SignalFire Sentinel-FS-3BIS User manual

1

SignalFire Telemetry

Rev 1.2

Interface Manual

Sentinel Float Scout

SignalFire Model: Sentinel-FS-3BIS

The SignalFire Sentinel Float Stick Node is an Intrinsically Safe device with the

following features:

-Standard SignalFire Sentinel RS485-Modbus Node

-RS485 connection to internal Float Stick Interface Board

-1 or 2 floats with temperature(s) supported

-Low power operation from an intrinsically safe high capacity lithium primary

battery pack

-Optional solar battery system for routing nodes or rapid data collection

-Sends data to a SignalFire Buffered Modbus Gateway

-AES 128bit encryption

2

SignalFire Telemetry

Rev 1.2

Specifications

Enclosure Size

3.5” tall ×5.0” wide ×5.0” deep

Power Source

Internal IS Lithium battery pack

SignalFire Part Number: 3BIS

External Solar battery system

SignalFire Part Number: Sentinel-HCSolar

DC-DC Converter

SignalFire Part Number: DCDC-Sentinel

Other external power supply meeting the power entity parameters from the

control drawing.

Temperature Rating

-40°C to +60°C

Radio Frequency

902-928MHz Ism Band, FHSS radio, internal antenna

Compliance

Measurement Resolution

Certified for use in Class I, Division 1 groups C and D. EXi [EXi] FCC/IC

(Certification Pending).

0.0001”

WARNING: Use of this equipment in a manner not specified by the manufacturer may

impair the protection provided by the equipment.

WARNING: The use of any parts not supplied by the manufacturer violates the safety rating

of the equipment.

The associated apparatus provides intrinsically safe outputs.

L’appareil associé fournit des sorties à sécurité intrinsèque.

Refer to control drawing “Sentinel –Control Drawing –Modbus, Thermocouple, RTD, and Float Stick for

requirements when used in a Class I Division 1 area.

