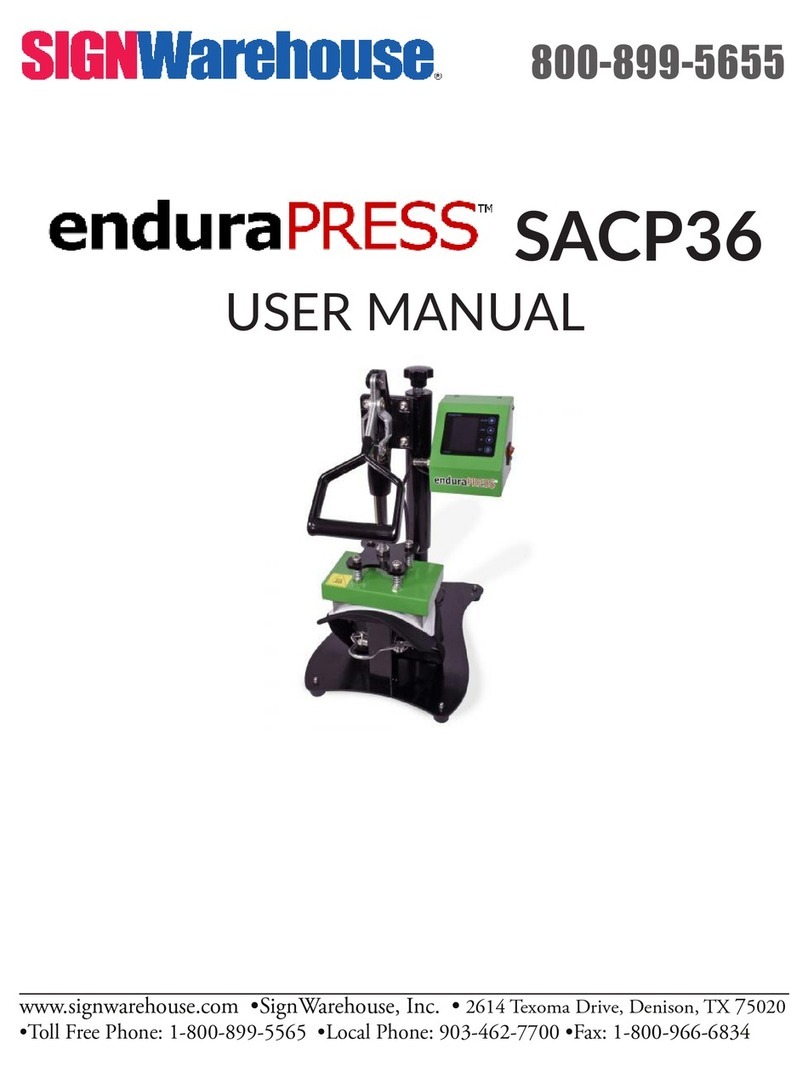

SignWarehouse enduraPRESS SD20 User manual

800-899-5655

www.signwarehouse.com •SignWarehouse, Inc. • 2614 Texoma Drive, Denison, TX 75020

•Toll Free Phone: 1-800-899-5565 •Local Phone: 903-462-7700 •Fax: 1-800-966-6834

USER MANUAL

enduraPRESS SD20

Rev 2/10/2020

800-899-5655

www.signwarehouse.com •SignWarehouse, Inc. • 2614 Texoma Drive, Denison, TX 75020

•Toll Free Phone: 1-800-899-5565 •Local Phone: 903-462-7700 •Fax: 1-800-966-6834

Table of Contents

Page

1

2

3

4

5

6

7

8

9

Specicaons

Operaon Instrucons Read Before Use

Control Panel Operaons

Leveling the Bed

SD20 Support Bracket and Regular Maintenance

SD20 Oponal Lower Platens

Heat Transfer Applicaon Guidelines

Troubleshoong Tips

Wiring Schemac

800-899-5655

www.signwarehouse.com •SignWarehouse, Inc. • 2614 Texoma Drive, Denison, TX 75020

•Toll Free Phone: 1-800-899-5565 •Local Phone: 903-462-7700 •Fax: 1-800-966-6834

Operaon Handle

Control Panel Pressure Knob

Silicone Pad

Lower Aluminum Plate

Power Switch Breaker

Heang Element

Specicaons:

Model NO: ENDURAPRESS SD20

Voltage: 120V/60Hz

Power: 15.5A, 1700W,

Control Panel: LCD Control Panel

Time Range: 0~999sec.

