SignalFire MIOM User manual

Rev 1.8 SignalFire Telemetry

1

Interface Manual

Modbus Multi I/O Module

SignalFire Number: MIOM

The SignalFire Modbus Multi I/O Module has the following features:

-Standard Modbus RTU server device

-Can be read with a SignalFire Modbus Stick or another Modbus client

-8 analog inputs (0-20mA or 0-5V)

-6 digital inputs (state, counter, and frequency up to 2kHz)

-4 relay outputs (2 DPDT, 2 SPST)

-Internal relay control logic for shutdown applications

-Wide range DC power input. 6 to 36VDC

-Very low power consumption

-DIN Rail mount with pluggable screw terminal blocks

-Status LEDs

-Analog scaling configuration

Rev 1.8 SignalFire Telemetry

2

Specifications

Power

6-36 VDC

5mA max @12V no relays energized, 40mA max @12V with all relays

energized. (excludes current for attached analog sensors)

Operating Temp

-40°C to +80°C

Analog Inputs

0-10V Max

Digital Inputs

Dry Contact or 30 Volts Max

Modbus Comm

Relay Rating

Modbus RTU Server

30 VDC @ 2 Amps

250 VAC @ 0.25 Amps

Rev 1.8 SignalFire Telemetry

3

Connections and Components

Modbus Multi I/O Module Connections

The Modbus Multi I/O module provides screw terminals for connection to a RS485

Modbus RTU Client’s A and B terminals. A second set of A/B RS485 terminals are available

for daisy chaining multiply modules or other Modbus devices.

Power must be provided by the Power Input screw terminals (10-30VDC). At 12VDC, the Module

requires only 2mA plus 7.5mA per energized relay channel.

Status LEDs

The Modbus Multi I/O has a green status LED which blinks indicating the module is running. In

addition there are TX/RX LEDs to indicate RS485 messages to/from the Modbus Client.

Each relay output also has a green LED which turns on while the relay is energized.