3

SignalFire Telemetry

Rev 1.2

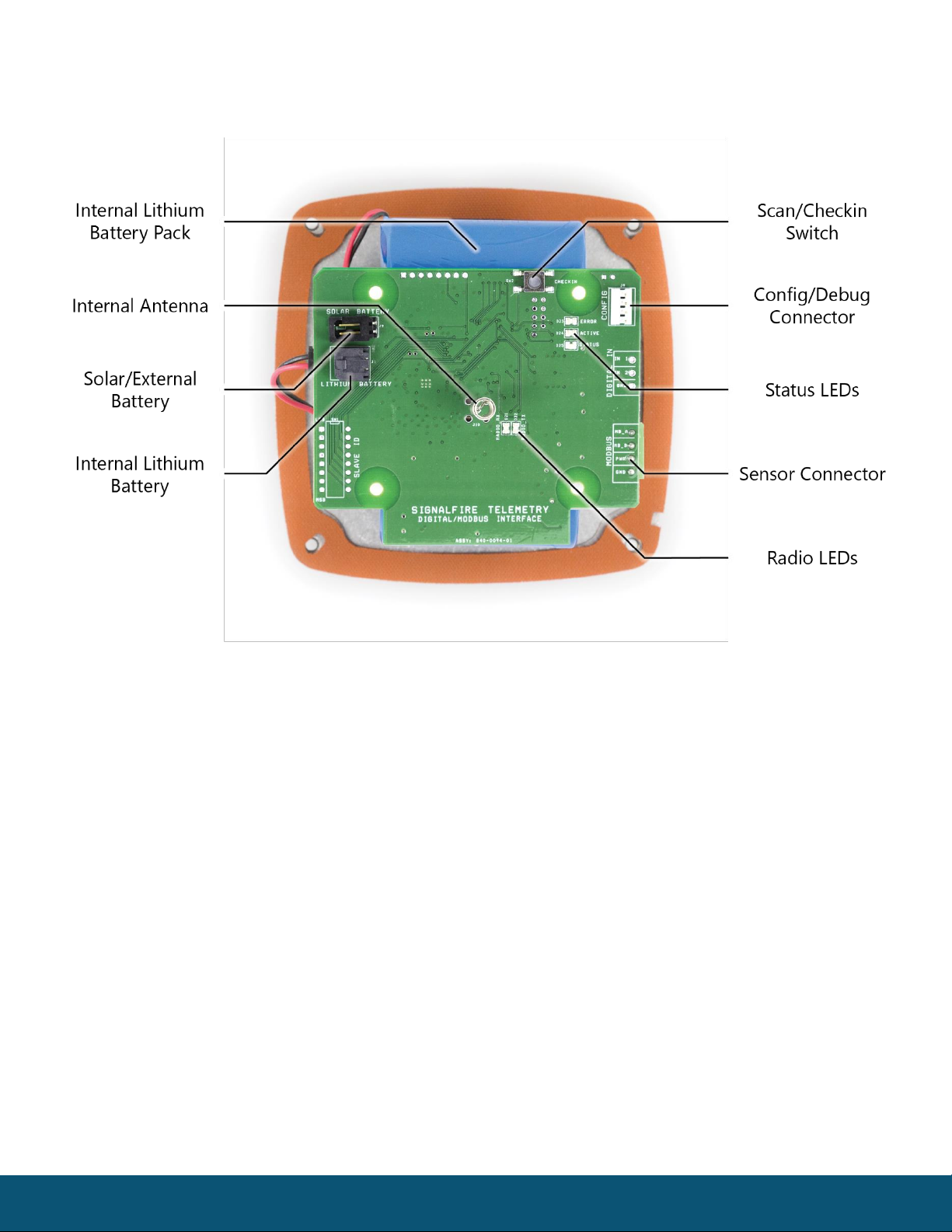

Connections and Components

Radio LEDs

-The Radio TX LED (green) flashes each time a radio packet is sent. This LED will blink rapidly while

searching for the radio network.

-The Radio RX LED (red) blinks on each received radio packet.

Status LEDs

-The Active LED (green) will blink at boot up and will blink rapidly when the sensor is being powered and

read.

-The ERROR LED (red) will blink to indicate an error condition.

Scan/Checkin Button

-If this button is pressed the Sentinel will take a reading from the Float Stick and send those values to

the gateway.

4

SignalFire Telemetry

Rev 1.2

Setup

The nodes need to be set up for correct operation before being fielded. The configurable items include:

-Network selection/Encryption settings

-Check-in period selection

-Float Stick mode enable

All settings are made using the SignalFire Toolkit PC application and a serial programming cable.

Using the SignalFire Toolkit

The SignalFire Toolkit application can be downloaded at www.signal-fire.com/customer. After installation,

launch the software and the main toolkit window will open:

Select the COM port associated with the Sentinel Node and click “Auto-Detect Device on COM Port.” This will

open the device configuration window, where all device settings can be configured.

WARNING: Perform the steps in this section (Setup) in a safe location only.