Temp. Range: 0~480°F

Max Open Height: 0.5”

Packaging: Double-walled Corrugated Paper Carton

Gross Weight: 126lbs (57kg)

1

800-899-5655

www.signwarehouse.com •SignWarehouse, Inc. • 2614 Texoma Drive, Denison, TX 75020

•Toll Free Phone: 1-800-899-5565 •Local Phone: 903-462-7700 •Fax: 1-800-966-6834

Operaon Instrucons

Read Before Use

1. Check the voltage before using it. The correct voltage is 110-120V/60Hz

2. Turn o the machine when not in use, and remove the power plug from socket.

3. Grasp the handle rmly when opening.

4. Keep children away from the machine.

5. Do not touch the heang platen and platen cover aer pressing whilst in operaon

6. Do not aempt to press products that are not intended for normal heat transfer

7. Do not set the temperature any higher than 480F as it may cause over heat and stop

working.

8. The heat press carries a ground line by default, please make sure the socket gets a

ground line protector.

2

800-899-5655

www.signwarehouse.com •SignWarehouse, Inc. • 2614 Texoma Drive, Denison, TX 75020

•Toll Free Phone: 1-800-899-5565 •Local Phone: 903-462-7700 •Fax: 1-800-966-6834

3

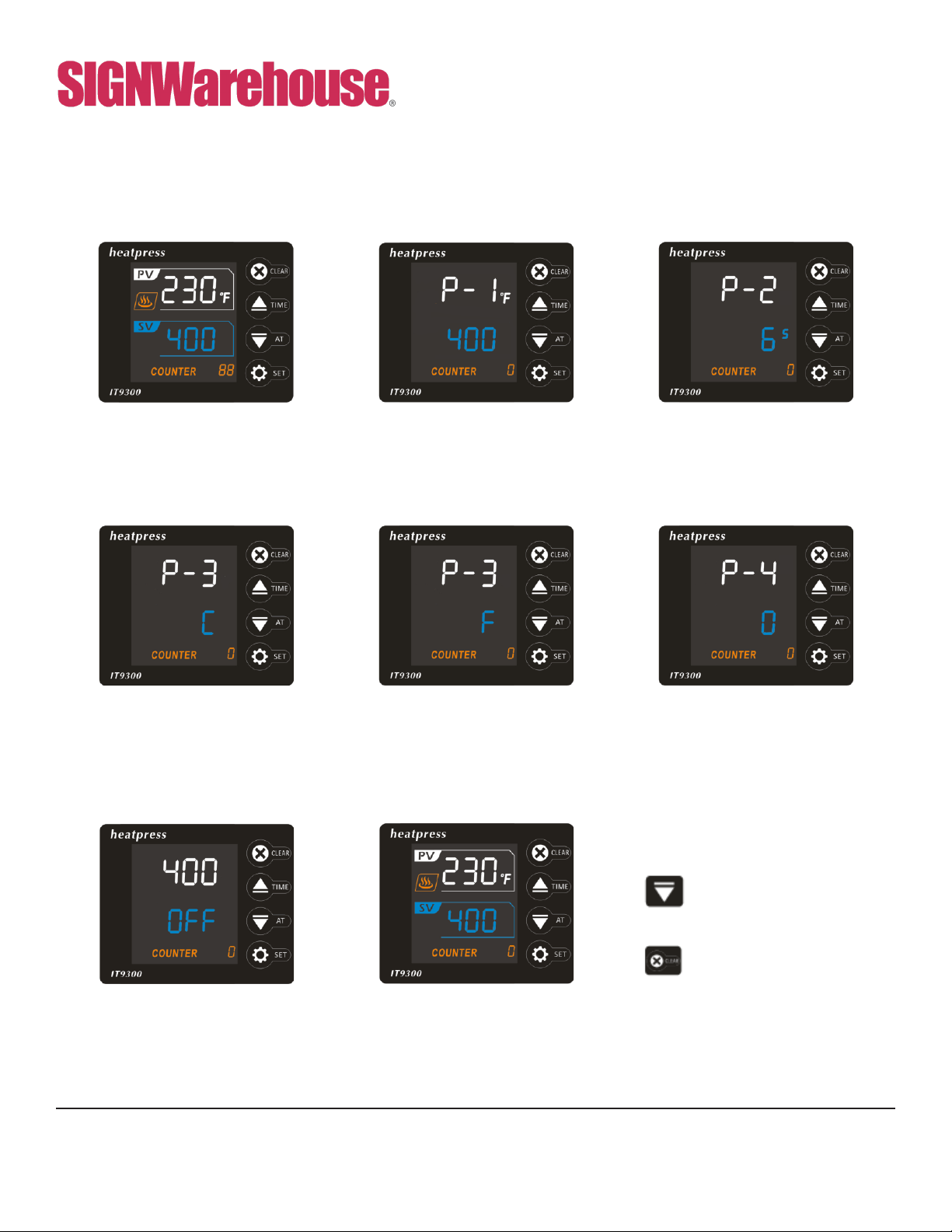

Control Panel Operaons

Control Panel Display P-1: Temperature Seng Mode

Hit SET & use the up and down arrows

to set temperature

P-3: ºC or ºF Read Out

Hit SET threee mes & use the up

and down arrows to select Celsius or

Fahrenheit

Auto Shut O Mode

The screen will read OFF and start to

cool down if heat press is inacved

To reheat the press, hit any buon

P-3: ºC or ºF Read Out

Hit SET threee mes & use the up

and down arrows to select Celsius or

Fahrenheit

P-2: Time Seng Mode

Hit SET twice & use the up and down

