew the 4 cross head screws on

instrument cover lid.

2. Slide lid back to reveal the internal assemblies of the instrument.

NOTE: Do not take the cover off with power connected.

3. Check that all PCBs are firmly in their mating connectors on the front of

each PCB.

4. Check for any loose or broken parts which may have occurred during

transit.

5. Slide lid back and re-do the screws (do this before connecting power).

6. Read through the rest of this manual thoroughly and then carry out the

installation.

SIGNAL GROUP LTD

s/sales/masters/manuals/noxgman.doc Page 5of 17

2.00 INTRODUCTION

Chemiluminescent NOx analysers, such as Signal’s own Model 4000 Series; rely

upon the efficiency of the NO2 to NO converter in the analyser. The converter

enables a measurement to be made of the total oxides of nitrogen in the sample

stream (NOx = NO + NO2).

The 1979 Heavy Duty Register of the U.S. Environmental Protection Agency

stipulates that such converters must be checked before the analyser is initially

used, and thereafter at weekly intervals, to ensure that they have an efficiency of

at least 90%. The Signal NOXGEN III provides known, accurate amounts of NO2

for converter efficiency testing, and fully meets the EPA requirements.

The instrument is compact, inexpensive and provides a precision of control and

repeatability of results that were unobtainable with the previous generation of

converter testers. Ozone is generated by a high energy lamp using an electronic

pulse, which can be varied to adjust the Ozone level. The Noxgen III produces no

NO from air, in contrast to the high voltage corona discharge technique.

Stability against mains power variations, and the consequent effects of NO2

concentrations, is ensured by the incorporation of a voltage stabilised electronic

circuit, feeding pulses to a high voltage transformer.

2.01 PRINCIPLES OF OPERATION

The instrument is fed with nitric oxide and oxygen, the latter being subjected to a

high-energy lamp, which partially converts the oxygen to ozone. The

oxygen/ozone mixture is passed to the nitric oxide flow, and the nitric oxide is

instantly converted by the ozone to give nitrogen dioxide. The reaction between

the remaining oxygen and nitric oxide again produces nitrogen dioxide, but this

reaction is so slow that it does not need to be taken into account for test

purposes.

The amount of nitrogen dioxide generated is determined by measuring the fall of

nitric oxide concentration. If, for example, this concentration falls by 400 vpm,

then 400 vpm nitrogen dioxide has correspondingly been generated, as the

oxidation is a 1 : 1 molecular reaction. The concentration of nitrogen dioxide is

therefore directly proportional to the concentration of ozone generated. When

connected to the analyser converter, the NO2, should be converted back to NO.

From the results obtained the converter efficiency can be determined.

SIGNAL GROUP LTD

s/sales/masters/manuals/noxgman.doc Page 6of 17

2.02 THE OZONIZER

The signal Model NOXGEN III utilises a very efficient high energy lamp system

which ionises oxygen to ozone. The ozonizer is built into a fully self contained

enclosure within the instrument. This should not be opened by unauthorised

personnel because very high voltages exist within the enclosure, even with power

off.

SIGNAL GROUP LTD

s/sales/masters/manuals/noxgman.doc Page 7of 17

Figure 2.03 Flow Scheme Diagram

SIGNAL GROUP LTD

s/sales/masters/manuals/noxgman.doc Page 8of 17

Figure 2.04 Remote Control Flow Scheme Diagram.

SIGNAL GROUP LTD

s/sales/masters/manuals/noxgman.doc Page 9of 17

3.00 INSTALLATION

3.01 GENERAL

The Signal NOXGEN III comes in a 19” rack type, 3 units high enclosure. It can

be bench top used or fitted into a 19” rack console. For bench top use there are

extendible feet at the front which can be used to tilt the angle of the instrument

back for ease.

When using this instrument in a 19” rack, the feet will need to be removed. To do

this, undo the 4 cross-head screws on the under cover and slide back the cover

to remove it. With the cover removed you can easily unscrew the four feet before

replacing the cover for installation.

This instrument is fitted with Parker CP1 stainless steel tube fittings. Because of

the presence of nitric oxide, nitrogen dioxide and ozone, all of which are toxic

gases, great care should be taken to ensure that no leaks occur throughout the

tube work. Make the compression fittings off in accordance with the

manufacturers recommendations and do not over-tighten the nut.

SIGNAL GROUP LTD

s/sales/masters/manuals/noxgman.doc Page 10 of 17

Figure 3.02 Installation Diagram.

SIGNAL GROUP LTD

s/sales/masters/manuals/noxgman.doc Page 11 of 17

3.03 SPAN GAS CONNECTION

The span gas should be nitric oxide in nitrogen at a concentration about the level,

which you expect to use the analyser. The rear of the instrument has a 1/4”

compression fitting and you should use either Teflon (PTFE) or stainless steel

tubing. DO NOT USE NYLON OR COPPER TUBE.

Do not set the pressure to this line until you start to operate the instrument

because as soon as you set a pressure on the gas inlets, a flow will start to

occur.

3.04 OXYGEN/AIR INLET

Connect the oxygen or air cylinder to this connection, again using Teflon (PTFE)

or stainless steel tubing. It is most common to use oxygen but dry air can be

used with almost as high an ozone production as that using oxygen. Also, the

Signal Model NOXGEN III has been carefully designed so that no nitric oxide is

generated from the nitrogen in air, which means that converter efficiency testing

using air can still be done without inaccuracies. The only difference seen will be

the level of nitric oxide in the span gas which can be lowered in reading by

conversion to nitrogen dioxide, i.e. using air will allow you to change less NO to

NO2, using oxygen will allow you to change more NO to NO2.

3.05 OUTLET

This connection, again a 1/4” compression fitting, should have Teflon or stainless

steel tube connected to the calibration inlet port of the NOx analyser being

tested.

