7

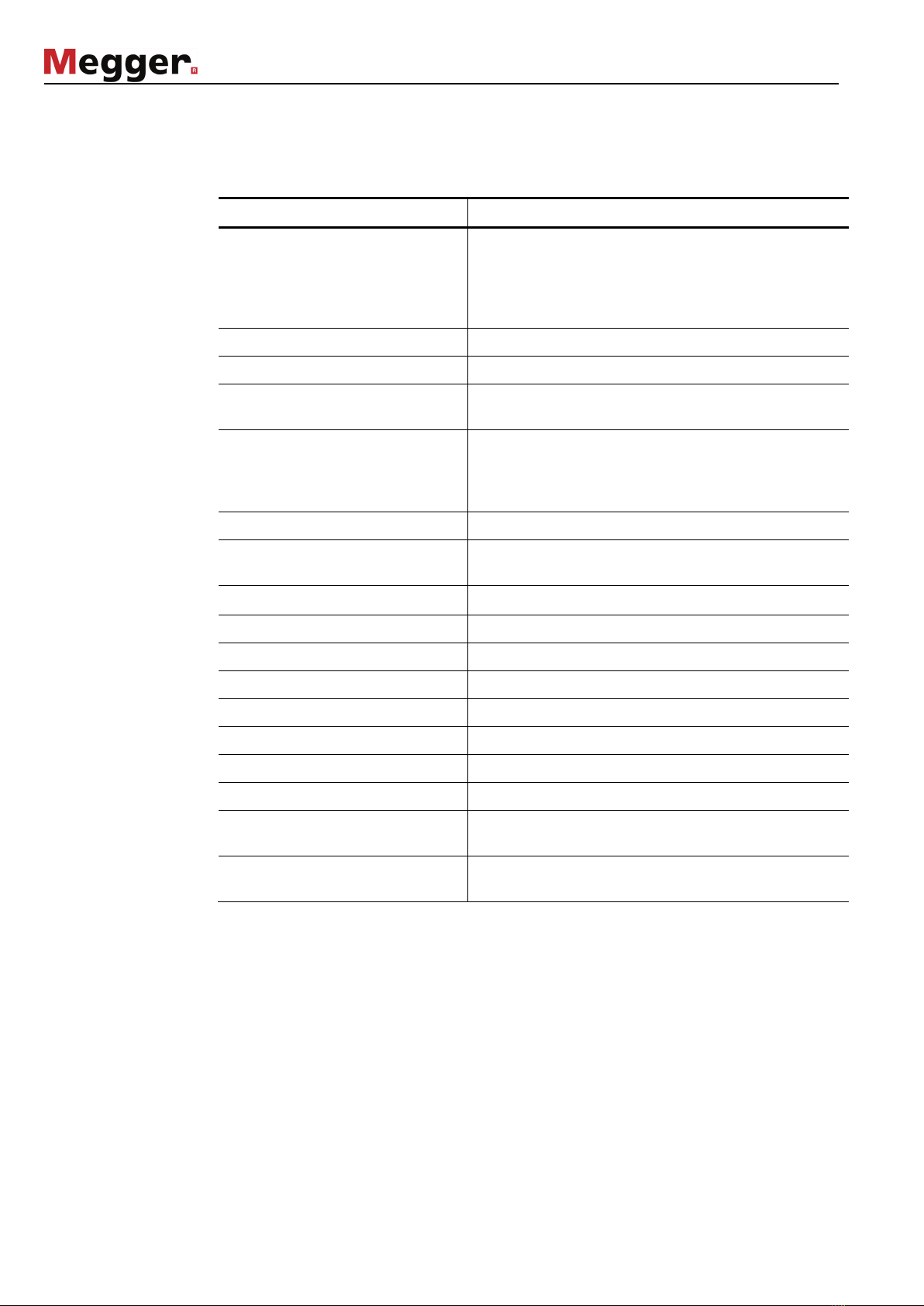

1.2 General Cautions and Warnings

Intended application Safe operation is only realised when using the equipment for its intended purpose (see

chapter 2.1). Usi

ng the equipment for other purposes may lead to human danger and

damage of equipment of involved installations.

The limits described under technical data may not be exceeded. Operating products of

Megger in condensing environment may lead to flash-over, d

anger and damage. The

instruments should only be operated under tempered conditions. It is not allowed to

operate Megger

products at direct contact with humidity, water or near aggressive

chemicals nor explosive gases and fumes.

Five safety rules

The five safety rules must always be followed when working with HV (High Voltage):

1. De-energise

2. Protect against re-energising

3. Confirm absence of voltage

4. Ground and short-circuit

5. Cover up or bar-off neighbouring energised parts

Using cardiac pacemaker

Physical processes during operation of high voltage may endanger persons wearing a

cardiac pacemaker when near these high voltage facilities.

Fire fighting in electrical installations

•According to regulations, carbon dioxide (CO2) is required to be used as

extinguishing agent for fighting fire in electrical installations.

•Carbon dioxide is electrically non conductive and does not leave residues. It is safe to

be used in energized facilities as long as the minimum distances are maintained. A

CO2fire extinguisher must be always available within electrical installations.

•If, contrary to the regulations, any other extinguishing agent is used for fire fighting,

this may lead to damage at the electrical installation. Megger disclaims any liability for

consequential damage. Furthermore, when using a powder extinguisher near high-

voltage installations, there is a danger that the operator of the fire extinguisher will get

an electrical shock from a voltage arc-over (due to the powder dust created).

•It is essential to observe the safety instruction on the extinguishing agent.

•Applicable is DIN VDE 0132.