5

SignalFire Telemetry

Rev 1.2

Network Setting

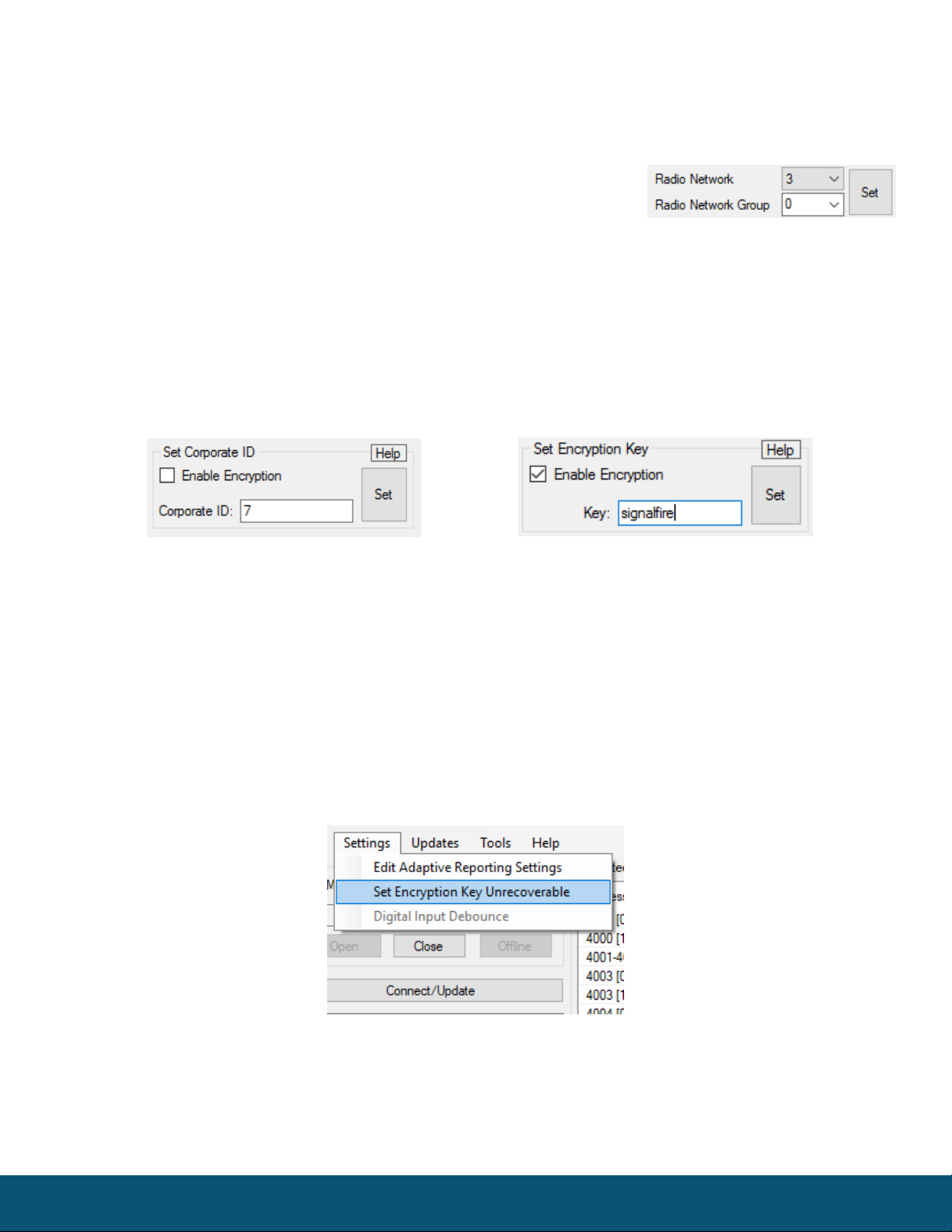

The network is set using the SignalFire Toolkit. The network, network group, and corporate ID/encryption key

settings must match those of the gateway for them to communicate.

Encryption

To protect your over-the-air data and prevent tampering, SignalFire networks come with encryption. Legacy

products use a Corporate ID, but can be switched over to use an encryption key if the firmware and ToolKit are

up to date.

To set up a legacy Sentinel to use encryption, click the checkbox labeled Enable Encryption inside the Set

Corporate ID box. All newer Sentinels come with this option enabled with “signalfire” as the default encryption

key.

The box will then change into a Set Encryption Key box, and it will prompt instead for the encryption key you

would like to use. Note that keys may not contain spaces or angle brackets. Enter it and then press Set. If you are

setting up a new network, you will need to set the encryption key on all of your devices. If you are adding a

Sentinel to a legacy network, you can simply set the Corporate ID without clicking the Enable Encryption box,

and it will remain compatible with the older system.

It is also possible to hide your encryption key so it cannot be read. This is the most secure option, but if you

forget your key, there is no way to recover it – you have to reset the key on every device on its network. To enable

this option, select Set Encryption Key Unrecoverable under the Settings menu.

Setting the encryption key to be unrecoverable.