3.06 MAINS POWER

Connect a 220/240V or (110V if specified on rear panel nameplate) using a

properly grounded (earthed) supply. 1 amp is the MAXIMUM POWER

DEMAND.

SIGNAL GROUP LTD

s/sales/masters/manuals/noxgman.doc Page 12 of 17

3.07 REMOTE CONTROL CONNECTIONS

The remote control option is to enable you to control the gas selection functions

using TTL inputs. The TTL levels can be either OV inputs via the earth return

pins or, for people without a transistor logic controller or computer, a simple short

circuit wire link with a switch for ON and OFF can be connected between any of

the four earth pins and the function pin.

Before any of the function pins can be utilised, the remote enable must be

operated and again, either an OV logic signals via the earth return or a short

circuit wire link can be used.

Without the remote enable function being operated, the instrument operates in

the same way as the non remote control instrument.

With no power connected, the instrument with the remote control option will shut

off all gas flows using the built-in solenoid valves.

PIN NO. FUNCTION

(15 WAY D CONNECTOR)

1 N/C

2 OV RETURN

3 OV RETURN

4 OV RETURN

5 OV RETURN

6 OV RETURN

7 OV RETURN

8 N/C

9 N/C

10 REMOTE ENABLE

11 OXYGEN ON

12 SPAN ON

13 OZONE ON

14 N/C

15 N/C

NOTE:

DO NOT MAKE ANY CONNECTIONS TO N/C PINS

SIGNAL GROUP LTD

s/sales/masters/manuals/noxgman.doc Page 13 of 17

Figure 4.00 Operational Controls

SIGNAL GROUP LTD

s/sales/masters/manuals/noxgman.doc Page 14 of 17

4.01 OPERATION

WARNING:DO NOT LEAVE OZONE ON WITHOUT GAS FLOW

1. Ensure that all connections have been made in accordance with the

installation instructions.

2. Set 10 psig or 0.75 bar gauge (approx.) to regulators of both the span

gas and NO cylinder and the oxygen/air cylinder.

3. Balance the NO and NOx modes of your NOx analyser, ensuring they

both zero and span correctly. Select no mode.

4. Press the Power ON switch but not the Ozone switch at this stage.

5. Select OFF position for oxygen.

6. Adjust the span flow control to a suitable rate for your NOx analyser and

leave to settle until a suitable reading of the NO span gas is obtained on the

analyser.

7. Open the oxygen ON/OFF flow valve on the Noxgen front panel (G) and

adjust the flow of this oxygen using the flow control (I) until the analyser reading

falls by about 10% of the original reading in step 6. Record this reduced

reading (Reading A).

8. Switch on the ozone using the Ozone ON/OFF button B and adjust the

ozone level using both the coarse adjust switch (H) and the fine

thumbwheel adjust switches (F).

This adjustment should be made until the analyser reading is further

reduced so that it is now about 20% of the reading taken in Step 6. At

this stage the ozone in the Noxgen is converting the NO span gas to

NO2 and the fall in reading corresponds to the level of NO2 now being

generated. Whatever you do, always allow 10% of the reading in Step

6 (A) to remain. Record this new reading from the analyser (Reading B).

9. Having recorded a stable reading B, switch the analyser to the NOx

mode and wait for a steady reading. Record this reading (Reading C).

SIGNAL GROUP LTD

s/sales/masters/manuals/noxgman.doc Page 15 of 17

10. Switch off the Ozone and allow the NOx analyser reading to stabilise and

record this new reading (Reading D).

11. Shut off the oxygen flow valve on the front panel and observe the

analyser reading. This reading should now represent the same as

obtained in Step 6. The only difference now from Step 6, is that you

have the analyser in its NOx mode, and therefore any NO2 which was

in the span cylinder will produce a correspondingly higher reading

than at Step 6.

12. Calculate the efficiency using the equation:-

Efficiency = (A)

(D x C-B) x 100

( A -B )

if A = D i.e. (NO span = NOx span)

the equation simplifies to:-

Efficiency = (C -B) x 100

(A -B)

SIGNAL GROUP LTD

s/sales/masters/manuals/noxgman.doc Page 16 of 17

4.02 REMOTE CONTROL OPERATION

The remote control option (when fitted) has facilities to enable you to control the

following functions from remote either TTL or contact closure. See installation

instructions for details.

1. Remote enable control ON/OFF.

2. Remote oxygen ON/OFF.

3. Remote span gas ON/OFF.

4. Remote Ozone ON/OFF.

When using the remote control facilities you must firstly set the instrument’s flow

control and Ozone level manually, exactly the same as previously explained in the

Operation Section. Therefore, all the settings will be made manually before

going to remote control.

Unless the remote enable control is activated, the instrument will behave the

same as the standard manual controlled Noxgen and the operation as explained

in Steps 1-11 can be carried out as normal.

With power off, all solenoids will close and gas will be automatically shut off.

(This is not so with the remote control versions).

Having set up the Noxgen III in the normal way, to carry out remote control

converter test you simply follow the following steps:-

1. Switch power on.

2. Activate remote enable.

3. Activate span gas ON (Reading A).

4. Activate Oxygen gas ON (Reading B).

5. Activate Ozone On (Reading C).

6. Switch analyser from NO to NOx mode (Reading D).

7. Deactivate the Ozone (Reading E).

8. Deactivate the Oxygen gas.

NOTE: In order to allow complete remote control for this test, Signal

has designed their own Model 4000 chemiluminescent NOx

analyser, complete with remote controlled NO/NOx modes.

SIGNAL GROUP LTD

s/sales/masters/manuals/noxgman.doc Page 17 of 17

Figure 4.02 Chart Display

Table of contents