arrows to set amount of me for

pressing

P-4: Auto Shut O Mode

Hit SET four mes & use the up and

down arrows to set auto shut o when

inacved, 0-120 minutes range

Clear Counter Number

Long hold the CLEAR buon to clear

your counter on the panel.

Other Funcons

If you need to calibrate your press, hold

the down arrow for a few seconds.

If you need to clear your counter, hold

your clear buon for a few seconds.

800-899-5655

www.signwarehouse.com •SignWarehouse, Inc. • 2614 Texoma Drive, Denison, TX 75020

•Toll Free Phone: 1-800-899-5565 •Local Phone: 903-462-7700 •Fax: 1-800-966-6834

Leveling the Bed

The SD20 comes with a mechanism designed to help you ensure that the bed is

perfectly level front-to-back and side-to-side. There are adjustable bolts under each

corner that can be adjusted with an allen wrench to raise or lower the lower platen. In

order to make the adjustment, you will need an 8mm allen wrench. Here are the steps.

1) Set the pressure in the medium range

2) Place four sheets of paper on the bed, one on each corner

3) Close the press and try to pull the sheets free, one at a me.

4) If one or more of the sheets can be removed, or if there are varying levels of resis-

tance, the bed is not perfectly level.

5) Use pliers to loosen the locking nuts. Then use the allen wrench to raise or lower

the four corner bolts. Test again with the press closed on the four sheets of paper unl

resistance is even at all four corners. Re-ghten the locking nuts to secure the bolts in

their new posion.

7) Turn the large central knob clockwise to lock in the new bed height.

4

800-899-5655

www.signwarehouse.com •SignWarehouse, Inc. • 2614 Texoma Drive, Denison, TX 75020