Encryption Enabled

Corporate ID

6

SignalFire Telemetry

Rev 1.2

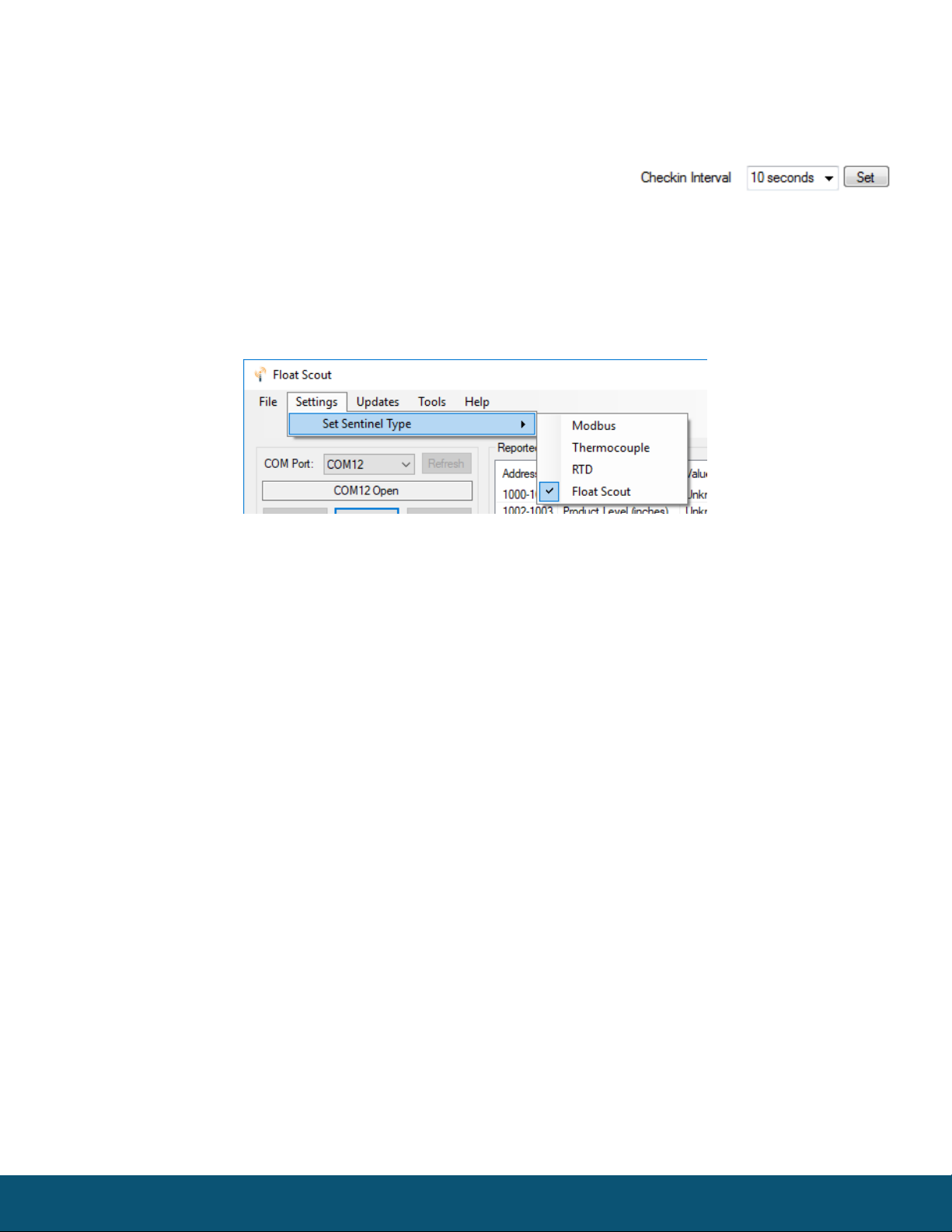

System Check-In Period

This setting controls how often the node will read the Modbus device and forward the register data to the

gateway.

Configuration

Since the Sentinel Float Stick uses a standard Sentinel Modbus Node with the Float Stick interface card it is

necessary to set the Sentinel type for Float Stick operation if it is in the default Modbus mode. To do this, select

Float Stick in the Set Sentinel Type option under the Settings pull down menu.

7

SignalFire Telemetry

Rev 1.2

Sensor Connections

Wiring Requirements

To ensure intrinsic safety is maintained it is required that the installer follow these guidelines when connecting

sensors to the SignalFire node. See pictures for proper wire routing examples.

-Strip the wires so that there is minimal exposed un-insulated wire when inserted into the screw

terminal.

-All wiring should be neat and orderly.

8

SignalFire Telemetry

Rev 1.2

Float Stick Connection

The Float Stick interface board is plugged into the Modbus connector on the Sentinel and has a 3-position

screw terminal block that is labeled with the wire colors from the Float Stick. Connect the Red, White and Black

wires to the correct terminals.