Rev 1.8 SignalFire Telemetry

4

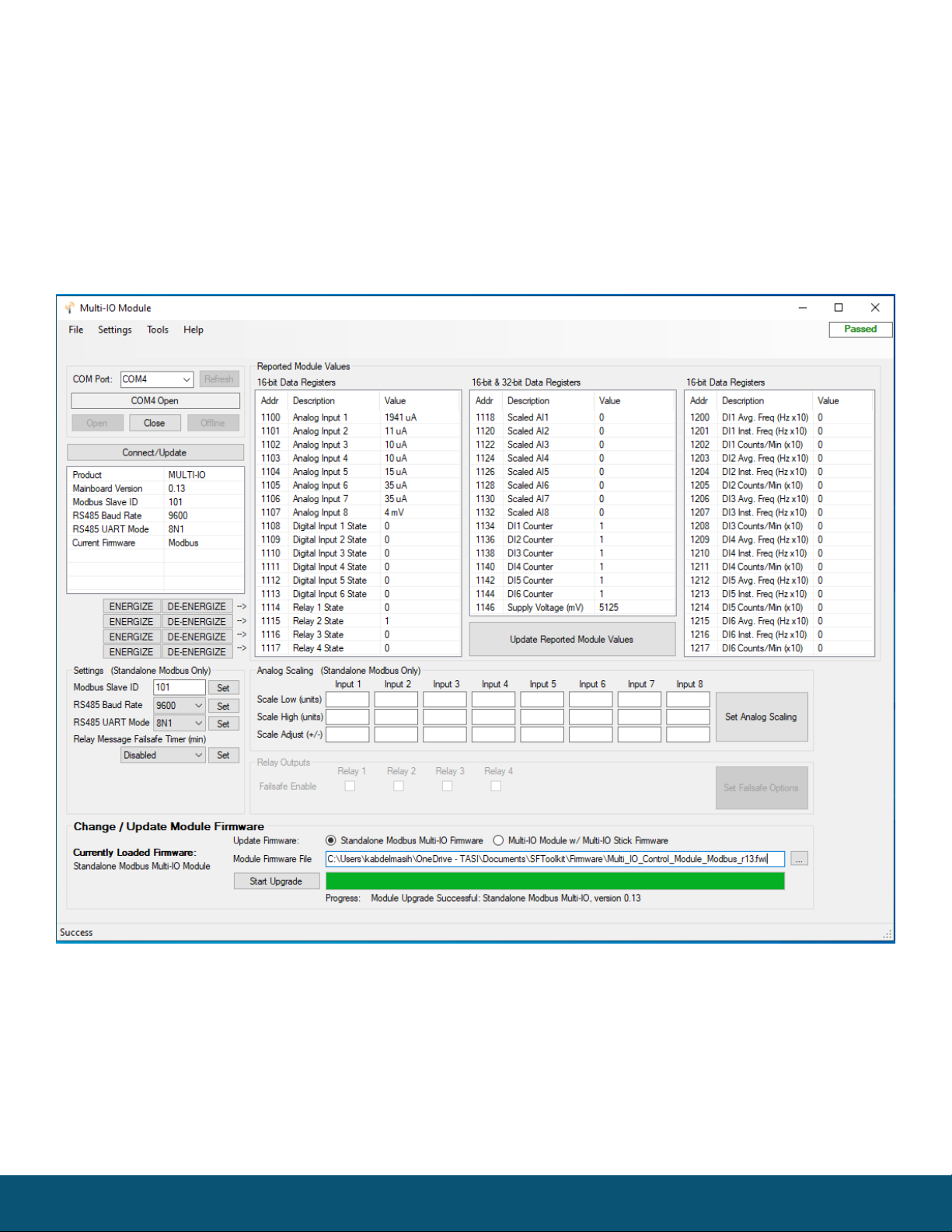

SignalFire Toolkit Configuration

Connect to the internal 4-pin connection using a SignalFire USB adapter cable. The

module will be auto-detected by the Toolkit. If the module is running “Multi IO System”

firmware it must be loaded with the “Modbus Multi IO Module” to support Modbus

functionality. Clicking on Update Reported Sensor Values will can the data to be refreshed and

displayed. Each relay channel has an Energize and De-Energize button which can be used to toggle

the relay state for testing. In addition, the counters may be zeroed using the tools menu.

Select Standalone Modbus Multi-I/O Firmware and click Start Upgrade to load the Modbus firmware

into the module.

Rev 1.8 SignalFire Telemetry

5

Operation

The SignalFire Modbus Multi I/O Module is intended to be used as a Modbus interfaced

analog and digital input/output (I/O) unit. It allows the user to interface to a variety of

sensor or control devices from a single Modbus port. It is DIN rail mounted and designed

to be easy to use.

Relay Outputs

The four digital outputs will be relays, with two of them being SPDT and two being DPDT.

There are two ways to control the relays:

-Direct control: The PLC writes to a coil register to energize or de-energize the relay.

-Pulse control: The PLC writes to a holding register with a number of seconds to energize the

relay. For example, if you write a 5 to this register, the relay will be energized for 5 seconds and

then automatically de-energized.

Analog Scaling

The Analog Inputs can be scaled so that they will report a 32 bit floating point number. For example, a

4-20mA analog input could be scaled from 0.0 to 5000.0 PSI. In addition each scaled value has an

option offset value (positive or negative) that can be entered and will be applied to the scaled value

result.

Rev 1.8 SignalFire Telemetry

6

Configuration

Modbus ID

The Modbus Multi I/O module requires that the Modbus Server ID be configured either

with the DIP switch or via software. If the DIP switch is set to zero then the Server ID must

be configured in software using either the SignalFire Toolkit or a Modbus write. The DIP switch must

be set to 0 to be configured with the SignalFire Toolkit.

Analog Inputs

The analog inputs may operate in either current (0-20mA/4-20mA) or voltage (0-5V/1-5V). The input

mode must be set by slide switches inside the module. Slide the switch corresponding to the input

channel up to Volts for a voltage input, or down to mA for a current input. To do this, first remove the

cover using a small flathead screwdriver. The cover is held on by clips.

Multi I/O Module with cover removed

Wire the analog voltage or current to the 8 individual sets of screw terminals.

The compliance voltage for a 4-20mA device must be provided externally. The analog current inputs

are passive.

Rev 1.8 SignalFire Telemetry

7

Digital Inputs

The digital inputs (6 total) can be dry contact or voltage (30 Volts max). Be sure to

connect the ground bus from the module to either the ground of the voltage device or

the dry contact.

The frequency of the digital inputs is calculated over a 2-second time period for the

Instantaneous Frequency and calculated over a 60-second window for the Average Frequency. For

example the Average Frequency register will be updated every 60-seconds and will contain the

average frequency of the previous 60-second period.

Digital Input Debounce

In cases where it is desired to accurately totalize digital input counts it may necessary to enable the

“digital input debounce” timer. The debounce timer is useful when dealing with dry contacts that may

otherwise produce extra counts when they close. To enable the digital debounce select “Digital Input

Debounce” from the settings pull-down menu. A typical value for a dry contact would be 100mS. Any

extra counts due to contact bounce within the debounce time setting will be ignored.