•Toll Free Phone: 1-800-899-5565 •Local Phone: 903-462-7700 •Fax: 1-800-966-6834

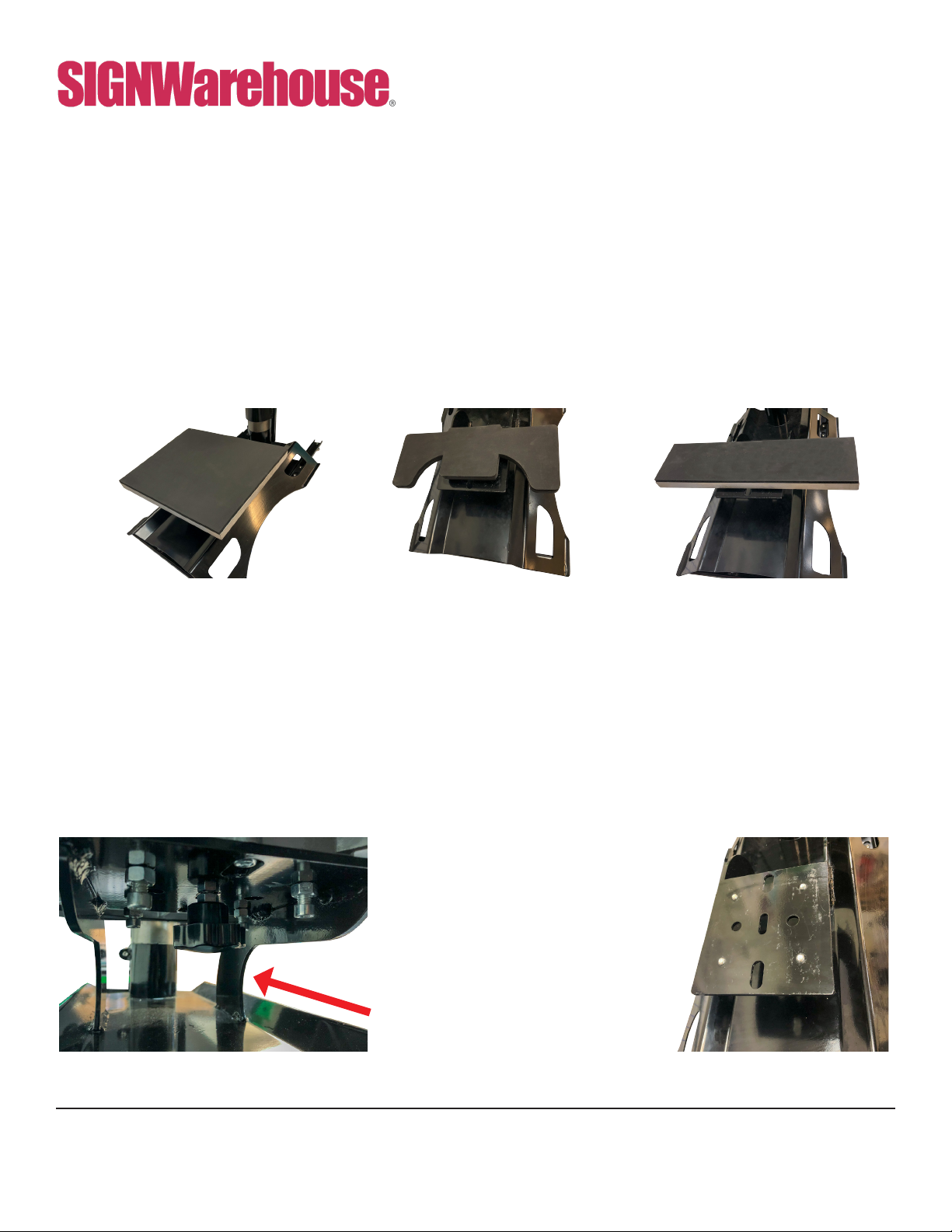

SD20 Support Brackets

Regular Maintenance

There are two sets of brackets added to provide more support for the base. This is intended to re-

duce the risk that the press may become top-heavy and unstable. If you experience any incidence of

instability when the press is rotated at 180° away from the closed posion, aach the bracket exten-

sions to extend and secure the base of the heat press.

To extend brackets, rst loosen the nuts indicated at le. Then

slide the brackets out from the frame to the desired extent.

When you have extended the brackets, re-ghten the nuts to

secure them.

The brackets are height-adjustable. Simply turn the feet clock-

wise or counter-clockwise to extend or retract the feet and

raise or lower the brackets. Adjust these to set the bracket

height parallel to the table so that the enre base of the heat

press is level and parallel with the work table.

Cauon! Only use the heat press on a secure, stable work

surface! Placing it on an unstable surface such as a folding or

temporary table may degrade performance and cause risk of

injury.

There are two points on

the SD20 that should be

lubricated regularly to

maintain good perfor-

mance. Use a standard

lubricant such as WD40 or

3-in-1 oil. Use lubricang

oil for regular maintenance

for these 4 columns above

the heang cover.

Use lubricang

oil for regular

maintenance for

the swing-arm

column.

5

800-899-5655

www.signwarehouse.com •SignWarehouse, Inc. • 2614 Texoma Drive, Denison, TX 75020

•Toll Free Phone: 1-800-899-5565 •Local Phone: 903-462-7700 •Fax: 1-800-966-6834

SD20 Oponal Lower Platens

How to Change Lower Platens

There are three oponal lower platens compable with the SD20. The normal platen that comes with the SD20

is a standard 16 inch by 20 inch platen. The oponal lower platens provide smaller tables suitable for decorang

small or oddly shaped objects. The oponal platens are for shoes, sleeves and youth sized shirts.