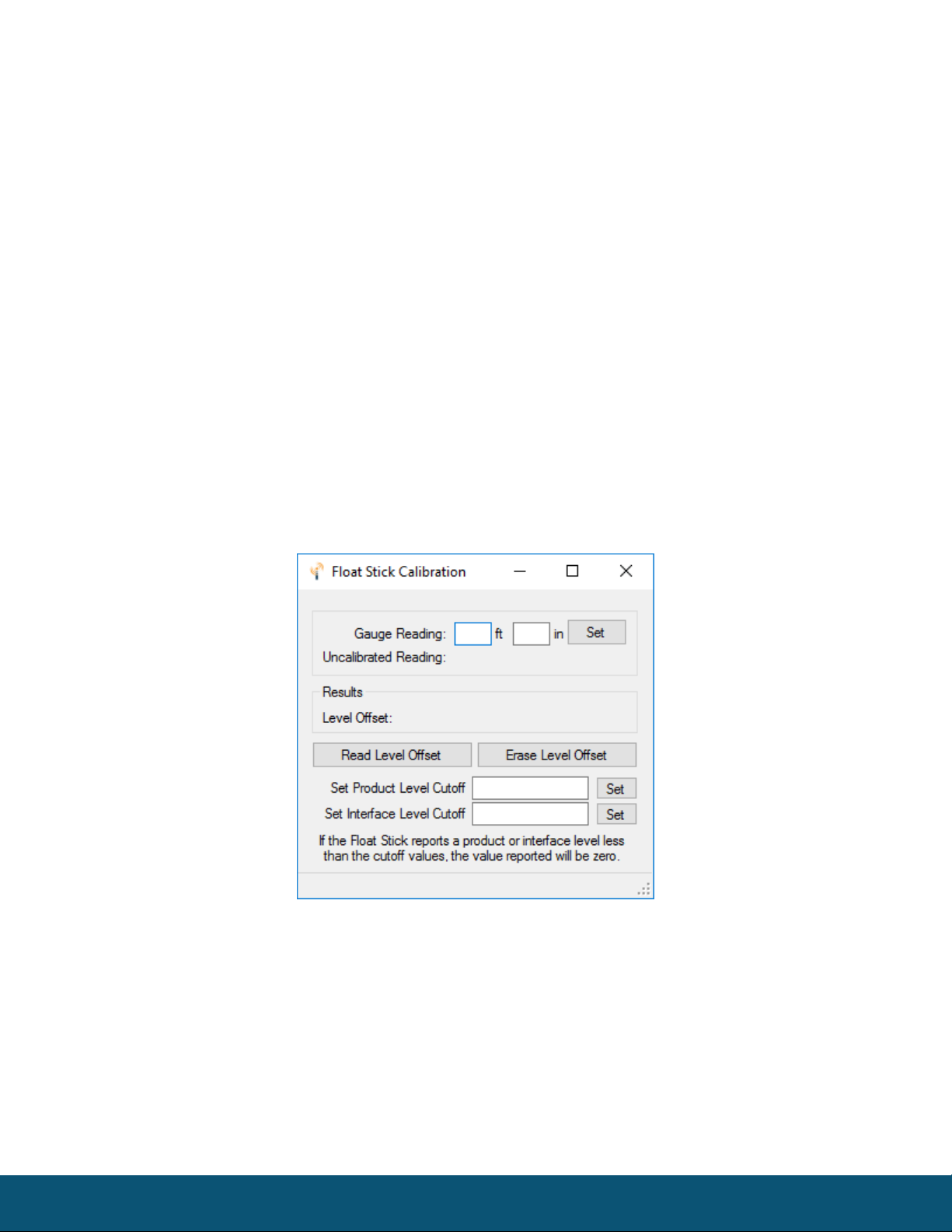

Float Stick Calibration Settings

After the Float Stick System is installed in a tank it will be necessary to calibrate the system to compensate for

the exact position of the device relative to the fluid level.

To calibrate the Float Stick System to match the level gauged in a tank, open the Float Stick Calibration

window from the Tools menu and enter the measured tank level in feet and inches and click Set. This will save

an offset value that will be applied to both the level and interface (for two float systems).

Optionally a “Level Cutoff” setting can be set for the product and/or level readings. Any reading at or below

the configured cutoff setting will be reported as zero. This is useful as the float cannot reach the actual bottom

of the tank due to the weight and required spacing.

9

SignalFire Telemetry

Rev 1.2

Remote Modbus Register Mapping

The Sentinel Node sends data to a SignalFire Telemetry Modbus Gateway. The data that is sent to

the gateway is available at the gateway in registers where it can then be read by a Modbus RTU.

The following data is sent to the Gateway:

Register Number

Register

Address

(offset)

Description

41001-41002

1000-1001

Float Stick Span (inches)

41003-41004

1002-1003

Product Level (inches)

41005-41006

1004-1005

Interface Level (inches

41007-41008

1006-1007

Temperature 1 (°C)

41009-41010

1008-1009

Temperature 2 (°C)

41011-41012

1010-1011

Temperature 3 (°C)

41013-41014

1012-1013

Temperature 4 (°C)

41015-41016

1014-1015

Temperature 5 (°C)

41017-41018

1016-1017

Communication Status (0=No errors; 1=No data received; 2=Only partial

data received; 3=Checksum error; 4=Float Stick internal error reported

49987

9986 or 65523

Low Battery Alarm (0 = battery above 3.0V, 1 = battery below 3.0V)