Digital (Relay) Outputs

There are four relay outputs. Two of the relays are SPDT and two are DPDT relays. The relays are rated

for the following:

30 VDC @ 2 Amps

250 VAC @ 0.25 Amps

Relay Failsafe Timers

The MIOM supports a configurable failsafe timer which is used to de-energize selected relays in event

of a communication failure.

Relay Message Failsafe Timer –This timer is reset anytime a coil write for any Modbus relay coil write

is received. Each relay can be individually enabled for failsafe operation.

If any timer expires all relays selected for “Failsafe Enable” will be de-energized.

When any relay is de-energized from a failsafe timer it will only be energized when a valid coil write is

received or the relay is commanded on from the Toolkit.

Rev 1.8 SignalFire Telemetry

8

Hazardous Location Certification

The MIOM Module is rated Class 1 Division 2 non-incendive.

Model: MIOM S/N: 00000001

Voltage: 6 –36 VDC

Current: 100 mA Max

Temperature: –40ºC to +85ºC

Class I, Division 2

Groups C, D T4

Hudson, MA

www.signal-fire.com

SignalFire Telemetry

Certified to CSA C22.2 No. 142 and CSA C22.2 No. 213

Conforms to ISA 12.12.01 and UL 916

WARNING –EXPLOSION HAZARD

Substitution of components may impair

suitability for Class I, Division 2

AVERTISSEMENT - RISQUE

D'EXPLOSION. La substitution de

composants peut rendre ce materiel

inacceptable pour les emplacements de classe I,

division 2

WARNING –EXPLOSION HAZARD

Do not connect while circuit is live unless area is

know to be nonhazardous

AVERTISSEMENT - RISQUE D'EXPLOSION.

Ne pas debrancher tant que le circuit est sous

tension, a moins qu’il ne s’agisse d’un emplacement

non dangereux.

Intertek

4003827

WARNING: Exposure to some chemicals may degrade the sealing properties of

materials used in the output relays.

ADVERTISSEMENT: L’exposition à certains produits chimiques peut degrader les

propriétés d’étanchéité de MATERIALS utilizes dans les dispositifs suivants:

