SignWarehouse enduraPRESS MF15 User manual

www.signwarehouse.com • SignWarehouse, Inc. • 2614 Texoma Drive, Denison, TX 75020

Table of Contents

Page

1

2

3

4

5

6

7

8

9

10

11

Specications

Operation Instructions Read Before Use

Control Panel Operations

The Shirt Press

Plate Attachments

Mug Attachment

Using the Mug Fittings

Cap Press Attachment

Heat Transfer Application Guidelines

Troubleshooting Tips

Wiring Schematic & Warranty

www.signwarehouse.com • SignWarehouse, Inc. • 2614 Texoma Drive, Denison, TX 75020

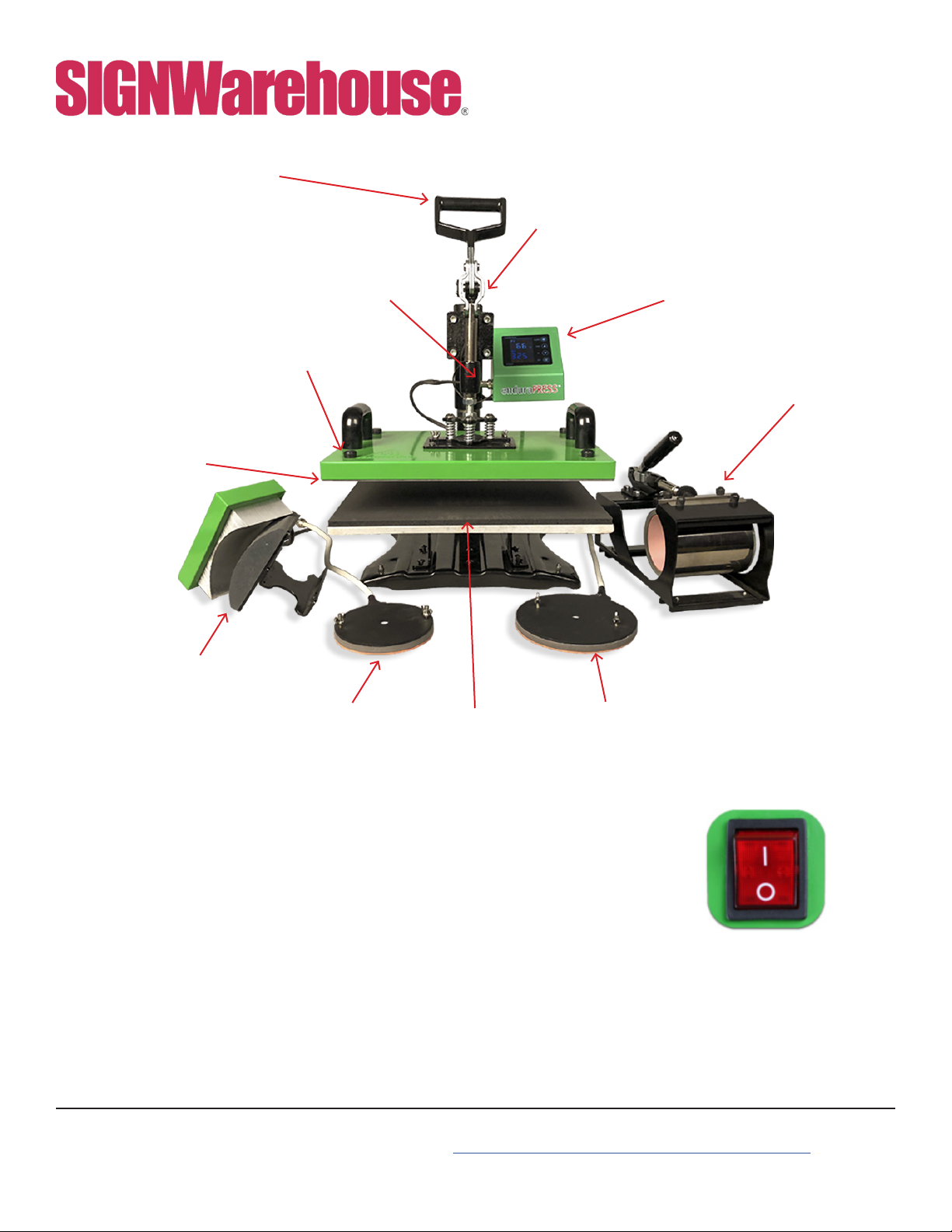

Operation Handle

Control Panel

Mug Attachment

Pressure Knob

Silicone Pad

4” Circle Press

Cap Attachment

and Lower Platen

6” Circle Press

Lower Aluminum Plate

Power Switch

Heating Element

Specications:

Model NO: ENDURAPRESS MF15

Multi-function combination heat press

Voltage: 120V/60Hz

Power: 10.5A, 1140W,

Control Panel: LCD Control Panel

Time Range: 0~999sec.

Temp. Range: 0~480°F

Max Open Height: 0.5”

Packaging: Double-walled Corrugated Paper Carton

Gross Weight: 77lbs (35kg)

Heating

Element

Plug

1

www.signwarehouse.com • SignWarehouse, Inc. • 2614 Texoma Drive, Denison, TX 75020

2

Operation Instructions

Read Before Use

1. Check the voltage before using it. The correct voltage is 110-120V/60Hz

2. Turn o the machine when not in use, and remove the power plug from

socket.

3. Grasp the handle rmly when opening.

4. Keep children away from the machine.

5. Do not touch the heating platen and platen cover after pressing whilst in

operation

6. Do not attempt to press products that are not intended for normal heat

transfer

7. Do not set the temperature any higher than 480F as it may cause over heat

and stop working.

8. The heat press carries a ground line by default, please make sure the

socket gets a ground line protector.

www.signwarehouse.com • SignWarehouse, Inc. • 2614 Texoma Drive, Denison, TX 75020