49988

9987 or 65524

Major revision number for the mainboard

49989

9988 or 65525

Minor revision number for the mainboard

49990

9989 or 65526

Major revision number for the radio

49991

9990 or 65527

Minor revision number for the radio

49992

9991 or 65528

High 16 bits of SFTS node address

49993

9992 or 65529

Low 16 bits of SFTS node address (the radio ID)

49994

9993 or 65530

Slave ID readback

49995

9994 or 65531

Received signal strength of last packet from the slave

49996

9995 or 65532

Battery voltage of the Sentinel-Float Stick, in millivolts

49997

9996 or 65533

Minutes until this slave will time out, unless new data is received

49998

9997 or 65534

Number of registers cached for this slave device

49999

9998 or 65535

Remote device type. 0x34 (52) for Sentinel Float Stick

Float Sticks configured for only one float will return 0 for the Interface Level. Float Sticks with only one

temperature sensor will return the same temperature reading for all five temperatures.

If there is any error communicating with the Float Stick all readings will return 999.9999.

Additionally, if there is an error the communication status register will contain additional information on the

cause of the error.

10

SignalFire Telemetry

Rev 1.2

Mounting and Care

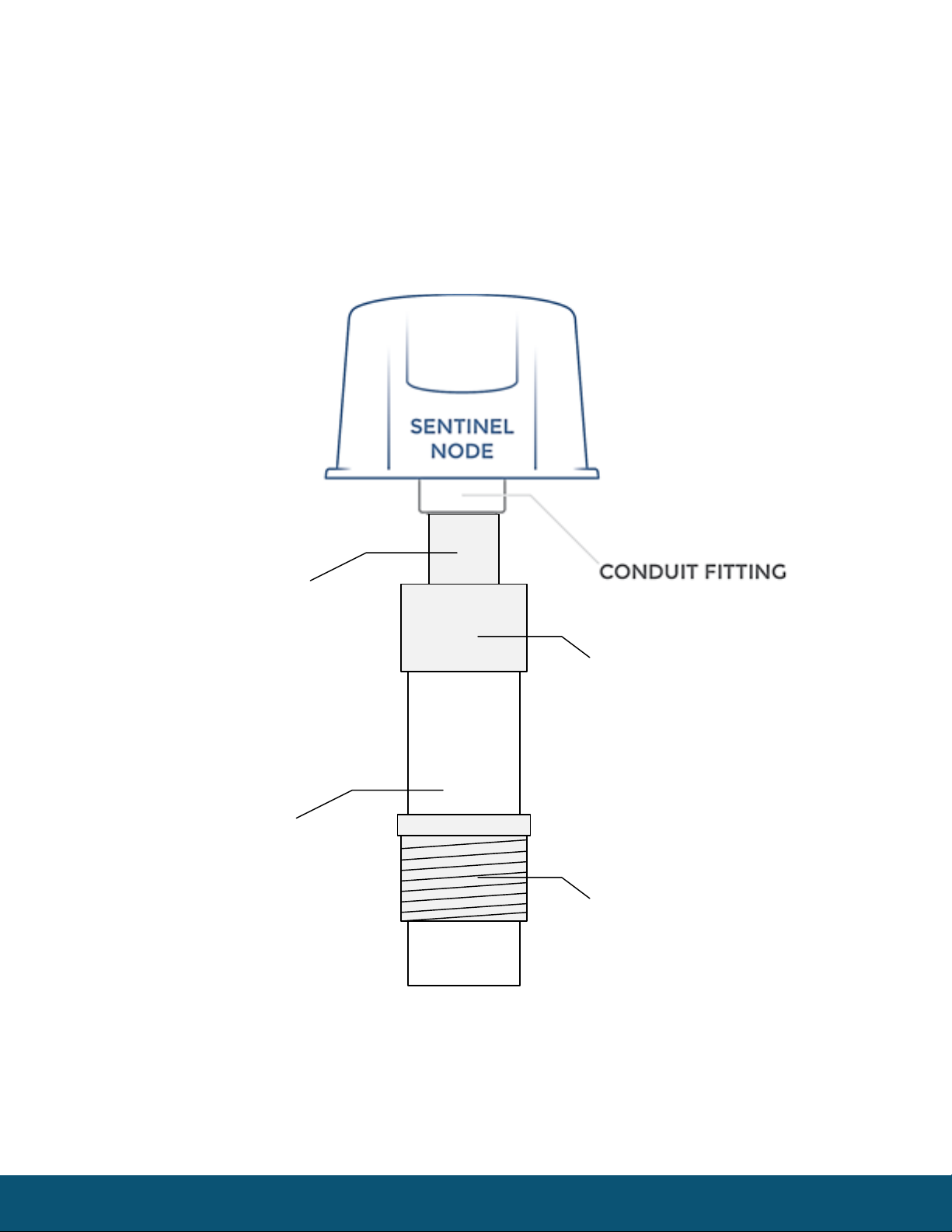

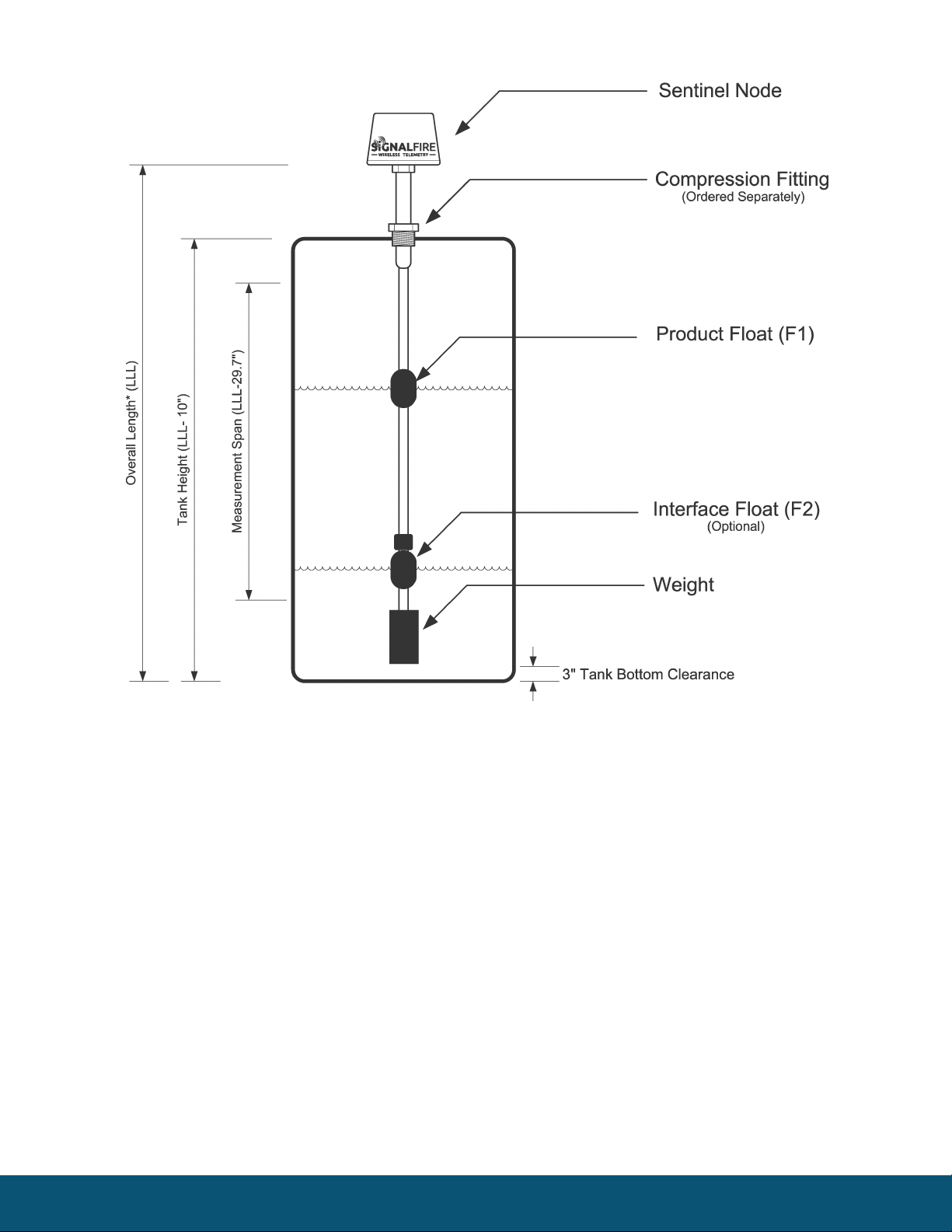

The unit comes with a watertight ½” NPT conduit fitting on the bottom mounting plate. The

Sentinel Float Stick also includes 2 NPT fittings for adapting the Sentinel to the Float Stick. Mounting is

pictured below.

In addition, a ¾” NPT compression fitting is supplied for mounting the assembly to a tank.