-Relais de sortie

Rev 1.8 SignalFire Telemetry

9

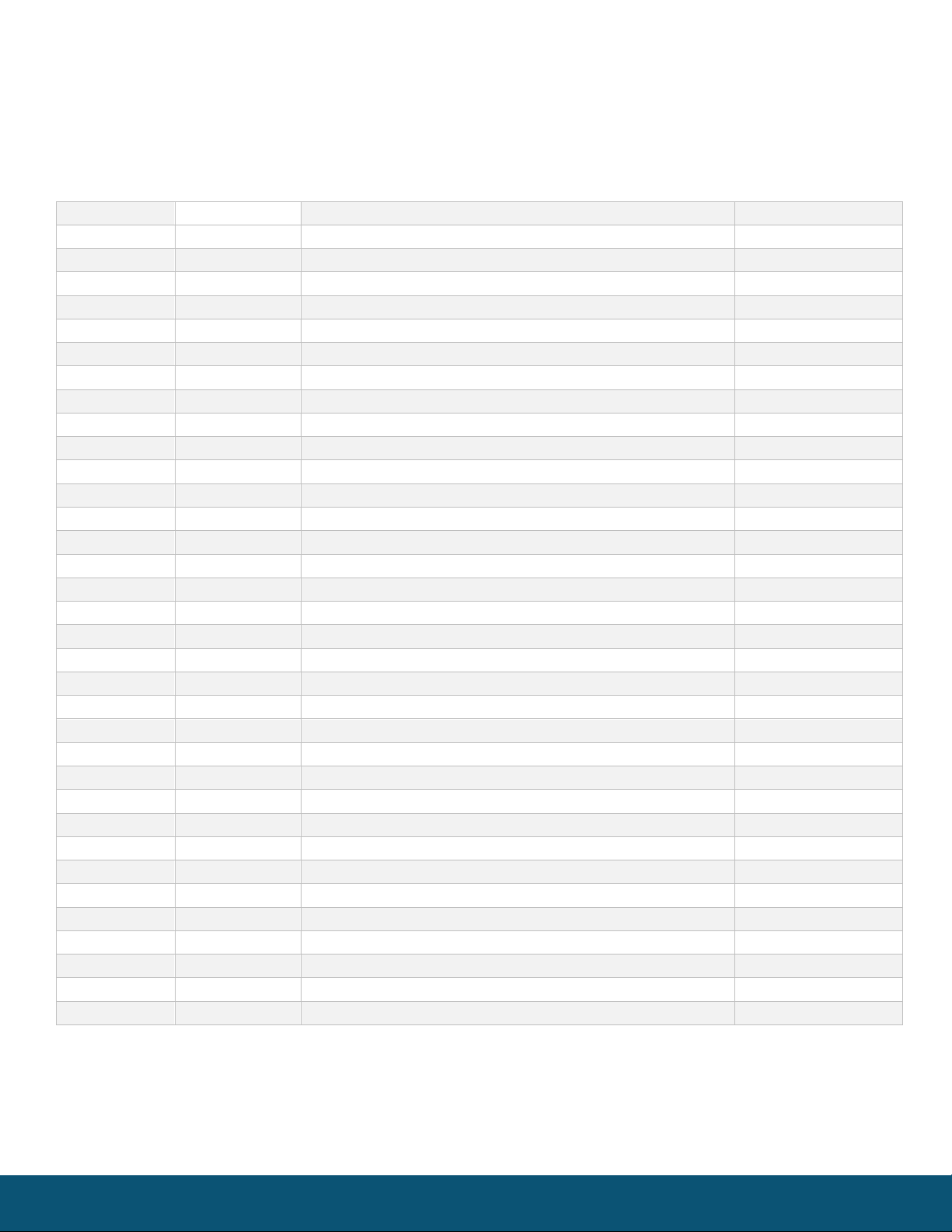

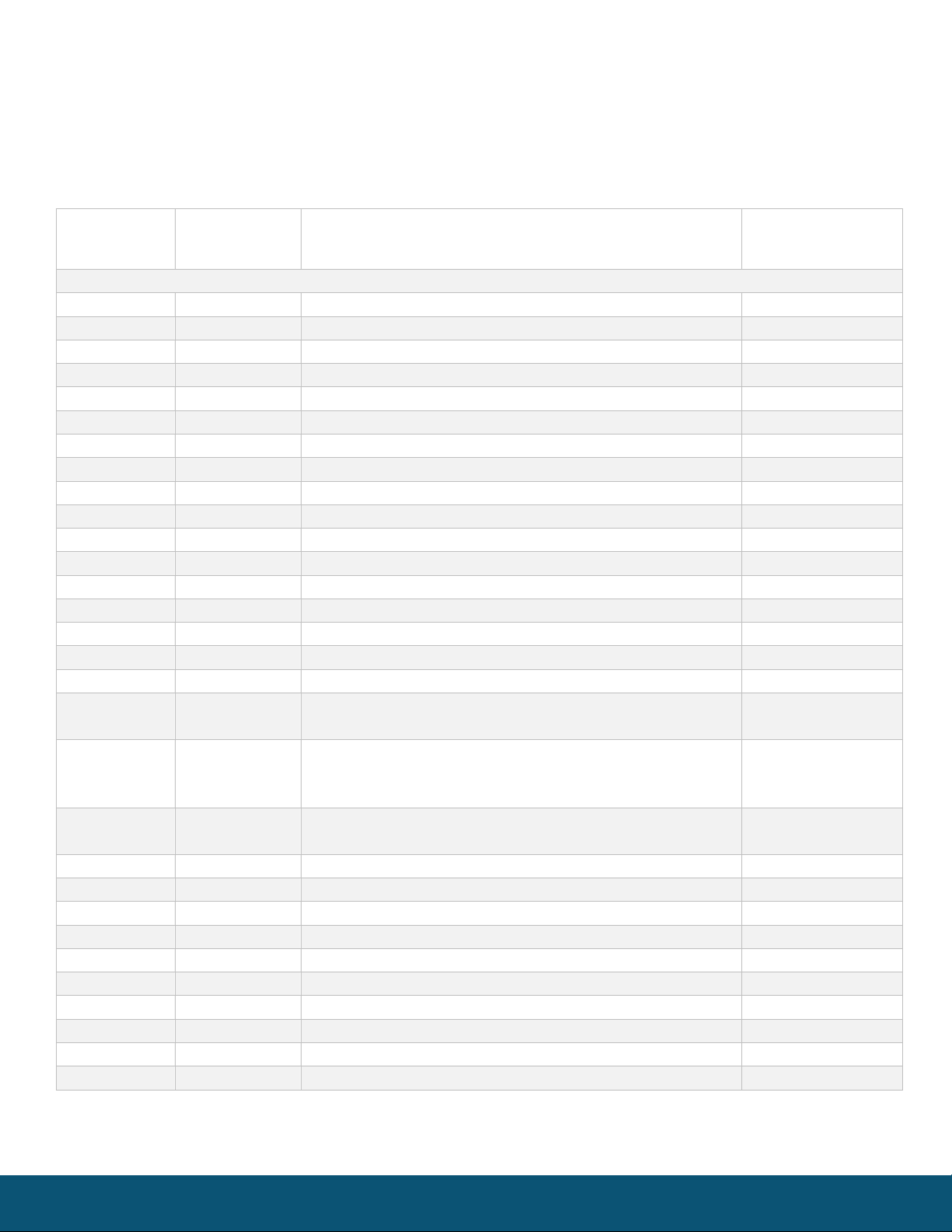

Modbus Register Map

Register

Number

Register

Address

Description

Function Codes

Coils (0xxxx)

Read/Write

00102

101

Relay1 Coil

01, 05, 15

00103

102

Relay2 Coil

01, 05, 15

00104

103

Relay3 Coil

01, 05, 15

00105

104

Relay4 Coil

01, 05, 15

Write-only

00112

111

Counter1 Reset Coil

05, 15

00113

112

Counter2 Reset Coil

05, 15

00114

113

Counter3 Reset Coil

05, 15

00115

114

Counter4 Reset Coil

05, 15

00116

115

Counter5 Reset Coil

05, 15

00117

116

Counter6 Reset Coil

05, 15

Discretes (1xxxx)