3

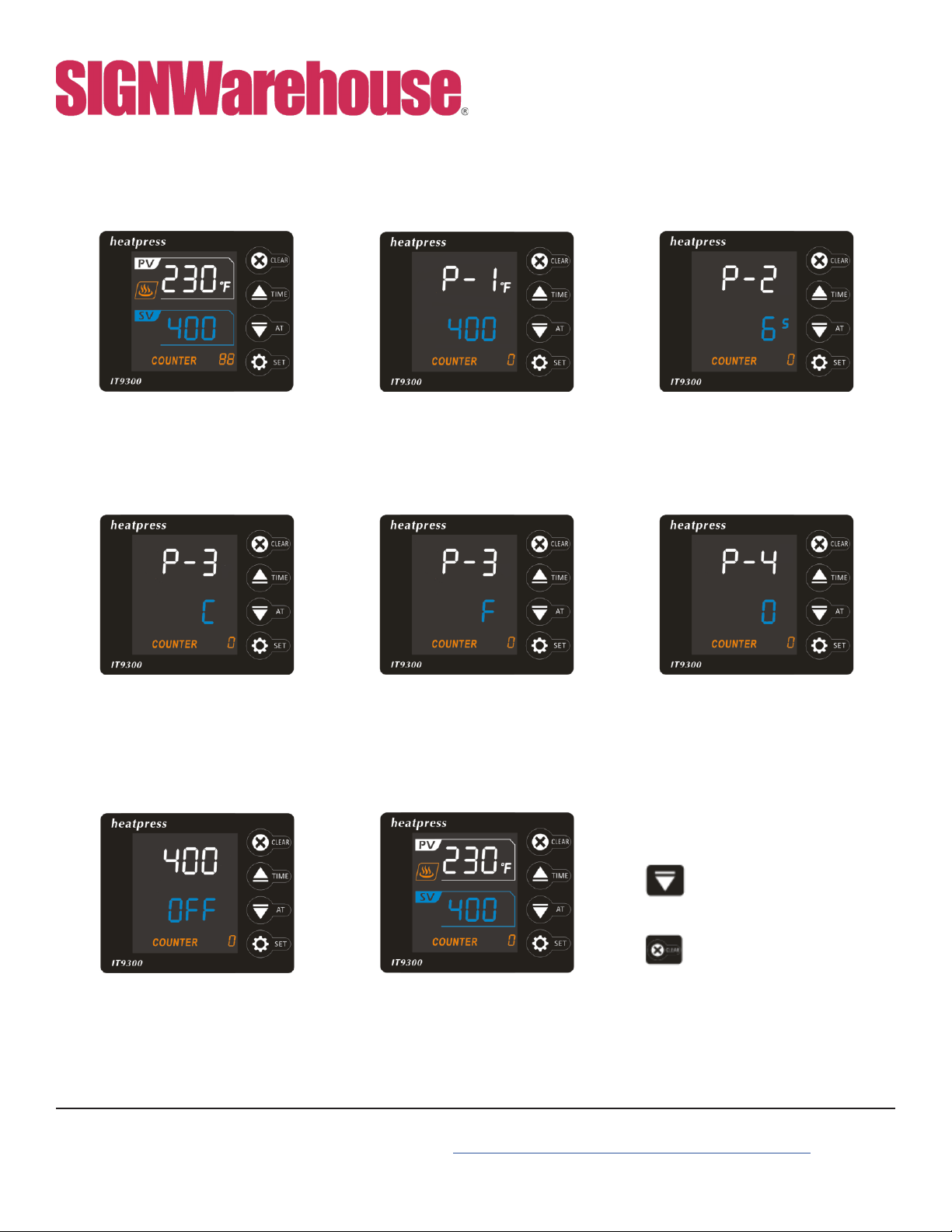

Control Panel Operations

Control Panel Display P-1: Temperature Setting

Mode

Hit SET & use the up and down

arrows to set temperature

P-3: ºC or ºF Read Out

Hit SET three times & use the up

and down arrows to select Celsius

or Fahrenheit

Auto Shut O Mode

The screen will read OFF and

start to cool down if heat press is

inactive

To reheat the press, hit any button

P-3: ºC or ºF Read Out

Hit SET three times & use the up

and down arrows to select Celsius

or Fahrenheit

P-2: Time Setting Mode

Hit SET twice & use the up and

down arrows to set amount of time

for pressing

P-4: Auto Shut O Mode

Hit SET four times & use the up and

down arrows to set auto shut o

when inactive 0-120 minutes range

Clear Counter Number

Long hold the CLEAR button to clear

your counter on the panel.

Other Functions

If you need to calibrate your press,

hold the down arrow for a few

seconds.

If you need to clear your counter,

hold your clear button for a few

seconds.

www.signwarehouse.com • SignWarehouse, Inc. • 2614 Texoma Drive, Denison, TX 75020

The Shirt Press

The basic setup out of the box is a 12″ x 15″ shirt press. This press is a swing away,

which makes placing and removing garments safe and easy. Unlike some presses that

can only swing open to the right, the MF15 can swing to the right or left.

Caution: to reduce risk of burns, use the black handles to swing the heat platen away

during use.

1) Turn o the press, let attachments cool before switching out.

2) Loosen the wing nuts.

3) Slide the heat platen towards the back of the press.

4) Slide new attachments into the track.

5) Tighten the wing nuts and make sure the platen is secure.

6) Connect the plug into the control panel, and make sure the plug is securely

connected.

7) Thread the screw cap and tighten all the way. This keeps the plug from coming

loose during production.