Sentinel Mounting to Float Stick

½” NPT Nipple

(supplied)

½” to ¾” NPT Adapter

(supplied)

FLOAT STICK

1" NPT Compression

Fitting

(ordered separately)

11

SignalFire Telemetry

Rev 1.2

Note: For dual float systems the lower float is marked with an “I” and the upper float is marked with a

“P”. For dual floats the foam float spacer is required between the floats.

12

SignalFire Telemetry

Rev 1.2

Internal Lithium Battery Replacement

Battery Packs can be changed with the node in place.

1Open the cover from the enclosure.

2Unplug the battery from the PCB, by depressing the locking clip on the connector.

3Loosen the screw holding the battery door and slide the old battery out.

4Slide in the new battery pack and tighten the battery door screw.

5Connect the battery to the main PCB battery connector.

6Install the enclosure cover.

WARNING: Use of any battery other than the SignalFire part number 810-0008-02 will

impair the protection provided by the equipment.

WARNING: If the internal battery is installed the external solar battery system or other

power source may not be connected!

Cleaning Instructions

The outside of the enclosure may be cleaned with water, mild soap, and a damp cloth as needed. High pressure

washing is not recommended.

WARNING: Electrostatic Discharge Hazard! Care must be taken to avoid the potential of

creating a change on the enclosure or antenna. Do not wipe with a dry cloth. Do not brush

against the enclosure with clothing or gloves.

13

SignalFire Telemetry

Rev 1.2

Configuration / Debug

WARNING: Only connect to the debug port in a safe area!

Debug and configuration information is available if a connection is made via the debug port on the main

board. A USB converter cable (available from SignalFire) must be used for this interface.

Debug and advanced configuration may be done using the SignalFire Toolkit PC application.

Technical Support and Contact Information

SignalFire Telemetry

140 Locke Dr, Suite B

Marlborough, MA 01752

(978) 212-2868

Revision

Date

Changes/Updates

1.0

12/15/15

Initial release

1.1

8/3/16

Updated diagrams, added section on encryption

1.2

2/8/19

Updated screenshots, descriptions

Minor format updates

14

SignalFire Telemetry

Rev 1.2

APPENDIX - FCC and IC Statements

Changes or modifications not expressly approved by SignalFire Telemetry, Inc could void the user’s authority to operate the equipment.

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions: (1) this device may not cause harmful

interference, and (2) this device must accept any interference received, including interference that may cause undesired operation.

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to Part 15 of the FCC Rules. These limits

are designed to provide reasonable protection against harmful interference in a residential installation. This equipment generates, uses and can radiate

radio frequency energy and, if not installed and used in accordance with the instructions, may cause harmful interference to radio communications.

However, there is no guarantee that interference will not occur in a particular installation. If this equipment does cause harmful interference to radio

or television reception, which can be determined by turning the equipment off and on, the user is encouraged to try to correct the interference by one

of the following measures:

-- Reorient or relocate the receiving antenna.

-- Increase the separation between the equipment and receiver.

-- Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

-- Consult the dealer or an experienced radio/TV technician for help.

Only the supplied coil antenna (Part number 810-0012-01) which is permanently soldered to the PCB may be used. This antenna has a maximum

gain of 3dB.

WARNING!

FCC and IC Radiation Exposure Statement:

This equipment complies with FCC’s and IC’s RF radiation exposure limits set forth for an uncontrolled environment under the following conditions:

1. This equipment should be installed and operated such that a minimum separation distance of 20cm is maintained between the radiator

(antenna) & user’s/nearby person’s body at all times.

2. This transmitter must not be co-located or operating in conjunction with any other antenna or transmitter.

Under Industry Canada regulations, this radio transmitter may only operate using an antenna of a maximum (or lesser) gain approved for this

transmitter by Industry Canada. To reduce potential radio interference to other users, the antenna type and its gain should be so chosen that the

equivalent isotropically radiated power (e.r.i.p.) is not more than that necessary for successful communication.

Table of contents

Other SignalFire Recording Equipment manuals

Popular Recording Equipment manuals by other brands

White Rodgers

White Rodgers 1F98EZ-1621 Homeowner user guide

Brotech Electronics

Brotech Electronics Mini Midi Sequencer+ user manual

Yamaha

Yamaha QX-3 owner's manual

Monitor Technologies

Monitor Technologies SiloPatrol Installation & operation

auray

auray RF-DT-10 owner's manual

Proximitar

Proximitar X27 user manual