Read-only

11109

1108

DI1 State

02,

11110

1109

DI2 State

02,

11111

1110

DI3 State

02,

11112

1111

DI4 State

02,

11113

1112

DI5 State

02,

11114

1113

DI6 State

02,

Rev 1.8 SignalFire Telemetry

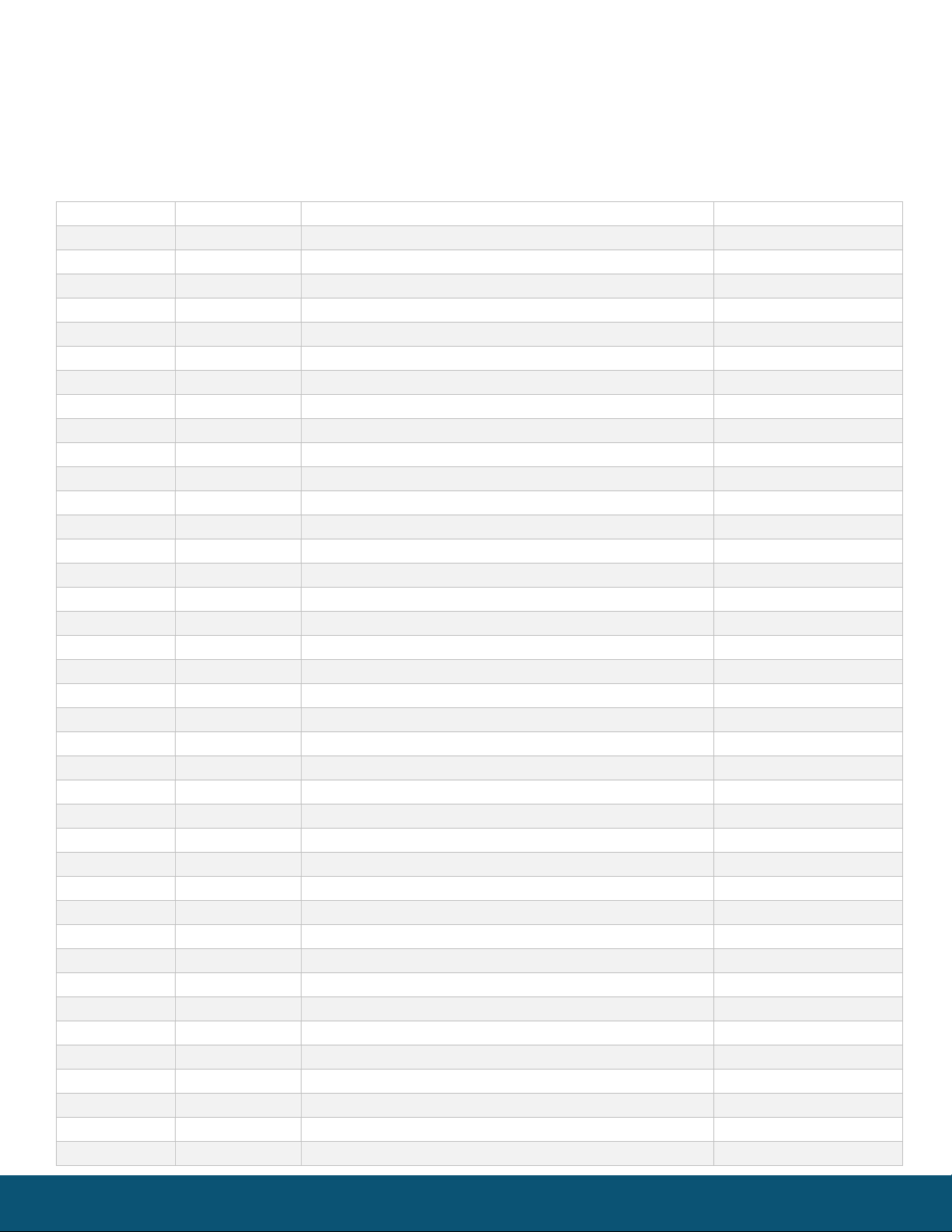

10

Register

Number

Register

Address

Description

Function Codes

Holding Registers (4xxxxx)

Write-only

40122

121

Relay1 Pulse (0 = Off, 1-255 = Pulse Time (sec))

06, 16

40123

122

Relay2 Pulse

06, 16

40124

123

Relay3 Pulse

06, 16

40125

124

Relay4 Pulse

06, 16

Read-only

41101

1100

AI1: Current or Voltage (Unsigned int, μA or mV)

03, 04

41102

1101

AI2: Current or Voltage Reading

03, 04

41103

1102

AI3: Current or Voltage Reading

03, 04

41104

1103

AI4: Current or Voltage Reading

03, 04

41105

1104

AI5: Current or Voltage Reading

03, 04

41106

1105

AI6: Current or Voltage Reading

03, 04

41107

1106

AI7: Current or Voltage Reading

03, 04

41108

1107

AI8: Current or Voltage Reading

03, 04

41109

1108

DI1: State (Unsigned int, 1 = Closed or 0 = Open)

03, 04

41110

1109

DI2: State

03, 04

41111

1110

DI3: State

03, 04

41112

1111

DI4: State

03, 04

41113

1112

DI5: State

03, 04

41114

1113

DI6: State

03, 04

41115

1114

Relay #1 State (Unsigned int, 1 = ON or 0 = OFF)

03, 04

41116

1115

Relay #2 State

03, 04

41117

1116

Relay #3 State

03, 04

41118

1117

Relay #4 State

03, 04

41119

1118

AI1: Scaled Reading (Float, High Word)

03, 04

41120

1119

AI1: Scaled Reading (Float, Low Word)

03, 04

41121

1120

AI2: Scaled Reading

03, 04

41122

1121

AI2: Scaled Reading

03, 04

41123

1122

AI3: Scaled Reading

03, 04

41124

1123

AI3: Scaled Reading

03, 04

41125

1124

AI4: Scaled Reading

03, 04

41126

1125

AI4: Scaled Reading

03, 04

41127

1126

AI5: Scaled Reading

03, 04

41128

1127

AI5: Scaled Reading

03, 04

41129

1128

AI6: Scaled Reading

03, 04

41130

1129

AI6: Scaled Reading

03, 04

41131

1130

AI7: Scale Reading

03, 04

Rev 1.8 SignalFire Telemetry

11

41132

1131

AI7: Scaled Reading

03, 04

41133

1132

AI8: Scaled Reading

03, 04

41134

1133

AI8: Scaled Reading

03, 04

41135

1134

DI1: Total Counts (Unsigned int, High Word)

03, 04

41136

1135

DI1: Total Counts (Unsigned int, Low Word)

03, 04

41137

1136

DI2: Total Counts

03, 04

41138

1137

DI2: Total Counts

03, 04

41139

1138

DI3: Total Counts

03, 04

41140

1139

DI3: Total Counts

03, 04

41141

1140

DI4: Total Counts

03, 04

41142

1141

DI4: Total Counts

03, 04

41143

1142

DI5: Total Counts

03, 04

41144

1143

DI5: Total Counts

03, 04

41145

1144

DI6: Total Counts

03, 04

41146

1145

DI6: Total Counts

03, 04

41147

1146

Supply Voltage (mV) 16-bit Max value of ~26000mV

03, 04

41201

1200

DI1: Average Frequency over 60 seconds (Hz x 10)

03, 04

41202

1201

DI1: Instantaneous Frequency over 2 seconds (Hz x 10)

03, 04

41203

1202

DI1: Counts per minute (x 10)

03, 04

41204

1203

DI2: Average Frequency (Hz x 10)

03, 04

41205

1204

DI2: Instantaneous Frequency (Hz x 10)

03, 04

41206

1205

DI2: Counts per minute (x 10)