*No tools needed for this process*

Changing Shirt Attachment

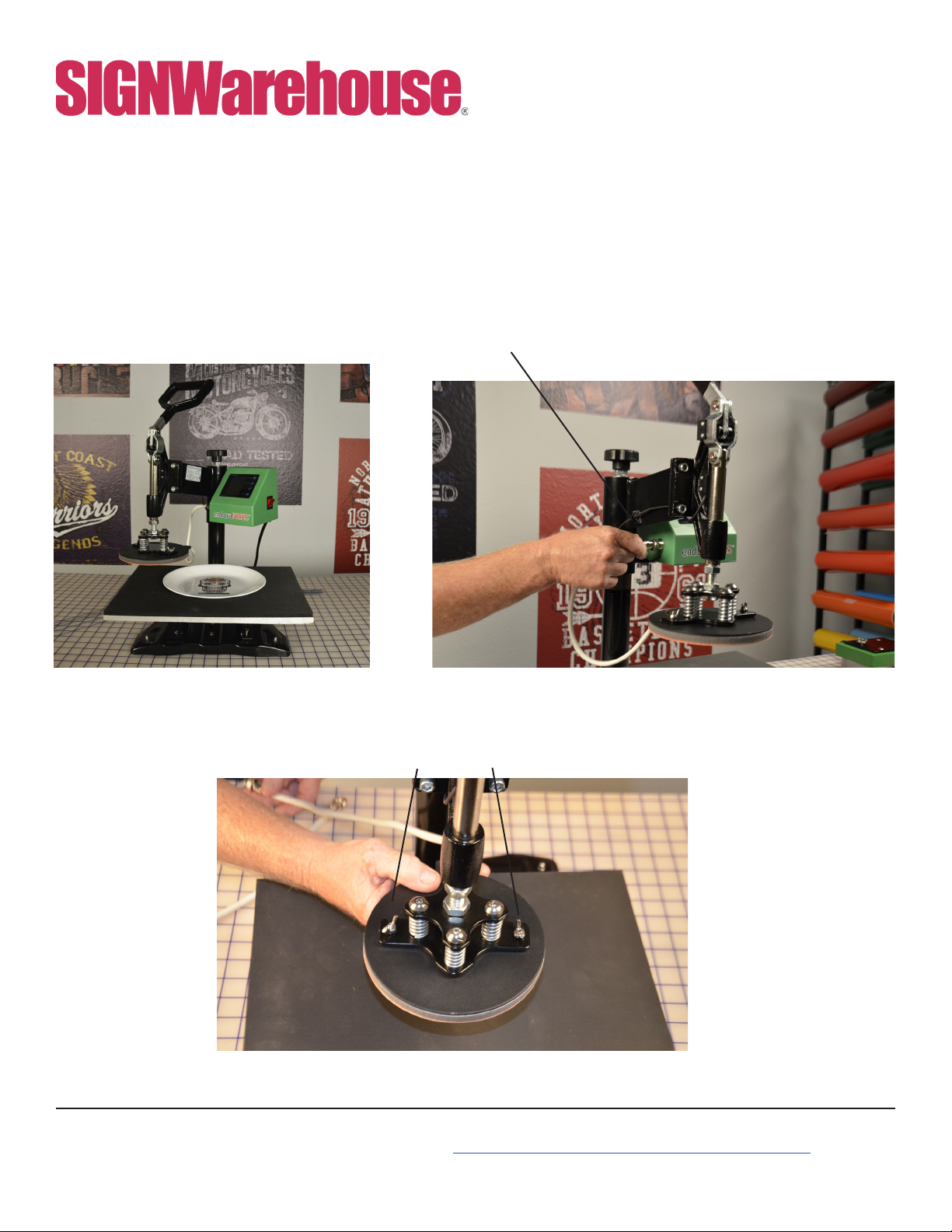

FIG 1: Remove the shirt aachment’s heat platen by

loosing the wing nuts.

FIG 2: To disconnect the power cable, loosen the

collar on the circular connector, then pull the plug

away from the control panel housing.

4

www.signwarehouse.com • SignWarehouse, Inc. • 2614 Texoma Drive, Denison, TX 75020

Plate Attachments

The MF15 combo heat press comes with two plate attachments. They’re 4.75”

and 6” in diameter. These replace the upper swingaway heat platen and close

on the standard 12” by 15” lower platen. When checking the pressure on this

attachment, do a few tests before committing to production.

Heating Element Plug.

FIG 5: Attach the plate heat platen using the wing nuts.

Make sure the platen is securely attached before use.

FIG 3: The plate attachments use the

standard base for the shirt attachment.

FIG 4: The plate attachment’s heat platen connects the

same way as the shirt attachment, using the circular

connector.