•The Youth platen measures 12 by 14 inches. This smaller platen helps you thread small shirts without over-

stretching the fabric.

•The sleeve platen measures 5 by 18 inches. This platen can also be used for decorang sleeves and pant legs.

This is a great opon for those customizinglike athleisure wear such as yoga pants.

• The shoe platen measres 5 by 14 inches and is shaped to support the side of most shoes. Make sure you

choose a heat transfer lm compable with the material from which the shoe surface is made.

CAUTION: Before aempng to change the platen, make sure the heat press is turned o and cooled

to room temperature.

Changing the platen is easy. Under the standard platen, there are four bolts and a large central knob

(See page 4). Loosen the bed-leveling bolts, but do not remove them. The large central knob is what

fastens the platen to the press. Loosen the knob and remove the standard 16 x 20 base platen.

Youth Platen

SE-XH-EP-OP-1214

Sleeve/Leg Platen

SE-XH-EP-OP-518

Shoe Platen

SE-XH-EP-OP-514

6

Once the platen is free, set it

to the side. Place the oponal

platen on the bed. Align the new

platen with the central hole and

the adjacent holes and use these

to fasten the large central knob

from the boom.

When the platen is in posion,

ghten the large central knob to

secure it to the bed.

800-899-5655

www.signwarehouse.com •SignWarehouse, Inc. • 2614 Texoma Drive, Denison, TX 75020

•Toll Free Phone: 1-800-899-5565 •Local Phone: 903-462-7700 •Fax: 1-800-966-6834

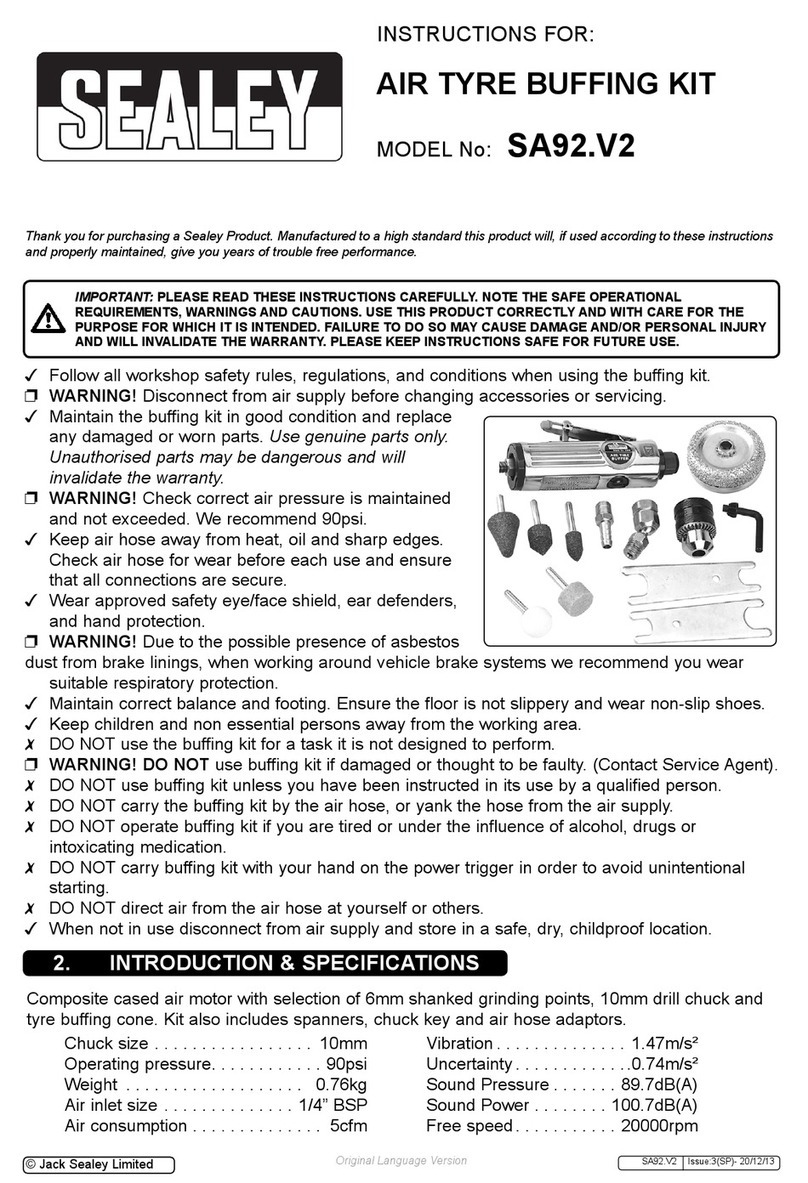

Heat Transfer Applicaon Guidelines

These are general guidelines. For specic me and temperature sengs for specic lms and/or

transfer papers, please refer to the instrucons for that parcular product.