03, 04

41207

1206

DI3: Average Frequency (Hz x 10)

03, 04

41208

1207

DI3: Instantaneous Frequency (Hz x 10)

03, 04

41209

1208

DI3: Counts per minute (x 10)

03, 04

41210

1209

DI4: Average Frequency (Hz x 10)

03, 04

41211

1210

DI4: Instantaneous Frequency (Hz x 10)

03, 04

41212

1211

DI4: Counts per minute (x 10)

03, 04

41213

1212

DI5: Average Frequency (Hz x 10)

03, 04

41214

1213

DI5: Instantaneous Frequency (Hz x 10)

03, 04

41215

1214

DI5: Counts per minute (x 10)

03, 04

41216

1215

DI6: Average Frequency (Hz x 10)

03, 04

41217

1216

DI6: Instantaneous Frequency (Hz x 10)

03, 04

41218

1217

DI6: Counts per minute (x 10)

03, 04

Rev 1.8 SignalFire Telemetry

12

Configuration via Modbus

In addition to configuring/reading the module settings using the Toolkit, the settings can

be viewed and changed via Modbus. See the register map below for details.

Register

Number

Register

Address

Description

Function Codes

Read/Write

41160

1159

AI1: Scale Low (signed int, Ex. 0 psi)

03, 04, 06, 16

41161

1160

AI1: Scale High (signed int, 3000 psi)

03, 04, 06, 16

41162

1161

AI2: Scale Low (Low = 0 and High = 0 disables scaling)

03, 04, 06, 16

41163

1162

AI2: Scale High

03, 04, 06, 16

41164

1163

AI3: Scale Low

03, 04, 06, 16

41165

1164

AI3: Scale High

03, 04, 06, 16

41166

1165

AI4: Scale Low

03, 04, 06, 16

41167

1166

AI4: Scale High

03, 04, 06, 16

41168

1167

AI5: Scale Low

03, 04, 06, 16

41169

1168

AI5: Scale High

03, 04, 06, 16

41170

1169

AI6: Scale Low

03, 04, 06, 16

41171

1170

AI6: Scale High

03, 04, 06, 16

41172

1171

AI7: Scale Low

03, 04, 06, 16

41173

1172

AI7: Scale High

03, 04, 06, 16

41174

1173

AI8: Scale Low

03, 04, 06, 16

41175

1174

AI8: Scale High

03, 04, 06, 16

41176

1175

Modbus Server ID (1-240) (Set DIP switch to 0 to use)

03, 04, 06

41177

1176

RS485 Baud Rate (1200, 2400, 4800, 9600, 19200, 38400,

57600)

03, 04, 06

41178

1177

RS485 UART Mode

8N1=0x00, 8E1=0xC0, 8O1=0x80, 8N2=0x08,

8E2=0xC8, 8O2=0x88

03, 04, 06

41179

1178

Mesg. Failsafe Timer (0 = disabled, 1-255 = duration

(minutes))

03, 04, 06, 16

41180

1179

Relay #1 Failsafe Enable (0 = disabled, 1 = enabled)

03, 04, 06, 16

41181

1180

Relay #2 Failsafe Enable

03, 04, 06, 16

41182

1181

Relay #3 Failsafe Enable

03, 04, 06, 16

41183

1182

Relay #4 Failsafe Enable

03, 04, 06, 16

41184

1183

DI1 Debounce Time in mS (0 = disabled)

03, 04, 06, 16

41185

1184

DI2 Debounce Time in mS

03, 04, 06, 16

41186

1185

DI3 Debounce Time in mS

03, 04, 06, 16

41187

1186

DI4 Debounce Time in mS

03, 04, 06, 16

41188

1187

DI5 Debounce Time in mS

03, 04, 06, 16

41189

1188

DI6 Debounce Time in mS

03, 04, 06, 16

Rev 1.8 SignalFire Telemetry

13

42019

1218

AI1:Scale Low (float, High Word)

03, 04, 06, 16

42020

1219

AI1:Scale Low (float, Low Word)

03, 04, 06, 16

42021

1220

AI1:Scale High (float, High Word)

03, 04, 06, 16

42022

1221

AI1:Scale High (float, Low Word)