Wing nuts

5

www.signwarehouse.com • SignWarehouse, Inc. • 2614 Texoma Drive, Denison, TX 75020

Mug Attachment

The mug attachment is like our MP5 mug press, the dierence is that this one is not a

stand-alone unit. The basic setup is ideal for 11 oz mugs, but we oer other ttings for

larger and smaller cups as well. The mug press is great for dye sublimation and laser

transfers. Remember that the dye sublimation will only work with polymer-coated

cups and mugs.

The mug attachment operation is a little dierent then the others.

Caution: The mug attachment has a very small platen so it heats up quickly

Make sure the press is powered o before attempting to attach the mug

attachment.

1) Remove the current attachment from the handle, and unplug it from control panel.

2) Plug in the mug attachment into the control panel, as seen below.

3) Check the pressure of the press. The mug attachment can be used with other heat

platens connected to the handle as long as it is plugged in.

4) Move the mug attachment handle backwards to open the sleeve and insert a mug.

Pull the handle forward to securely contain the mug in the sleeve.

5) To activate the timer for mug attachment use, the handle must be lowered as if you

are using the shirt attachment.

Changing to Mug Attachment

6

FIG 6: The mug aachment is

ready to press. The lower platen

can be removed or stay on the

main base. The mug aachment

will work both ways.

FIG 7: The mug aachment’s

heat platen connects the same

way as the shirt aachment,

using the circular connector.

www.signwarehouse.com • SignWarehouse, Inc. • 2614 Texoma Drive, Denison, TX 75020

Phillips screws

FIG 8: Use a phillips screw-

driver to remove the screws

holding the ttings to the

mug attachment frame

The mug attachment operation is a little dierent then the others.

Caution: The mug attachment has a very small platen so it heats up quickly. Make sure

the press is powered o before attempting to attach the mug attachment.

1) Check the pressure of the press. The mug attachment can be used with other heat

platens connected to the handle as long as it is plugged in.

2) Move the mug attachment handle backwards to open the sleeve and insert a mug. Pull

the handle forward to securely contain the mug in the sleeve.

3) To activate the timer for mug attachment use, the handle must be lowered as if you

are using the shirt attachment. Once you have placed your mug in the sleeve, lower

the heat press handle to start the cycle timer. At the end of the cycle, raise the heat

press handle to silence the alarm and push the mug attachment handle backward to

remove the mug.

4) Like the standalone MP5 EnduraPress mug press, you can use various mug ttings

with the mug attachment to decorate mugs of dierent diameters. The default tting

is designed for 11oz mugs. To change to a larger or smaller tting, remove the screws

with a phillips head screw driver and disconnect the power cable from the control

panel. For more information on mug ttings, please click here or refer to the MP5

User Manual.

TIP: Sublimation continues as long as the surface temperature remains at or near 400°F.

If the mug is still hot after the transfer paper is removed, the ink may sublimate as

heat rises from the mug surface resulting in ‘ghosting’ or hazy blurry transfers. To stop

the sublimation process after you remove the transfer paper, dip the mug in a bucket

of cool water. This will ensure a clear, sharp transfer.

Using the Mug Attachment

7

www.signwarehouse.com • SignWarehouse, Inc. • 2614 Texoma Drive, Denison, TX 75020

Cap Press Attachment

The MF15’s cap attachment is a lot alike our SA-CP36 cap press. For best results,

make sure you choose a heat transfer lm suitable for the cap’s fabric. Use the time,

temperature and pressure settings for that particular HTV.

To use the cap attachment, replace both the heat platen and table. Changing the lower

table from the shirt attachment to the cap attachment requires the use of a (8mm) allen

wrench and a pair of pliers.

Change the lower platen before attaching the cap press.

1) Use the 5mm allen wrench to loosen the table for the shirt attachment.

2) Place to the side and place the cap platen on the base.

3) Use the piers to secure the washer on the bottom of the table while adjusting the hex

head bolts with the allen wrench.

4) Make sure the platen is secure.