** The EnduraPRESS CS15, CS15-AR, CS16, and CS16-AR are not recommended for use with two-

step laser transfer papers. For these demanding applicaons, we recommend the EnduraPRESS SA12

or SD20.

TRANSFERS Device Fabric TEMP. TIME PRESSURE

Sublimaon Paper Ricoh, Epson Polyester 400°F 25~30sec. 30Psi

Ink Tran. Paper Inkjet Printer Light Color 365°F 15sec. 30Psi

Dark Color 330°F 25sec. 30Psi

Laser Transfer Paper** Laser Printer Light Color 345°F 30sec. 30Psi

Laser Printer Dark Color 260 - 320°F 35 - 120 sec. 25Psi

Transfer Vinyls Cung Ploer / 300~320°F 8~10sec. 30Psi

Plassol Transfer / / 335°F 12sec. 50Psi

7

800-899-5655

www.signwarehouse.com •SignWarehouse, Inc. • 2614 Texoma Drive, Denison, TX 75020

•Toll Free Phone: 1-800-899-5565 •Local Phone: 903-462-7700 •Fax: 1-800-966-6834

Troubleshoong Tips

Q. Why isn’t my heat transfer vinyl scking to the fabric?

A. This can be caused by three things. Insucient pressure, or temperature, or me.

Time: Some heat transfer lms need a few seconds to cool before you remove the liner. Try a warm or

cold peel rst.

Temperature: If that doesn’t work, check to make sure you are using the recommended me and tem-

perature sengs. If you are, your press may not be pung out the correct amount of heat. Use a Geo

Knight IR thermometer to check the actual temperature of the platen. If it is more than 5° dierent

from the LCD display (PV), adjust it using step four in the control panel (see page 4).

Pressure: If the temperature is correct, adjust the pressure. Some lms require more pressure to bond

the adhesive to the fabric. There should be some resistance when you close the press. If you have

veried all of these and the lm doesn’t sck, contact SIGNWarehouse customer service or Technical

Support for further assistance.

Q. Why does my sublimated transfer look washed out?

A. This is usually caused by insucient temperature. Sublimaon works best at or near 400°F. If your

transfer is faded, check the output of the heat platen with a contact thermometer and make sure the

output matches the displayed temperature. If not, adjust as directed above. Then repress at 390 -

400°F.

Q. Why are my transfers are scking to the heang element of the upper platen?

A. If T-shirt vinyl is scking to the heang element, you have it upside down. Remove any adhesive

residue, ip it over and try again. If an inkjet or laser transfer is scking to the heang element, it’s

because the heat is aecng the ink. Cover it with a Teon sheet or sheet of silicone Kra paper to

prevent this. Using a Teon sheet or Kra paper is recommended for almost all heat transfer applica-

ons.

Q. Why is it so hard to peel the liner when I’m done pressing the paper?

A. A hot or warm peel lm may become hard to peel if allowed to cool. Always peel the lm or transfer

paper in accordance with the product’s recommendaons.

8

800-899-5655

www.signwarehouse.com •SignWarehouse, Inc. • 2614 Texoma Drive, Denison, TX 75020

•Toll Free Phone: 1-800-899-5565 •Local Phone: 903-462-7700 •Fax: 1-800-966-6834

Wiring Schemac

WARRANTY

Thank you for choosing our products, you are entled to one year free warranty service for our

products. All exceeds warranty period we will sll provide technical supports and maintenance

guidance.

9

This manual suits for next models

1

Table of contents

Other SignWarehouse Power Tools manuals

Popular Power Tools manuals by other brands

Phoenix Contact

Phoenix Contact CF 500-230V user manual

Max

Max RB655 Operating and maintenance manual

Black & Decker

Black & Decker KX2000 Original instructions

Hercules

Hercules HD83B Owner's manual & safety instructions

Pentair

Pentair Caddy MAC2 Series instruction sheet

Cleco

Cleco W-2120-12 Service and parts manual