03, 04, 06, 16

42023

1222

AI2:Scale Low

03, 04, 06, 16

42024

1223

AI2:Scale Low

03, 04, 06, 16

42025

1224

AI2:Scale High

03, 04, 06, 16

42026

1225

AI2:Scale High

03, 04, 06, 16

42027

1226

AI3:Scale Low

03, 04, 06, 16

42028

1227

AI3:Scale Low

03, 04, 06, 16

42029

1228

AI3:Scale High

03, 04, 06, 16

42030

1229

AI3:Scale High

03, 04, 06, 16

42031

1230

AI4:Scale Low

03, 04, 06, 16

42032

1231

AI4:Scale Low

03, 04, 06, 16

42033

1232

AI4:Scale High

03, 04, 06, 16

42034

1233

AI4:Scale High

03, 04, 06, 16

42035

1234

AI5:Scale Low

03, 04, 06, 16

42036

1235

AI5:Scale Low

03, 04, 06, 16

42037

1236

AI5:Scale High

03, 04, 06, 16

42038

1237

AI5:Scale High

03, 04, 06, 16

42039

1238

AI6:Scale Low

03, 04, 06, 16

42040

1239

AI6:Scale Low

03, 04, 06, 16

42041

1240

AI6:Scale High

03, 04, 06, 16

42042

1241

AI6:Scale High

03, 04, 06, 16

42043

1242

AI7:Scale Low

03, 04, 06, 16

42044

1243

AI7:Scale Low

03, 04, 06, 16

42045

1244

AI7:Scale High

03, 04, 06, 16

42046

1245

AI7:Scale High

03, 04, 06, 16

42047

1246

AI8:Scale Low

03, 04, 06, 16

42048

1247

AI8:Scale Low

03, 04, 06, 16

42049

1248

AI8:Scale High

03, 04, 06, 16

42050

1249

AI8:Scale High

03, 04, 06, 16

42051

1250

AI1:Scale Adjust (float, High Word)

03, 04, 06, 16

42052

1251

AI1:Scale Adjust (float, Low Word)

03, 04, 06, 16

42053

1252

AI2:Scale Adjust

03, 04, 06, 16

42054

1253

AI2:Scale Adjust

03, 04, 06, 16

42055

1254

AI3:Scale Adjust

03, 04, 06, 16

42056

1255

AI3:Scale Adjust

03, 04, 06, 16

42057

1256

AI4:Scale Adjust

03, 04, 06, 16

42058

1257

AI4:Scale Adjust

03, 04, 06, 16

Rev 1.8 SignalFire Telemetry

14

42059

1258

AI5:Scale Adjust

03, 04, 06, 16

42060

1259

AI5:Scale Adjust

03, 04, 06, 16

42061

1260

AI6:Scale Adjust

03, 04, 06, 16

42062

1261

AI6:Scale Adjust

03, 04, 06, 16

42063

1262

AI7:Scale Adjust

03, 04, 06, 16

42064

1263

AI7:Scale Adjust

03, 04, 06, 16

42065

1264

AI8:Scale Adjust

03, 04, 06, 16

42066

1265

AI8:Scale Adjust

03, 04, 06, 16

Relay Control Logic

The Modbus MIOM supports local relay control logic if it is running firmware version r7 or later. The

logic is similar to the RSD control logic in the SignalFire Gateway.

Note: If more than one rule is assigned to the same Output Relay, then all of the rules must meet

the energize condition for the relay to be energized.

Alternatively, this means that if any one of the input channels logic results in the “de-energize”

condition being true the relay will be de-energized.

Rev 1.8 SignalFire Telemetry

15

Input Channel Section

The input channel section is used to select the source register for the logic rule.

Input Channel –One of the Analog or Digital input channels on the MIOM module is

selected for each rule line.

Current Input Value –Once the rules are write to the MIOM this column shows the current value of

the input. Click the Update button to refresh.

Relay Control Logic Section

The relay control logic section is used to trigger thresholds for the selected source data.

Energize Relay When… –Select the logic operand to use for the energize logic evaluation.

Value –The value that the relay will be energized. Note that the energized state is the normal

“operating” state of the relay.

De-Energize Relay When… –The logic operand to use for the de-energize logic evaluation. This will

automatically be the opposite of the selection for the energize case. Note that the de-energized state

is the SAFE state of the relay.

Value –The value that the relay will be de-energized. Note the de-energized state is the “safe” state

of the relay.

Debounce (seconds) –This field contains the number of seconds that the source data must meet the

de-energize threshold before the relay is de-energized. This is useful so that a single (possibly a

glitch) reading does not cause the relay to de-energize. A single reading that meets the energize

criteria will result in the relay being energized. The default is 0 where each reading will cause the rule

to be evaluated with no delay.

Output Channel Section

Output Relay –Select the relay to control (1 through 4).

After filling out the table, click Write Remote Shutdown Settings to Gateway to store the settings in

the Gateway Stick.

Table of contents

Other SignalFire Recording Equipment manuals