5) Attach the cap press heat platen using the wing nuts, as seen below (Fig 11).

6) Place the crown of the cap over the curved base. Place your HTV transfer on the

crown, cover with a Teon Sheet, and lower the curved heat platen. Be sure to adjust

the pressure using the pressure knob (Page 3) to produce sucient pressure for a

successful transfer.

Changing the Lower Platen

Wing Nuts

FIG 9: A pair of

piers and an 5mm

allen wrench to

help change out the

platen

FIG 10: Slide the heating

platen into the track and

tighten the wing nuts.

FIG 11: When attaching the lower platen,

make sure the holes line up. Always check

the platen is secured.

8

www.signwarehouse.com • SignWarehouse, Inc. • 2614 Texoma Drive, Denison, TX 75020

9

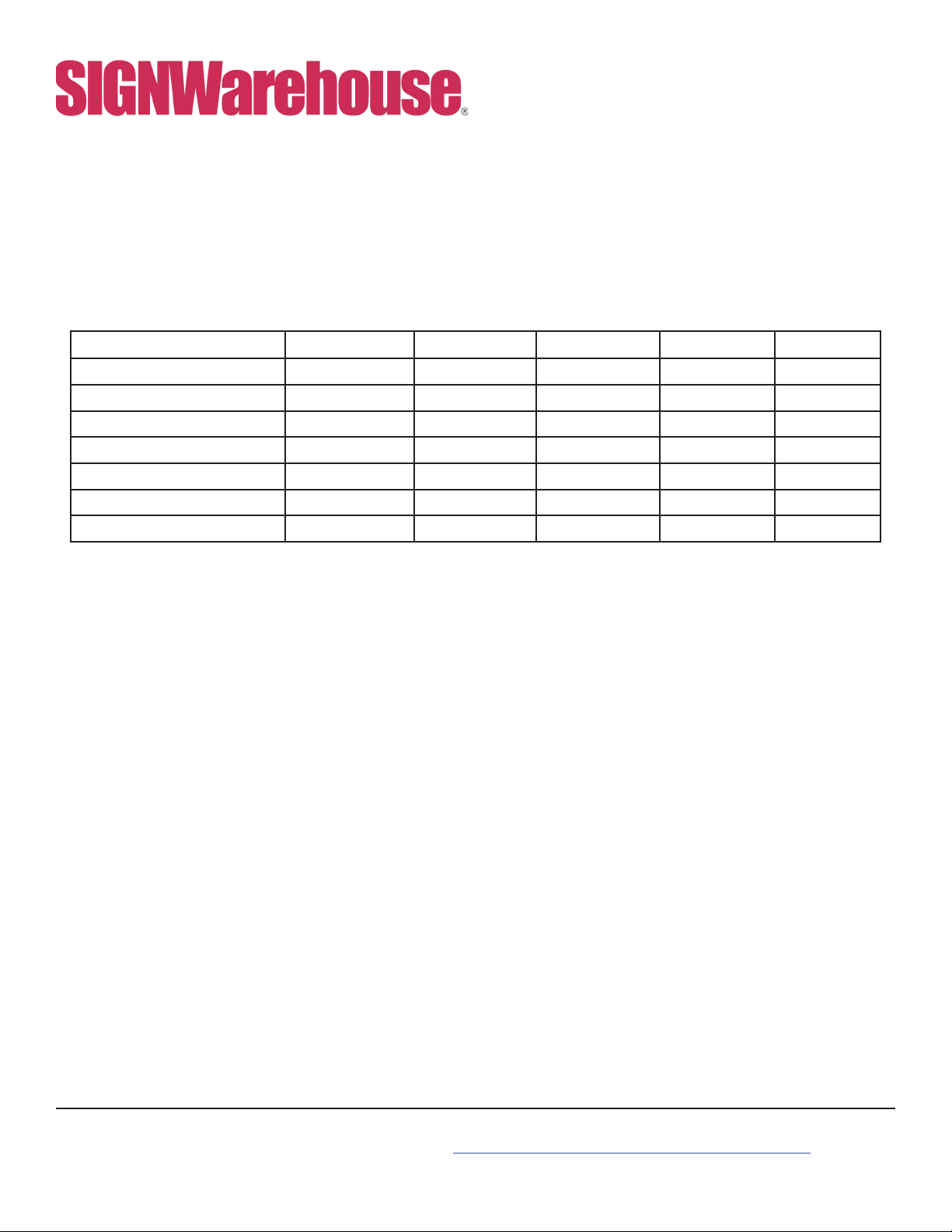

Heat Transfer Application Guidelines

These are general guidelines. For specic time and temperature settings for specic lms

and/or transfer papers, please refer to the instructions for that particular product.

** The EnduraPRESS CS15, CS15-AR, CS16, and CS16-AR are not recommended for use

with two-step laser transfer papers. For these demanding applications, we recommend the

EnduraPRESS SA12 or SD20.

TRANSFERS Device Fabric TEMP. TIME PRESSURE

Sublimation Paper Ricoh, Epson Polyester 400°F 25~30sec. 30Psi

Ink Tran. Paper Inkjet Printer Light Color 365°F 15sec. 30Psi

Dark Color 330°F 25sec. 30Psi

Laser Transfer Paper** Laser Printer Light Color 345°F 30sec. 30Psi

Laser Printer Dark Color 260 - 320°F 35 - 120 sec. 25Psi

Transfer Vinyls Cutting Plotter / 300~320°F 8~10sec. 30Psi

Plastisol Transfer / / 335°F 12sec. 50Psi

www.signwarehouse.com • SignWarehouse, Inc. • 2614 Texoma Drive, Denison, TX 75020

10

Troubleshooting Tips

Q. Why isn’t my heat transfer vinyl sticking to the fabric?

A. This can be caused by three things. Insucient pressure, or temperature, or time.

Time: Some heat transfer lms need a few seconds to cool before you remove the liner. Try a

warm or cold peel rst.

Temperature: If that doesn’t work, check to make sure you are using the recommended time and

temperature settings. If you are, your press may not be putting out the correct amount of heat.

Use a Geo Knight IR thermometer to check the actual temperature of the platen. If it is more

than 5° dierent from the LCD display (PV), adjust it using step four in the control panel (see

page 4).

Pressure: If the temperature is correct, adjust the pressure. Some lms require more pressure to

bond the adhesive to the fabric. There should be some resistance when you close the press.

If you have veried all of these and the lm doesn’t stick, contact SIGNWarehouse customer

service or Technical Support for further assistance.

Q. Why does my sublimated transfer look washed out?

A. This is usually caused by insucient temperature. Sublimation works best at or near 400°F.

If your transfer is faded, check the output of the heat platen with a contact thermometer and

make sure the output matches the displayed temperature. If not, adjust as directed above.

Then repress at 390 - 400°F.

Q. Why are my transfers are sticking to the heating element of the upper platen?

A. If T-shirt vinyl is sticking to the heating element, you have it upside down. Remove any

adhesive residue, ip it over and try again. If an inkjet or laser transfer is sticking to the heating

element, it’s because the heat is aecting the ink. Cover it with a Teon sheet or sheet of

silicone Kraft paper to prevent this. Using a Teon sheet or Kraft paper is recommended for

almost all heat transfer applications.

Q. Why is it so hard to peel the liner when I’m done pressing the paper?

A. A hot or warm peel lm may become hard to peel if allowed to cool. Always peel the lm or

transfer paper in accordance with the product’s recommendations.

www.signwarehouse.com • SignWarehouse, Inc. • 2614 Texoma Drive, Denison, TX 75020

11

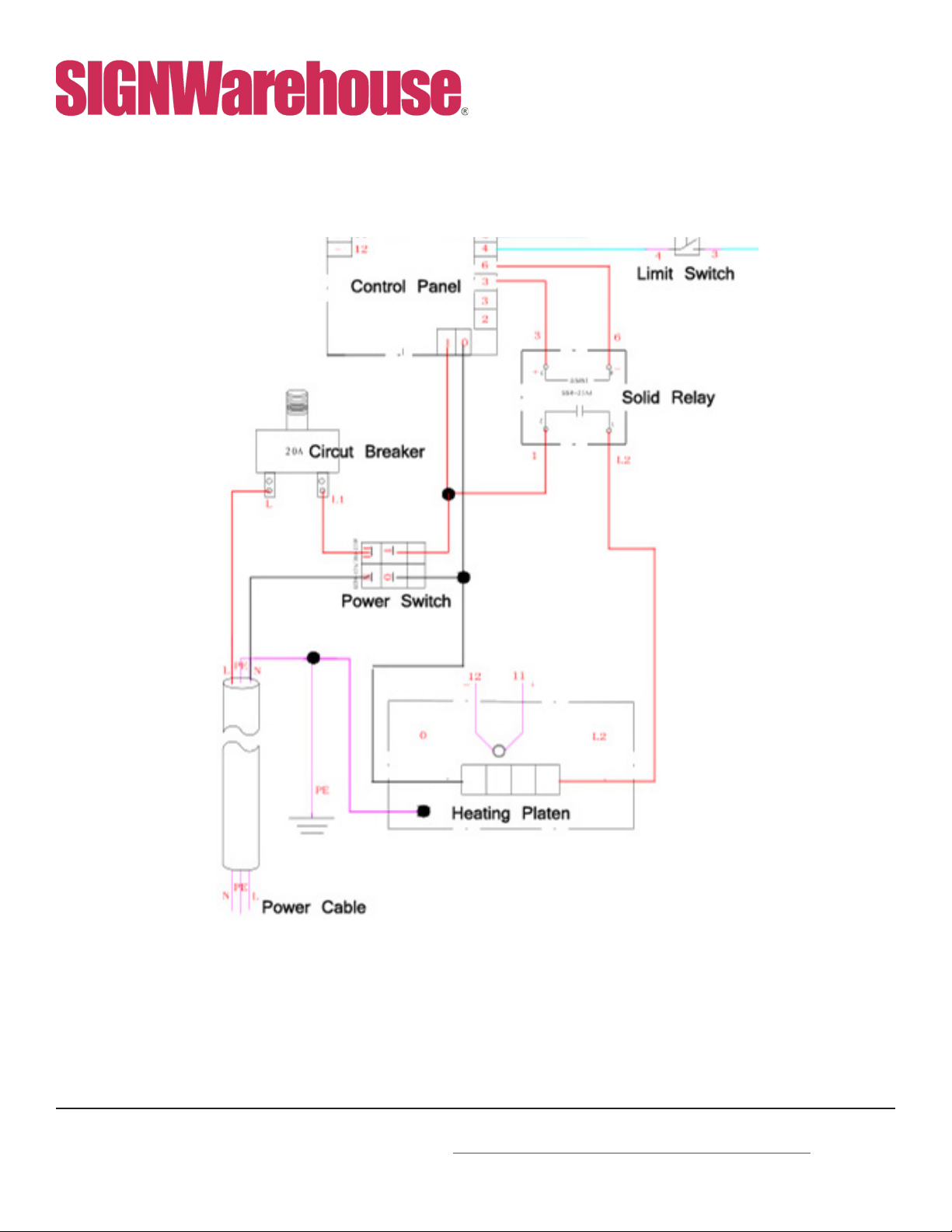

Wiring Schematic

WARRANTY

Thank you for choosing our products, you are entitled to one year free warranty service

for our products. All exceeds warranty period we will still provide technical supports and

maintenance guidance.

This manual suits for next models

2

Table of contents

Other SignWarehouse Power Tools manuals

Popular Power Tools manuals by other brands

Makita

Makita HM0810T instruction manual

Parkside

Parkside PFBS 12 B3 Translation of the original instructions

Black & Decker

Black & Decker BDCD8 Original instructions

Texas Pneumatic Tools

Texas Pneumatic Tools TX456 Service and operation manual

Makita

Makita DHR202SYE instruction manual

Bauer

Bauer 1632E-B Owner's manual & safety instructions